t03 Hitachi

Diunggah oleh

jacklyn ade putraJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

t03 Hitachi

Diunggah oleh

jacklyn ade putraHak Cipta:

Format Tersedia

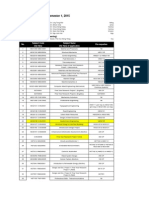

SECTION 3

COMPONENT OPERATION

CONTENTS

Group 1 Pump Device

Group 4 Pilot Valve

Outline .....................................................T3-1-1

Outline .....................................................T3-4-1

Main Pump1, 2 .........................................T3-1-2

Operation .................................................T3-4-2

Regulator .................................................T3-1-6

Pilot Pump..............................................T3-1-22

Group 5 Travel Device

N Sensor (Engine Speed Sensor) ...........T3-1-22

Outline .....................................................T3-5-1

Pump Delivery Pressure Sensor .............T3-1-22

Travel Reduction Gear..............................T3-5-2

Travel Motor .............................................T3-5-3

Group 2 Swing Device

Travel Brake Valve ...................................T3-5-6

Outline .....................................................T3-2-1

Travel Motor Swash Angle Control..........T3-5-14

Swing Motor .............................................T3-2-2

Parking Brake.........................................T3-5-19

Swing Parking Brake ................................T3-2-3

Valve Unit .................................................T3-2-4

Swing Reduction Gear..............................T3-2-6

Group 6 Others (Upperstructure)

Pilot Shut-Off Valve ..................................T3-6-1

Shockless Valve .......................................T3-6-2

Group 3 Control Valve

Solenoid Valve Unit ..................................T3-6-4

Outline .....................................................T3-3-1

Torque Control Solenoid Valve, Pump 2

Hydraulic Circuit .......................................T3-3-6

Flow Rate Control Solenoid Valve ...........T3-6-6

Flow Combiner Valve..............................T3-3-10

Pilot Relief Valve ......................................T3-6-8

Pump Control Valve................................T3-3-12

EC Motor ..................................................T3-6-8

Main Relief Valve....................................T3-3-14

Overload Relief Valve .............................T3-3-15

Group 7 Others (Undercarriage)

Arm Regenerative Valve .........................T3-3-16

Swing Bearing ..........................................T3-7-1

Boom Regenerative Valve ......................T3-3-18

Center Joint..............................................T3-7-2

Bucket Regenerative Valve.....................T3-3-20

Track Adjuster ..........................................T3-7-3

Arm Anti-Drift Valve (Bottom Side)..........T3-3-22

Arm Anti-Drift Valve (Rod Side) /

Boom Anti-Drift Valve ...........................T3-3-25

Bucket Flow Rate Control Valve .............T3-3-26

Travel Flow Rate Control Valve...............T3-3-28

Bypass Shut-Out Valve ...........................T3-3-30

Needle Valve ..........................................T3-3-32

1HH-3-1

(Blank)

1HH-3-2

COMPONENT OPERATION / Pump Device

OUTLINE

The pump device consists of the transmission, main

pumps, and pilot pump. The transmission transfers

engine power to gears via the coupling and drives the

main pumps and pilot pump. The gear ratio to the main

pumps and pilot pump is 1, and 1, respectively.

The main pump is a bent-axis type variable displacement axial plunger pump. The pilot pump is a gear type.

The engine speed sensor (N sensor) and pump delivery pressure sensor (P sensor) are provided to control

the engine, pump, and valves.

7

3

T173-03-01-001

T173-03-01-003

T173-03-01-002

1 - Main Pump 1

3 - Main Pump 2

2 - Pilot Pump

4 - Pump 1 Delivery

Pressure Sensor

5 - Pump 2 Delivery

Pressure Sensor

6 - Transmission

T3-1-1

7 - N Sensor

8 - Coupling

COMPONENT OPERATION / Pump Device

MAIN PUMP 1, 2

The main pump supplies pressure oil to the hydraulic

actuators such as motors, and cylinders. Shaft (3) is

connected to each pump cylinder block (6) via 7

plungers (4) so that the shaft and the cylinder block

rotate together. When cylinder block (6) is rotated,

plunders (4) reciprocate in the cylinder block, suctioning and delivering the hydraulic oil. Each pump is

equipped with a regulator to control the delivery oil flow

rate.

Shaft

4

T173-03-01-004

1 - Regulator

2 - Housing

3 - Shaft

4 - Plunger

5 - Valve Plate

T3-1-2

6 - Cylinder Block

COMPONENT OPERATION / Pump Device

Operational Principle

Engine torque is transferred to the shaft and the

seven plungers, causing the cylinder block to rotate

while sliding along the valve plate surface. The

plungers reciprocate in the cylinder block bores to alternately draw and deliver hydraulic oil.

Plunger

Valve Plate

Shaft

Cylinder Block

T105-02-03-002

T3-1-3

COMPONENT OPERATION / Pump Device

Increasing and Decreasing Flow Rate

Changing inclination of the cylinder block, causes the

plunger stroke to increase or decrease depending on

the slant angle which in turn controls the main pump

flow rate. Up-down movement of the servo piston

changes inclination of the cylinder block. The servo

piston is interlocked with the valve plate via the pin.

The one end of the cylinder block is kept in contact

with the surface of the valve plate and slides along it.

Cylinder Block

Maximum Displacement Angle:

Plunger

Pin

Shaft

Cylinder Block

Servo

Piston

T105-02-03-021

Minimum Displacement Angle

T105-02-03-022

T3-1-4

Valve Plate

Plunger

T173-03-01-004

COMPONENT OPERATION / Pump Device

(Blank)

T3-1-5

COMPONENT OPERATION / Pump Device

REGULATOR

The regulator controls the main pump flow rate in response to the various command signal pressures so

that the pump driving power doesnt exceed the engine

power. Pump 1 and pump 2 are provided with one

regulator each. The major parts of the regulator are

spring (1), sleeve A (2), sleeve B (7), spool A (3), spool

B (6), piston (4), load piston (5), outer spring (8), and

inner spring (9). According to the various command

signal pressures, the regulator opens or closes the

circuit to servo piston (10), causing the inclination of

cylinder block (11) to change, by which the pump flow

rate is controlled.

