Flupec Technical Specs Filter SC PDF

Diunggah oleh

Secret64Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Flupec Technical Specs Filter SC PDF

Diunggah oleh

Secret64Hak Cipta:

Format Tersedia

COMPONENTS

SUCTION

F I LT E R S

SC

STANDARD SERIES

MATERIALS

SC31 & SC41

Cover & head: Aluminium alloy

Bowl: Polyammide

SC71 & SC81

Cover & housing: Aluminium

Shut-off valve:

Polyammide

Seals:

NBR Nitrile

(FKM - on request fluoroelastomer)

Indicator housing:

Brass

PRESSURE (ISO 10771-1:2002)

Collapse, differential

for the filter element (ISO 2941):

100 kPa (1 bar)

WORKING TEMPERATURE

APPLICATION EXAMPLE

From -25 to + 110 C

COMPATIBILITY (ISO 2943:1999)

Full with fluids: HH-HL-HM-HV-HTG

(according to ISO 6743/4)

For fluids different than the above

mentioned, please contact our Sales

Department.

19

SC

STANDARD

SERIES

S U C T I O N F I LT E R S

INSTALLATION DRAWING

STANDARD SERIES

Tank mounting pattern

45

88

1

26

FSC 31

45

M

8

1/8

Tank mounting pattern

10

M

32

1

104

FSC 41

1/8

60

H1

123

Tank mounting pattern

D1

1/8

146

180

FSC 71

30

51

1

M1

2

30

H2

60

H1

122

D1

1/8

Tank mounting pattern

D2

H3

210

FSC 81

30

81

1

M1

2

30

H2

D2

H3

FILTER HOUSING

kg

D1

D2

H1

H2

H3

FSC31

1 1/4

42

80

275

250

22

1,6

FSC41

1 1/2 - 2 - 2 1/2

66

120

322

300

32

3,0

FSC71

220

110

82

265

348,5

250

10

5,5

FSC81

242

110

82

264

348,5

250

10

6,0

20

S U C T I O N F I LT E R S

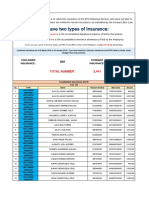

ORDERING AND OPTION CHART

FAMILY, NOMINAL SIZE & LENGTH

PORT TYPE

B = BSP thread

F = SAE flange 3000 psi

PORT SIZE

10 = 1" 1/4 (B10 only)

12 = 1" 1/2 ( B12 only)

16 = 2" (F16 only)

20 = 2" 1/2 (F20 only)

24 = 3"

32 = 4"

W BYPASS VALVE

W = without

SEALS

N = NBR Nitrile

F = FKM Fluoroelastomer

G = treatment for water-glycol

F

B

F

B

F

B

F

B

31

41

71

81

B

-

B

F

10

-

12

16

20

-

24

32

F

G

N

F

G

N

F

G

N

F

G

ME

ME

ME

ME

FILTER MEDIA

ME = metal wire mesh 60 m

MF = metal wire mesh 90 m

MG = metal wire mesh 250 m

MF

MG

MF

MG

MF

MG

MF

MG

CLOGGING INDICATOR

04 = nr. 2 x 1/8" seats, plugged

10 = vacuum gauge, rear connection

04

10

04

10

04

10

04

10

91 = SPDT, vacuum switch

ACCESSORIES

W = without

91

M = magnetic core

ACCESSORIES

W = without

S = safety microswitch

FILTER ELEMENT

91

ELEMENT

FAMILY

SIZE & LENGTH

91

SEALS

X = not applicable

G = for water glycol

FILTER MEDIA

ME = w. mesh 60 m

MF = w. mesh 90 m

MG = w. mesh 250 m

91

Area (cm2)

kg

ESC31

29,5

70

163

0,25

1.600

ESC41

65

99

198

0,50

1.845

ESC71

77

120

196

0,80

2400

ESC81

93

136

196

0,90

2600

Media M+

S C

TYPE

F = FILTER COMPLETE

B = FILTER HOUSING

A

B

SC

STANDARD

SERIES

E

S C

SC

S U C T I O N F I LT E R S

STANDARD

SERIES

FLUID SPEED

when selecting the lter size, we suggest to consider also the max recommended uid speed (in suction lines normally 0,1< v < 1 m/s)

600

Recommended

range

550

500

[l/min]

400

FLOW RATE

450

300

0,1< v < 1 m/s

350

250

200

150

100

50

0

1 1/4

1 1/2

2 1/2

PORT SIZE

PRESSURE DROP CURVES (p)

The Assembly Pressure Drop (p) is obtained by adding the pressure drop values of the Filter Housing and of the Clean Filter

Element corresponding to the considered Flow Rate and it must be lower than 3 kPa (0,03 bar).

