1801 2-InertoSafe-SIL2 V1 1 - en

Diunggah oleh

vipinJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1801 2-InertoSafe-SIL2 V1 1 - en

Diunggah oleh

vipinHak Cipta:

Format Tersedia

1801.

2

InertoSafe SIL 2

+ SIL 2-certified according to EN 61511

+ ATEX-certified components

+ Suitable for all kinds of vessel

+ DCS independent inertisation system with integrated logic

+ Low maintenance

Key functions

The InertoSafe SIL 2 inertisation system provides a safe and inert

environment inside any vessel. After an initial purging process the

system changes to a pressure conservation mode for maximum

safety. The system is based on pressure monitoring and is

therefore failsafe and virtually maintenance free.

Applications which require inert vessels to eliminate the risk of

explosion often demand increased safety measures for the entire

system. InertoSafe SIL 2 is certified SIL 2 according to

EN61511-1 and therefore suitable for any application requiring

failsafe control. InertoSafe SIL 2 is designed to operate with any

kind of primary control system. InertoSafe SIL 2 provides a highly

integrated and failsafe system. Two dual channel safety contacts

are provided for external safety stop functions.

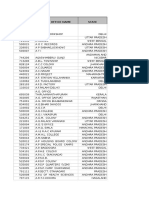

General P & I

FISAL

PISALH

N2

Vent

PCV002

self-adjusting

Purge panel

PCV001

adjustable

On / Off valve

SOV 01

Bearing purge

Vessel

(e.g. centrifuge)

Siphon

InertoSafe SIL 2

Technical data

InertoSafe SIL 2-system

SIL controller

Approvals

SIL 2 acc. to EN 61511-1:2004

ATEX certificates for components

UL certificates for components

Operation

Operation with integrated controls

Power supply

24 V DC 10 %

Max. power consumption

Admissible ambient

temperatures

Design

Rack mounted (also available in

enclosure)

Dimensions (W x H x D)

500 x 700 x 250 mm

ATEX approvals

n/a (optionally also available for

installation in Zone 2 or Zone 1)

2A

Interface

Digital and analogue E/A

Storage -20C to +40C

Operation 0C to +40C

Weight

approx. 30 kg

Purge panel

Material

Stainless steel

Dimensions (W x H x D)

500 x 500 x 300 mm

ATEX approvals

Zone 1

Weight

approx. 18 kg

Configuration

The InertoSafe SIL 2 system includes

Purge panel in stainless steel for installation in the

hazardous area

Pre-wired SIL controller for installation in a safe area

(optional enclosures available)

Flow switch type Rota Yokogawa RAMC

Pressure transmitter type Cerabar

Operator manual and certificates

General Layout

Interface

Control cabinet

PLC

Inerting system active

Power supply 24 V/DC

Control ON / OFF

Interface

Control room

Failure at start

see details

Purge active

Purge failure

Pressure maintain active

Safety circuit

with feedback

SIL Controller

Pressure maintain failure

Emergency

stop

FSL

SIL Inertisation

PSL

PSH

N2 solenoid open / close

FISAL

PISALH

Vent

PCV002

self-adjusting

Purge panel

PI pressure 4 20 mA

N2

PCV001

adjustable

Monitored feedback contacts

On / Off valve

SOV 01

Vessel

(e.g. centrifuge)

Siphon

Safety circuit with feedback

Bearing purge

Safe auxiliary contacts

Ferrum Ltd. | Business Unit Centrifuge Technology | CH-5503 Schafisheim | www.ferrum.net | zentrifugen@ferrum.net

Ferrum Ltd. reserves the copyright for this document and all enclosures at all times. Subject to technical changes.

EN 1.1 / 09.14 / MMA

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- CTR 8540 - 8300 E0.3.4Dokumen220 halamanCTR 8540 - 8300 E0.3.4nea317100% (3)

- Improved Koren Pentode Conductance ModelDokumen14 halamanImproved Koren Pentode Conductance ModelThomas W KotowskiBelum ada peringkat

- V F Corporation NYSE VFC FinancialsDokumen10 halamanV F Corporation NYSE VFC FinancialsvipinBelum ada peringkat

- 524all India Pin Code ListDokumen578 halaman524all India Pin Code Listvipin100% (1)

- Nike Inc Nyse Nke FinancialsDokumen10 halamanNike Inc Nyse Nke FinancialsvipinBelum ada peringkat

- MA1B 4 03 Calculating RatiosDokumen2 halamanMA1B 4 03 Calculating RatiosvipinBelum ada peringkat

- Headspace Oxygen Measurement in Vials and AmpoulesDokumen4 halamanHeadspace Oxygen Measurement in Vials and AmpoulesGhanta Ranjith KumarBelum ada peringkat

- VCTDS-01042 Models Y1 BV-1 RA-Blanketing Regulator-EnDokumen6 halamanVCTDS-01042 Models Y1 BV-1 RA-Blanketing Regulator-EnvipinBelum ada peringkat

