Pages From Pipesupportscat - Final

Diunggah oleh

ljv004Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pages From Pipesupportscat - Final

Diunggah oleh

ljv004Hak Cipta:

Format Tersedia

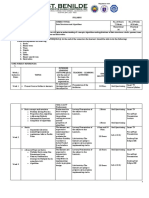

SLIDE

PLATES

PTFE, 25% Glass Filled - Graphite - Bronzphite - Marinite

SLIDE PLATES

http://www.pipingtech.com/slideplates

X 11 X 120 GRAPHITE SLIDE PLATES FOR 1,000 F

MARINITE SLIDE PLATE

PTFE, 25% GLASS FILLED SLIDE PLATES

BRONZPHITE SLIDE PLATES

177

SLIDE BEARING PLATES

DESCRIPTION

PAGE

Introduction ............................................................................................................................................................................... 179

PTFE, 25% Glass Filled Slide Plates

PTFE, 25% Glass Filled Data Sheet .................................................................................................................................

Load and Temperature Limits ..........................................................................................................................................

Coefficient of Friction Vs. Load ........................................................................................................................................

PTFE, 25% Glass Filled Specifications ...........................................................................................................................

180

181

181

182

Graphite Slide Plates

SLIDE PLATES

Graphite Data Sheet ........................................................................................................................................................... 183

Graphite Specifications ...................................................................................................................................................... 184

Standard Assembly Configurations ...................................................................................................................... 185

Bronzphite

Bronzphite Data Sheet ..................................................................................................................................................... 186

SLIDE PLATE ASSEMBLIES WITH 2 MARINITE BLOCKS

43 ANGLED PIPE SHOE WITH PTFE SLIDE PLATE

8 DIA. HD-2 HOLD DOWNS LINED WITH PTFE, 25% GLASS FILLED SLIDE PLATES

178

www.pipingtech.com/slideplates

SLIDE BEARING PLATES

Slide bearing plates are a very cost-effective way of providing for movement of mechanical systems. Piping Technology

& Products, Inc. supplies slide bearing plates for a variety of applications including support of piping, heavy equipment

such as pressure vessels, and structural steel members. The plates provide a surface with a low coefficient of friction

which can be attached to a supporting structure. This combination provides support while simultaneously allowing an

object to move (slide) freely along the supporting surface.

Most designers use the sandwich concept when applying slide plates to their systems. Diagram A (on Page 180) shows a

sandwich composed of two identical slide plates, one on top and another on the bottom. Each slide plate is composed

of two components: a metal backing plate (which is like the bun of the sandwich) and a low coefficient of friction material which is bonded to the metal backing plate.

One combination of materials that we recommend is that of PTFE, 25% glass filled, bonded to stainless steel. Both materials resist oxidation and have long lives even in stressful environments. For large slide plates, galvanized steel can be used

in place of stainless to reduce the cost.

TEMPERATURE CONSIDERATIONS

PTFE, 25% glass filled, provides a low coefficient of friction for most combinations of temperature and load. Diagram B,

on Page 181, shows the recommended conditions for 332 PTFE, 25% glass filled. For most applications, PTFE, 25% glass

filled, is adequate when the temperature is less than 400 F. When the slide bearing plate must function at higher temperatures, graphite can be used instead of PTFE, 25% glass filled. The load-bearing capacity of graphite is not sensitive

to increases in temperature, but the adhesive used to bond the graphite to its metal backing is. It is good practice to use

additional mechanical fasteners such as counter-sunk screws to help hold the graphite in place when the temperatures

are above 500 F. For combinations of temperature and load beyond the capabilities of graphite, special designs must be

considered.

ATTACHMENT CONSIDERATIONS

Welding is the most common method of attaching the slide bearing plate to supporting metal structures. When this

approach is used a lip must be built since the weldings extreme temperature may break the bond between the lowfriction material and the metal plate. A lip is adequate for most welded installations. When welding cannot be used

(for safety or other reasons) to attach the slide plates, bolting is the most common substitute.

Before we begin constructing your slide bearing plates, we need to know the following:

The material you desire for the low-friction surface, based on the highest combinations of temperature and

load the component will experience. PTFE, 25% glass filled and graphite are the most common choices.

The desired size and shape for the low-friction surface.

