Us3311056 PDF

Diunggah oleh

checolonoskiDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Us3311056 PDF

Diunggah oleh

checolonoskiHak Cipta:

Format Tersedia

March 28, 1967

G. A. NODDIN

3,311,056

NON-RUPTURING DE TTTTTTTTTTT DS

eeeeeeeeeeee bl

'

INVEN

(JEORGE A. Now/m

BY

TOR

V)

A] 1 ORNEY

March 28, 1967

G. A. NODDIN

3,311,056

NON-RUPTURING DETONATING CORDS

Filed March 22, 1965

2 Sheets-Sheet 2

EXPLOSIVE

LEAD SHEATH

POLYURETHANE

ELASTOHER

,- EXPLOSIVE

\_ LEAD SHEATH

--- POLYUR

NE

ELASTO

INVENTOR

F_GEORGE A. NODDIN

ATTORNEY

United States Patent 0

3,311,050

Patented Mar. 28, 1967

3,311,056

In addition to polyurethanes of the type described in the

above patents which patents are incorporated herein

amines, glycols, etc., and particularly water or hydrazine.

NON -RUPTURING DETONATING CORDS

George A. Noddin, Mantua, N.J., assignnr to E. I. du

by reference, other polyurethane elastomers useful in

Pont de Nemours and Company, Wilmington, Del., a

corporation of Delaware

Filed Mar. 22, 1965, Ser. No. 441,772

4 Claims. (Cl. 102-27)

this invention include those of the types described in US.

Patent 2,729,618 and US. Patent 3,012,992, each of which

are also included herein by reference.

The explosives used in the cords of this invention can

This invention relates to a product, and more particu

be any of the wide variety of explosives conventionally

larly to non-rupturing detonating cords.

used in detonating cords.

Detonating cords, i.e., articles comprising a core of

Chief among these are cap

sensitive organic nitrates, nitramines and nitro compounds

detonating explosive usually surrounded by a metal sheath,

e.g., of lead, or by fabrics or other conventional covering

as well as inorganic QZldES. Examples of such explo

sives are pentaerythritol tetranitrate (PETN), cyclotri

materials, have found wide use in the explosive arts as

a means propagating a detonation from one point to 15

methylenetrinitramine (RDX), cyclotetr-amethylenetetra

nitramine (HMX), tetryl, tetranitrodibenzotetraazapentyl

another. One very large use of such products is in blast

enes such as tetranitrodibenzo-l,3a,4,6a-tetraazapentylene,

ing. Detonating cords have also been used in metal form

trinitrotoluene (TNT), lead styphnate, nitromannite, pic

ing and other metal working operations as well as for

ryl sulfone, 'bis(trinitroethyl) urea or a mixture of one

actuating mechanical devices. In recent years, detonating

or more of the foregoing explosives. Explosives such

cords have found wide space-age application, e.g., in 20 as those just mentioned can be used alone or in combina

missle-stage separation. Though current devices have

tion with one or more additives, for example, powdered

served well in the aforementioned applications, there has

metals such as aluminum, magnesium, boron, titanium,

been an increasing need for detonating cords which are

zirconium, tellurium and selenium as well as mixtures of

strong, light, tough and abrasion resistant yet do not re

one or more of the foregoing metals; one or more inor

lease the products of detonation of the explosive contained 25 ganic oxidizing salts such as ammonium nitrate, sodium

therein. This invention provides such detonating cords.

nitrate, red lead and alkali and alkaline-earth metal chlo

The detonating cords provided by this invention are

rates and perchlorates; and various binders for the ex

rapidly expanding and non-rupturing and comprise a core

plosive compositions such as natural and synthetic rub

of detonating explosive surrounded by a sheath of elas

bers, e.g., butyl rubber, nitrocellulose and epoxy resins '

tomeric polyurethane. The sheath thickness increases

as well as plasticizers for such binders. A preferred

With the explosive loading, with the particular core struc

multi-component core composition is the type of deform

ture and, to a certain extent, with the explosive employed.

able, self-supporting composition used in sheet explosives.

Normally, the ratio of explosive loading, in grains/ft, to

Of these, compositions of the type shown in US. Patent

sheath thickness, in inches, is less than 130/ 1, and prefer

2,992,087 containing, e.g., PETN, nitrocellulose and a tri

35 alkyl ester of Z-acetoxy-1,2,3-propanetircarboxylic acid

ably from about 10/1 to 100/1.

