Stainless Steel Specs

Diunggah oleh

Robert MarcoliniHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Stainless Steel Specs

Diunggah oleh

Robert MarcoliniHak Cipta:

Format Tersedia

6985 Stainless Steel

6/19/01

4:19 PM

Page 3

DESIGNER

HANDBOOK

S TA I N L E S S

with Directory of

STEEL FOR

Stainless Steel

Structural Producers

STRUCTURAL

A P P L I C AT I O N S

Stainless

Steel

The

Value

Option

6985 Stainless Steel

6/19/01

4:19 PM

Page 4

TABLE OF CONTENTS

INTRODUCTION .......................................................................................................... 1

GENERAL INFORMATION ON

STAINLESS STEEL .................................................................................................. 2

Alloys

Condition

Product Forms

STAINLESS STEEL STRUCTURES .......................................................... 3

Fabrication

Connections

CONCRETE REINFORCEMENT.................................................................... 4

FABRICATED COMPONENTS

(Angles, I-Beams, Boxed Structures)

................................................ 5

ROLLED ANGLES .................................................................................................... 6

EXTRUDED ANGLES

............................................................................................ 6

TUBULAR COMPONENTS ................................................................................ 7

BARS AND RODS ...................................................................................................... 8

FRAMES ............................................................................................................................ 9

INVESTMENT CASTINGS .................................................................................. 9

WALL TIES AND ANCHORS ........................................................................ 10

EXTRUSIONS

............................................................................................................ 11

REFERENCES............................................................................................................ 12

ACKNOWLEDGMENTS .................................................................................... 12

DIRECTORY OF STAINLESS STEEL

STRUCTURAL PRODUCERS ..........................................inside back cover

The material presented in this booklet has been

prepared for the general information of the reader.

The Specialty Steel Industry of North America

(SSINA) and the individual companies it represents

have made every effort to ensure that the information presented is technically correct. However,

neither the SSINA nor its member companies

warrants the accuracy of the information contained

in this handbook or its suitability for any general

and specific use. The SSINA assumes no liability

or responsibility of any kind in connection with the

use of this information. The reader is advised that

the material contained herein should not be used

or relied on for any specific or general application

without first securing competent advice with respect

to its suitability.

6985 Stainless Steel

6/19/01

4:19 PM

Page 5

INTRODUCTION

Stainless steel is not a single alloy, but

rather the name applies to a group of

iron based alloys containing a minimum

10.5% chromium. Other elements are

added and the chromium content

increased to improve the corrosion

resistance, improve heat resisting properties, enhance mechanical properties,

and/or to improve fabricating characteristics. There are over 50 stainless steel

grades that were originally recognized

by the American Iron and Steel Institute

(AISI). Three general classifications are

used to identify stainless steel. They

are: 1. Metallurgical structure. 2. The

AISI numbering system (200, 300 and

400 series numbers). 3. The Unified

Numbering System, which was

developed by the American Society

for Testing Materials (ASTM) and the

Society of Automotive Engineers

(SAE) to apply to all commercial metals

and alloys.

The various types of stainless steel

are detailed in a designer handbook,

Design Guidelines for the Selection and

Use of Stainless Steel available from

the Specialty Steel Industry of North

America (SSINA). Several other

publications are also available, including:

Stainless Steel Fabrication, Stainless

Steel Fasteners, Stainless Steel

Finishes, Stainless Steel Specifications,

and Stainless Steel Architectural Facts,

to mention a few.

6985 Stainless Steel

6/19/01

4:19 PM

Page 6

GENERAL INFORMATION ON STAINLESS STEEL

ALLOYS

The following grades of stainless steel

are often used in structural applications:

304 has an austenitic metallurgical

structure. It is the basic 18-8 alloy

(18% chromium, 8% nickel UNS

S30400), is the most readily available

grade, and is often specified for allpurpose applications. It has excellent

corrosion resistance and unusually

good formability.

316 is basically a 304 grade with the

addition of 2 to 3% molybdenum. It

has greater corrosion resistance than

304 and is usually preferred for long

term service in aggressive industrial,

chemical and seacoast atmospheres.

409 has a ferritic metallurgical

structure. It is a straight chrome alloy

(11 to 12% chromium UNS S40900).

It has good ductility and corrosion

resistance. It is mainly used for

internal applications.

410-3 is a dual phase alloy (UNS

S41003) with micro alloy element

control that permits welding in up to

1 1/4 inches (30mm).

2205 has a duplex structure which is

typically about equal parts of austenite

and ferrite (21% chromium, 4.5%

nickel, 2.5% molybdenum UNS

32304). It has excellent corrosion

resistance and exhibits about twice

the yield strength as conventional

grades.