Dr

Pi

Pd2

Air

Bleeding

Circuit

Pps

Dr

Pd1

NOTE: Pilot oil pressure is constantly supplied in

the smaller side chamber of servo piston

(10).

Pg

10

12

Increase

Decrease

Cylinder Block Inclination

8, 9

T1HH-03-01-018

Pd1 -Pump 1 Delivery Pressure

Pd2 -Pump 2 Delivery Pressure

Dr - Returning to Hydraulic

Oil Tank

T3-1-6

Pi - Pump Control Pressure

Pps -Torque Control Pressure

Pg - Primary Pilot Pressure

(From Pilot Pump)

COMPONENT OPERATION / Pump Device

1

T1HH-03-01-002

12

11

10

T173-03-01-004

1 - Spring

2 - Sleeve A

3 - Spool A

4 - Piston

5 - Load Piston

6 - Spool B

7 - Sleeve B

8 - Inner Spring

9 - Outer Spring

T3-1-7

10 - Servo Piston

11 - Cylinder Block

12 - Link

COMPONENT OPERATION / Pump Device

Regulator Functions

The regulator has the three following functions:

Control by Pump Control Pressure

The pump control valve in the control valve controls

pressure in response to the movements of the spool.

The regulator receives this pump control pressure

signal and controls the pump flow rate as follows.

When the control valve spool is moved and the

pump control pressure is increased, the regulator increases the pump flow rate.

When the control valve spool is returned to the neutral position and the pump control pressure is reduced, the regulator decreases the pump flow rate.

(Refer to the Control Valve group pages.)

Flow Rate (Q)

Pump Control Pressure (Pi)

Control by Pump Delivery Pressure

The delivery pressure of both main pump 1 and

main pump 2 are routed to the regulator. When the

average pressure of the two pumps exceeds the

specified P-Q line, the regulator reduces both pump

flow rates so that the pump performance is returned

to the specified P-Q line. Thus, the engine is protected from overloads. The designed P-Q line has

been determined based on the two pump performance. Therefore, both pump flow rates are set to almost equal value. Accordingly, the high pressure

pump is loaded heavier than the low pressure pump.

Then, the total output of the two pumps is equal to

the engine output (Total Horsepower Control).

Flow Rate (Q)

Pressure Increase

Flow Rate Decrease

Pressure (P)

Control by Pilot Pressure from Solenoid Valve Unit

(SD)

The MC (main controller) compares the engine target speed with the actual engine speed and sends

control signals to solenoid valve unit (SD).

The solenoid valve unit (SD) delivers the pilot oil

pressure in response to control signal from the MC

to the regulator. When the regulator receives the pilot pressure, the regulator reduces the pump flow

rate (Speed Sensing [Horsepower Reduction] Control). (Refer to the Control System group pages.)

Flow Rate (Q)

T3-1-8

Pressure (P)

COMPONENT OPERATION / Pump Device

Control by Pilot Pressure from Flow Rate Control

Flow

Rate (Q)

Solenoid Valve (Pump 2 Side Only)

When the MC receives signals from the work mode

switch, pressure sensor (optional) [auxiliary] or attachment mode switch (optional), the MC send signals to the maximum pump flow rate control solenoid valve. Then, in response to the signals from the

MC, the maximum pump flow rate control solenoid

valve reduces pump control pressure Pi, limiting the

maximum pump flow rate. (Pump Flow Rate Limit

Control)

(Refer to the CONTROL SYSTEM section.)

Pump Control Pressure (Pi)

Flow

Rate (Q)

0

Dr

Pg

Pressure (P)

Pi

Pps

Pd2

Pd1

T1HH-03-01-016

NOTE: This indicates the regulator when the engine stops.

Pd1 -Pump 1 Delivery Pressure

Pd2 -Pump 2 Delivery Pressure

Dr - Returning to Hydraulic Oil

Tank

T3-1-9

Pi - Pump Control Pressure

Pps -Torque Control Pressure

Pg - Primary Pilot Pressure

(From Pilot Pump)

COMPONENT OPERATION / Pump Device

Control by Pump Control Pressure

Flow

Rate (Q)

Increasing Flow Rate

1. When a control lever is operated, pump control

pressure Pi increases (Refer to control valve

group).

2. Piston (4) pushes spool A (3) and spring (1) so

that spool A (3) is moved in the direction of the arrow.

3. Then, the circuit from the large chamber of servo

piston (10) is opened to the hydraulic oil tank.

4. The pilot oil pressure is always routed into the

small chamber of servo piston (10). Thereby,

servo piston (10) is moved toward the direction of

the arrow. Then, the cylinder block rotated in the

maximum inclination direction, increasing the

pump flow rate.

5. The movement of the cylinder block is transmitted

to sleeve A (2) via link (12). Then, sleeve A (2) is

moved in the same direction as spool A (3).

6. When sleeve A (2) is moved by the same stroke

as spool A (3), the circuit from the large chamber

of servo piston (10) to the hydraulic oil tank is

closed so that servo piston (10) is stopped, completing flow rate increase operation.

