Risk Management in EPC Contract - Risk Identification: Rahul Bali and Prof M.R Apte

Diunggah oleh

Akhileshkumar PandeyJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Risk Management in EPC Contract - Risk Identification: Rahul Bali and Prof M.R Apte

Diunggah oleh

Akhileshkumar PandeyHak Cipta:

Format Tersedia

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X, Volume 11, Issue 1 Ver. IV (Feb. 2014), PP 07-12

www.iosrjournals.org

Risk Management in EPC Contract - Risk Identification

Rahul Bali1 and Prof M.R Apte2

1

M. E Civil [C & M] MIT College, Pune.

Guide & Professors Civil Eng. Dept., MIT College, Pune.

Abstract: In this paper, we discuss the major risks identified in an EPC Contract which may affect the project.

These are the practices as a part of risk management. The key benefits of this process is the documentation of

existing risks and the knowledge and ability it provides to the project team to anticipate events.

Risk identification is an iterative process, new risks may evolve or become known, as the project progresses

through its life cycle. The frequency of iteration and participation in each cycle will vary by situation. The

process should involve the project team so they can develop and maintain a sense of ownership and

responsibility for the risks and associated risk response actions. Stakeholders outside the project team may

provide additional objective information.

A case study of construction of a Radial Intake well (an EPC Contract) for a Thermal Power Plant has

been considered for this research work.

Key Words: Risks, Risk Identification, Risk Management, Radial Intake Wells, EPC Contract.

I.

Introduction

Project risk management is the art and science of managing risks caused by unforeseen changes

(uncertainties) which may require deviations from the planned approach and may therefore affect the

achievement of the project objectives. It involves systematically identifying, analyzing, planning and controlling

risks.

Paper highlights the risks identified in Engineering Procurement & Construction Contracts (Turnkey)

(E.P.C) as a part of risk management process. Identifying the major risk sources and quantifying them w.r.t

likelihood, impact and severity in a complex infrastructure projects. The Case study for the research has been

taken as construction of Raw Water Intake System for a Thermal Power Plant in Maharashtra, India by

constructing a Radial Intake Well (Radial Collector well).

II.

Case Study

Owner planned to set up a coal based thermal power plant in close proximity of all major resources. For that

purpose a broad gauge railway connection availability along with the perennial river source of water, which is

considered for the consumptive water requirement of the power station, were the priorities. To utilize both

railway connection for bringing coal and getting water from the river for its consumptive use the site was

finalized. Consultants were appointed to carry out a pumping out test to find feasibility of drawing water based

on the field permeability of sand along with the depth of sand bed in river and the type and quality of sand.

M/S PRATHAMESH Project Engineering and Management Consultants, Nagpur (PRA) carried out the

required tests and feasibility for the project and recommended Radial Collector Well for the project. The

recommendations were made based on water required for the life span of project, site data conditions, pumping

out tests, field permeability tests, depth of sand bed in river, quality of sand, geotech investigation, topographic

surveys, field surveys, flood records, project maximum flood, project design flood, calculating highest flood

level in river, references, standard codes and Manual on Water Supply and Treatment of The Central Public

Health and Environmental Engineering Organisation [CPHEEO].

Keeping risks of all stakeholders under consideration owner approved the recommendations and tender was

floated as a Lump Sum EPC turnkey contract on single responsibility (design and build) basis. Parties were

invited with expertise in similar kind of job. Scope was set which included designing, construction of Radial

Well in river, approach bridge, switchgear room, rising main from radial well to plant end reservoir with all

appurtenances, pumping machinery at radial well, substation at radial well location and at plant end, 33KV

overhead, single circuit, transmission line, full SCADA system etc and ROW.

Construction commenced in month of March-April 2011, execution work was divided in phases to organize the

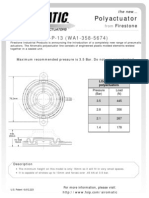

scope Radial well of ID- 9.2 m ID and OD- 12 m, by sinking method 10 m below RBL of total height 27 m with

overhead pump house of size 16 x12x11.2 m. Approach Bridge with foundation and piers in RCC of width 5 m

and length 150 m. Switch yard and sub-station, all pipe line structures. Radials: 300 mm dia steel radials pushed

at 7 m below RBL. Total 15 nos of 525 m length. Bottom Plugging: by Tremie Method. Ref Figure 1 and Figure

1.1

www.iosrjournals.org

7 | Page

Risk Management in EPC Contract - Risk Identification

FIGURE 1 : RADIAL WELL IN RIVER BED AQUIFER

FIGURE 1.1: SECTIONAL VIEW OF RADIAL WELL

III.