CONDITION

Stainless steel is usually available in the

Hot Rolled and Annealed condition

and has a yield strength of about 42 ksi.

The austenitic grades can be hardened

by cold working the material. 301, a

modification of 304, (with the chromium

and nickel lowered slightly to increase

the work hardening rate), can be supplied in various tempers up to full hard

with a yield strength of 140 ksi.

The American Society of Civil

Engineers (ASCE) has a standard ANSI/

ASCE -8 -90 Specifications for the

Design of Cold Formed Stainless Steel

Structural Members, 1 which details the

design information on cold formed

stainless steel.

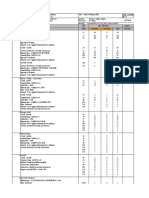

Table 1 CLASSIFICATION OF STAINLESS STEEL PRODUCT FORMS*

Item

Sheet

Strip

Plate

Description

Thickness

Width

Diameter or Size

under 0.1875" (4.76mm)

24.000" (609.6mm) and over

Cold Rolled No. 2D, 2B,

Bright Annealed, TR

under 0.1875" (4.76mm)

24.000" (609.6mm) and over

Polished No. 3, 4, 6, 7 & 8

under 0.1875" (4.76mm)

24.000" (609.6mm) and over

Coils and cut lengths:

Hot Rolled No. 1

under 0.1875" (4.76mm)

under 24.000" (609.6mm)

Cold Rolled No. 2D, 2B,

Bright Annealed, TR

under 0.1875" (4.76mm)

under 24.000" (609.6mm)

Polished No. 3, 4, 6, 7 & 8

under 0.1875" (4.76mm)

under 24.000" (609.6mm)

0.1875" (4.76mm) and over

over 10.000" (254mm)

0.1875" (4.76mm) and over

over 10.000" (254mm)

0.250" (6.35mm)

and over

0.125" (3.18mm) and over

0.250" (6.35mm) to

10.000" (254mm)

Cold finished rounds, squares,

octagons and hexagons

0.062" (1.59mm)

and over

Cold finished flats

0.375" (9.53mm) and over

Hot Rolled coils may be annealed

and/or descaled

0.200" (5.54mm)

and over

0.010" (0.254mm) to

under 0.185" (4.76mm)

0.062" (1.59mm) to

under 0.375" (9.35mm)

Coils and cut lengths:

Hot Rolled No. 1

Coils and cut lengths:

Hot Rolled, annealed & pickled

Polished available for

special applications

Bar

Straight lengths:

Hot finished rounds, squares,

octagons and hexagons

Hot finished flats

Rod

Wire

Dimensions

Cold finishes only:

Rounds, squares, octagons

and hexagons

Flat wire (coils only)

Pipe &

Tube

Several different classifications with differing specifications are available.

For more information on standard sizes, consult your local Steel Service Center or the SSINA.

Extrusions

Not considered standard shapes, but available.

Currently limited in size to approximately 6.50" (165.1 mm) diameter circle, or structurals to 5.00 (127 mm) diameter.

*Ingots, Slabs, Hot Bands, Angles and Rolled Shapes are also available.

0.500" (12.7mm)

and under

6985 Stainless Steel

6/19/01

4:19 PM

PRODUCT FORMS

The forms of stainless steel used in

structural applications are: plate and

sheet (often fabricated into structural

shapes), extrusions, forgings, preformed

products (tubes and angles), bar and

rod, wire, and castings.

Plate:

Plate is defined as material that has a

thickness of 3/16" or greater (Table 1).

It is usually available in widths of 48,

60, 72 and 96". It can be supplied as

individual flat plates or in coil form

(some limits on thickness and width).

Many structural shapes are produced

by fabricating the plate into beams,

angles and other components. For information, contact the Steel Plate Fabricators Association (708-298-0880).

Sheet:

Sheet is defined as material that has

a thickness of less than 3/16" (Table 1),

and is usually supplied in either 48 or

60" wide coils.

Extrusions:

Stainless steel can be extruded into

several complex shapes as detailed in

the Designer Handbook The Selection

and Use of Stainless Steel.

Also contact: Al Tech Specialty Steel

Corporation (716-366-1000),

Plymouth Tube Company

(1-800-323-9506).

Forging:

Stainless steel forging are also

available in several shapes. For

information, contact the Forging

Industry Association (216-781-0102).

Preformed Products:

Angles are available as a hot

rolled product. Contact Slater Steel

Corporation (219-432-2561).

Hot rolled and cold rolled shapes,

as well as cold-drawn shapes can

also be made from stainless steel as

detailed in the Designer Handbook

The Selection and Use of Stainless

Steel.