FILTER HOUSING

PRESSURE DROP

(mainly depending

on the port size)

0,04

0,03

0,02

0,01

1

0

CLEAN FILTER ELEMENT

PRESSURE DROP

(pressure drop values of

the elements by ME - MF

MG media are very similar)

FSC31 - 41

p (bar) p (kPa)

2

1 1/2

50

0,03

0,04

0,03

0,02

0,01

1

0

100 150 200 250 300

l/min

p (bar) p (kPa)

0,04

2 1/2

1 1/4

p (bar) p (kPa)

ESC 31

0,03

0,02

0,02

0,01

0,01

25

p (bar) p (kPa)

0,04

0,03

50

75 100 125 150

l/min

ESC 71

p (bar) p (kPa)

0,04

0,03

0,02

0,02

0,01

0,01

50

100 150 200 250 300

l/min

3"

4"

100 200 300 400 500 600

l/min

p (bar) p (kPa)

0,04

FSC 71 - 81

ESC 41

50

100 150 200 250 300

l/min

ESC 81

100 200 300 400 500 600

l/min

N.B. All the curves have been obtained with mineral oil having a kinematic viscosity 30 cSt and specic gravity 0,9 kg/dm3; for uids with different features, please consider

the factors described in the rst part of this catalogue. All the curves are obtained from test done at the UFI HYDRAULIC DIVISION Laboratory, according to the specication

ISO 3968:2005. In case of discrepancy, please check the contamination level, viscosity and features of the uid in use.

S U C T I O N F I LT E R S

SC

STANDARD

SERIES

CLOGGING INDICATOR

A visual or electrical indicator

allows monitoring of the element

condition. The port for the indicator is a standard feature.

MAGNETIC CORE

The optional magnetic core is an

additional safeguard that prefilters magnetic particles.

FAST REPLACEMENT

Loosening four screws will allow

removal of quick release cover

and replacement element.

EASY MAINTENANCE

Operated by a hexagonal cover

stud the shut-off valve isolates

the tank oil allowing easy element replacement without

emptying the reservoir.

CLOGGING INDICATOR

For further technical informations

and other options see page 187.

SPARE SEAL KIT

SERIES 10

NBR

FKM

FSC31

521.0088.2

521.0090.2

FSC41

521.0023.2

521.0091.2

FSC71

521.0097.2

521.0098.2

FKM

FSC81

521.0099.2

521.0100.2

FILTER HOUSING

B S C

SAFETY MICROSWITCH

FILTER ELEMENT

(For filling up see table Ordering and option chart)

CLOGGING INDICATOR

ACCESSORY

ACCESSORY

MAGNETIC CORE

SAFETY MICROSWITCH

E S C

Is this datasheet

the latest release?

Please check

on our website.

Technical data subject to variations without prior notice. SC-STD - EN - 06/2011

SPARE PARTS ELEMENTS

SERIES 91

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- 0299 504 1 Sys Hy en 144Dokumen168 halaman0299 504 1 Sys Hy en 144api-1948325050% (4)

- DIESEL ENGINES D-245S3A М, D-245.2S3A М, D-245.5 S3A М, D-245.43 S3A М PDFDokumen89 halamanDIESEL ENGINES D-245S3A М, D-245.2S3A М, D-245.5 S3A М, D-245.43 S3A М PDFSecret64Belum ada peringkat

- 0297 595 4 Sys Hy en 144Dokumen245 halaman0297 595 4 Sys Hy en 144api-19483250100% (2)

- 0293 595 0 Sys El en 144Dokumen94 halaman0293 595 0 Sys El en 144api-1948325033% (3)