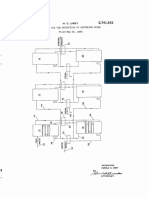

In the attached drawings, FIGURES 1 and 2 illus

and the compositions of US. Patent 2,999,743 containing

trate schematically transverse and longitudinal cross-sec

e.g., PETN, butyl rubber and terpene resin, are particu

tions of one embodiment of cords of this invention.

FIGURES 3 and 4 illustrate schematically transverse

larly preferred.

In the products of this invention, the explosive core

and longitudinal cross-sections of an alternativeembodi 40 can be directly in contact with the elastome'ric polyure

ment.

'

The polyurethane elastomers used in accordance with

this invention are rubbery polymers having the recurring

linkage

thane sheath. Alternately, the polyurethane sheath which

surrounds the core can be in contact with a metal sheath

which in turn is in contact with the explosive, core.

For

45 example, a piece of conventional detonating cord, either

countered or uncountered, can be inserted within a poly

urethane sheath. Thus, the products of this invention

comprise a core of detonating explosive surrounded by a

polyurethane elastomer sheath which can be directly in

Preferably, these polyurethanes contain polyester or

polyether moities linked by moities derived from urethane

contact therewith or separated from the core by one or

contributing reactions usually isocyanates or amines. Ex 50 more layers, e.g., of metal such as lead or aluminum,

amples of such polyurethanes are those described in US.

plastic or fabric, as in the case, for example, where a

Patent 2,929,802 formed by the'reaction of (1) a low

conventional detonating cord is inserted in the sheath.

molecular weight bis(chloroformate) and a diamine with

Some applications require devices in which the detonation

(2) a bis(chloroformate) of a polyether glycol, pref

products are completely contained while others require

erably a polyalkylene ether glycol such as polyethylene 55 only a degree of containment, so that the system is not

ether glycol or polypropylene ether glycol. Other ex

exposed to detonation products such as gases and metal

amples of polyurethanes are polyester urethanes such as

fragments. In the former case the polyurethane sheath

those described in US. Patent 2,871,218 formed by re

completely encapsulates and covers the ends of the core,

acting a polyester of an aliphatic dicarboxylic acid and an

while in the latter case the explosive of the core may be

aliphatic glycol with a diphenyl diisocyanate, e.g., di 60 exposed at one or both ends of the core. In"the case of

phenylmethane diisocyanate, and free glycol, e.g., butane

complete con?nement, preferably the initiation means,

1,4-diol. Other examples of polyurethanes include arnide/

for example, a miniaturized blasting cap, may be inserted

urethane/ether polymers such as those in US. Patent 2,

with the sheath adjacent the explosive of the core and the

929,801 formed by reacting monomeric diamine with an

polyurethane sheath sealed around the device. In the

65

amide-forming derivative of a difunctional acid and a

case where the core is exposed, it is often convenient to

polyether bis(haloformate), particularly segmented poly

mers of high and low molecular weight constituents.

Still other polyurethanes include chain-extended elasto

mers such as those shown in US. Patent 3,000,757 and

attach a conventional initiator, such as an electric blast

ing cap, to the core in the arrangement in which the cords

of this invention are employed. Usually, the amount of

explosive and material surrounding the core is such the

US. Patent 3,100,721 formed by chain-extending poly 70 polyurethane sheath expands at least 25%, and preferably

ester- or polyalkylene ether glycol-diisocyanate prepoly

mers with difunctional chain-extending agents including

50 to 150% in diameter on detonation of the core as

measured by a framing camera.

3,311,058

The amount of explosive employed depends on the

amount of expansion of the cord, the strength of the

glycol, 1,4-butanediol bis(chloroformate) and piperazine

detonation impulse desired, the explosive used, the de

commercially known as Texin 480A and Estane

gree of con?nement of the core, and the structure of the

sheath. Generally, the amount of explosive increases

with the expansion and impulse and, for a given expan

sion, increases with number and thickness of the layer or

layers of material surrounding the core. Usually, the

loading of explosive, excluding additives such as metallic

fuels, binders and plasticizers, ranges from 1 to 400, and

preferably 2 to 100 grains per foot.

in a molar ratio of 1:4:5.

Polyurethane-s C and D are

5740, respectively, and are the reaction products of 4,4

diphenylrnethane diisocyanate, polyalkyleneglycol adipate

and a small proportion of low molecular weight diol.

The properties of these polyurethane elastomers are

shown in the following table:

Polyurethane Elastomcr

Property

AS'IM

Method

The non-rupturing cords of this invention can be pre

pared, particularly in short lengths, by merely inserting

a preformed core of explosive in a preformed tube of

polyurethane.