Tubular products are commonly used

for structural applications either in

round or square sections. Further information is available for the Specialty

Tubing Group (202-342-8400).

Bar and Rod: Bar is defined as hot

finished or cold finished rounds,

square, octagons and hexagons and

flats (Table 1).

Page 7

ponents such as I beams and angles.

Tubular products are available in round

tubes or square hollows.

Table 2 shows the relative fabrication

characteristics of the various grades of

stainless steel.

Wire:

Wire is cold finished only, produced

in coils, as round, square, octagon,

hexagon, and flat wire (Table 1).

Castings:

Stainless steel casting can be produced

for structural applications. For information,

contact the Steel Founders Society of

America (847-299-9160).

Connections:

Stainless steel structures must be

connected by using stainless steel

fasteners. The SSINA has a Designer

Handbook Stainless Steel Fasteners A

Systematic Approach to Their Selection

which details a method of selecting

stainless steel fasteners.

Stainless steel is also readily welded,

although the welding rods and techniques are different from that of mild

steel. The American Welding Society

(800-443-WELD) and the Nickel

Development Institute (416-591-7999)

have information available on welding

stainless steels.

STAINLESS STEEL STRUCTURES

Fabrication:

Stainless steel can be fabricated by

methods similar to those used for carbon steel. However, other considerations

must be taken into account because of

the difference in material properties,

such as yield strength and rate of work

hardening. The SSINA Designer Handbook Stainless Steel Fabrication, 2 has

several suggestions on techniques for

cutting, bending, forming and finishing

the austenitic and ferritic stainless

steels. For example, 304 requires 50%

more power to bend it than carbon steel.

Duplex grades like 2205 have roughly

twice the yield strength of 304 or 316.

Once the yield strength is exceeded,

the plastic deformation takes place just

as easily as with the austenitic material.

Heavy gauge material (over 3/16") is

usually fabricated into structural com-

Table 2

Characteristic

Austenitic Austenitic Ferritic Dual Phase

304

316

409

410-3

Duplex

2205

Bending

Deep Drawing

Hot Forming

Cold Forming

Punching

Shearing

Welding

Machining

Code: E = Excellent G = Good F = Fair P = Poor

6985 Stainless Steel

6/19/01

4:19 PM

Page 8

CONCRETE REINFORCEMENT

Stainless steel rebars

being installed in a

bridge on highway 407

in Ontario, Canada

Applications for Rebars:

Preformed rebars for columns

Supports for reinforced concrete (i.e., bridge decks)

Marine construction, piers and wharfs

Balconies and frames for front-elevation units

Anchorages and any kind of joints

Off-shore platforms

Framers and anchorages for damp environments, tunnels,

underpasses and subways

Bridges, viaducts, overpasses

Cement frameworks with amagnetic characteristics

Frameworks which are prone to breaking up due to frost or because

of low temperatures

Concrete slabs for drainage in environments with corrosive agents

Supports/restoration for statues, monuments, cement, stone and

marble works

6985 Stainless Steel

6/19/01

4:19 PM

Page 9

FABRICATED COMPONENTS

Stainless steel is becoming the material

of choice for concrete reinforcement. It

has a high resistance to corrosion

particularly in chloride bearing concrete

(from de-icing salts or seacoast

exposure). Significant reductions in

maintenance and repair will result in

applications where the structure is

subject to adverse corrosion.

An article, published in the May 1995

issue of Concrete International, 3 by

D. B. McDonald; M. R. Sherman;

D. W. Pfeifer, and Y. P. Virmani, concludes

that both field and laboratory data have

shown that stainless steel rebars are

capable of maintaining excellent

corrosion resistance in severe chloride

environments, and that the chloride

tolerance for stainless steel was shown

to be significantly greater than that of

mild steel. This article also concludes

that the use of stainless steel may be

warranted when guaranteed long-term

corrosion resistance is required. The

Ladders and walkways and rails fabricated

by ENERFAB a Bishopric Company

Entrance hall of an allstainless steel building

in Japan 4

Arches, strut light covers and traffic signal poles (not in photo)

were fabricated from 316L Stainless steel by the Offenhauser

Company. The project is in the Galleria area in Houston.

A showroom of an all-stainless steel building in Japan

Applications for Fabricated

Components:

Columns and Pillars

Walkways, Railings and Ladders

Arches

Storage Units

Processing Vessels

Structural Supports

Wall and Ceiling Panels

5

6985 Stainless Steel

6/19/01

4:19 PM

Page 10

ROLLED ANGLES

EXTRUDED ANGLES

overall cost increase due to the use

of stainless steel reinforcing bars is

considered to be reasonably low.