Methodology

To achieve the objective of this research, Brain-storming secessions and analysis of historic data for similar

projects were found to be the most preferred method. Consultant (PRA) have achieved core competence in the

field of water infrastructure with a vast experience, studies and detailed analysis, designs of various similar

types of projects carried out overs years.

Experiences shared by managers, engineers, supervisors in tackling risks at various levels in these projects

put forth during planning stage of a new project helps in overviewing the project and identifying the expected

risk.

3.1) An unforeseen situation leading to an event, the occurrence of which is likely to deviate from the

estimated or forecast value or planned path.

3.2) The probability of occurrence of the event.

3.3) Likely impact of that event, i.e loss or gain.

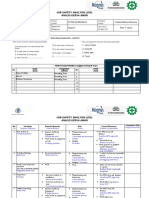

These major components of risks get covered during brainstorming secessions. Project schedule are very

helpful in this respect. Summery schedule sheet of present case study can be seen in Figure 2.

Figure 2 Summery Schedule Chart

While executing the project there were some delays in individual activities, as risk identification and sorting out

was done in time by concerned stakeholders and thus ultimate effect on overall project was minimum.

www.iosrjournals.org

8 | Page

Risk Management in EPC Contract - Risk Identification

Risks divided into risk events, most of them identified by breaking down the risk sources into manageable

levels of details either by project objectives, work packages, management functions, brainstorming or judgment

based on the knowledge of experts or combination of these. This breakdown enables the risk planners to

recognize the nature of risk events likely to be encountered.

IV.

Sources of Risk

Number of risks are encountered with modern projects, right from concept to commissioning.

Commonly encountered risk sources are commercial risks, design risks, natural disaster risk, cost overrun risk

and time overrun risk. Some of the project risk sources are shown in table 1

Table 1 Project Risk Sources

External Environments

Predictable Sources

Political and Legal

Design and Specification

Financial and Economical

Internal Environment

Scope change, Time

overrun, Cost Overrun

Technology Change

Quality and

specification failure

Leadership and

organizational

failure

Resource Failure

Contractor Failure

External Environments

Unknown uncertainties

Acts of God

Ecology

Safety and Health

Based on project risk sources in Table 1, generalized risk identifications and classification involved in

project are ref Table 2

Table 2 Classification of Risks Involved in Project

S. no

1

2

3

4

5

6

7

Risk Description

Project Scope Risk / Feasibility Risk

Design & Specification Risk

Quality Risk

Time overrun Risk

Cost Overrun Risk

Leadership Risk

Organizational Risk

Physical Resource mobilization and utilization

Risk

Technology Risk

Contractual Risk

8

9

10

S.no

11

12

13

14

15

16

17

18

19

Risk Description

Force majeure & ecological Risk

Political, Legal and Social Risks

Financial & Economical Risk

Safety Health and environmental Risk

Funding Failure Risk

Communication and network failure Risks

Project Execution Risks

Installation Risks of Mechanical and Electrical

works.

Purchase and Procurement Risks

As sources of risks are identified, classifications are made and risks are indicated to various activities. Work

is breakdown into manageable activities to get the grip on project and minimize the construction risks and

delays. This breakdown and risk indication enables the risk planners to recognize the nature of risk events likely

to be encountered. Details are furnished in table 3.

TABLE: 3 Work Breakdown with Risk identification

Sno

1

2

3

4

5

5

6

7

8

9

10

11

12

13

14

15

16

17

Activities

Permissions, Sanctions, ROWs(Right of Way) for

Pipeline alignments, etc complete

Site Mobilization, Site Office setup Approach Road etc

Complete

Socketing and Sinking of Well

Placing RCC Concrete Plug (Bottom Plug)

Additional Soil investigations and test to overcome

problems (if any)

Fixing temp Platform in side well

Radials Pushing

Construction of Intake well up to pump house floor.

Construction of Pump house up to roof bottom

Pump house roof completion

Complete finishing of Pump house and electrification.