Alternately, and preferably for longer

lengths, the polyurethane sheath can be continuously ex

truded around a preformed explosive core in a precentered

die, e.g., such as that used in wire coating. A strip of

polyurethane also can be wound around the core with

overlapped edges securely sealed to prevent rupture of 20

the polyurethane sheath on detonation of the core.

As indicated hereinbefore, the thickness of the elasto

meric polyurethane sheath depends upon the expansion

desired, the explosive charge, the degree of con?nement

Hardness, Shore A _________ ..

._t___

D676.__..

13

86

85

85

83

875

905

740

975

1,220

____ c.

Stress-strain (room temp):

Mm, p s.i ______________ __

Mm, D.S.i_____.

M300, p 51. __ _

TB, 1).S.i.____

En, percent"

_

_

1,125

D4412

1, 705

1. 800

1.900

4, 375

(V0

'1, 600

525

2,000

3-10

120

87

20

32

29

28

04

"

47

as

121

143

I16

Sn, percent- ____ _.

Compression set, pore

22 hrs. at room temp__

_.

...

22 hrs/70" o ___________ __ i'D 3MB)- {60-70

Split Tear, lh./linear in _____ __

1,330

1,450

"" 4, 800

600

D470_____

120

Yertlov Resilience, percent" D4345.-.

..

80

83

Low Temp. Brittle PL, F

D440.-.

106

l60

NBS Abrasion, percent ____ ._

D394_____

300

693

75

40

ll0 <02

245

____ __

of the core, and the interposed layers between the core 25

In the table the modulus M is given in p.s.i., at the in

and the sheath, but, in any case, should be sufficient to

dicated elongations, for example, a stress of 875 p.s.i.

prevent rupturing of the sheath on detonation of the core.

gives an elongation of 100% for A. TB is the tensile

Usually, to prevent rupturing, the ratio of detonating ex

plosive exclusive of additives, in grains per foot, to wall

thickness, in inches, is less than 130/1 and preferably

10/1 to 100/1. If the core has a lead sheath, e.g., as in

the case Where a conventional detonating cord is inserted

in a polyurethane sheath, lower ratios, e.g., 50 grains per

foot/inch or lower are normally employed. Where com

pletely con?ned cords are employed, that is, where the

polyurethane sheath surrounding the core also covers the

ends of the core and the initiating means, it is also often

desirable to use somewhat lower ratios of explosive load

strength at break; EB is elongation at break; and SB is

the tension set at break.

Examples 1 t0 5

Non-rupturing detonating cords are prepared by in

serting the following cores in preformed sections of

0.130-inch I.D., 0.550-inch O.D. tubing of polyurethane

elastomer A. To test the characteristics of the cords, a

No. 6 blasting cap is attached to one end of each cord,

extending beyond the end of the polyurethane sheath,

then initiated in air. The results are:

ing to sheath thickness.

The products of this invention are characterized by the 40

fact that they are rapidly expanding and non-rupturing,

Core

and are strong, lightweight, tough and abrasion resistant.

Example

Weight of

Freedom from detonation products is particularly im

Composition

Explosive

portant in space-age uses where, for example, such prod

(excluding

ucts might follow an orbiting satellite obscuring or effect

additives),

grains/it.

ing the satellites data-gathering mission, or in any other

Result

use where released combustion products would have a

PETN A ______________ __

17.5

Did not rupture.

deleterious effect. Since the cords do not rupture, danger

PETN 1 ______________ __

20.0

Do.

PIEIN in .105 in. 0.1).

10

Do.

from shrapnel from metal surrounding the core and

load sheath.

danger from combustion heat and ?ame is eliminated.

PEIN B ______________ __

27

Ruptured in 1st

trial. Did not

Thus, if temperature-sensitive materials are adajcent the

rupture in 2nd

cord, the risk of their decompositions is eliminated. The

trial.

5_________ PETN I ______________ __

37

Siieatnruptnred.

cords of this invention also greatly muffle the noise of

detonation.

The cords of this invention can be used in those appli 55 11 Self-supporting mixture of about 85% of PETN and 15% of an equi

weignt mixture of butyl rubber and terpene resin (1iccolyte S-lO and

cations where detonating cords are used conventionally.

S40 grades).