The type of metal you desire for the plate backing. Most designers choose galvanized or stainless steel.

The size and shape for the metal plate backing of the low-friction surface.

Slide bearing plates are components of many products Piping Technology & Products, Inc. supplies such as guided pipe

shoes and upthrust constants. As a result, we have extensive experience in bonding PTFE, 25% glass filled, and graphite

to metal plates. Modern adhesives are adequate for most applications. However, mechanical fasteners such as countersunk screws can be added when needed. If you have unique applications, we will be happy to custom design a practical

solution for your application.

www.pipingtech.com/slideplates

179

SLIDE PLATES

In a typical application, a slide bearing plate is welded to a structural steel member which is strong enough to provide

the required support, but whose coefficient of friction is too high. When the pipe supported by the member moves (due

to thermal expansion, for example) it slides across the surface of the bearing plate without contacting the steel beam. To

return to our sandwich metaphor, the top half of the sandwich is bonded to the pipe, and the bottom half to the steel

beam.

PTFE, 25% GLASS FILLED SLIDE PLATE

DIAGRAM A

ASSEMBLY:

Standard Assembly: 2 units of 332 PTFE, 25% glass filled, bonded to 18 carbon steel. For field

tack welding, lip. Loads to 2,000 PSI, temperature: -320 F to 500 F.

Full Weld Assembly: 2 units of 332 PTFE, 25% glass filled, bonded to indicated backing material

with lip all around for full welding. Loads to 2,000 PSI, temperature: -320 F to 500 F.

SLIDE PLATES

PART # -- PTP -- 332 PTFE, 25% GLASS FILLED -- 10 GA. SS -- LIP AND SIZE

ADVANTAGES:

APPLICATIONS:

Bridges: Highway bridges, overpasses, railroad bridges.

Ease of installation.

No setting problems.

Low coefficient of friction.

No surface treatments, grouting, or expensive mechanical attachment necessary.

Chemically inert.

Unaffected by weather conditions.

Ability to absorb dirt and grit within itself.

Self-aligning when used in conjunction with elastomeric backing pads.

Architectural in Wood, Concrete or Steel: Cross beam and girder slip joints, roof slabs and

corbels, vibration pads, airport hangar doors, domes.

Industrial: Heat exchangers, dust collectors, heavy machinery, refinery equipment, wind tunnels, penstocks, vessels, pipelines, air preheaters, atomic energy applications, transmission towers, storage tanks, offshore drilling rigs.

ORDERING:

1.

2.

3.

INSTALLATION:

Please specify the dimensions of the upper plate and dimensions of the lower plate. It is

common practice that the upper plate is generally larger than the lower plate.

Specify lip dimension (if different than standard ).

Specify base plate thickness (if different than standard 18).

Prior to Welding: Locate the slide plate base in the appropriate position on the existing steel

surface. Place a protective covering on the PTFE, 25% glass filled. Where seal welding is not

required, follow the diagram shown which indicates 18 thick fillet weld, 1 long every 4 around

entire perimeter of the base. For welding, use GMAW 0.035 wire or SMAW 332 stick.

Where full seal welding is required, use a similar pattern of welding until a full weld is obtained.

This method will prevent damage to the PTFE, 25% glass filled (A full weld will help prevent seepage of water between the slide bearing plate and the support structure.). Avoid overheating,

which may destroy the bonding of the PTFE, 25% glass filled to the base plate.

Installing in Concrete: Secure the top and bottom elements together with paper adhesive

tape. Then attach the bottom element anchor bolts with wire to the form. After the bottom

pour is made, repeat on top element. During the first expansive cycle, the tape will break.

180

www.pipingtech.com/slideplates

PTFE, 25% GLASS FILLED, TEMPERATURE AND FRICTION GRAPHS

It has been determined from basic testing that the ideal thickness of PTFE,

25% Glass Filled, should be 332. If the

design engineer follows the given chart

(left) for the Effect of Temperature on

PTFE, 25% Glass Filled, there will not be

a failure.