Stainless steel can be fabricated into several structural components from sheet, plate,

bars or strip. There are many fabrication shops that are experienced in fabricating

stainless steel (for more information contact the Steel Plate Fabricators Association

708-562-8750). Steel service centers also can perform some fabrication services such

as brake forming and cutting custom shapes and sizes (contact the Steel Service Center

C

C

Unequal

Equal

Institute 216-694-3630).

Leg

Angles

Leg Angles

Stainless steel is usually the material

A

Stainless angles were used to construct a Bar

Screen (Series 1000 from Envirex, INC) for a

water treatment application.

2

2-1/2

3

1-1/2

2

2

2-1/2

2-1/2

2-1/2

3

3

3

3-1/2

3-1/2

4

3

3-1/2

4

2-1/2

2-1/2

3

3

3-1/2

3-1/2

4

5

3

3

3

3-1/2

3-1/2

4

5

1-1/2

2

2

1

1

1-1/2

1-1/4

1-1/2

2

1-1/2

2

2-1/2

2-1/2

3

3

2

2-1/2

3

1-1/2

2

1-1/2

2

2-1/2

3

3

3

1

1-1/2

2

1-1/2

3

3

3

3/16

3/16

3/16

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/4

5/16

5/16

5/16

3/8

3/8

3/8

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

1/2

1/2

1/2

1/2

Approx. Wt.

Lbs. per Ft.

2.12

2.75

3.07

1.92

2.34

2.77

2.85

3.19

3.62

3.51

4.10

4.50

4.90

5.40

5.80

5.00

6.10

7.20

4.70

5.30

5.30

5.90

7.20

7.90

8.50

9.80

6.01

6.85

7.70

7.64

10.20

11.10

12.80

1-1/2

1-3/4

2

2-1/2

3

1-1/4

1-1/2

1-3/4

2

2-1/2

3

3-1/2

4

2

2-1/2

3

3-1/2

4

2

2-1/2

3

3-1/2

4

2-1/2

3

3-1/2

4

1-1/2

1-3/4

2

2-1/2

3

1-1/4

1-1/4

1-3/4

2

2-1/2

3

3-1/2

4

2

2-1/2

3

3-1/2

4

2

2-1/2

3

3-1/2

4

2-1/2

3

3-1/2

4

3/16

3/16

3/16

3/16

3/16

1/4

1/2

1/4

1/4

1/4

1/4

1/4

1/4

5/16

5/16

5/16

5/16

5/16

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

1/2

Approx. Wt.

Lbs. per Ft.

1.80

2.12

2.44

3.07

3.71

1.92

2.34

2.75

3.19

4.10

4.90

5.80

6.60

3.92

5.00

6.10

7.05

8.20

4.70

5.90

7.20

8.50

9.80

7.70

9.40

11.10

12.80

of choice in the food, beverage,

pharmaceutical and chemical industries, but is often specified where long life

and attractive appearance are desired

in other applications. For example,

stainless steel is often used as a column cover where the outer skin is stainless; however, it can also be used as the load bearing member.

6985 Stainless Steel

6/19/01

4:19 PM

Page 11

TUBULAR COMPONENTS

Stainless steel angles are produced by

hot rolling, annealing, blast cleaning

and chemical passivation. Angles can

be formed from sheet and plate or rolled

from billets creating various structural

components. A popular use involves

bending the angle into a ring and

welding the ends together for use as

an outer strengthening component in

Tubular sections form the La Grande Arch

structure in Paris.

Stainless steel trusses (20 meters) for bracing and end frames for skylight supports.

Applications for Tubular

Components:

Structural tubes, filled with water, used as an

external fire prevention system.

Space frames

Trusses

Bracing and end frames

Lattices

Load bearing member

Light poles

Overhead signs

7

6985 Stainless Steel

6/19/01

4:19 PM

Page 12

BARS AND RODS

cyclindrical structures. Typical sizes are

listed in Table 3.

(photo, above)

Stainless steel was used to

support a lightweight PTFE

coated glass fiber woven

fabric roof (not yet installed).

(photo, left)

Stainless steel tie rods linked

to stainless steel tubular columns

to maintain the roof membrane

in tension.

The Minnesota Department

of Transportation replaced

conventional low alloy steel

with stainless steel hinge pins

and hangers on the Blatnik

Bridge in Duluth, Minnesota.

Applications for Bars and Rods:

Structural members in tension

Load transfer devices

Tie rods

Bridge pins

A continuous reinforced concrete slab supported by

44 stainless steel rods provides pedestrians and

cyclists a bridge over the Humber River in Toronto.