Pump Control Pressure (Pi)

Dr

Pi

Pd2

Air

Bleeding

Circuit

Pps

Dr

Pd1

Pg

10

12

Increase

Decrease

Cylinder Block Inclination

T1HH-03-01-018

1 - Spring

2 - Sleeve A

3 - Spool A

4 - Piston

10 - Servo Piston

12 - Link

Pd1 -Pump 1 Delivery Pressure

Pd2 - Pump 2 Delivery Pressure

Dr - Returning to Hydraulic

Oil Tank

Pi - Pump Control Pressure

T3-1-10

Pps -Torque Control Pressure

Pg - Primary Pilot Pressure

(From Pilot Pump)

ANIMATION

COMPONENT OPERATION / Pump Device

To Hydraulic Oil tank

Primary Pilot Pressure

Pump Control

Pressure Pi

12

10

T1HH-03-01-004

To Hydraulic Oil tank

Primary Pilot Pressure

Pump Control

Pressure Pi

12

10

T1HH-03-01-005

T3-1-11

COMPONENT OPERATION / Pump Device

Decreasing Flow Rate

1. When a control lever is returned, the pump control

pressure Pi decreases.

2. Piston (4) and spool A (3) is pushed by spring (1)

so that spool A (3) is moved in the direction of the

arrow.

3. Then, the pilot oil pressure is also routed onto the

large chamber of servo piston (10).

4. Due to the difference in diameter between the

large and small chambers, servo piston (10) is

moved toward the direction of the arrow so that

the cylinder block is rotated in the minimum inclination direction, decreasing the pump flow rate.

5. The movement of the cylinder block is transmitted

to sleeve A (2) via link (12). Then, sleeve A (2) is

moved in the same direction as spool A (3).

6. When sleeve A (2) is moved by the same stroke

as spool A (3), the pilot oil pressure circuit to

servo piston (10) through sleeve A (2) and spool A

(3) is closed so that servo piston (10) is stopped,

completing flow rate decrease operation.

Flow

Rate (Q)

Pump Control Pressure (Pi)

Dr

Pi

Air

Bleeding

Circuit

Pd2

Pps

Dr

Pd1

Pg

10

12

Increase

Decrease

Cylinder Block Inclination

T1HH-03-01-018

1 - Spring

2 - Sleeve A

3 - Spool A

4 - Piston

10 - Servo Piston

12 - Link

Pd1 -Pump 1 Delivery Pressure

Pd2 -Pump 2 Delivery Pressure

Dr - Returning to Hydraulic

Oil Tank

Pi - Pump Control Pressure

T3-1-12

Pps -Torque Control Pressure

Pg - Primary Pilot Pressure

(From Pilot Pump)

ANIMATION

COMPONENT OPERATION / Pump Device

To Hydraulic Oil tank

Primary Pilot Pressure

Pump Control

Pressure Pi

12

10

T1HH-03-01-006

To Hydraulic Oil tank

Primary Pilot Pressure

Pump Control

Pressure Pi

12

10

T1HH-03-01-007

T3-1-13

COMPONENT OPERATION / Pump Device

Control by Own or Opponent Pump Delivery

Pressure

Decreasing Flow Rate

Flow

Rate (Q)

1. When the pump is loaded by operating any of the

control levers, either pump 1 delivery pressure

Pd1 or pump 2 delivery pressure Pd2 increases.

(During operation, pump control pressure Pi is increased.)

2. Load piston (5) moves spool B (6) and inner and

outer springs (8 and 9) toward the direction of the

arrow.

3. Due to the movement of spool B (6), the pilot oil

pressure is routed into the large chamber of servo

piston (10).

4. Due to the difference in diameter between the

large and small chambers, servo piston (10)

moved toward the direction of the arrow so that

the cylinder block is rotated in the minimum inclination direction, decreasing the pump flow rate.

5. The movement of the cylinder block is transmitted

to sleeve B (7) via link (12). Then, sleeve B (7) is

moved in the same direction as spool B (6).

6. When sleeve B (7) is moved by the same stroke

as spool B (6), the pilot oil pressure circuit to

servo piston (10) through sleeve B (7) and spool B

(6) is closed so that servo piston (10) is stopped,

completing flow rate decrease operation.

Pressure (P)

Dr

Pi

Pd1

Air

Bleeding

Circuit

Dr

Pps

Pd2

6

10

Pg

12

Increase

Decrease

Cylinder Block Inclination

5678-

Load Piston

Spool B

Sleeve B

Inner Spring

Pd1 - Pump 1 Delivery

Pressure

Pd2 - Pump 2 Delivery

Pressure

Dr - Returning to Hydraulic

Oil Tank

T3-1-14

8, 9

T1HH-03-01-018

9 - Outer Spring

10 - Servo Piston

12 - Link

Pi - Pump Control Pressure

Pps -Torque Control Pressure

Pg - Primary Pilot Pressure

(From Pilot Pump)

ANIMATION

COMPONENT OPERATION / Pump Device

To Hydraulic Oil tank

Pump Control

Pressure Pi

Primary Pilot Pressure

Pump 2 Delivery

Pressure Pd 2

12

Pump 1 Delivery

Pressure Pd 1

10

T1HH-03-01-008

To Hydraulic Oil tank

Pump Control

Pressure Pi

Primary Pilot Pressure

Pump 2 Delivery

Pressure Pd 2

12

Pump 1 Delivery

Pressure Pd 1

10

T1HH-03-01-009

T3-1-15

COMPONENT OPERATION / Pump Device

Increasing Flow Rate

1. When the pump load is reduced, either pump 1

delivery pressure Pd1 or pump 2 delivery pressure Pd2 decreases. (During operation, pump

control pressure Pi is kept increased.)

2. Load piston (5) and spool B (6) are pushed by inner and outer springs (8 and 9) toward the direction of the arrow.

3. Due to the movement of spool B (6), the circuit

from the large chamber of servo piston (10) is

opened to the hydraulic oil tank.

4. Since the pilot oil pressure is constantly routed in

to the small chamber of servo piston (10), servo

piston (10) is moved toward the direction of the arrow. Then, the cylinder block is rotated in the

maximum inclination direction, increasing the

pump flow rate.

