Reinsulate Chilled Water Pipes

Diunggah oleh

Francis Mayowa EzekielDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Reinsulate Chilled Water Pipes

Diunggah oleh

Francis Mayowa EzekielHak Cipta:

Format Tersedia

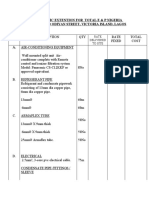

PROJECT JUSTIFICATION DOCUMENT (PJD)

FOR THE CHILLED WATER PIPING INSTALLATION

JUSTIFICATION STATEMENT

Re-insulation of a condensing chilled water piping with deteriorated insulation. To

avoid the condensation of chilled water piping as a result of heat gain by the exposed

pipes from external sources, there must be proper insulation around the piping, so as to

restrict the heat transfer from the warmer temperature to the exposed surface of pipe.

Chilled water piping insulation works plays a significant role in the functionality and

the temperature control of the entire HVAC installations of any air-conditioning central

system. As such, there is need for proper and enduring insulation with adequate Rvalue insulating material with other accessories alongside good workmanship on all

chilled water piping installation both on the supply and the return piping, including all

fittings, valves, gauges, etc.

PROBLEMS/ISSUES

Worn out insulation on installed pipes due for replacement as this as resulted to

moisture condensation on the CHWPS & CHWPR, and if not quickly remedied will

eventually resulted to rusty pipes. These two occurrences/issues are expensive and

disruptive to the entire facilities.

SOLUTIONS

All damaged and worn out insulation either as a result of poor/aged installation are to

be immediately replaced.

WORKING PROCEDURE FOR EXISTING FACILITIES

All equipment servicing the chilled water piping would be shut-off.

All damaged or worn-out insulation on the chilled water piping would be strip-

off completely.

All exposed chilled water piping would be inspected for rust to ensure no rust on

any of the piping network.

If any part of the piping is noticed to have rusted, such affected areas would be

coated with anti-rust material before re-insulating the pipes.

All the chilled water piping would be made clean and dry to ensure there is no

moisture and other foreign material before the commencement of the new

insulation.

All insulation material would be cut to diameter of the various sizes as

installed/existing.

Pipe insulation would be kept at dry & clean place.

If pipe insulation is not dirty then can be installed, if pipe insulation is dirty,

clean the internal and external surface to reasonable free from other foreign

material.

Before install insulation, the pipes should be tested and painted completely.

SLIP INSULATION

Jointing between pipe insulation should be coated with adhesive, allow the

adhesive to set for 3 to 5minutes, before pressing the joints together.

SLIT INSULATION

Slit insulation tube lengthwise on one side, for pipe up to 150 mm. dia. and snap

it over the pipe.

Jointing between pipe insulation should be coated lengthwise slit surface and

butt joints with adhesive, allow the adhesive to set for 3 to 5 minutes, before

pressing the joints together.

SHEET INSULATION

Use for large pipe above 150 mm. diameter, fittings, valves & equipment.

In case of the thickness of insulation over 32 mm., the installation must use 2

layers of insulation

Joint between insulation sheets should be coated lengthwise slit surface and butt

joints with adhesive, allow the adhesive to set for 3 to 5 minutes, before pressing

the joints together both 1st layers but the lengthwise slit surface and butt joints of

1st & 2nd layers shall not be the same position.

QUALITY CONTROL

o Quality control works should be performed in the particular works as

described in the following.

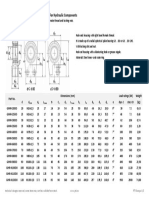

PIPE INSULATION DIMENSION & THICKNESS

o Pipe insulation dimension and thickness should be performed in

accordance with approved shop drawing.

MATERIALS

o Armaflex sheet, closed cell expanded foam insulation with a calculated

thickness to retard heat gain and control condensation drip from chilled

o

o

o

o

o

water systems or

Polystyrene.

Aerotape.

Adhesives Gum.

Vapour barrier.

Abro sealants.

PERSONNEL

Qualified personnel with over two decades years of experience in ducting,

insulation and cladding.