6985 Stainless Steel

6/19/01

4:19 PM

Page 13

INVESTMENT

CASTING

FRAMES

Stainless steel has been specified in

bus and rail cars for internal frames and

for the entire structure.

Table 3 ANGLES

Slater is able to produce the following sizes

of angles in the Hot Rolled, Annealed and

Descaled condition:

1 x 1 x 18

1 x 1 x 316

1 x 1 x 14

1-14 x 1-14 x 18

1-14 x 1-14 x 316

1-14 x 1-14 x 14

1-12 x 1-12 x 18

1-12 x 1-12 x 316

2 x 2 x 14

2 x 2 x 516

2 x 2-38

2-12 x 2-12 x 316

2-12 x 2-12 x 14

2-12 x 2-12 x 516

2-12 x 2-12 x 38

3 x 3 x 14

Tubular supports for the roof structure of the

Canadian Archives Building.

Rail coal carriers fabricated from stainless steel.

Truck mirror frame.

Complex stainless steel investment

casting connecting the tubular structure

with the glass wall.

Applications for Frames:

Applications for Castings:

Bus and transit frames

Coal cars

Space frames

Mirror mount frames

Anchors

Support housings

Joints

6985 Stainless Steel

6/19/01

4:19 PM

Page 14

WALL TIES AND ANCHORS

1-12 x 1-12 x 14

2 x 2 x 18

2 x 2 x 316

3 x 3 x 516

3 x 3 x 38

Tolerance information is as follows:

Leg Tolerance (length)....+18"

Weight Tolerance............+7-12%

Right Angle Tolerance.....+2

Straightness or Camber...18" in 5 feet

Lewis bolts (top) and threaded inserts for

hanging stone (bottom) show variety of stainless

steel fastening devices used in stone and

concrete anchoring systems.

BASIC SYSTEM

STONE PANEL VENEER

MASONRY WIRE TIES

WIRE TIES FOR STONE VENEER

Rectangular Eye & Dowel

10

Modified Vee Ties

Stainless steel tie bar.

6985 Stainless Steel

6/19/01

4:19 PM

Page 15

EXTRUSIONS

Stainless steel can be extruded in many shapes including angles. Angles are

produced with parallel surfaces on the legs. Typical sizes are listed in Table 4.

Table 4

Beams

Tees

Channels

1-1/2

1-1/2

2

2-1/2

3 (T)

4 (T)

1

1

1-1/4

1-1/2

2-3/8

2-3/4

3/16

1/4

1/4

1/4

1/4

1/4

(T) standard tapered sections

Approx. Lbs.

per Ft.

2.02

2.64

3.43

4.22

6.60

8.44

1-1/4

1-1/2

1-1/2

1-1/2

2

1

1-1/2

1-1/2

2

2

2-1/2

2-1/2

3

1-1/2

2

2-1/2

2-1/2

2-1/2

2

2

1-1/2

2

2-3/8

2

1-1/4

1-1/2

2

1-1/4

2

1-1/2

2-1/2

3

1-1/2

2

2

2-1/2

3

2

3/16

3/16

3/16

3/16

3/16

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/4

3/8

3/8

3/8

3/8

3/8

1/2

Approx. Wt.

Lbs. per Ft.

1.94

1.65

2.09

2.37

2.44

1.69

2.34

2.75

2.57

3.19

3.19

4.10

4.91

3.60

4.70

5.29

5.90

6.70

6.38

1-1/2

2 (T)

2

2 (T)

2-1/2 (T)

3 (T)

1-1/4

1-1/2

2

2

2-1/2

3

4 (T)

5 (T)

3/4

9/16

3/4

1

5/8

1-3/8

1

1

5/8

1

1

1-1/2

1-3/4

1-7/8

3/16

3/16

3/16

3/16

3/16

3/16

1/4

1/4

1/4

1/4

1/4

1/4

1/4

3/8

Approx. Wt.

Lbs. per Ft.

1.75

1.85

2.02

2.60

2.40

4.19

2.33

2.57

2.37

3.15

3.57

4.75

6.69

10.43

(T) standard tapered sections

Specifications:

The following specifications can be

applied to structural products:

ASTM A276

QQS-763

ASTM A479

Grades:

304

316

304L

316L

Other grades available upon request.

Not all sizes available in all grades.

11

6985 Stainless Steel

6/19/01

4:19 PM

Page 16

REFERENCES:

ACKNOWLEDGMENTS

American Society of Civil Engineers:

ANSI/ASCE 8-90: Specification for the

Design of Cold Formed Stainless Steel

Structural Members

Specialty Steel Industry of North

America: Designer Handbook Series:

Stainless Steel Fabrication

The Specialty Steel Industry of North

America wishes to acknowledge the

assistance of the following individuals

and organizations for their help and

assistance in providing data and photographs for this publication. Their contributions were paramount in the development of this Designer Handbook.