Raft reinforcement with shuttering of switchgear room

Concreting of raft

Column and Beams up to slab

Stacking of boulder and murrum, back Filling Complete

Reinforcement of shuttering for roof slab

Construction of Columns Beams and roof slab of

switchgear room

Plastering of switchgear room

Risks Involved

(Ref Table 2)

7,6,10,12,17,18

1,4,6,8,14,16

1,2,3,4,5,8,9,11,14,17,18

1,2,3,4,5,8,9,11,14,17,18

1,2,4,5,9,13

2,3,4,8,9,14,17,18

1,2,3,4,5,8,9,11,14,17,18

2,3,4,6,8,9,11,14,17,18

1,2,3,4,5,6,8,9,11,14,17,18

1,2,3,4,5,6,8,9,11,14,17,18

1,2,3,4,5,6,8,9,11,14,17,18

1,2,3,4,6,8,9,11,14,17,18

1,2,3,4,6,8,9,11,14,17

1,2,3,4,6,8,9,11,14,17

1,2,3,4,5,6,8,9,10,11,14,17

1,2,3,4,6,8,9,11,14,17,18

1,2,3,4,6,8,9,11,14,17,18

1,2,3,4,6,8,9,11,14,17

www.iosrjournals.org

9 | Page

Risk Management in EPC Contract - Risk Identification

18

19

20

21

22

23

24

25

26

27

28

Painting of switchgear room

Fixing of side railing and electrification of switchgear

room

Construction of precast concrete girder

Construction of Pile work including pile cap

Fabrication of shuttering for piers

Construction of piers

Placing of bridges girders & bridge slab casting

Plant end substation layout making

Construction of transformer foundation and firewall

Construction of outdoor equipment foundation

Laying of pipeline work along with PWD road

29

Laying of pipeline complete including all accessories

30

31

35

Overhead line approvals

Electric items for substation and switchgear

Procurement

Electric items for substation and switchgear Installation

Conductor, cables and hardware for transmission lineProcurement

Conductor, cables and hardware for transmission lineInstallation

Pumps and motors with ancillary- Procurement

36

Pumps and motors with ancillary- Installation

37

39

Step up Transformer, CNR panel etc at plant end

Procurement

Step up Transformer, CNR panel etc at plant end

Installation

Instrumentation panel Procurement

40

Instrumentation panel Installation & Commissioning

41

All mechanical appurtenances like valves, EJ, etc Procurement

All mechanical appurtenances like valves, EJ, etc

Installing

32

33

34

38

42

1,2,3,4,6,8,9,11,14,17

2,3,8,14,18

1,2,3,4,5,6,8,9,11,14,17,18

1,2,3,4,5,8,9,11,14,17,18

1,2,3,4,6,8,9,11,14,17,18

1,2,3,4,5,8,9,11,14,17,18

1,2,3,4,5,8,9,11,14,17,18

1,2,4,6,8,10,11,17

1,2,3,4,6,8,9,11,14,17,18

1,2,3,4,6,8,9,11,14,17,18

1,2,3,4,5,6,8,9,10,11,12,13,

14,15,16,17,18

1,2,3,4,5,6,8,9,10,11,12,13,14,15,16,1

7,18

7,10,12

1,2,3,4,5,6,7,8,9,11,14,

15, 19

1,2,3,4,5,6,7,8,9,11,14,15,18

1,2,3,4,5,6,7,8,9,11,14,

15,19

1,2,3,4,5,6,7,8,9,11,14,

15,18

1,2,3,4,5,6,7,8,9,11,14,

15,19

1,2,3,4,5,6,7,8,9,11,14,

15,18

1,2,3,4,5,6,7,8,9,11,14,

15,19

1,2,3,4,5,6,7,8,9,11,14,

15,18

1,2,3,4,5,6,7,8,9,11,14,

15,19

1,2,3,4,5,6,7,8,9,11,14,

15,18

1,2,3,4,5,6,7,8,9,11,14,

15,19

1,2,3,4,5,6,7,8,9,11,14,

15,18

Execution completed in 15-16 months overshooting the stipulated completion time of 11 months. As

shown in summery schedule sheet figure 2 above. Major idle time delays and reasons recorded are tabulated in

table 4.

Table 4: Delay / Idle Time

Delay/Idle time

(Days)

Sno

Remarks

42

Due to Heavy rains & Floods

39

Due to Govt Clearance problem

It is reflected from data that nearly 3 moths of time overrun occurred, resulted in linked cost overrun of

overall project. Apart from this delay of nearly 3 months, project underwent smooth execution till completion.

Present day status is project stands completed and is fully commissioned. Contractor has received major part of

financial dues from owners side and project stated as success for all stakeholders.

V.

Approach to Risk Identification & Risk Management

Risk identification is an iterative process that involves the project team, stakeholders and other managers

affected by or who affect the project, and finally outside individuals who can comment on the completeness of

the risk identification based on their similar experiences.

The challenge lies in identifying beforehand all the risks that you might face so that the project team is well

equipped and ready to mitigate it systematically. While it is a well-known fact that risk identification is a step by

step process, i.e. new risks might appear only when the project reaches a certain level, this is exactly where

analysis of historical data comes into play. The project team has to collect all possible relevant data of previous

projects and take into account all the similar risks that can be linked even remotely. This can be done with the

help of checklists and brain- storming sessions.