Anda mungkin juga menyukai

- TRICLAMP Tube Fitting Catalogue and Spec: Cadgroup Australia Pty LTD P: 1300 765 654Dokumen3 halamanTRICLAMP Tube Fitting Catalogue and Spec: Cadgroup Australia Pty LTD P: 1300 765 654denginBelum ada peringkat

- Method Statement For Insulation Works and JacketingDokumen8 halamanMethod Statement For Insulation Works and JacketingThomas100% (8)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDari EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDari Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsPenilaian: 4 dari 5 bintang4/5 (1)

- Chilled Water Pipe Insulation Method StatementDokumen2 halamanChilled Water Pipe Insulation Method StatementGündoğdu Akın75% (4)

- INSULATION INSTALLATION GUIDEDokumen8 halamanINSULATION INSTALLATION GUIDEMark Darrel AranasBelum ada peringkat

- Clay Drainage Air Test InstructionsDokumen2 halamanClay Drainage Air Test InstructionsGabi CristacheBelum ada peringkat

- HVAC VRF Installation Method StatementDokumen8 halamanHVAC VRF Installation Method StatementFrancis Mayowa Ezekiel100% (2)

- Hydraulic Calculation TableDokumen4 halamanHydraulic Calculation TableFrancis Mayowa EzekielBelum ada peringkat

- Suspended ScaffoldsDokumen29 halamanSuspended ScaffoldsJason Leo100% (1)

- Thermobreak Tube Installation InstructionsDokumen8 halamanThermobreak Tube Installation Instructionssurya325kiranBelum ada peringkat

- Installation Instructions Single RoomDokumen14 halamanInstallation Instructions Single RoomTony Bou-GhariosBelum ada peringkat

- Basic Radiant Design & Construction ManualDokumen12 halamanBasic Radiant Design & Construction ManualDavid JonesBelum ada peringkat

- Thermal Insulation Application GuideDokumen7 halamanThermal Insulation Application GuideAbhishek KumarBelum ada peringkat

- Rowan University Design Guide 2013Dokumen10 halamanRowan University Design Guide 2013zeliteBelum ada peringkat

- Pexgol - Instructions For InstallationDokumen4 halamanPexgol - Instructions For InstallationFlorin StanciuBelum ada peringkat

- Hydro Testing ProcedureDokumen12 halamanHydro Testing ProcedureGaapchuBelum ada peringkat

- Underground Piping SystemsDokumen5 halamanUnderground Piping SystemsBinodh DanielBelum ada peringkat

- Method of Statement For Installation of Domestic Hot & Cold Water Supply Cop PDFDokumen4 halamanMethod of Statement For Installation of Domestic Hot & Cold Water Supply Cop PDFCool SharyBelum ada peringkat

- Installation ManualDokumen38 halamanInstallation ManualNicu JirosBelum ada peringkat

- HVAC Ductwork SpecificationDokumen4 halamanHVAC Ductwork SpecificationhvacwallyBelum ada peringkat

- Gas Supply Installation and Safety EssentialsDokumen8 halamanGas Supply Installation and Safety EssentialsSylvia MasakiBelum ada peringkat

- SHT Technical Book PDFDokumen21 halamanSHT Technical Book PDFfatamorgganaBelum ada peringkat

- Requirements For Plumbing Design To Drainage SystemsDokumen6 halamanRequirements For Plumbing Design To Drainage SystemsJelyn DamoslogBelum ada peringkat

- ALMARC P20 Installation GuideDokumen1 halamanALMARC P20 Installation GuideKs LimBelum ada peringkat

- InsulationDokumen23 halamanInsulationchesspupilBelum ada peringkat

- R12 - Renovations and Extensions: Underfloor Heating SystemDokumen6 halamanR12 - Renovations and Extensions: Underfloor Heating SystemDavis FioBelum ada peringkat

- Chill-In Insulation KitsDokumen4 halamanChill-In Insulation KitsAuburnMfgBelum ada peringkat

- How To Install A Split System Air ConditionerDokumen3 halamanHow To Install A Split System Air Conditioneralive2flirtBelum ada peringkat