Concrete International: May 1995:

Stainless Steel Reinforcing as

Corrosion Protection: D.B.McDonald;

M.R.Sherman; D.W. Pfeifer, and

Y.P.Virmani.

Steel Today & Tomorrow: News of

Japanese Steel Jan.-Mar. 1996: Page 9

A New Steel Structure Stainless steel

Buildings

With a special acknowledgment and

thanks to Mr. David J. Cochrane, consultant to the Nickel Development Institute for a significant contribution.

Ontario Ministry of Transportation:

Dr. Alan K.C. Ip, Mr. Frank Pianca

and Mr. Ranjit S. Reel

Envirex Inc.

P.O. Box 1604

Waukesha, WI 53187-1604

Mr. William P. Schmitz

Enerfab

A Bishorpric Company

4955 Spring Grove Ave.

Cincinnati, OH 45232

Ms. Sandra Pena

Offenhauser Company

P.O. Box 230068

2201 Telephone Rd.

Houston, TX 77223-0068

Mr. Robert H. Dillard

Al Tech Specialty Steel Corp.

P.O. Box 152

Dunkirk, NY 14048

Mr. Bernard H. Neuhart

Slater Steel Corp.

2400 Taylor Street West

Fort Wayne, IN 46801

Mr. Jon Schmaucher

Plymouth Tube

P.O. Box 768

Warrenville, IL 60555

Mr. Don Ferguson

12

6985 Stainless Steel

6/19/01

4:19 PM

Page 2

Stainless

Steel

The

Value

Option

STAINLESS STEEL PRODUCERS

SPECIALTY STEEL INDUSTRY OF NORTH AMERICA

Allegheny Ludlum Corporation

An Allegheny Teledyne Company

1000 Six PPG Place

Pittsburgh, PA 15222-5479

(412) 394-2800

www.alleghenyteledyne.com

Allvac

An Allegheny Teledyne Company

2020 Ashcraft Avenue

P.O. Box 5030

Monroe, NC 28111

(704) 289-4511 or (800) 841-5491

www.allvac.com

AL Tech Specialty Steel Corporation

90 Willowbrook Avenue

P.O. Box 152

Dunkirk, NY 14048

(716) 366-1000

Armco Inc.

One Oxford Centre

301 Grant Street

Pittsburgh, PA 15219-1415

(412) 255-9800

www.armco.com

Atlas Specialty Steels

Division of Atlas Steels, Inc.

One Centre Street

P.O.Box 1000

Welland, OT L3B 5R7

CANADA

(800) 263-5712

www.atlasspecialtysteels.com

Atlas Stainless Steels

Division of Atlas Steels, Inc.

1640 rue Marie Victorin

Tracy, Quebec J3R 4R4

CANADA

(514) 746-5000

Carpenter Technology Corporation

P.O. Box 14662

Reading, PA 19612-4662

(610) 208-2000

www.cartech.com

Talley Metals Technology, Inc.

A Carpenter Company

P.O. Box 2498

Hartsville, SC 29551

(803) 335-7540

G.O. Carlson, Inc.

350 Marshallton Road

P.O. Box 526

Thorndale, PA 19372-0526

(610) 384-2800

J&L Specialty Steel, Inc.

P.O. Box 3373

Pittsburgh, PA 15230-3373

(412) 338-1600

www.jlspecialty.com

Mexinox S.A. de C.V.

AV. Industrias 4100

Zona Industrial C.P. 78090

San Luis Potosi, S.L.P.

Mexico

011-52-48-24-0640

http://slpmex.infosel.net.mx/industria/

mexinox/mexinoxing.htm

North American Stainless

6870 Highway 42 East

Ghent, KY 41045

(502) 347-6000

Precision Specialty Metals, Inc.

3301 Medford Street

Los Angeles, CA 90063

(213) 267-3200

www.psm-inc.com

Republic Technologies International

3770 Embassy Parkway

Akron, Ohio 44333-8367

(330) 670-3000

Special Metals Corporation

Middle Settlement Road

New Hartford, NY 13413

(315) 798-2900

www.specialmetals.com

Techalloy Company, Inc.