5. The movement of the cylinder block is transmitted

to sleeve B (7) via link (12). Then, sleeve B (7) is

moved in the same direction as spool B (6).

6. When sleeve B (7) is moved by the same stroke

as spool B (6), the pilot oil pressure circuit to

servo piston (10) through sleeve B (7) and spool B

(6) is closed so that servo piston (10) is stopped,

completing flow rate increase operation.

Flow

Rate (Q)

Pressure (P)

Dr

Pi

Air

Bleeding

Circuit

Pd2

Pps

Dr

Pd1

6

10

Pg

12

Increase

Decrease

Cylinder Block Inclination

5678-

Load Piston

Spool B

Sleeve B

Inner Spring

Pd1 -Pump 1 Delivery Pressure

Pd2 -Pump 2 Delivery Pressure

Dr - Returning to Hydraulic

Oil Tank

T3-1-16

8, 9

T1HH-03-01-018

9 - Outer Spring

10 - Servo Piston

12 - Link

Pi - Pump Control Pressure

Pps -Torque Control Pressure

Pg - Primary Pilot Pressure

(From Pilot Pump)

ANIMATION

COMPONENT OPERATION / Pump Device

To Hydraulic Oil tank

Pump Control

Pressure Pi

Primary Pilot Pressure

Pump 2 Delivery

Pressure Pd 2

12

Pump 1 Delivery

Pressure Pd 1

10

T1HH-03-01-010

To Hydraulic Oil tank

Pump Control

Pressure Pi

Primary Pilot Pressure

Pump 2 Delivery

Pressure Pd 2

12

Pump 1 Delivery

Pressure Pd 1

10

T1HH-03-01-011

T3-1-17

COMPONENT OPERATION / Pump Device

Control by Pilot Pressure from Torque Control Solenoid Valve

Decreasing Flow Rate

1. When the torque control solenoid valve is activated by the signals from the MC, torque control

pressure Pps increases.

2. Torque control pressure Pps and either own pump

delivery pressure Pd1 or opponent pump delivery

pressure Pd2 are combined and applied to load

piston (5).

3. Load piston (5) pushes spool B (6) and inner and

outer springs (8 and 9) toward the direction of the

arrow.

4. Due to the movement of spool B (6), the pilot oil

pressure is routed into the large chamber of servo

piston (10).

5. Due to the difference in diameter between the

large and small chambers, servo piston (10) is

moved toward the direction of the arrow. Then, the

cylinder block is rotated in the minimum inclination

direction, decreasing the pump flow rate.

6. The movement of the cylinder block is transmitted

to sleeve B (7) via link (12). Then, sleeve B (7) is

moved in the same direction as spool B (6).

7. When sleeve B (7) is moved by the same stroke

as spool B (6), the pilot oil pressure circuit to the

large chamber of servo piston (10) through sleeve

B (7) and spool B (6) is closed so that servo piston

(10) is stopped, completing flow rate decrease

operation.

Flow

Rate (Q)

Pressure (P)

Dr

Pi

Air

Bleeding

Circuit

Pd2

Pps

Dr

Pd1

6

10

Pg

12

Increase

Decrease

Cylinder Block Inclination

5678-

Load Piston

Spool B

Sleeve B

Inner Spring

Pd1 -Pump 1 Delivery Pressure

Pd2 - Pump 2 Delivery Pressure

Dr - Returning to Hydraulic

Oil Tank

T3-1-18

8, 9

T1HH-03-01-018

9 - Outer Spring

10 - Servo Piston

12 - Link

Pi - Pump Control Pressure

Pps -Torque Control Pressure

Pg - Primary Pilot Pressure

(From Pilot Pump)

ANIMATION

COMPONENT OPERATION / Pump Device

To Hydraulic Oil tank

Pump Control

Pressure Pi

Primary Pilot Pressure

Torque Control

Pressure Pps

Pump 2 Delivery

Pressure Pd 2

12

Pump 1 Delivery

Pressure Pd 1

10

T1HH-03-01-012

To Hydraulic Oil tank

Pump Control

Pressure Pi

Primary Pilot Pressure

Torque Control

Pressure Pps

Pump 2 Delivery

Pressure Pd 2

12

Pump 1 Delivery

Pressure Pd 1

10

T1HH-03-01-013

T3-1-19

COMPONENT OPERATION / Pump Device

Control by Pilot Pressure from Flow Rate Control

Solenoid Valve

Flow

Rate (Q)

Limiting Maximum Flow Rate (Pump 2 Only)

1. The maximum pump flow rate control solenoid

valve in the pump control pressure Pi circuit is activated by the signals from the MC.

2. The maximum pump flow rate control solenoid

valve functions as a reducing valve, limiting pump

control pressure Pi.

3. Piston (4) pushes spool A (3) and spring (1) toward the direction of the arrow.

4. Due to the movement of spool A (3), the circuit

from the large chamber of servo piston (10) is

opened to the hydraulic oil tank.

5. Since the pilot oil pressure is constantly routed

into the small chamber of servo piston (10), servo

piston (10) is moved toward the direction of the arrow so that the cylinder block is rotated in the

maximum inclination direction, increasing the

pump flow rate.

6. The movement of the cylinder block is transmitted

to sleeve A (2) via link (12). Then, sleeve A (2) is

moved in the same direction as spool A (3).

7. When sleeve A (2) is moved by the same stroke

as spool A (3), the pilot oil pressure circuit to the

large chamber of servo piston (10) is closed so

that servo piston (10) is stopped, completing flow

rate increase operation.

8. As the pump control pressure is restricted, the

maximum flow rate is reduced more than normal.