SLIDE PLATES

Diagram B

The Coefficient of Friction of PTFE, 25% Glass Filled, slide plates has been reported to be from 0.01 to 0.2. This depends on

the surface preparation, loading, velocity, and the duration of the test. Bonding PTFE, 25% Glass Filled, to metal increases

the load capabilities in excess of 2,000 PSI (For design purposes, use 500 PSI). This table shows the coefficient of friction

due to the load applied. A maximum coefficient of 0.1 can be used in PTFE, 25% Glass Filled, slide bearing designs without

considering sliding speed, temperature, or maintenance.

www.pipingtech.com/slideplates

181

PTFE, 25% GLASS FILLED, SPECIFICATIONS

MECHANICAL

PROPERTY

VALUE

Specific Gravity Measured

2.1 - 2.3

D638

Water Absorption (%)

0.013

D570-59T

Hardness, Shore D

@ 78 F

@ 300 F

57

56

Wear Factor K

less than 10 x 10-10

Tensile Strength (PSI)

2,000 min.

D1457-56T

Tensile Elongation (%)

200 - 250

D1457-56T

Flexural Strength (PSI)

606

D790-59T

D2240

SLIDE PLATES

Modulus (PSI)

2.39 x 10

D638

Compressive Strength (PSI)

0.2% offset

1870

D695-54

Deformation at 78 F, 2000 PSI

24 hr.

Permanent Deformation (%)

7.1

3.9

D621-59 (modified)

Deformation at 78 F, 2000 PSI

100 hr.

Permanent Deformation (%)

8.9

4.4

Coefficient of Friction

ELECTRICAL

PROPERTY

182

0.06 for loads

> 500 PSI static

VALUE

Modified

ASTM TEST METHOD

Dielectrical Strength in air (v per mil)

327

D149A

Dielectrical Constant @ 60 cps

2.63

D150-54T

13

D257-57T

Volume Resistivity (ohm-cm)

THERMAL

ASTM TEST METHOD

PROPERTY

10

VALUE

ASTM TEST METHOD

Coefficient of Linear Thermal Expansion

(per F)

6.98 x 10-5

D694-44

Coefficient of Thermal Conductivity

(Btu-In.) hr-sq. (ft. F)

3.12

Cenco-Fitch

Continuous Service Temperature (F)

550

Various

Weatherability

Unaffected

Physical exposure

www.pipingtech.com/slideplates

GRAPHITE SLIDE PLATE

ASSEMBLY:

Standard Assembly: 2 units of graphite bonded to 18 carbon steel. For field welding, lip.

Loads to 2,000 PSI, temperature: 1,000 F air, 3,000 F inert.

Full Weld Assembly: 2 units of graphite bonded to indicated backing material with lip all

around for full welding. Loads to 2,000 PSI, temperature: 1,000 F air, 3,000 F inert.

SLIDE PLATES

PART # -- PTP -- GRAPHITE ( OR ) -- CS -- LIP AND SIZE

ADVANTAGES:

APPLICATIONS:

Bridges: Highway bridges, overpasses, railroad bridges.

High operating temperature.

Ease of installation.

No setting problems.

Low coefficient of friction.

No surface treatments, grouting, or expensive mechanical attachment necessary.

Chemically inert.

Unaffected by weather conditions.

Architectural in Wood, Concrete or Steel: Cross beam and girder slip joints, roof slabs and corbels, vibration pads, airport hangar doors, domes.

Industrial: Heat exchangers, dust collectors, heavy machinery, refinery equipment, wind tunnels,

penstocks, vessels, pipelines, air preheaters, atomic energy applications, transmission towers, storage tanks, offshore drilling rigs.

ORDERING:

1.

2.

3.

INSTALLATION:

Please specify the dimensions of the upper plate and dimensions of the lower plate. It is common practice that the upper plate is generally larger than the lower plate.

Specify lip dimension (if different than standard ).

Specify base plate thickness (if different than standard ).

Prior to Welding: Locate the slide plate base in the appropriate position on the existing steel

surface. Place a protective covering on the graphite. Where seal welding is not required, follow

the diagram shown which indicates 18 thick fillet weld, 1 long every 4 around entire perimeter of

the base. For welding, use GMAW 0.035 wire or SMAW 332 stick.

Where full seal welding is required, use a similar pattern of welding until a full weld is obtained.

This method will prevent damage to the graphite (A full weld will help prevent seepage of water

between the slide bearing plate and the support structure.). Avoid overheating, which may

destroy the bonding of the graphite to the base plate.