In space applications, they ?nd particular utility in sepa

The procedure described above can be repeated using

rating metal parts, e.g., missile stages. In such applica

an

equivalent weight of RDX, HMX or tetranitrodibenzo

tion, the cord is usually juxtaposed a groove or other

weakened area at the line of desired separation. Detona 60 tetraazapentylene instead of PETN in the core to yield

non-rupturing cords having properties similar to the above

tion of the core expands the sheath and separates the

cords. Similarly, the sheath can be prepared from poly

parts along a line adjacent the cord. The products ?nd

urethanes

B, C or D to yield similar non-rupturing cords

utility generally in any application where the environment

of this invention.

through which the cord passes is sensitive to shocks, noise,

Example 6

combustion products or heat and ?ame.

65

In the following more speci?c examples which further

A core of 5 grains per foot of the commercially known

illustrate this invention, parts and percentages are by

Pyrocore (60/40, lead azide/aluminum, lead jacketed

weight unless otherwise indicated. In the following ex

with an OD. of 0.088 inch) is covered with a sheath of

amples, polyurethane A was prepared -by reacting the

polyurethane A having a wall thickness of 0.25 inch. The

following materials in the indicated ratio by the general

polyurethane is disposed on the lead~covered core by ex

truding the polyurethane around the Pyrocore core in

procedures shown in the aforementioned patents: 1 mole

a precente-red-die extruder. Detonation of the lead azide

of polytetramethyleneether glycol bis(chloroformate), 2

mixture does not rupture the cord. If the polyurethane

moles of 1,4-butanediol bis(chloroforrnate), 4 moles of

jacket is omitted, detonation of the lead azide mixture.

piperazine and 1 mole of adipyl chloride. Polyurethane

completely consumes the cord and lead covering.

elastomer B was prepared from polytetramethyleneether

3,311,056

I claim:

1. Non-rupturing detonating cords comprising a core

of cap-sensitive detonating high explosive and a sheath of

polyurethane elastomer, the ratio of the amount of ex

plosive in grains per foot to sheath thickness in inches

2,992,087

7/ 196-1

Fassnacht et a1. _..__ 10227 X

2,999,743

3,129,663

9/1961

4/1964

B'reza et a1 _______ __ 102_27 X

Schnepfe ________ __ 1o2_-70 X

being about from 101 to 1 to 130 to 1.

2. A cord of claim 1 wherein said core consists es

sentially of 2 to 210 grains per foot of PETN in a lead

815,534

FOREIGN PATENTS '

References Cited by the Applicant

sheath.

3. A cord of claim 1 wherein said core consists es

sentially of a mixture of PETN, butyl rubber and terpene

UNITED STATES PATENTS

10

resm.

2,863,353

4. A cord of claim 1 wherein said core consists es

sentially of a mixture of PETN, nitrocellulose and a tri

2,982,210

2,993,236

3,032.35 6

al-kyl ester of 2-acetoxy-1,2,3~propanetricarboxylic acid. 15

References Cited by the Examiner

UNITED STATES PATENTS

2,687,553

8/1954

6/1959 Great Britain.

Colombo ________ __ 102-27 X 20

12/ 1958 Brimley.

5/1961 Andrews et al.

7/ 19611 Brimley et a1.

5/ 1962 Botsford.

BENJAMIN A. BORCHELT, Primary Examiner.

V. R. P-ENDEGRASS, Assistant Examiner.

Anda mungkin juga menyukai

- United States Patent (191 Toyet A1.: Conduci Ive Polymer CompositionsDokumen9 halamanUnited States Patent (191 Toyet A1.: Conduci Ive Polymer CompositionsceshesolBelum ada peringkat

- United States PatentDokumen5 halamanUnited States PatentDaniel LiuBelum ada peringkat

- US4235766Dokumen5 halamanUS4235766هیمن مBelum ada peringkat

- Ipj E92010205Dokumen27 halamanIpj E92010205Jayadev KarthaBelum ada peringkat

- PolyesterDokumen4 halamanPolyesterPei LingBelum ada peringkat

- United States Patent (19) 4,588,855: Kutsuwa Et Al. (45) Date of PatentDokumen9 halamanUnited States Patent (19) 4,588,855: Kutsuwa Et Al. (45) Date of PatentceshesolBelum ada peringkat

- Sept. 20, 1966 - Alfllle 3,274,069: Filed June 17. 1965 5 Sheets $heet 1Dokumen6 halamanSept. 20, 1966 - Alfllle 3,274,069: Filed June 17. 1965 5 Sheets $heet 1kikkuri13Belum ada peringkat