Pump Control Pressure (Pi)

Flow

Rate (Q)

Pressure (P)

Dr

Pi

Air

Bleeding

Circuit

Pd2

Pps

Dr

Pd1

Pg

10

12

Increase

Decrease

Cylinder Block Inclination

T1HH-03-01-018

1 - Spring

2 - Sleeve A

3 - Spool A

4 - Piston

10 - Servo Piston

12 - Link

Pd1 - Pump 1 Delivery Pressure

Pd2 - Pump 2 Delivery Pressure

Dr - Returning to Hydraulic

Oil Tank

Pi - Pump Control Pressure

T3-1-20

Pps -Torque Control Pressure

Pg - Primary Pilot Pressure

(From Pilot Pump)

ANIMATION

COMPONENT OPERATION / Pump Device

To Hydraulic Oil tank

Primary Pilot Pressure

Pump Control Pressure Pi Regulated by

Maximum Pump Flow

Rate Control Solenoid Valve

12

10

T1HH-03-01-014

To Hydraulic Oil tank

Primary Pilot Pressure

Pump Control Pressure Pi Regulated by

Maximum Pump Flow

Rate Control Solenoid Valve

12

10

T1HH-03-01-015

T3-1-21

COMPONENT OPERATION / Pump Device

PILOT PUMP

Drive gear (1) is driven by the engine via the transmission which in turn rotates driven gear (2) as they are

meshed together.

When drive gear (1) rotates, driven gear (2) is also

rotated. The hydraulic oil, routed from the inlet port, fills

the spaces between the teeth on each gear, is transferred along the inside surface of the housing, and discharged from the outlet port.

1 - Drive Gear

Inlet Port

2 - Driven Gear

Outlet Port

T137-02-03-005

N SENSOR (ENGINE SPEED SENSOR)

The N sensor detects the engine speed, which is used

to control various operations. The N sensor is located

close to the transmission teeth so that the sensor converts the number of teeth passing by the sensor into

pulse signals, effectively sensing the engine speed.

3 - Tooth

4 - Output

5 - Output

T178-03-01-020

PUMP DELIVERY PRESSURE SENSOR

This sensor detects the pump delivery pressures,

which are used to control various operations. When oil

pressure is applied onto diaphragm (9), the diaphragm

is deformed. The deformation of the diaphragm is detected as electrical signals.

6 - Ground

7 - Output

8 - Power Source (5V)

9 - Pressure Receiving Area

(Diaphragm)

T3-1-22

9

T1HH-03-01-017

COMPONENT OPERATION / Swing Device

OUTLINE

The swing device consists of the valve unit, swing motor, and swing reduction gear. The valve unit prevents

cavitation in the swing circuit from occurring and protects the circuit from being overloaded. The swing motor is a swash plate type axial plunger motor with a

built-in swing parking brake. The swing motor is driven

by pressure oil delivered from the pump, and drives the

swing reduction gear.

The swing reduction gear converts the swing motor

output into slow large torque to rotate the shaft.

Thereby, the upperstructure is rotated.

Valve Unit

Swing Motor

Swing Reduction Gear

T1HH-03-02-001

T3-2-1

COMPONENT OPERATION / Swing Device

SWING MOTOR

The swing motor consists of the swash plate, rotor,

plungers, valve plate, housing and swing parking brake

(springs, brake piston, plates, friction plates, and

switch valve). The rotor in which the plungers are inserted is splined onto the shaft.

When pressure oil is supplied from the pump, the

pressure oil pushes the plungers. Since the swash

plate is inclined, the shoes on top of the plungers slide

along the swash plate, causing the rotor and shaft to

rotate. The shaft tip end is splined into the first stage

sun gear in the swing reduction gear so that shaft rotation is transmitted to the swing reduction gear.

Valve Plate

Spring

Rotor

Brake Piston

Housing

Plate,

Friction Plate

Plunger

Switch Valve

Shoe

Swash Plate

T1HH-03-02-002

Shaft

T3-2-2

COMPONENT OPERATION / Swing Device

SWING PARKING BRAKE

The swing parking brake is a wet-type multi-disc brake.

The brake is released when brake release pressure

enters into the brake piston chamber (negative brake

type). Brake release pressure is supplied from the pilot

pump only when a front attachment and/or swing operation is made. During operations other than swing

and/or front attachment or while the engine is stopped,

brake release pressure is returned to the hydraulic oil

tank so that the brake is automatically applied by

spring.

Releasing Brake:

1. When the swing and/or front attachment control

levers are operated, the spool in the control valve

is shifted.

2. Thereby, the pilot signal circuit is blocked and the

pressure in the pilot signal circuit increases. The

pressure in the pilot signal circuit shifts the switch

valve.

3. Then, the brake release pressure from the pilot

pump flows to brake piston chamber (b) via hydraulic oil timer check valve and acts on brake piston (2).

Consequently, plates (3) and friction plates (4)

are free, so the brake is released.

Applying Brake:

1. When the swing and/or front attachment control

levers are released, the spool in the control valve

is returned to neutral so that the pressure of the

pilot signal circuit is reduced.

2. Therefore, the switch valve is shifted by the spring

force. The brake release pressure flows to the hydraulic oil tank port via the orifice of the hydraulic

oil timer.

3. Consequently, spring force (1) is applied to plates

(3) and friction plates (4) which are meshed with

the outer diameter of rotor (6) and inner diameter

of motor housing (5) respectively via brake piston

(2). Then, the rotor (6) outer diameter is held with

friction force. While the engine is stopped, no

pressure in the pilot signal circuit is routed, allowing the brake to be automatically applied.