- VCTDS-01061 Sizing of Tank Blanketing System-EnDokumen3 halamanVCTDS-01061 Sizing of Tank Blanketing System-EnvipinBelum ada peringkat

- Ferrum Product Folder enDokumen6 halamanFerrum Product Folder envipinBelum ada peringkat

- AAI - ATC Physics 2Dokumen7 halamanAAI - ATC Physics 2armaan626742Belum ada peringkat

- GRB200 (Decentralized) Brochure - 18005-G2A-0.10Dokumen39 halamanGRB200 (Decentralized) Brochure - 18005-G2A-0.10krishna mohanBelum ada peringkat

- SMAC Actuators User Manual 05-05Dokumen52 halamanSMAC Actuators User Manual 05-05joaoluBelum ada peringkat

- Site Survey For Solar PVDokumen4 halamanSite Survey For Solar PVLavancha Renewables100% (1)

- Hydrogen-Related R&D - DTU Wind - Nov 2023Dokumen29 halamanHydrogen-Related R&D - DTU Wind - Nov 2023gisele.goesBelum ada peringkat

- Explain How Multiplexing Is So Cost-Effective. How Is Interference Avoided by Using Frequency Division Multiplexing?Dokumen3 halamanExplain How Multiplexing Is So Cost-Effective. How Is Interference Avoided by Using Frequency Division Multiplexing?Fahad RuhulBelum ada peringkat

- Pic16f887 MicrocontrollerDokumen12 halamanPic16f887 MicrocontrollerShameerBelum ada peringkat

- Watchman Oil MonitorDokumen6 halamanWatchman Oil MonitorSensors Systems - The Winter Fuel ShopBelum ada peringkat

- VLSI ManualDokumen37 halamanVLSI ManualDeekshithaBelum ada peringkat

- F Frame Snubber Resistor Replacement For 1336 PLUS, PLUS II, Force, Impact and Regen DrivesDokumen6 halamanF Frame Snubber Resistor Replacement For 1336 PLUS, PLUS II, Force, Impact and Regen DrivesAnonymous GbfoQcCBelum ada peringkat

- GPG Findings 028-Control Optimization System 1535393590Dokumen4 halamanGPG Findings 028-Control Optimization System 1535393590angga.snc29Belum ada peringkat

- Premier Electronics - Stock ListDokumen10 halamanPremier Electronics - Stock ListRushabhShahBelum ada peringkat

- System Description of BL ABSDokumen32 halamanSystem Description of BL ABSPhan VănBelum ada peringkat

- Bowers Wilkins 600 Series 3 User ManualDokumen14 halamanBowers Wilkins 600 Series 3 User ManualEd StepkoBelum ada peringkat

- Are Excel BOM Templates Right For YOU?: Want More Info On BOM Management?Dokumen20 halamanAre Excel BOM Templates Right For YOU?: Want More Info On BOM Management?brian santosBelum ada peringkat

- Data SheetDokumen13 halamanData SheetbhagvataBelum ada peringkat

- Monitor LG M227wap-Pm (LCD)Dokumen32 halamanMonitor LG M227wap-Pm (LCD)Ryan Brady0% (1)

- Cqm1 Cqm1h ManualDokumen75 halamanCqm1 Cqm1h ManualCicero MelloBelum ada peringkat

- Cata GB 2013 Dxn3Dokumen2 halamanCata GB 2013 Dxn3Vincenzo GiaconiaBelum ada peringkat

- Installation Manual: Dynamic Series Amps EA-DYN-2D-200 EA-DYN-8D-100 EA-DYN-12D-100 EA-DYN-16D-100Dokumen12 halamanInstallation Manual: Dynamic Series Amps EA-DYN-2D-200 EA-DYN-8D-100 EA-DYN-12D-100 EA-DYN-16D-100Ryan JonesBelum ada peringkat

- RAN3308: Flexi RFM 3T6R 2100Dokumen2 halamanRAN3308: Flexi RFM 3T6R 2100Reza BordbarBelum ada peringkat

- CYMGrdDokumen2 halamanCYMGrdingeisaaclgBelum ada peringkat

- QRP DSB Pentru 40 Si 20mDokumen8 halamanQRP DSB Pentru 40 Si 20mfox7878Belum ada peringkat

- KPI Formula - UpdatedDokumen22 halamanKPI Formula - UpdatedGazi Nazmul HoqBelum ada peringkat

- VLSI Device Isolation TechniquesDokumen24 halamanVLSI Device Isolation Techniquesसुधांशु जनवाड़करBelum ada peringkat

- Instrument LegendDokumen2 halamanInstrument LegendAlfon TampubolonBelum ada peringkat

- EDC LAB Manual PDFDokumen110 halamanEDC LAB Manual PDFAbhishek PathakBelum ada peringkat

- Cha 3 PDFDokumen25 halamanCha 3 PDFamareBelum ada peringkat