By identifying risks at an early stage of planning a construction project or a tender and assessing their

relative importance, the project management can be adapted to reduce the risks and allocate them to the parties

www.iosrjournals.org

10 | Page

Risk Management in EPC Contract - Risk Identification

best able to control them or absorb them when they occur. Studies should be carried out early in the life of a

project.

VI.

Important Tools/Aspects in Risk Identification and Assessment

6.1) Work Breakdown Structure:

Before the commencement of the project all tasks are listed, broken down into manageable subtasks&

the schedule is prepared via MS Project or Primavera. It breaks down activities into smaller and more specific

sub-tasks which gives an exact idea of what needs to be done and the amount of resources to be spent on that

task. It can have as many levels as possible. A WBS with the schedule is imperative in the risk identification

particularly in an industrial project involving structural steel. The WBS in the schedule can be used to generate a

BIM or VDC (Virtual Design Construction or 3D models) video which would give a clear idea of the activities

to be performed in a chronological order.

6.2) Product Specification:

Product Specifications is a literature given to the contractors by the owners which gives a detailed

description on how the product is to be executed. There are additional or new (other than the common ones)

risks for products which have particularly different specification.

6.3) Method Statements for Typical activities:

During execution some activities are very typical. They require a prescribe way for successful completion

for achieving 100% objective. Chronology and correct procedure of these activities & method statements

prepared in advance and modified during executions are shared with contractor. This results speedy work and

minimizing risks and delays.

6.4) Resource Plan:

Resources refer to men, materials & machinery. Resources are the Achilles heel of all the construction

processes. In India there are more risks arising out of the lack of or management of resources rather than the

activities themselves. Hence while brainstorming it is very important to assign the activities just the right

amount of resources required.

Once Risks are identified, suitable engineering staff should work on:

Defining readjustments in execution of activity if any,

o During execution of activity.

o After completion of activity.

Increasing inputs in form of men materials labors in subsequent activities to reduce impact of

delays & ultimate completion of project.

VII.

Conclusion & Recommendations

Project Management is effective and efficient only when there is awareness of risk exposures and

method of handling risks. The project being an EPC turnkey contract minimises the owners risks to some

extent. But in situations where time is essence and completion of project is priority, efforts are equally taken by

all stakeholders in the interest of project. Infrastructure projects related to marine conditions are more prone to

risks as they directly come in contact with flowing water and harsh climatic conditions like floods etc .These

projects require permissions and sanctions from various govt departments & require to collect data on floods

and rainfalls for up to periods of 100 years which is a time consuming affair. Social impacts are comparatively

high.

It is sometimes argued that risk identification process induces negative and cautious attitudes among

the team or the project sponsors. Contrary to this, it can be said that the risk identification process, if developed

with the participation of the project team, enables effective management of project.

Fast changing, unstable, risk prone environments cannot be stopped, however managers can prepare

themselves for the resulting impacts of risks to their project. This in turn reduces exposure to project time, cost

and performance risks.

Acknowledgement

The author would like to thank M/S PRATHAMESH Project Engineering and Management Consultants,

Nagpur, Maharashtra and site contractors IVRCL Infrastructures & Projects ltd for their support and guidance in

collection of data to complete research for the case study.

www.iosrjournals.org

11 | Page

Risk Management in EPC Contract - Risk Identification

Reference

[1].

[2].

[3].

[4].

[5].

[6].

[7].

A Guide to Project Management Body of Knowledge, (PMBOK) Fifth Edition, 2013 Project Management Institute, Inc.

Debasis Sarkar & Goutam Datta (2011) A Framework of Project Risk Management for the Underground Corridor Construction of

Metro Rail , IIM Ahmedabad, W.P No 2011-02-05

Kinnaresh Patel (2013) A study on risk assessment and its management in India, American Journal of Civil Engineering. Vol. 1, No.

2, 2013, pp. 64-67. doi: 10.11648 / j.ajce .20130102.13

K K Chitkara, Construction Project Management, Second Edition, Tata McGraw Hill Pvt Ltd.