Installing in Concrete: Secure the top and bottom elements together with paper adhesive tape.

Then attach the bottom element anchor bolts with wire to the form. After the bottom pour is

made, repeat on top element. During the first expansive cycle, the tape will break.

www.pipingtech.com/slideplates

183

GRAPHITE SPECIFICATIONS

SLIDE PLATES

PROPERTY

(ROOM TEMPERATURE)

UNITS

AVERAGE

UNITS (METRIC)

AVERAGE

Bulk Density

lb. /ft.3

99.26

Mg/m3

1.59

Specific Resistance

With Grain

Across Grain

10-4 ohm-in.

Flexural Strength

With Grain

Across Grain

PSI

Tensile Strength

With Grain

Across Grain

PSI

Compressive Strength

With Grain

Across Grain

PSI

Youngs Modulus

With Grain

Across Grain

106 PSI

Coefficient of Thermal Expansion

With Grain

Across Grain

10-6 / F

Thermal Conductivity

With Grain

Across Grain

BTU x ft

hr. x ft.2 x F

ohm-meter

1297

995

713

630

2877

2802

0.96

0.61

184

k Pa

(kN/m2)

k Pa

(kN/m2)

k Pa

(kN/m2)

M Pa

(MN/m2)

8940

6860

4920

4340

19840

19320

6620

4210

10-6 / C

0.72

1.35

1.32

2.43

W / m x C

152

107

88

62

Darcys

Permeability

With Grain

Across Grain

Coefficient of Friction

8.47

12.05

3.33

4.74

0.493

0.444

0.15

www.pipingtech.com/slideplates

0.15

STANDARD ASSEMBLY CONFIGURATIONS

WELDING DIAGRAMS FOR PTFE, 25% GLASS FILLED SLIDE PLATES AND GRAPHITE SLIDE PLATES

Notes:

1. Pressure range: 75 PSI to 2,000 PSI

2. Temperature range: -320 F to 400 F

3. Alternate backing materials are available.

SLIDE PLATES

SLIDE PLATES FOR WELDING TO MATING SURFACES

SLIDE PLATES FOR HIGHER LOAD CAPACITIES

Notes:

1. Pressure range: 75 PSI to 2,200 PSI

2. Temperature range: -320 F to 400 F

3. Alternate backing materials are available.

SLIDE PLATES FOR DEFLECTION & EXPANSION AT HIGHER

LOADS

SLIDE PLATES FOR HIGH TEMPERATURE & HIGH LOAD

BEARING

Notes:

1. Pressure range: 75 PSI to 1,500 PSI

2. Temperature range: -50 F to 200 F

3. Alternate thicknesses of reinforced elastomer available.

Notes:

1. Pressure range: 100 PSI to 2,500 PSI

2. Temperature range insulator: 400 F to 800 F

3. Coefficient of friction:

0.10 @ min. pressure

0.06 @ max. pressure

www.pipingtech.com/slideplates

185

BRONZPHITE SLIDE PLATE

SLIDE PLATES

ASSEMBLY:

Standard Assembly: Graphite impregnated bronze plate combined with a carbon steel backing

plate, to be field welded. Loads up to 5000 PSI, temperature: up to 1100 F.

ADVANTAGES:

APPLICATIONS:

Bridges: Highway bridges, overpasses, railroad bridges.

Maintenance free.

Self lubricating.

High wear resistance.

Has an extended life.

Lubrication does not deteriorate with wear.

Prevents accumulation of dust and debris.

Higher durability than standard graphite.

Withstands extreme pressures and high temperatures.

Architectural in Wood, Concrete or Steel: Cross beam and girder slip joints, roof slabs and

corbels, vibration pads, airport hangar doors, domes.

Industrial: Heat exchangers, dust collectors, heavy machinery, refinery equipment, wind tunnels, penstocks, vessels, pipelines, air preheaters, atomic energy applications, transmission towers, storage tanks, offshore drilling rigs.

ORDERING:

1.

2.

INSTALLATION:

Please specify the dimensions of the upper plate and dimensions of the lower plate. It is

common practice that the upper plate is generally larger than the lower plate.

Specify base plate thickness.

Welding: Generally, tack weld with the electric arc along the outside edge for a solid installation.