370 Franklin Turnpike

Mahwah, NJ 07430

(201) 529-0900

www.manufacturing.net/techalloy

3050 K Street, N.W.

Washington, D.C. 20007

TEL: (202) 342-8630 or (800) 982-0355

FAX: (202) 338-5534

9-99-5000

Anda mungkin juga menyukai

- Three Phase Power Power Factor Correction CircuitsDokumen245 halamanThree Phase Power Power Factor Correction CircuitsmawaistpsBelum ada peringkat

- Designing With RubberDokumen1 halamanDesigning With RubberRobert MarcoliniBelum ada peringkat

- 3-Phase Transformers Part 1Dokumen38 halaman3-Phase Transformers Part 1Robert MarcoliniBelum ada peringkat

- Awc Spantables2015 DVJR 1505Dokumen28 halamanAwc Spantables2015 DVJR 1505mlamourBelum ada peringkat

- Frame WoodDokumen0 halamanFrame WoodAdoba Francisc100% (2)

- Curved Beam PDFDokumen1 halamanCurved Beam PDFRobert MarcoliniBelum ada peringkat

- Awc Spantables2015 DVJR 1505Dokumen28 halamanAwc Spantables2015 DVJR 1505mlamourBelum ada peringkat

- K Sankara Rao PDFDokumen86 halamanK Sankara Rao PDFSelva Raj62% (13)

- Differential Equations by NP BaliDokumen457 halamanDifferential Equations by NP BaliADITI Library71% (7)

- 3-Phase Transformers Part 2Dokumen18 halaman3-Phase Transformers Part 2Robert MarcoliniBelum ada peringkat

- Los Alamos National Laboratory's Chemistry Division Presents a Periodic Table of the ElementsDokumen1 halamanLos Alamos National Laboratory's Chemistry Division Presents a Periodic Table of the ElementsRobert MarcoliniBelum ada peringkat

- Enabling AHCI Mode in Windows 10Dokumen1 halamanEnabling AHCI Mode in Windows 10Robert MarcoliniBelum ada peringkat

- Commercial Standard Lumber Sizes Table ChartDokumen4 halamanCommercial Standard Lumber Sizes Table ChartRobert Marcolini100% (1)

- Frame WoodDokumen0 halamanFrame WoodAdoba Francisc100% (2)

- Water Use Tracking TableDokumen1 halamanWater Use Tracking TableRobert MarcoliniBelum ada peringkat

- Enabling AHCI Mode in Windows 10Dokumen1 halamanEnabling AHCI Mode in Windows 10Robert MarcoliniBelum ada peringkat

- Heat Transfer Mechanisms PDFDokumen53 halamanHeat Transfer Mechanisms PDFRobert MarcoliniBelum ada peringkat

- Magnetic Induction and Exponental CurvesDokumen30 halamanMagnetic Induction and Exponental CurvesRobert MarcoliniBelum ada peringkat

- Heat Transfer Mechanisms PDFDokumen53 halamanHeat Transfer Mechanisms PDFRobert MarcoliniBelum ada peringkat

- Commercial Load Electrical CalculationsDokumen7 halamanCommercial Load Electrical CalculationsRobert MarcoliniBelum ada peringkat

- Three Phase MotorsDokumen24 halamanThree Phase MotorsRobert MarcoliniBelum ada peringkat

- Article 100 - Basic Requirements For Electrical InstallationsDokumen10 halamanArticle 100 - Basic Requirements For Electrical InstallationsRobert MarcoliniBelum ada peringkat

- Differential EquationsDokumen8 halamanDifferential EquationsRobert MarcoliniBelum ada peringkat

- Transformer Losses CalculationDokumen4 halamanTransformer Losses CalculationRobert Marcolini100% (1)

- Arc Fault Circuit InterruptersDokumen16 halamanArc Fault Circuit InterruptersRobert MarcoliniBelum ada peringkat

- Short Circuit CalculationDokumen46 halamanShort Circuit Calculationratnesh_xp1Belum ada peringkat

- Residential Load CalculationsDokumen5 halamanResidential Load CalculationsRobert MarcoliniBelum ada peringkat

- Three-Phase Power Generation ExplainedDokumen47 halamanThree-Phase Power Generation ExplainedRobert MarcoliniBelum ada peringkat

- ASHRAE Example Room - Cooling LoadsDokumen14 halamanASHRAE Example Room - Cooling LoadsSaiful Islam100% (2)

- Methods For Securing Substation Relay Communications PDFDokumen21 halamanMethods For Securing Substation Relay Communications PDFRobert MarcoliniBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- C.0738.PP9.05P - Bulk Piping & Fittings BOQ For Process Water SupplyDokumen4 halamanC.0738.PP9.05P - Bulk Piping & Fittings BOQ For Process Water Supplyfakir mohammadBelum ada peringkat

- 10 Marla House Construction Cost GuideDokumen8 halaman10 Marla House Construction Cost GuideTauseef Taj KianiBelum ada peringkat