Manual on Water Supply and Treatment i.e The Central Public Health and Environmental Engineering Organisation

[CPHEEO].GOI under MoUD, para 5.2.6.3, page81, edition 3

Project Risk Management Handbook, Scalable Approach, Ver 1, June 2012

Patrica Gallowoway,PE, 1750, Design-Build/EPC Contractors Heightened Risk Changes in a Changing World CEO PegasusGlobal Holdings, Inc, Emerick Rd,Cle Elum, WA 98922

www.iosrjournals.org

12 | Page

Anda mungkin juga menyukai

- Construction ManagementDokumen4 halamanConstruction ManagementJournalNX - a Multidisciplinary Peer Reviewed JournalBelum ada peringkat

- 1 PDFDokumen3 halaman1 PDFGokul KrishnanBelum ada peringkat

- The Risk of Using Risk Matrices PDFDokumen12 halamanThe Risk of Using Risk Matrices PDFJack SparoBelum ada peringkat

- 2008 How Contractors Price in RiskDokumen15 halaman2008 How Contractors Price in RiskindikumaBelum ada peringkat

- Risk Assessment and Management in Construction Projects: 1.1. Definition of Risk 1.3. Risk ExposureDokumen10 halamanRisk Assessment and Management in Construction Projects: 1.1. Definition of Risk 1.3. Risk ExposureThanh PhamBelum ada peringkat

- English Grammar Review Level 4Dokumen125 halamanEnglish Grammar Review Level 4arementeBelum ada peringkat

- Types and Causes of Construction Claims IJERTV3IS120582Dokumen4 halamanTypes and Causes of Construction Claims IJERTV3IS120582Yelisa Danny DenzelBelum ada peringkat

- Contract Management Handbook PDFDokumen87 halamanContract Management Handbook PDFsurafel getachewBelum ada peringkat

- Risk Management in Construction Projects: A Knowledge-Based ApproachDokumen10 halamanRisk Management in Construction Projects: A Knowledge-Based ApproachStephen De GuzmanBelum ada peringkat

- Contract Management Lecture No. 1Dokumen40 halamanContract Management Lecture No. 1Ishfaque AhmedBelum ada peringkat

- Risk Analysis in Construction ProjectDokumen5 halamanRisk Analysis in Construction ProjectEditor IJTSRDBelum ada peringkat

- Risk Attitude and Risk Controllability: Their Implications On The Subjective Quantification of Risk in International Construction ProjectsDokumen13 halamanRisk Attitude and Risk Controllability: Their Implications On The Subjective Quantification of Risk in International Construction ProjectsIJAERS JOURNALBelum ada peringkat

- Topic 2 - Contract - 2 PDFDokumen92 halamanTopic 2 - Contract - 2 PDFPositive VibeBelum ada peringkat

- Mospi Contract DocumentDokumen120 halamanMospi Contract DocumentrohanregeBelum ada peringkat

- A Risk and Cost ManagementDokumen8 halamanA Risk and Cost ManagementRoberto CastroBelum ada peringkat

- Contract Management From CAGDokumen7 halamanContract Management From CAGpriyasingh1682Belum ada peringkat

- Contract Administration 2017. Assignment BrifeDokumen3 halamanContract Administration 2017. Assignment BrifeHumphrey OmolloBelum ada peringkat

- Bickmorecrtmanualv 1Dokumen114 halamanBickmorecrtmanualv 1api-322956236Belum ada peringkat

- Contracts Classification: in Construction ProjectsDokumen23 halamanContracts Classification: in Construction ProjectsNaoufal ElouardiBelum ada peringkat

- Recent Research Trends in Business AdministrationDokumen147 halamanRecent Research Trends in Business AdministrationPrem KnowlesBelum ada peringkat

- Handbook Pay and Allowances 2023Dokumen320 halamanHandbook Pay and Allowances 2023GagandeepBelum ada peringkat

- Adapt-Felt 2011 User ManualDokumen126 halamanAdapt-Felt 2011 User Manualmhan100% (1)

- Construction Risks and Contracting PracticesDokumen12 halamanConstruction Risks and Contracting PracticeshymerchmidtBelum ada peringkat

- EPC Contract and Project Management How To Reach MilestonesDokumen2 halamanEPC Contract and Project Management How To Reach MilestonespamlidBelum ada peringkat

- Bqs 2203 Construction Law II Course OutlineDokumen4 halamanBqs 2203 Construction Law II Course OutlineShinet V MlamboBelum ada peringkat

- VMoran - HK Causation Presentation Draft FinalDokumen26 halamanVMoran - HK Causation Presentation Draft FinalMohamed Talaat ElsheikhBelum ada peringkat

- Toc - 44r-08 - Risk Analysis RangDokumen4 halamanToc - 44r-08 - Risk Analysis RangdeeptiBelum ada peringkat

- FIDIC Seminar BrochureDokumen4 halamanFIDIC Seminar Brochure8790922772Belum ada peringkat

- Case 41-53 PDFDokumen135 halamanCase 41-53 PDFMan HernandoBelum ada peringkat

- Contractor Evaluation6Dokumen18 halamanContractor Evaluation6inrsafety9742Belum ada peringkat