Wherever full weld is desired, a weld is used along the sides of the base plate to the substrate.

The full weld would prevent seepage of water between the Bronzphite bearing and the support

structure.

Installing in Concrete: When installing Bronzphite slide plate assemblies in concrete, anchor

bolts will be integrated into the base plates for attachment to either the concrete form rebar

structure or simply within the concrete itself.

186

www.pipingtech.com/slideplates

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Indigenous World 2018 PDFDokumen640 halamanIndigenous World 2018 PDFFrancesca SorbaraBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Simulation ModelsDokumen1 halamanSimulation Modelsljv004Belum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- 3.2.1 Example - WBS, V 1.0.1Dokumen3 halaman3.2.1 Example - WBS, V 1.0.1Saleha Quadsia100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Gantt Chart TemplateDokumen8 halamanGantt Chart TemplateospurbaBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Integral CalculusDokumen408 halamanIntegral CalculusCharlyn FloresBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Advanced CalculusDokumen592 halamanAdvanced Calculusjosemarcelod7088Belum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- A Freecad ManualDokumen181 halamanA Freecad ManualCleber_Rocha_Santos88% (8)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- PSV N Arrangement PDFDokumen1 halamanPSV N Arrangement PDFljv004Belum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Presentation 1Dokumen1 halamanPresentation 1ljv004Belum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Presentation 1Dokumen1 halamanPresentation 1ljv004Belum ada peringkat

- Model SamplesDokumen1 halamanModel Samplesljv004Belum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Simulation ModelsDokumen1 halamanSimulation Modelsljv004Belum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- PSV N ArrangementDokumen1 halamanPSV N Arrangementljv004Belum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- YourFile As REquested JLVDokumen164 halamanYourFile As REquested JLVljv004Belum ada peringkat

- Refrigeration Basics and LNGDokumen43 halamanRefrigeration Basics and LNGEnrico GambiniBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rotating Stall and Viscous DampnersDokumen4 halamanRotating Stall and Viscous Dampnersljv004Belum ada peringkat

- Piping Vibration TrainingDokumen2 halamanPiping Vibration Trainingljv004Belum ada peringkat

- GAS GAS Vib Rep PDFDokumen15 halamanGAS GAS Vib Rep PDFljv004Belum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Reporte Prodom Vendor 20-6-2015Dokumen1.452 halamanReporte Prodom Vendor 20-6-2015ljv004Belum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- IpvDokumen1 halamanIpvljv004Belum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Thermal Effects On MaterialsDokumen43 halamanThermal Effects On Materialsljv004Belum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Sample Calculation of LOF of Process PipeDokumen1 halamanSample Calculation of LOF of Process Pipeljv004Belum ada peringkat

- Guidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) Analysis (Blanked) PDFDokumen5 halamanGuidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) Analysis (Blanked) PDFljv004Belum ada peringkat

- PolyurethaneDokumen44 halamanPolyurethaneljv004Belum ada peringkat

- A Masters Guide To Ships PipingDokumen42 halamanA Masters Guide To Ships PipingArdyas Wisnu BaskoroBelum ada peringkat

- Piping Code Paradoxes B31 3 Appen PDokumen16 halamanPiping Code Paradoxes B31 3 Appen Psammar_10Belum ada peringkat

- WatsonDokumen38 halamanWatsonVisas SivaBelum ada peringkat

- Bimetallic CorrosionDokumen20 halamanBimetallic CorrosionchristophedepaepeBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Norsok L-004-CR Ror OgDokumen29 halamanNorsok L-004-CR Ror OgWissam Jarmak100% (2)

- A Sample Script For Public SpeakingDokumen2 halamanA Sample Script For Public Speakingalmasodi100% (2)

- NIFT GAT Sample Test Paper 1Dokumen13 halamanNIFT GAT Sample Test Paper 1goelBelum ada peringkat

- GT I9100g Service SchematicsDokumen8 halamanGT I9100g Service SchematicsMassolo RoyBelum ada peringkat

- 2018 H2 JC1 MSM Differential Equations (Solutions)Dokumen31 halaman2018 H2 JC1 MSM Differential Equations (Solutions)VincentBelum ada peringkat