- Grade 9 Integrated Science Summary and Exercise Chemistry 4 Chemical ReactionDokumen5 halamanGrade 9 Integrated Science Summary and Exercise Chemistry 4 Chemical Reactionnana widyaBelum ada peringkat

- Boq of Dire Dawa Project Final Price AdjustedDokumen67 halamanBoq of Dire Dawa Project Final Price Adjustedbings1997 BiniamBelum ada peringkat

- Effect of Elastane Denier and Draft Ratio of Core-Spun Cotton Weft Yarns On The Mechanical Properties of Woven FabricsDokumen10 halamanEffect of Elastane Denier and Draft Ratio of Core-Spun Cotton Weft Yarns On The Mechanical Properties of Woven FabricsDyeing DyeingBelum ada peringkat

- Welding and Heat Treatment of AISI 4130Dokumen66 halamanWelding and Heat Treatment of AISI 4130Дмитрий РыбаковBelum ada peringkat

- Stock CompletoDokumen1 halamanStock CompletoFaraz HaiderBelum ada peringkat

- Signature Towers E BrochureDokumen9 halamanSignature Towers E BrochureYogesh YadavBelum ada peringkat

- Report On Non-Traditional Machining ProcessDokumen29 halamanReport On Non-Traditional Machining ProcessRahul JHABelum ada peringkat

- NIP - Weld Check SheetDokumen1 halamanNIP - Weld Check SheetAlanka Prasad100% (2)

- Crockmaster 680Dokumen2 halamanCrockmaster 680dyetex100% (1)

- Ams 2175 Rev.Dokumen22 halamanAms 2175 Rev.Johnny OhBelum ada peringkat

- Gate Valve Forged B564 UNS N10276 Body, Hastelloy™ C276 TrimDokumen1 halamanGate Valve Forged B564 UNS N10276 Body, Hastelloy™ C276 TrimGiovanni PetrizzoBelum ada peringkat

- C - Ficha Tecnica - M2T MEGAFLEX SAE 100 R16Dokumen1 halamanC - Ficha Tecnica - M2T MEGAFLEX SAE 100 R16Rafael TorresBelum ada peringkat

- Hydrothermal MethodDokumen16 halamanHydrothermal Methodavni vatsBelum ada peringkat

- For Rolling Element Bearings - Aircraft Engine, Engine Gearbox, and Accessory Applications - Surface Temper EtchDokumen13 halamanFor Rolling Element Bearings - Aircraft Engine, Engine Gearbox, and Accessory Applications - Surface Temper Etchmohamed senoussiBelum ada peringkat

- CH 3.4 Law of Definite Proportions 11-12Dokumen14 halamanCH 3.4 Law of Definite Proportions 11-12Sumera SarwarBelum ada peringkat

- Simplified Estimate by Max FajardoDokumen300 halamanSimplified Estimate by Max FajardoRyan David MacayanBelum ada peringkat

- Gypsum Partition & Dry Wall: AlpineDokumen10 halamanGypsum Partition & Dry Wall: Alpinekushagra agrawalBelum ada peringkat

- Prelim CMTDokumen18 halamanPrelim CMTDeadlyDagger2Belum ada peringkat

- SATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalDokumen2 halamanSATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalmominBelum ada peringkat

- Tiling BibleDokumen8 halamanTiling BibleAdrian FavellBelum ada peringkat

- Bulacan Loft: Product SpecificationsDokumen22 halamanBulacan Loft: Product SpecificationsLang AwBelum ada peringkat

- Gas Turbine Engines: Seals: Raymond E. Chupp, Robert C. Hendricks, and Bruce M. SteinetzDokumen14 halamanGas Turbine Engines: Seals: Raymond E. Chupp, Robert C. Hendricks, and Bruce M. Steinetzarda akkayaBelum ada peringkat

- Staircase DetailDokumen1 halamanStaircase DetailsadafBelum ada peringkat

- Masterseal 590: Description Colours Typical Physical PropertiesDokumen1 halamanMasterseal 590: Description Colours Typical Physical PropertiesKannan MurugesanBelum ada peringkat

- Volza - China To IndiaDokumen28 halamanVolza - China To Indiamohammed.surangiwalaBelum ada peringkat

- Linda - Review W CKI - 04mar20 - Increasing 10percent of Contract Unit RateDokumen54 halamanLinda - Review W CKI - 04mar20 - Increasing 10percent of Contract Unit RateoktianaBelum ada peringkat

- Stock Register - 2Dokumen6 halamanStock Register - 2gayan_sarindaBelum ada peringkat

- Dimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingDokumen1 halamanDimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraBelum ada peringkat