- Us2783138 PDFDokumen3 halamanUs2783138 PDFchecolonoskiBelum ada peringkat

- Food and Nutritional Analysis Packaging MaterialsDokumen12 halamanFood and Nutritional Analysis Packaging MaterialsClara2772Belum ada peringkat

- Heterocyclic Tin Flame Retardants Smoke Suppressants and Halogen Containing PolymerDokumen7 halamanHeterocyclic Tin Flame Retardants Smoke Suppressants and Halogen Containing PolymerVansala GanesanBelum ada peringkat

- CH 08Dokumen42 halamanCH 08chimenBelum ada peringkat

- SBR LetixDokumen6 halamanSBR LetixzaighumBelum ada peringkat

- Plastics 319445 (1) Plastic DefectDokumen105 halamanPlastics 319445 (1) Plastic Defectmanuanil1989100% (1)

- Us7247372 PDFDokumen12 halamanUs7247372 PDFrevider451Belum ada peringkat

- Thermoplastic Polyurethane Elastomers: Synthesis, and Study of Effective Structural ParametersDokumen5 halamanThermoplastic Polyurethane Elastomers: Synthesis, and Study of Effective Structural Parametersabraham silva hernandezBelum ada peringkat

- Us5080735 PDFDokumen4 halamanUs5080735 PDFchecolonoskiBelum ada peringkat

- United States Patent 0. ": Patented Def. 5, 1965Dokumen6 halamanUnited States Patent 0. ": Patented Def. 5, 1965Ersa Nurul YarizsaBelum ada peringkat

- Polymers: Thermoplastics Thermosets Elastomers Synthetic FibersDokumen14 halamanPolymers: Thermoplastics Thermosets Elastomers Synthetic Fibersmahua khagBelum ada peringkat

- ACFrOgB7eh xQWVzYJ6IqaiIB4xlLjf0flRS4bcl5WZO3hnL6ommJYGQA27MXeFLLEFdde1oAi9RO2a1nVxlYcyk 8PmjwDUsucB5pxvecERT9qRU1L1eZfod5j07wU Print TrueDokumen9 halamanACFrOgB7eh xQWVzYJ6IqaiIB4xlLjf0flRS4bcl5WZO3hnL6ommJYGQA27MXeFLLEFdde1oAi9RO2a1nVxlYcyk 8PmjwDUsucB5pxvecERT9qRU1L1eZfod5j07wU Print TrueNaveed UR RehmanBelum ada peringkat

- Us7081297 PDFDokumen11 halamanUs7081297 PDFrevider451Belum ada peringkat

- PLASTICOSDokumen61 halamanPLASTICOSJohn TorrezBelum ada peringkat

- Thermal Degradation of PE and PTFE During Vacuum EvaporationDokumen4 halamanThermal Degradation of PE and PTFE During Vacuum EvaporationSteven BosscherBelum ada peringkat

- Us 5237927Dokumen4 halamanUs 5237927wewewewBelum ada peringkat

- 111Dokumen24 halaman111giovanniBelum ada peringkat

- Us20090306280 PDFDokumen8 halamanUs20090306280 PDFrevider451Belum ada peringkat

- List of Synthetic PolymerDokumen4 halamanList of Synthetic PolymermoussafourBelum ada peringkat

- Polymer Engineering-1Dokumen60 halamanPolymer Engineering-1Prem GiriBelum ada peringkat

- PolyesterDokumen7 halamanPolyesterkgaviolaBelum ada peringkat

- Tr-18 Weatherability Thermo Pipe SystemsDokumen11 halamanTr-18 Weatherability Thermo Pipe SystemsA.ABelum ada peringkat

- PolyurethaneDokumen13 halamanPolyurethaneAnwesh SatapathyBelum ada peringkat

- PolyesterDokumen7 halamanPolyesterRanjan KumarBelum ada peringkat

- Radiation Crosslinking of PolymersDokumen9 halamanRadiation Crosslinking of Polymerskalidas_295Belum ada peringkat

- Overview Polymer ProcessingDokumen9 halamanOverview Polymer Processingeduardo_umBelum ada peringkat

- Elastomer-Ptfe Compositions, Additives, and Manufacturing Methods - Us4962136Dokumen16 halamanElastomer-Ptfe Compositions, Additives, and Manufacturing Methods - Us4962136Franco GentiliBelum ada peringkat

- The Composition, Structure, and Properties of PlasticsDokumen14 halamanThe Composition, Structure, and Properties of PlasticsCharlee CanopinBelum ada peringkat