- Risk ManagementDokumen6 halamanRisk ManagementAkhileshkumar PandeyBelum ada peringkat

- Craig Enderbury Prolongation Cost Claims The Basic Principles1Dokumen6 halamanCraig Enderbury Prolongation Cost Claims The Basic Principles1Genesis T. TagailoBelum ada peringkat

- A Comprehensive Literature Review On Construction Project Risk Analysis PDFDokumen16 halamanA Comprehensive Literature Review On Construction Project Risk Analysis PDFAsif HameedBelum ada peringkat

- Michael Harris: ONG NternationalDokumen25 halamanMichael Harris: ONG NternationalAjaya KumarBelum ada peringkat

- Standard Form Contract GuideDokumen24 halamanStandard Form Contract GuideManojBelum ada peringkat

- Amending Standard Form ContractsDokumen10 halamanAmending Standard Form ContractsHoang Vien DuBelum ada peringkat

- Legal and Contractual Issues SyllabusDokumen2 halamanLegal and Contractual Issues SyllabusChow Kwan HangBelum ada peringkat

- Float Ownership Part2Dokumen4 halamanFloat Ownership Part2Walied AbdeldayemBelum ada peringkat

- Risk Assessment FundamentalsDokumen26 halamanRisk Assessment FundamentalsTAHER AMMARBelum ada peringkat

- Framework To Contract DratingDokumen25 halamanFramework To Contract DratingDr.Ajit PatwardhanBelum ada peringkat

- Contracts & Claims Management Training Workshop Session - IiDokumen66 halamanContracts & Claims Management Training Workshop Session - IiEmadBelum ada peringkat

- Very Important XPS - Thermal Insulation BoardsDokumen10 halamanVery Important XPS - Thermal Insulation BoardsPravin MundeBelum ada peringkat

- Contract Administration Core Curriculum Participant's Manual and Reference Guide 2006Dokumen198 halamanContract Administration Core Curriculum Participant's Manual and Reference Guide 2006Larry Lyon100% (1)

- Comparing Risk Allocation in Standard and General Construction ContractsDokumen18 halamanComparing Risk Allocation in Standard and General Construction ContractsSunil PatilBelum ada peringkat

- MP Public Works Contract ManagementDokumen30 halamanMP Public Works Contract ManagementAkhilesh AgrawalBelum ada peringkat

- Procurement Management: Not Suitable For Fast Track ProjectsDokumen11 halamanProcurement Management: Not Suitable For Fast Track ProjectsJ GanzoBelum ada peringkat

- PPG#1 CONTRACTS AND CLAIMS 4TH EDITION SCHEDULE MANAGEMENTDokumen29 halamanPPG#1 CONTRACTS AND CLAIMS 4TH EDITION SCHEDULE MANAGEMENTdanudmwBelum ada peringkat

- Analizing Schedule Delay of Mega ProjectDokumen14 halamanAnalizing Schedule Delay of Mega ProjectJorge Carranza EscalanteBelum ada peringkat

- Pacing Why Hurry Up and WaitDokumen6 halamanPacing Why Hurry Up and WaitMohamed Talaat ElsheikhBelum ada peringkat

- Society of Construction Law (UAE)Dokumen11 halamanSociety of Construction Law (UAE)Ahmed AbdulShafiBelum ada peringkat

- Causes of Delay in Construction Projects in PakistanDokumen16 halamanCauses of Delay in Construction Projects in PakistanYasir NasimBelum ada peringkat

- Modul 1 讲义Dokumen352 halamanModul 1 讲义Yimo WangBelum ada peringkat

- Procurement Tender: Contracts Management & Advanced Quantity Surveying PracticeDokumen5 halamanProcurement Tender: Contracts Management & Advanced Quantity Surveying Practicenice mideaBelum ada peringkat

- Project Delivery Method A Complete Guide - 2020 EditionDari EverandProject Delivery Method A Complete Guide - 2020 EditionBelum ada peringkat

- Risk Management in EPC Contract - Risk IdentificationDokumen6 halamanRisk Management in EPC Contract - Risk IdentificationTharach JanesuapasaereeBelum ada peringkat

- Risk Management and Analysis in Hydro-Electric Projects in IndiaDokumen7 halamanRisk Management and Analysis in Hydro-Electric Projects in IndiaAlejandro Duvan Lopez RojasBelum ada peringkat

- Analyzing Risk in Refinery Projects Using Composite FactorsDokumen15 halamanAnalyzing Risk in Refinery Projects Using Composite FactorsJean-Louis KouassiBelum ada peringkat