- Polyembryony &its ImportanceDokumen17 halamanPolyembryony &its ImportanceSURIYA PRAKASH GBelum ada peringkat

- Differential Calculus ExamDokumen6 halamanDifferential Calculus ExamCaro Kan LopezBelum ada peringkat

- Letter of Acceptfor TDokumen3 halamanLetter of Acceptfor TCCSBelum ada peringkat

- II. Put The Verbs in The Correct FormsDokumen3 halamanII. Put The Verbs in The Correct FormsNguyễn Bích DiệpBelum ada peringkat

- Activity Sheet Housekeeping Week - 8 - Grades 9-10Dokumen5 halamanActivity Sheet Housekeeping Week - 8 - Grades 9-10Anne AlejandrinoBelum ada peringkat

- Previous Year Questions Tnusrb S. I - 2010: Part - A': General KnowledgeDokumen21 halamanPrevious Year Questions Tnusrb S. I - 2010: Part - A': General Knowledgemohamed AzathBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- B2B Marketing: Chapter-8Dokumen23 halamanB2B Marketing: Chapter-8Saurabh JainBelum ada peringkat

- ERBS UPDATE John Doe ProceedingDokumen3 halamanERBS UPDATE John Doe ProceedingtpeppermanBelum ada peringkat

- Cuentos CADEDokumen6 halamanCuentos CADEMäuricio E. González VegaBelum ada peringkat

- Ezpdf Reader 1 9 8 1Dokumen1 halamanEzpdf Reader 1 9 8 1AnthonyBelum ada peringkat

- T10 - PointersDokumen3 halamanT10 - PointersGlory of Billy's Empire Jorton KnightBelum ada peringkat

- Name: Mercado, Kath DATE: 01/15 Score: Activity Answer The Following Items On A Separate Sheet of Paper. Show Your Computations. (4 Items X 5 Points)Dokumen2 halamanName: Mercado, Kath DATE: 01/15 Score: Activity Answer The Following Items On A Separate Sheet of Paper. Show Your Computations. (4 Items X 5 Points)Kathleen MercadoBelum ada peringkat

- Silk Road Ensemble in Chapel HillDokumen1 halamanSilk Road Ensemble in Chapel HillEmil KangBelum ada peringkat

- Intertext: HypertextDokumen8 halamanIntertext: HypertextRaihana MacabandingBelum ada peringkat

- Hansen Aise Im Ch12Dokumen66 halamanHansen Aise Im Ch12Rizki19maretBelum ada peringkat

- Prediction of Mechanical Properties of Steel Using Artificial Neural NetworkDokumen7 halamanPrediction of Mechanical Properties of Steel Using Artificial Neural NetworkInternational Association of Scientific Innovations and Research (IASIR)Belum ada peringkat

- Pepcoding - Coding ContestDokumen2 halamanPepcoding - Coding ContestAjay YadavBelum ada peringkat

- BBO2020Dokumen41 halamanBBO2020qiuBelum ada peringkat

- 2017-04-27 St. Mary's County TimesDokumen32 halaman2017-04-27 St. Mary's County TimesSouthern Maryland OnlineBelum ada peringkat

- Data Structures and Algorithms SyllabusDokumen9 halamanData Structures and Algorithms SyllabusBongbong GalloBelum ada peringkat

- The Function and Importance of TransitionsDokumen4 halamanThe Function and Importance of TransitionsMarc Jalen ReladorBelum ada peringkat

- Session 1: Strategic Marketing - Introduction & ScopeDokumen38 halamanSession 1: Strategic Marketing - Introduction & ScopeImrul Hasan ChowdhuryBelum ada peringkat

- AYUSH Warli Art 100628Dokumen10 halamanAYUSH Warli Art 100628adivasi yuva shakti0% (1)

- Beer Lambert'S Law: Dr. Swastika Das Professor of ChemistryDokumen19 halamanBeer Lambert'S Law: Dr. Swastika Das Professor of ChemistryShabanaBelum ada peringkat

- Geography NotesDokumen2 halamanGeography NotesMinethegroundBelum ada peringkat

- Unit: 1: Newton's Laws of Motion & Principle of Transmissibility of ForceDokumen5 halamanUnit: 1: Newton's Laws of Motion & Principle of Transmissibility of ForceKunal SinghBelum ada peringkat