2

b

3

4

5

6

T157-02-04-007

Brake OFF

Hydraulic Oil

Timer

Brake

Release

Pressure

OFF

Pilot Signal

Circuit

Swing

Motor

Switch

Valve

Spool

T157-02-04-005

Brake ON

Hydraulic Oil

Timer

Brake

Release

Pressure

ON

Pilot Signal

Circuit

Swing

Motor

Switch

Valve

Spool

T157-02-04-004

1 - Spring

2 - Brake Piston

3 - Plate

T3-2-3

4 - Friction Plate

5 - Motor Housing

6 - Rotor

COMPONENT OPERATION / Swing Device

VALVE UNIT

The valve unit consists of the make-up valves and the

relief valves. The make-up valves prevents cavitation

in the circuit. The relief valves prevent surge pressure

and overloads in the circuit.

Make-Up Valve

During swing stop operation, the swing motor is

driven by inertia force of the upperstructure. The motor is rotated by inertia force more than by pressure

oil delivered from the pump, causing cavitation to develop in the circuit. To prevent cavitation, when pressure in the swing circuit is reduced more than the return circuit (port C) pressure, the poppets are opened

so that hydraulic oil is drawn into the circuit from the

hydraulic oil tank to compensate for the lack of oil in

the circuit.

Relief Valve

Make-Up Valve

Port C

Control Valve

T107-02-04-013

Relief Valve

Poppet

Make-Up Valve

Make-Up Valve

T1HH-03-02-003

T3-2-4

COMPONENT OPERATION / Swing Device

Relief Valve

When starting or stopping swing operation, oil

pressure in the swing circuit becomes high. The relief

valve prevents the circuit pressure from rising higher

than the specified pressure. The plunger is pushed to

the left by pressure (Pp) force of the swing circuit in

pressure-receiving area A2.

However, plunger is also pushed back to the right by

spring force and pressure Pg at chamber (g) in

pressure-receiving area A1.

Chamber (g) is routed to port through orifice (m).

When the force acting on the right is higher than that

on the left, the relief valve operates.

g

Return Circuit

(Port C)

Swing Circuit

(Pressure Pp)

A1

Plunger

T3-2-5

A2

T107-02-04-020

COMPONENT OPERATION / Swing Device

SWING REDUCTION GEAR

The swing reduction gear is a two-stage planetary gear

type.

Ring gear (2) is provided on the inside of the housing, it

is fixed and does not rotate.

The motor output shaft of the swing motor drives first

stage sun gear (8).

Then, rotary power is transmitted to second stage sun

gear (6) via first stage planetary gear (1) and first stage

carrier (7). Second stage sun gear (6) rotates shaft

(output shaft)(4) via second stage planetary gear (3)

and second stage carrier (5).

As shaft (4) meshes with the internal gear of the swing

bearing bolted to the undercarriage, the upperstructure

is rotated.

8

1

T1HH-03-02-001

1 - First Stage Planetary

Gear

2 - Ring Gear

3 - Second Stage Planetary

Gear

4 - Shaft (Output Shaft)

5 - Second Stage Carrier

7 - First Stage Carrier

6 - Second Stage Sun Gear

8 - First Stage Sun Gear

T3-2-6

COMPONENT OPERATION / Control Valve

OUTLINE

The control valve controls oil pressure, flow rate and

flow direction in the hydraulic circuit. The major components of the control valve are the flow combiner

valve, pump control valve, main relief valve, overload

relief valve, arm regenerative valve, boom regenerative valve, bucket regenerative valve, arm anti-drift

valve (both the bottom and rod sides), boom anti-drift

valve, bucket flow rate control valve, travel flow rate

control valve, bypass shut-out valve, needle valve, and

spools.

The spool arrangement in the 4-spool section (seen

from the front) is the travel (right), bucket, boom 1, and

arm 2. The spool arrangement in the 5-spool section

(seen from the front) is the travel (left), auxiliary, boom

2, arm 1, and swing. Each spool is operated by pilot

pressure oil.

Arm 2

4-Spool Side

Boom 1

5-Spool Side

Bucket

Travel (Right)

Swing

Main Relief Valve

Arm 1

Boom 2

Auxiliary

Travel (Left)

Machine Front

T1HH-01-02-005

T3-3-1

COMPONENT OPERATION / Control Valve

System Layout

1

Travel Motor (Left)

Travel Motor (Right)

8

9

39

10

38

11

Bucket

Cylinder

37

12

13

14

36

Arm

Cylinder

35

34

Boom

Cylinder

15

16

17

33 32 31

30

18

19

20

29

28 27 26 25 24

23 22 21

Swing Motor

Pump 2

Pump 1

T1HH-03-03-001

1 - Pump Control Valve

(In 5-Spool Section)

2 - Check Valve

(Main Relief Circuit)

3 - Main Relief Valve

11 - Overload Relief Valve

(Bucket)

12 - Load Check Valve

(Boom 1 Parallel Passage)

13 - Boom Regenerative Valve

4 - Check Valve

(Main Relief Circuit)

5 - Flow Combiner Valve

14 - Boom Anti-Drift Valve

(Check Valve)

15 - Overload Relief Valve

(Boom)

16 - Arm Regenerative Valve

6 - Check Valve (Flow Combiner Valve Circuit)

7 - Check Valve With Orifice

(Bucket Combination)

8 - Bucket Flow Rate Control

Valve (Poppet Valve)

9 - Bucket Flow Rate Control

Valve (Switch Valve B)

10 - Bucket Regenerative Valve

21 - Load Check Valve

(Arm 2 Tandem Passage)

22 - Needle Valve

23 - Boom Anti-Drift Valve

(Switch Valve)

24 - Orifice

25 - Load Check Valve

(Arm 2 Parallel Passage)

26 - Load Check Valve

(Arm 1 Parallel Passage)

27 - Orifice

17 - Check Valve (Arm Regenerative Valve Circuit)

18 - Bucket Flow Rate Control

Valve (Switch Valve A)

19 - Bypass Shut-Out Valve

28 - Load Check Valve

(Arm 1 Tandem Passage)

29 - Load Check Valve (Swing)

20 - Pump Control Valve

(In 4-Spool Section)