- Kucuk Ali 2014Dokumen17 halamanKucuk Ali 2014Alejandro Duvan Lopez RojasBelum ada peringkat

- 180 DR P M DeshpandeR Singh-Done22Dokumen15 halaman180 DR P M DeshpandeR Singh-Done22GnamaSayaBelum ada peringkat

- 22 ChaleDokumen18 halaman22 Chalemesemo tadiwosBelum ada peringkat

- LCA Family Handbook 2021 2022 Final 1Dokumen86 halamanLCA Family Handbook 2021 2022 Final 1Akhileshkumar PandeyBelum ada peringkat

- Reference Correlation of The Thermal Conductivity of Sulfur Hexafluoride From The Triple Point To 1000 K and Up To 150 MpaDokumen10 halamanReference Correlation of The Thermal Conductivity of Sulfur Hexafluoride From The Triple Point To 1000 K and Up To 150 MpaAkhileshkumar PandeyBelum ada peringkat

- Document 1Dokumen1 halamanDocument 1Akhileshkumar PandeyBelum ada peringkat

- Eurosun2014-Proceedings - ImportentDokumen1.524 halamanEurosun2014-Proceedings - ImportentAkhileshkumar PandeyBelum ada peringkat

- Lit Reviews For RX Students v7Dokumen20 halamanLit Reviews For RX Students v7Joshua McdonaldBelum ada peringkat

- Handwriting Practice Resources for KidsDokumen1 halamanHandwriting Practice Resources for KidsUmairAkhtarBelum ada peringkat

- Electrical Breakdown in SF6 GasDokumen11 halamanElectrical Breakdown in SF6 GasAkhileshkumar PandeyBelum ada peringkat

- Sheath and Arc-Column Voltages in High-Pressure Arc DischargesDokumen11 halamanSheath and Arc-Column Voltages in High-Pressure Arc DischargesAkhileshkumar PandeyBelum ada peringkat

- 3 Pure Substance PDFDokumen11 halaman3 Pure Substance PDFAkhileshkumar PandeyBelum ada peringkat

- Chapter 3 Equations of StateDokumen65 halamanChapter 3 Equations of StateManoj Tiwari100% (1)

- Measurement of Air Breakdown Voltage and Electric Field Using Standard Sphere Gap MethodDokumen65 halamanMeasurement of Air Breakdown Voltage and Electric Field Using Standard Sphere Gap MethodGaurav KukadeBelum ada peringkat

- Sun Haibin 200612 PHDDokumen168 halamanSun Haibin 200612 PHDAkhileshkumar PandeyBelum ada peringkat

- World Energy Perspectives Energy Efficiency Technologies Overview ReportDokumen36 halamanWorld Energy Perspectives Energy Efficiency Technologies Overview ReportAkhileshkumar PandeyBelum ada peringkat

- Origins of Public Speaking: Chapter Objectives Chapter OutlineDokumen13 halamanOrigins of Public Speaking: Chapter Objectives Chapter OutlineAkhileshkumar PandeyBelum ada peringkat

- On Creating First ImpressionDokumen7 halamanOn Creating First ImpressionAkhileshkumar PandeyBelum ada peringkat

- Analytical DR - AymanDokumen44 halamanAnalytical DR - AymanAkhileshkumar PandeyBelum ada peringkat

- Business Communication For SuccessDokumen763 halamanBusiness Communication For Successvenkat_raj_38Belum ada peringkat

- Construction ManagementDokumen12 halamanConstruction ManagementSeble GetachewBelum ada peringkat

- 100 Best First LinesDokumen11 halaman100 Best First LinesPhilip Finlay Bryan100% (4)

- Comparison of Ageing Deterioration of Silicone Rubber Outdoor Polymer Insulator Under Salt Water Dip Wheel Test PDFDokumen8 halamanComparison of Ageing Deterioration of Silicone Rubber Outdoor Polymer Insulator Under Salt Water Dip Wheel Test PDFAkhileshkumar PandeyBelum ada peringkat

- Why Listening Is So ImportantDokumen5 halamanWhy Listening Is So ImportantAkhileshkumar PandeyBelum ada peringkat

- Handling a Bad BossDokumen10 halamanHandling a Bad Bossoudy525i2000Belum ada peringkat

- 05 High Voltage CablesDokumen27 halaman05 High Voltage Cablesdaegerte100% (5)

- Handling a Bad BossDokumen10 halamanHandling a Bad Bossoudy525i2000Belum ada peringkat

- Geotechnical Risks On Large Civil Engineering ProjectsDokumen12 halamanGeotechnical Risks On Large Civil Engineering ProjectsrobbyonBelum ada peringkat