- MMZ Catalog PDFDokumen28 halamanMMZ Catalog PDFSecret64Belum ada peringkat

- Operators Manual CLAAS Dominator 150 PDFDokumen390 halamanOperators Manual CLAAS Dominator 150 PDFSecret64Belum ada peringkat

- N45ENT 104kW E PDFDokumen3 halamanN45ENT 104kW E PDFSecret64Belum ada peringkat

- Workshop Manual Engine Man D 0836 Le PDFDokumen144 halamanWorkshop Manual Engine Man D 0836 Le PDFSecret6480% (5)

- Breaker Guide PDFDokumen100 halamanBreaker Guide PDFvijayanBelum ada peringkat

- Primus en PDFDokumen20 halamanPrimus en PDFSecret64Belum ada peringkat

- Operation Manual: Feeder Protection Relay REF615Dokumen120 halamanOperation Manual: Feeder Protection Relay REF615Secret64Belum ada peringkat

- Belarus 1025, 1025.2, 1025.3 Operation Manual MTZDokumen205 halamanBelarus 1025, 1025.2, 1025.3 Operation Manual MTZMtzindex100% (4)

- DRY Transformer MaintenanceDokumen44 halamanDRY Transformer MaintenanceAdebayo O. Johnson100% (1)

- REF630 - Broch - 756382 - LRENe Feeder Protection and Control REF630 Flexibility - ABB PDFDokumen6 halamanREF630 - Broch - 756382 - LRENe Feeder Protection and Control REF630 Flexibility - ABB PDFSecret64Belum ada peringkat

- Operation Manual: Feeder Protection Relay REF615Dokumen120 halamanOperation Manual: Feeder Protection Relay REF615Secret64Belum ada peringkat

- EDS-408A405A Hardware Installation Guide v5 - Moxa EDS-408A-3Fiber - HIG - 1e 1 PDFDokumen16 halamanEDS-408A405A Hardware Installation Guide v5 - Moxa EDS-408A-3Fiber - HIG - 1e 1 PDFSecret64Belum ada peringkat

- Shell Diala Oil D PDFDokumen2 halamanShell Diala Oil D PDFSecret64Belum ada peringkat

- Transformadores de Instrumento AT PDFDokumen72 halamanTransformadores de Instrumento AT PDFAlbino Calderon MendezBelum ada peringkat

- Assembly Instruction Zinc Oxide Surge Arresters Pexlim PDFDokumen28 halamanAssembly Instruction Zinc Oxide Surge Arresters Pexlim PDFSecret64Belum ada peringkat

- EDS-405A 408A Series PDFDokumen2 halamanEDS-405A 408A Series PDFSecret64Belum ada peringkat

- Cordex125 4k4W 5thed PDFDokumen36 halamanCordex125 4k4W 5thed PDFSecret64Belum ada peringkat

- Cordex125 4k4W 5thed PDFDokumen36 halamanCordex125 4k4W 5thed PDFSecret64Belum ada peringkat

- Cordex125 4k4W 5thed PDFDokumen36 halamanCordex125 4k4W 5thed PDFSecret64Belum ada peringkat

- Surge Arrester Pexlim I Pexlink enDokumen28 halamanSurge Arrester Pexlim I Pexlink enRazvan MaresBelum ada peringkat

- Gpcdoc Gtds Shell Diala s3 Zx-I (En) TdsDokumen2 halamanGpcdoc Gtds Shell Diala s3 Zx-I (En) TdsSecret64Belum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- PMI Framework Processes PresentationDokumen17 halamanPMI Framework Processes PresentationAakash BhatiaBelum ada peringkat

- 2019 06 28 PDFDokumen47 halaman2019 06 28 PDFTes BabasaBelum ada peringkat

- Task 5 Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Dokumen5 halamanTask 5 Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Samir Mosquera-PalominoBelum ada peringkat

- Science and TechnologyDokumen21 halamanScience and TechnologyPat MillerBelum ada peringkat

- Science 9 Q4 SML17 V2Dokumen15 halamanScience 9 Q4 SML17 V2HotdogBelum ada peringkat