- Mechanical Insulation Standards at UT AustinDokumen8 halamanMechanical Insulation Standards at UT Austinrizviabbas2012Belum ada peringkat

- JCR-190623-TTSB-F3201-signed For Insulation WorksDokumen12 halamanJCR-190623-TTSB-F3201-signed For Insulation WorksFadzil AmalludinBelum ada peringkat

- 3LPE Coating SpecificationDokumen21 halaman3LPE Coating SpecificationHướng PhạmBelum ada peringkat

- Manual Uponor MeltawayDokumen12 halamanManual Uponor MeltawayUPOTERMBelum ada peringkat

- Specification For Hot and Cold Insulation WorkDokumen13 halamanSpecification For Hot and Cold Insulation WorkchintanBelum ada peringkat

- Trymer Installation GuidlinesDokumen26 halamanTrymer Installation GuidlinesElankumaran PeriakaruppanBelum ada peringkat

- Dyplast Product InsulationDokumen20 halamanDyplast Product InsulationbargezBelum ada peringkat

- Domestic Gas Installation TestingDokumen2 halamanDomestic Gas Installation TestingKosala KamburadeniyaBelum ada peringkat

- Midea Air Conditioning Units Installation GuideDokumen12 halamanMidea Air Conditioning Units Installation GuideMichal MlčúchBelum ada peringkat

- Method Statement For Insulation Works and JacketingDokumen8 halamanMethod Statement For Insulation Works and Jacketingred patriotBelum ada peringkat

- Fripex-San Export Englisch Druckbogen 08-2015 75dpi PDFDokumen5 halamanFripex-San Export Englisch Druckbogen 08-2015 75dpi PDFMuhammad ArslanBelum ada peringkat

- Insulation SeminarDokumen55 halamanInsulation SeminarDelta akathehuskyBelum ada peringkat

- Installation For Drainage PipingDokumen4 halamanInstallation For Drainage Pipingamg007Belum ada peringkat

- Installation Manual for Premium Preheat Ventilation Heat PumpsDokumen15 halamanInstallation Manual for Premium Preheat Ventilation Heat PumpsZo NetBelum ada peringkat

- Manual HRVDokumen25 halamanManual HRVNam AlbertBelum ada peringkat

- SECTION 15083: Pipeing Insulation 15083Dokumen8 halamanSECTION 15083: Pipeing Insulation 15083fatREVITBelum ada peringkat

- Mos (Hvac System)Dokumen6 halamanMos (Hvac System)Syed Abbad QuadriBelum ada peringkat

- Eurotrace Installation Instructions: Installation On A PipeDokumen6 halamanEurotrace Installation Instructions: Installation On A PipeNicolas150956Belum ada peringkat

- Advantages of uPVC Drainage SystemsDokumen34 halamanAdvantages of uPVC Drainage SystemsChowKC0350% (2)

- Domestic Water Piping Systems GuideDokumen15 halamanDomestic Water Piping Systems Guideroinbanerji100% (1)

- Hotels Electrical and Mechanical SpecificationsDokumen32 halamanHotels Electrical and Mechanical SpecificationsArchanaShenoyBelum ada peringkat

- INSTALLATION GUIDEDokumen13 halamanINSTALLATION GUIDEmchelcioiuBelum ada peringkat

- Installing and Maintaining Split System Air ConditionersDokumen34 halamanInstalling and Maintaining Split System Air ConditionersKim Christian TampoyBelum ada peringkat

- Specification of Pipe InsulationDokumen6 halamanSpecification of Pipe InsulationNoldz SantosBelum ada peringkat

- Basic Installation GuideKFR32GW - NEW 0409Dokumen12 halamanBasic Installation GuideKFR32GW - NEW 0409B_ogdanBelum ada peringkat

- How To Lay A New Water Supply PipeDokumen4 halamanHow To Lay A New Water Supply PipeNasir KamalBelum ada peringkat

- Insulation Engineered For: Cold SystemsDokumen0 halamanInsulation Engineered For: Cold SystemsjeewanaaBelum ada peringkat