30 - Arm Anti-Drift Valve:

Rod Side (Switch Valve)

T3-3-2

31 - Arm Anti-Drift Valve:

Bottom Side (Switch Valve)

32 - Arm Anti-Drift Valve:

Bottom Side (Check Valve)

33 - Arm Anti-Drift Valve:

Bottom Side (Relief Valve)

34 - Overload Relief Valve

(Arm)

35 - Arm Anti-Drift Valve:

Rod Side (Check Valve)

36 - Load Check Valve

(Boom 2 Parallel Passage)

37 - Load Check Valve

(Aux. Parallel Passage)

38 - Travel Flow Rate Control

Valve

39 - Load Check Valve

(Travel Tandem Passage)

COMPONENT OPERATION / Control Valve

22

34

Machine Front

23

Machine Front

11

20

15

30

3

9

35

29

7

27

32

33

14

24, 25

36

12

21

1

T173-03-03-050

39

38

T173-03-03-051

Machine Front

A

B

C

D

E

F

G

T1HH-03-03-002

Section A

Section B

Section C

Travel (Left)

Travel (Right)

5

6

1

4

2

38

39

3

T1HH-03-03-003

T1HH-03-03-004

T3-3-3

COMPONENT OPERATION / Control Valve

1

Travel Motor (Left)

Travel Motor (Right)

8

9

39

10

38

11

Bucket

Cylinder

37

12

13

14

36

Arm

Cylinder

35

34

Boom

Cylinder

15

16

17

33 32 31

30

18

19

20

29

28 27 26 25 24

23 22 21

Swing Motor

Pump 2

Pump 1

T1HH-03-03-001

1 - Pump Control Valve

(In 5-Spool Section)

2 - Check Valve

(Main Relief Circuit)

3 - Main Relief Valve

11 - Overload Relief Valve

(Bucket)

12 - Load Check Valve

(Boom 1 Parallel Passage)

13 - Boom Regenerative Valve

4 - Check Valve

(Main Relief Circuit)

5 - Flow Combiner Valve

14 - Boom Anti-Drift Valve

(Check Valve)

15 - Overload Relief Valve

(Boom)

16 - Arm Regenerative Valve

6 - Check Valve (Flow Combiner Valve Circuit)

7 - Check Valve With Orifice

(Bucket Combination)

8 - Bucket Flow Rate Control

Valve (Poppet Valve)

9 - Bucket Flow Rate Control

Valve (Switch Valve B)

10 - Bucket Regenerative Valve

21 - Load Check Valve

(Arm 2 Tandem Passage)

22 - Needle Valve

23 - Boom Anti-Drift Valve

(Switch Valve)

24 - Orifice

25 - Load Check Valve

(Arm 2 Parallel Passage)

26 - Load Check Valve

(Arm 1 Parallel Passage)

27 - Orifice

17 - Check Valve (Arm Regenerative Valve Circuit)

18 - Bucket Flow Rate Control

Valve (Switch Valve A)

19 - Bypass Shut-Out Valve

28 - Load Check Valve

(Arm 1 Tandem Passage)

29 - Load Check Valve (Swing)

20 - Pump Control Valve

(In 4-Spool Section)

30 - Arm Anti-Drift Valve:

Rod Side (Switch Valve)

T3-3-4

31 - Arm Anti-Drift Valve:

Bottom Side (Switch Valve)

32 - Arm Anti-Drift Valve:

Bottom Side (Check Valve)

33 - Arm Anti-Drift Valve:

Bottom Side (Relief Valve)

34 - Overload Relief Valve

(Arm)

35 - Arm Anti-Drift Valve:

Rod Side (Check Valve)

36 - Load Check Valve

(Boom 2 Parallel Passage)

37 - Load Check Valve

(Aux. Parallel Passage)

38 - Travel Flow Rate Control

Valve

39 - Load Check Valve

(Travel Tandem Passage)

COMPONENT OPERATION / Control Valve

22

Section E

Section D

Boom 2

Auxiliary

Boom 1

23

Bucket

11

15

8

37

14

12

36

9

13

10

11

15

T1HH-03-03-006

T1HH-03-03-005

Section F

Arm 1

Section G

Arm 2

Swing

30

19

34

20

32

31

35

16

26

17

27

24, 25

29

21

34

33

28

T1HH-03-03-008

18

T1HH-03-03-007

T3-3-5

COMPONENT OPERATION / Control Valve

HYDRAULIC CIRCUIT

Main Circuit

1. The pressure oil from pump 1 flows to the travel

(right), the bucket, boom 1, and arm 2 spools in

the 4-spool side control valve.

2. The pressure oil from pump 2 flows to the swing,

arm 1, boom 2, auxiliary, and the travel (left)

spools in the 5-spool side control valve.

3. The main circuits in both the 4 and 5-spool sections have parallel passages to make combined

operations possible.

4. An oil flow combining passage is provided in both

the boom and the arm circuits so that when a single operation is made, the pressure oil from both

pump 1 and 2 is supplied to the boom or the arm

cylinder.

5. The pump control valves are provided down

stream of the neutral passages in both the 4 and 5

spool sections.

6. The oil pressure in the main circuit (between the

pump and the actuator) is controlled by the main

relief valve preventing the man circuit oil pressure

from increasing higher than the set pressure.

7. The overload relief valves are located in the boom,

the arm and the bucket actuator circuits between

the control valve and the actuator.

The overload relief valve prevents the surge pressure from being developed by the external loads

in the actuator circuit and prevents the pressure in

the circuit from rising more than the set pressure

when the control spool is in neutral.