- United States Patent (19) : Symon Et Al. 45) Feb. 21, 1984Dokumen5 halamanUnited States Patent (19) : Symon Et Al. 45) Feb. 21, 1984EceBelum ada peringkat

- III Iii Iihiii: United States PatentDokumen5 halamanIII Iii Iihiii: United States PatentThuận LêBelum ada peringkat

- Studies On The Dynamic Mechanical and Vibration Damping Properties of Yether Urethane and Epoxy CompositesDokumen7 halamanStudies On The Dynamic Mechanical and Vibration Damping Properties of Yether Urethane and Epoxy Compositesravi kumar B v ABelum ada peringkat

- A Review of Flame Retardant Polypropylene FibresDokumen22 halamanA Review of Flame Retardant Polypropylene FibresArif AnsariBelum ada peringkat

- Stress Corrosion Cracking of HDPEDokumen14 halamanStress Corrosion Cracking of HDPEmo.masoomiBelum ada peringkat

- 20221128materi - 21027141 - Polimer (MKP) - Q - 9Dokumen12 halaman20221128materi - 21027141 - Polimer (MKP) - Q - 9Frizka VietantiBelum ada peringkat

- Synthesis and Characterization of Expandable GraphiteDokumen66 halamanSynthesis and Characterization of Expandable GraphitequiqueBelum ada peringkat

- United States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980Dokumen4 halamanUnited States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980KundanBelum ada peringkat

- UrethaneDokumen14 halamanUrethaneMuhammad Yazid TharmiziBelum ada peringkat

- Us 4058649Dokumen6 halamanUs 4058649yigitilgazBelum ada peringkat

- Thermoplastic OlefinDokumen2 halamanThermoplastic OlefinpepeBelum ada peringkat

- Earing Ournal: Best Polymer Selection For Quality UpgradesDokumen2 halamanEaring Ournal: Best Polymer Selection For Quality UpgradesImaduddin ShaBelum ada peringkat

- US4453015 Paten MEK 2Dokumen4 halamanUS4453015 Paten MEK 2Lathifa Rahma AstutiBelum ada peringkat

- Introduction To PolymersDokumen110 halamanIntroduction To Polymersykhamidi3889100% (1)

- Materials For Oxygen ServicesDokumen4 halamanMaterials For Oxygen Services陳0鴻Belum ada peringkat

- ElastomerDokumen111 halamanElastomersaurabhsriBelum ada peringkat

- Design and Economic Study of Polystyrene Production Plan1Dokumen88 halamanDesign and Economic Study of Polystyrene Production Plan1Ahmed Nasr100% (1)

- INVISTA North America S.A.R.L. Et Al. v. M&G USA Corporation, Et Al., C.A. No. 11-1007-SLR-CJB (D. Del. June 25, 2013) .Dokumen40 halamanINVISTA North America S.A.R.L. Et Al. v. M&G USA Corporation, Et Al., C.A. No. 11-1007-SLR-CJB (D. Del. June 25, 2013) .YCSTBlogBelum ada peringkat

- Us 3257801 Pyrotechnic Composition Comprising Solid Oxidizer, Boron and Aluminum Additive and BinderDokumen3 halamanUs 3257801 Pyrotechnic Composition Comprising Solid Oxidizer, Boron and Aluminum Additive and Binderpepixx985Belum ada peringkat

- Making Plastics From Monomer To Polymer CEP Sep 2015Dokumen6 halamanMaking Plastics From Monomer To Polymer CEP Sep 2015Juan Sebastian SánchezBelum ada peringkat

- Us8668988 PDFDokumen16 halamanUs8668988 PDFKhoi Nguyen DangBelum ada peringkat

- Us5098778 PDFDokumen7 halamanUs5098778 PDFAl Saraaf MohammedBelum ada peringkat

- EP0439259A1Dokumen9 halamanEP0439259A1senmuraBelum ada peringkat

- Initiation System: 4.1 Detonators 4.1.1 Brief History On DetonatorsDokumen33 halamanInitiation System: 4.1 Detonators 4.1.1 Brief History On DetonatorsRonal Edinson Tenorio QuispeBelum ada peringkat

- Poly(Ethylene Terephthalate) Based Blends, Composites and NanocompositesDari EverandPoly(Ethylene Terephthalate) Based Blends, Composites and NanocompositesP.M. VisakhBelum ada peringkat

- Benzocaine (2 Steps)Dokumen11 halamanBenzocaine (2 Steps)checolonoski0% (1)