- Kaiflex Specification DomesticDokumen5 halamanKaiflex Specification Domesticnaseema1Belum ada peringkat

- HDPE Drainage ManualDokumen48 halamanHDPE Drainage ManualTransgulf2013Belum ada peringkat

- Plumbing Pipe Insulation Specification Submitted By: Armacell LLCDokumen5 halamanPlumbing Pipe Insulation Specification Submitted By: Armacell LLCKarthy GanesanBelum ada peringkat

- Installation Guide 12000BTUDokumen9 halamanInstallation Guide 12000BTUBao VuBelum ada peringkat

- IPM-L0105 Thermal InsulationDokumen14 halamanIPM-L0105 Thermal InsulationmonohinBelum ada peringkat

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- Clinic AHU-C2 Air Balancing ReportDokumen1 halamanClinic AHU-C2 Air Balancing ReportFrancis Mayowa EzekielBelum ada peringkat

- Organogram - SicnarfDokumen1 halamanOrganogram - SicnarfFrancis Mayowa EzekielBelum ada peringkat

- Ventilation Calculation SheetDokumen12 halamanVentilation Calculation SheetFrancis Mayowa EzekielBelum ada peringkat

- Commercial Kitchen Hood Airflow CalculationDokumen16 halamanCommercial Kitchen Hood Airflow CalculationFrancis Mayowa EzekielBelum ada peringkat

- Ventilation Calculation SheetDokumen6 halamanVentilation Calculation SheetFrancis Mayowa EzekielBelum ada peringkat

- Golden Tulip Hotel Ducting CalculationDokumen44 halamanGolden Tulip Hotel Ducting CalculationFrancis Mayowa EzekielBelum ada peringkat

- Reinsulate Chilled Water PipesDokumen7 halamanReinsulate Chilled Water PipesFrancis Mayowa EzekielBelum ada peringkat

- Commercial Kitchen Hood Airflow CalculationDokumen16 halamanCommercial Kitchen Hood Airflow CalculationFrancis Mayowa EzekielBelum ada peringkat

- Inspection Request FormDokumen1 halamanInspection Request FormFrancis Mayowa EzekielBelum ada peringkat

- List of Shortcut Keys MS EXCEL 2007Dokumen7 halamanList of Shortcut Keys MS EXCEL 2007Ali ArsalanBelum ada peringkat

- Ambitious But AimlessDokumen2 halamanAmbitious But AimlessFrancis Mayowa EzekielBelum ada peringkat

- Ventilation Calculation SheetDokumen6 halamanVentilation Calculation SheetFrancis Mayowa EzekielBelum ada peringkat

- VAV SystemDokumen15 halamanVAV SystemFrancis Mayowa EzekielBelum ada peringkat

- Hazard AnalysisDokumen4 halamanHazard AnalysisFrancis Mayowa Ezekiel100% (1)

- QG II Onshore Project LNG Storage Facilities Test ReportDokumen3 halamanQG II Onshore Project LNG Storage Facilities Test ReportFrancis Mayowa Ezekiel100% (1)

- Cover LetterDokumen2 halamanCover LetterFrancis Mayowa EzekielBelum ada peringkat

- Price MaterialDokumen2 halamanPrice MaterialFrancis Mayowa EzekielBelum ada peringkat

- E& P Total BillDokumen7 halamanE& P Total BillFrancis Mayowa EzekielBelum ada peringkat

- National Building Code ReviewerDokumen16 halamanNational Building Code ReviewerZoeBelum ada peringkat

- Akpark: Cover Sheet - ElectricalDokumen10 halamanAkpark: Cover Sheet - ElectricalEngr M.Arshad KhalidBelum ada peringkat

- Design and Optimization of Aircraft Assembling Based On Comprehensive Simulation of Manufacturing Processes - A. Rozhdestvensky, O. SamsonovDokumen10 halamanDesign and Optimization of Aircraft Assembling Based On Comprehensive Simulation of Manufacturing Processes - A. Rozhdestvensky, O. SamsonovSamuel JiménezBelum ada peringkat

- ECO AUDIT STEAM IRONDokumen7 halamanECO AUDIT STEAM IRONUlisses Heredia0% (1)