- FailuresDokumen43 halamanFailuresAkhileshkumar PandeyBelum ada peringkat

- Classic Collection-22 Short Stories PDFDokumen146 halamanClassic Collection-22 Short Stories PDFSecon PauloBelum ada peringkat

- Heart FailureDokumen66 halamanHeart FailureAkhileshkumar PandeyBelum ada peringkat

- Greek and Latin RootsDokumen38 halamanGreek and Latin RootsAkhileshkumar PandeyBelum ada peringkat

- Kalani BookDokumen149 halamanKalani Bookniranjan_nitjBelum ada peringkat

- Wilderness 1500 X Study Plans Complete A 4Dokumen29 halamanWilderness 1500 X Study Plans Complete A 4Anonymous eiCiKcVkBelum ada peringkat

- Z Drive TechnologyDokumen16 halamanZ Drive Technologyebey_endun100% (1)

- DENSO Brochure enDokumen32 halamanDENSO Brochure enRudy BakriBelum ada peringkat

- User Exit Macro BAdi Wid ExampleDokumen19 halamanUser Exit Macro BAdi Wid ExampleSundaran NairBelum ada peringkat

- Professional PracticeDokumen3 halamanProfessional Practiceforbeska100% (1)

- Tired Dimension SymbolsDokumen8 halamanTired Dimension Symbolsengrfrancis052993Belum ada peringkat

- Auto Parts Inventory SystemDokumen4 halamanAuto Parts Inventory SystemVince Ryan L. ArboledaBelum ada peringkat

- RC SCM310 ProductionOrdersDokumen327 halamanRC SCM310 ProductionOrdersRRROMANCABelum ada peringkat

- Wa1 358 5674Dokumen30 halamanWa1 358 5674MROstop.comBelum ada peringkat

- IC Simple Cost Benefit AnalysisDokumen8 halamanIC Simple Cost Benefit Analysislord yoloBelum ada peringkat

- SR EN ISO 3452-1 (2021e PDFDokumen34 halamanSR EN ISO 3452-1 (2021e PDFAdrian100% (6)

- Venkata Maheedhar K V Voice:9441797872Dokumen6 halamanVenkata Maheedhar K V Voice:9441797872anon-739858Belum ada peringkat

- Foldable Puzzle Mat Game MatDokumen36 halamanFoldable Puzzle Mat Game MatAaronBelum ada peringkat

- A4 G970 - G990 Product Brochure enDokumen17 halamanA4 G970 - G990 Product Brochure endalibor_bogdan100% (3)

- SPHINX'18: Malaviya National Institute of Technology JaipurDokumen7 halamanSPHINX'18: Malaviya National Institute of Technology JaipurTushar Mani AgarwalBelum ada peringkat

- 1100 Series: Designed To Perform ..Dokumen2 halaman1100 Series: Designed To Perform ..dcoronado0487100% (2)

- PCI GFRC Manual 2nd EditionDokumen183 halamanPCI GFRC Manual 2nd EditionNuno Ferreira100% (4)

- MPA 344(a)/2017 Corrosion Protection TendersDokumen2 halamanMPA 344(a)/2017 Corrosion Protection TendersVeenoyBelum ada peringkat

- Racing Drones Market Key Players, Size, Trends, Opportunities and Growth AnalysisDokumen2 halamanRacing Drones Market Key Players, Size, Trends, Opportunities and Growth Analysissurendra choudharyBelum ada peringkat

- Lean Toolbox 0304Dokumen3 halamanLean Toolbox 0304bhplibBelum ada peringkat

- JSA Unstuffing Air Charge Intake...Dokumen5 halamanJSA Unstuffing Air Charge Intake...warryBelum ada peringkat

- EPCM TheMisunderstoodContractDokumen6 halamanEPCM TheMisunderstoodContractmonikatickoo4412100% (2)

- Hub and Spoke System PresentationDokumen13 halamanHub and Spoke System PresentationShreyasBelum ada peringkat

- Chap1 2Dokumen23 halamanChap1 2Neeraj SharmaBelum ada peringkat

- TWI Control of Welding DistortionDokumen12 halamanTWI Control of Welding DistortionClaudia Mms100% (2)

- TCS' Testing Service CapabilitiesDokumen19 halamanTCS' Testing Service Capabilitiesvinai.20100% (1)

- Biw Basic Document - Iit ProjectDokumen6 halamanBiw Basic Document - Iit ProjectArshadBelum ada peringkat

- Jet Kit InstallDokumen2 halamanJet Kit InstallmihaisimoBelum ada peringkat

- Beam Analysis BS5950Dokumen229 halamanBeam Analysis BS5950cataiceBelum ada peringkat