- ماذا يثول الكتاب المقدس عن محمدDokumen51 halamanماذا يثول الكتاب المقدس عن محمدAbu Ahmed GhariebBelum ada peringkat

- Patent - 一种用结晶控制技术制备球形化黑索今的方法 One Technique for Preparing ... - Google PatentsDokumen9 halamanPatent - 一种用结晶控制技术制备球形化黑索今的方法 One Technique for Preparing ... - Google PatentschecolonoskiBelum ada peringkat

- Anti-Corrosion Methods and Materials: Article InformationDokumen6 halamanAnti-Corrosion Methods and Materials: Article InformationchecolonoskiBelum ada peringkat

- Us 541899Dokumen1 halamanUs 541899checolonoskiBelum ada peringkat

- لماذا محمد صلى الله عليه و سلم هو الأعظم - أحمد ديداتDokumen32 halamanلماذا محمد صلى الله عليه و سلم هو الأعظم - أحمد ديداتahmed.ne7970100% (1)

- 1734 DDokumen11 halaman1734 DPasha TanBelum ada peringkat

- Soap N Detergent2 PDFDokumen13 halamanSoap N Detergent2 PDFXsey Doh TukarnamoBelum ada peringkat

- Us5032391 PDFDokumen4 halamanUs5032391 PDFchecolonoskiBelum ada peringkat

- 1734 DDokumen11 halaman1734 DPasha TanBelum ada peringkat

- جورنال عراقى (جامعة تكريت) PDFDokumen10 halamanجورنال عراقى (جامعة تكريت) PDFchecolonoskiBelum ada peringkat

- Urey1932 PDFDokumen2 halamanUrey1932 PDFchecolonoskiBelum ada peringkat

- Amphetamine Leucart ReactionDokumen1 halamanAmphetamine Leucart Reactionlukasz_wieczorek_praca100% (3)

- 1734 DDokumen11 halaman1734 DPasha TanBelum ada peringkat

- Us2741543 PDFDokumen6 halamanUs2741543 PDFchecolonoskiBelum ada peringkat

- Us4278480 PDFDokumen3 halamanUs4278480 PDFchecolonoskiBelum ada peringkat

- بي PDFDokumen2 halamanبي PDFchecolonoskiBelum ada peringkat

- Us2787587 PDFDokumen6 halamanUs2787587 PDFchecolonoskiBelum ada peringkat

- Us2942965 PDFDokumen2 halamanUs2942965 PDFchecolonoskiBelum ada peringkat

- Us3457127 PDFDokumen5 halamanUs3457127 PDFchecolonoskiBelum ada peringkat

- Us2589532 PDFDokumen7 halamanUs2589532 PDFchecolonoskiBelum ada peringkat

- Us2344840 PDFDokumen3 halamanUs2344840 PDFchecolonoskiBelum ada peringkat

- Us857580 PDFDokumen2 halamanUs857580 PDFchecolonoskiBelum ada peringkat

- Us4216720 PDFDokumen7 halamanUs4216720 PDFchecolonoskiBelum ada peringkat

- Us2758006 PDFDokumen16 halamanUs2758006 PDFchecolonoskiBelum ada peringkat

- Ravi2011 PDFDokumen11 halamanRavi2011 PDFchecolonoskiBelum ada peringkat

- Urey1931 PDFDokumen9 halamanUrey1931 PDFchecolonoskiBelum ada peringkat

- fل PDFDokumen2 halamanfل PDFchecolonoskiBelum ada peringkat

- PEPUNNUManuscript11jan2013 PDFDokumen25 halamanPEPUNNUManuscript11jan2013 PDFchecolonoskiBelum ada peringkat

- Gb191022030a PDFDokumen2 halamanGb191022030a PDFchecolonoskiBelum ada peringkat

- Chemistry ProjectDokumen23 halamanChemistry Projectkavishree sBelum ada peringkat

- Potassium ChlorideDokumen3 halamanPotassium ChlorideRobinBelum ada peringkat

- Chao Guo and Kaida ChenDokumen7 halamanChao Guo and Kaida ChenSaghar FarajzadehBelum ada peringkat

- BK 2021 1380.ch001Dokumen24 halamanBK 2021 1380.ch001kamaBelum ada peringkat

- Branson 3510 UltrasonicDokumen34 halamanBranson 3510 Ultrasoniccav4444Belum ada peringkat

- FRP Catalogue NewDokumen82 halamanFRP Catalogue Newamol ganvirBelum ada peringkat