- Avk Saudi National Price ListDokumen46 halamanAvk Saudi National Price Listjanpaul2481Belum ada peringkat

- Contractor Design and Standard Form ContractsDokumen14 halamanContractor Design and Standard Form ContractskuvjBelum ada peringkat

- 15570Dokumen6 halaman15570JhoBelum ada peringkat

- Carpentry 10: Caridad ST., Brgy. 3 Loing, Piddig, Ilocos NorteDokumen6 halamanCarpentry 10: Caridad ST., Brgy. 3 Loing, Piddig, Ilocos NorteDanielLarryAquinoBelum ada peringkat

- Iso898 2Dokumen19 halamanIso898 2Ricardo VitorianoBelum ada peringkat

- ENG 3731 Materials and Methods Construction Course OverviewDokumen21 halamanENG 3731 Materials and Methods Construction Course OverviewJanina Frances RuideraBelum ada peringkat

- GIHR-K..DO - Rod Ends For Hydraulic ComponentsDokumen1 halamanGIHR-K..DO - Rod Ends For Hydraulic ComponentsQuintrae DelfinBelum ada peringkat

- Handle InstallationDokumen36 halamanHandle InstallationNoz KiBelum ada peringkat

- Hashi Complete WD 30.05.2023Dokumen2 halamanHashi Complete WD 30.05.2023tocheckpapershadow01Belum ada peringkat

- Hand & Mechanical Directional Valves: ISO 4401 Sizes 06, 10, 16 and 25Dokumen6 halamanHand & Mechanical Directional Valves: ISO 4401 Sizes 06, 10, 16 and 25aaaBelum ada peringkat

- Lec 14 MasonryDokumen10 halamanLec 14 Masonryamjad aliBelum ada peringkat

- Documentation On Construction of Small Scaled Strap Footing: Cover PageDokumen5 halamanDocumentation On Construction of Small Scaled Strap Footing: Cover PageGlaiza MarieBelum ada peringkat

- Presentasi Ahu DXDokumen17 halamanPresentasi Ahu DXpt.esasurya arcapadaBelum ada peringkat

- V. Hari Krishna, R111794, Civil Engineering 4 Year, RGUKT, RK Valley, IdupulapayaDokumen24 halamanV. Hari Krishna, R111794, Civil Engineering 4 Year, RGUKT, RK Valley, IdupulapayaMahesh RamtekeBelum ada peringkat

- DXB SHJ Freezone ListDokumen444 halamanDXB SHJ Freezone ListFaiza KhalidBelum ada peringkat

- 0.6/1 KV N2Xry - Cu/Xlpe/Pvc/Swa/Pvc: ConstructionDokumen2 halaman0.6/1 KV N2Xry - Cu/Xlpe/Pvc/Swa/Pvc: ConstructionIvan Nur BhaktiBelum ada peringkat

- RECYCLING-PASSPORTDokumen4 halamanRECYCLING-PASSPORTDonBelum ada peringkat

- Top 25 ASA Product ListDokumen1 halamanTop 25 ASA Product Listmizan sallehBelum ada peringkat

- View Tower Foundation DesignDokumen6 halamanView Tower Foundation Designkabira12Belum ada peringkat

- P 615 SN 4147526Dokumen52 halamanP 615 SN 4147526Dan Alin MirceaBelum ada peringkat

- 1 20 PDFDokumen1 halaman1 20 PDFRushil ShahBelum ada peringkat

- Handouts of The Presentations - Seminar On Introduction To New Guidelines For Seismic Design of Road BridgesDokumen105 halamanHandouts of The Presentations - Seminar On Introduction To New Guidelines For Seismic Design of Road BridgesChaitu Rishan100% (1)

- Design of Sewer SystemDokumen8 halamanDesign of Sewer Systemknight912Belum ada peringkat

- Ground Floor-Key Plan Mirror Part Plan at 2000Mm LVL: ArchitectureDokumen1 halamanGround Floor-Key Plan Mirror Part Plan at 2000Mm LVL: ArchitectureDhairyaBelum ada peringkat