- Chemical Quick Guide PDFDokumen1 halamanChemical Quick Guide PDFAndrejs ZundaBelum ada peringkat

- NORSOK M-630 Edition 6 Draft For HearingDokumen146 halamanNORSOK M-630 Edition 6 Draft For Hearingcaod1712100% (1)

- REV Description Appr'D CHK'D Prep'D: Tolerances (Unless Otherwise Stated) - (In)Dokumen2 halamanREV Description Appr'D CHK'D Prep'D: Tolerances (Unless Otherwise Stated) - (In)Bacano CapoeiraBelum ada peringkat

- E61 DiagramDokumen79 halamanE61 Diagramthanes1027Belum ada peringkat

- ISO 45001:2018 & OHSAS 18001:2007 Clause-Wise Comparison MatrixDokumen3 halamanISO 45001:2018 & OHSAS 18001:2007 Clause-Wise Comparison MatrixvenkatesanBelum ada peringkat

- WWW Spectrosci Com Product Infracal Model CVH PrinterFriendlDokumen3 halamanWWW Spectrosci Com Product Infracal Model CVH PrinterFriendlather1985Belum ada peringkat

- Service Bulletins For Engine Model I0360kb.3Dokumen6 halamanService Bulletins For Engine Model I0360kb.3Randy Johel Cova FlórezBelum ada peringkat

- Keratoconjunctivitis Sicca FinalDokumen91 halamanKeratoconjunctivitis Sicca FinalJanki GajjarBelum ada peringkat

- AFMAN91-201 NewDokumen458 halamanAFMAN91-201 NewbombtechBelum ada peringkat

- Nutrition & You - Chapter 6Dokumen40 halamanNutrition & You - Chapter 6Bridget KathleenBelum ada peringkat

- Education in America: The Dumbing Down of The U.S. Education SystemDokumen4 halamanEducation in America: The Dumbing Down of The U.S. Education SystemmiichaanBelum ada peringkat

- Principles of Health Management: Mokhlis Al Adham Pharmacist, MPHDokumen26 halamanPrinciples of Health Management: Mokhlis Al Adham Pharmacist, MPHYantoBelum ada peringkat

- Method StatementDokumen29 halamanMethod StatementZakwan Hisyam100% (1)

- The Effects of Violent Video Games Research Paper English Comp2Dokumen11 halamanThe Effects of Violent Video Games Research Paper English Comp2api-451442670Belum ada peringkat

- Jeremy A. Greene-Prescribing by Numbers - Drugs and The Definition of Disease-The Johns Hopkins University Press (2006) PDFDokumen337 halamanJeremy A. Greene-Prescribing by Numbers - Drugs and The Definition of Disease-The Johns Hopkins University Press (2006) PDFBruno de CastroBelum ada peringkat

- Plica PDFDokumen7 halamanPlica PDFIVAN VERGARABelum ada peringkat

- 6 Kuliah Liver CirrhosisDokumen55 halaman6 Kuliah Liver CirrhosisAnonymous vUEDx8100% (1)

- Yogananda Scientific HealingDokumen47 halamanYogananda Scientific HealingSagar Pandya100% (4)

- Viscoline Annular UnitDokumen4 halamanViscoline Annular UnitjoquispeBelum ada peringkat

- Present Continuous Exercises Test 1 - Positive Statements ExerciseDokumen2 halamanPresent Continuous Exercises Test 1 - Positive Statements Exerciseangel omar peraltaBelum ada peringkat

- Lesson 1 - Intro To Highway EngineeringDokumen15 halamanLesson 1 - Intro To Highway EngineeringSaoirseBelum ada peringkat

- CXC - Past - Paper - 2022 Solutions PDFDokumen17 halamanCXC - Past - Paper - 2022 Solutions PDFDarren Fraser100% (1)

- How McDonald'sDokumen2 halamanHow McDonald'spratik khandualBelum ada peringkat

- DOWSIL™ 2-9034 Emulsion: Features & BenefitsDokumen5 halamanDOWSIL™ 2-9034 Emulsion: Features & BenefitsLaban KantorBelum ada peringkat

- Multi-Wing Engineering GuideDokumen7 halamanMulti-Wing Engineering Guidea_salehiBelum ada peringkat