- c4 Revision Checklist - Chemical ChangesDokumen4 halamanc4 Revision Checklist - Chemical Changesapi-422428700Belum ada peringkat

- Carbon Compound 2011Dokumen4 halamanCarbon Compound 2011Keman MjBelum ada peringkat

- Analysis of Phytochemical Constituents and AntDokumen5 halamanAnalysis of Phytochemical Constituents and AntJoseph BernardoBelum ada peringkat

- US2465319Dokumen7 halamanUS2465319Sebastian GonzalezBelum ada peringkat

- Pharmacognosy Lecture # 4 (Isothiocyanate, Lactone, Aldehyde & Misc Glycosides) (By, Sir Tanveer Khan)Dokumen17 halamanPharmacognosy Lecture # 4 (Isothiocyanate, Lactone, Aldehyde & Misc Glycosides) (By, Sir Tanveer Khan)Arslan Abdullah100% (1)

- Reactii Sulfonare, NitrareDokumen30 halamanReactii Sulfonare, NitrareDaniel PaulBelum ada peringkat

- Fats Igcse Biology: Fats Are Also Known As LIPIDSDokumen10 halamanFats Igcse Biology: Fats Are Also Known As LIPIDSRufaro MhariwaBelum ada peringkat

- BCSJ 42 643Dokumen8 halamanBCSJ 42 643Maria Luisa Sandoval OchoaBelum ada peringkat

- Learning Activity Sheet General Chemistry 2 (Q4 - Lessons 3 and 4) Acid-Base Equilibrium and Its ApplicationsDokumen15 halamanLearning Activity Sheet General Chemistry 2 (Q4 - Lessons 3 and 4) Acid-Base Equilibrium and Its ApplicationsJeffrey YumangBelum ada peringkat

- Lab ManualDokumen35 halamanLab ManualOla Eman100% (1)

- Lecture #9 Introduction To Organic Chemistry Organic ChemistryDokumen10 halamanLecture #9 Introduction To Organic Chemistry Organic ChemistryG8 ODL Mary Angeline M. GalmanBelum ada peringkat

- Alginate Derivatization - A Review of Chemistry, Properties and ApplicationsDokumen27 halamanAlginate Derivatization - A Review of Chemistry, Properties and ApplicationsJonatas LopesBelum ada peringkat

- Iodometry: Iodometry, Known As Iodometric Titration, Is A Method ofDokumen4 halamanIodometry: Iodometry, Known As Iodometric Titration, Is A Method oftaysi tafriBelum ada peringkat

- NamingcompoundshandoutDokumen11 halamanNamingcompoundshandoutRhofa Mae AcevedoBelum ada peringkat

- Determination of Total Hardness of Water by EDTA Titration.Dokumen3 halamanDetermination of Total Hardness of Water by EDTA Titration.Saharbano awanBelum ada peringkat

- 037 Forever Nature Min ENGDokumen1 halaman037 Forever Nature Min ENGManuel ManeaBelum ada peringkat

- Neet PrepDokumen36 halamanNeet PrepNeetika SharmaBelum ada peringkat

- Synergism of Clay and Heteropoly Acids As Nano-Catalysts For The Development of Green Processes With Potential Industrial ApplicationsDokumen21 halamanSynergism of Clay and Heteropoly Acids As Nano-Catalysts For The Development of Green Processes With Potential Industrial ApplicationsJOSEPH HERBERT MABELBelum ada peringkat

- Lubrizol Graphic Arts Product GuideDokumen24 halamanLubrizol Graphic Arts Product GuideRashid Saleem100% (2)

- BufferDokumen72 halamanBufferBijaya GiriBelum ada peringkat

- Boiler Water TreatmentDokumen73 halamanBoiler Water Treatmentsantosh_rajuBelum ada peringkat

- Produced Water Treating Systems: Dr. Fatma AshourDokumen18 halamanProduced Water Treating Systems: Dr. Fatma AshourMahmoud Ahmed Ali AbdelrazikBelum ada peringkat

- 1956 - Rapid Colorimetric Methods For Simultaneous Determination of Total Reducing Sugars and Fructose in Citrus Juices PDFDokumen4 halaman1956 - Rapid Colorimetric Methods For Simultaneous Determination of Total Reducing Sugars and Fructose in Citrus Juices PDFbryanBelum ada peringkat

- The Transition Metals PDFDokumen1 halamanThe Transition Metals PDFmuammal abbasBelum ada peringkat