T3-3-6

COMPONENT OPERATION / Control Valve

Pump Control Valve

(In 5-Spool Section)

Main Relief Valve

Travel (Left)

4-Spool Side Parallel Passage

Travel (Right)

Auxiliary

Neutral

Passage

Bucket

Overload

Relief Valves

Boom 1

Boom 2

Overload

Relief Valve

Arm 1

Arm 2

Neutral

Passage

Swing

Flow

Combining

Passages

To the 5-Spool Section.

To the 4-Spool Section.

5-Spool Side Parallel

Passage

Pump 2

Pump Control Valve

(In 4-Spool Section)

Pump 1

T173-03-03-009

T3-3-7

COMPONENT OPERATION / Control Valve

Pilot Control Circuit

The pilot pressure oil (indicated by figures) from the

pilot valve is routed to the end face of each spool in

the control valve so that the spool is operated. While

operating the spools, the pilot pressure oil functions

as follows:

When raising the boom, pilot pressure oil (1) is

routed to the bucket flow rate control valve (switch

valve B) via the bucket flow rate control valve

(switch valve A) and to the travel flow rate control

valve. Then, both valves are activated.

When lowering the boom, pilot pressure oil (2) is

routed to activate the boom anti-drift valve (switch

valve).

When rolling out the arm, pilot pressure oil (3 and

3A) is routed to activate the arm bottom side antidrift valve (switch valve).

When rolling in the arm, pilot pressure oil (4) is

routed to activate the arm rod side anti-drift valve

(switch valve) and the bucket flow rate control

valve (switch valve A).

The air bleeder circuit is provided in the upper section

of the control valve so that the air trapped inside the

control valve is automatically exhausted.

Pilot Signal Circuit

The pressure oil from the pilot pump flows through

the control valve as signal pilot pressure. When traveling, the travel spool restricts the signal pilot oil flow,

increasing the circuit pressure. The pressure sensor

(travel) monitors the pressure increase.

When operations other than travel are performed, the

signal pilot pressure circuits other than travel are restricted, increasing the circuit pressure. The pressure

sensor (front attachment) monitors the pressure increase. The flow combiner valve and swing parking

brake switch valve (swing motor) are also operated.

Solenoid Valve Pilot Signal Circuit

The pilot pressure from solenoid valve unit (SC)

shifts the arm regenerative valve.

The pilot pressure from solenoid valve unit (SG)

increases the pressure setting of the main relief

valve.

(Refer to SYSTEM / Control System group.)

T3-3-8

COMPONENT OPERATION / Control Valve

Pressure Sensor

(Front Attachment)

From Pilot Pump

Pressure Sensor (Travel)

From Pilot

Pump

To Swing

Parking Brake

Main Relief Valve

Pilot Signal Circuit Other than

Travel

From Solenoid Valve Unit (SG)

Travel Pilot Signal Circuit

Flow Combiner Valve

From Pump 1

10

Travel Flow Rate

Control Valve

13

14

Arm Anti-Drift Valve

(Switch Valve): Rod

Side

2

12

11

Bucket Flow Rate

Control Valve

(Switch Valve B)

8

7

Boom Anti-Drift

Valve

(Switch Valve)

Arm Regenerative

Valve

3A

From

Solenoid

Valve Unit

(SC)

Arm AntiDrift Valve

(Switch

Valve): Bottom Side

Bucket Flow

Rate Control

Valve (Switch

Valve A)

5

6

Air Bleeder Circuit

From Pilot

Pump

From Pump 2

T1HH-03-03-009

1 - Boom Raise

2 - Boom Lower

3 - Arm Roll-Out

3 A- Arm Roll Out

4 - Arm Roll-In

5 - Left Swing

6 - Right Swing

7 - Bucket Roll-Out

8 - Bucket Roll-In

9 - Left Travel Forward

T3-3-9

10 - Left Travel Reverse

11 - Right Travel Forward

12 - Right Travel Reverse

COMPONENT OPERATION / Control Valve

FLOW COMBINER VALVE

1. When the front attachment and/or swing function

is operated, the spools in the control valve restrict

the signal pilot pressure oil other than travel so

that the circuit pressure is increased and the flow

combiner valve is activated.

2. At this time, when the travel function is operated,

the pressure oil from pump 1 is routed to the right

travel spool and the left travel spool via the flow

combiner valve and the check valve.

Pilot Signal Circuit

Other than Travel

3. Consequently, the pressure oil from pump 1 is

routed simultaneously to both right and left travel

spools. The pressure oil from pump 2 is routed to

the front attachment and swing spools. Therefore,

when a combined operation of the travel and front

attachment, and/or swing is performed, the machine can travel straight.

Flow Combiner Valve

Check Valve

To Left Travel Spool

Pressure Oil from Pump 1

T1HH-03-03-010

T3-3-10

COMPONENT OPERATION / Control Valve

From the

Pilot Pump.

Travel Motor (Left)

Flow Combiner Valve

Pilot Signal Circuit

Other than Travel

Travel Motor

(Right)

Travel (Right)

Travel

(Left)

Arm

Cylinder

Arm 1

Arm 2

Pump 2

Pump 1

T173-02-02-003

T3-3-11

COMPONENT OPERATION / Control Valve

PUMP CONTROL VALVE

The pump control valves are located down stream of

the neutral passages in both the 4 and 5-spool sections. (Refer to T3-3-7.)

The pump control pressure is regulated by the pump

control valve and is routed to the pump regulator to

control the pump displacement angle. (Refer to the

pump device group.)

The pump control pressure is monitored by the pump

control pressure sensor. Then, the sensing signals are

used to control the travel motor displacement angle.

(Refer to the Control System group in the SYSTEM

section.)

When All Control Levers are in Neutral:

1. When all control levers are in neutral, the control

valve neutral passage isnt restricted as all control

valve spools are in neutral.

2. All oil flow is routed to the hydraulic oil tank from

the neutral passage via spool (B), acting on the

spool (A) in the pump control valve.

3. The oil flow through spool (B) acts on the spring

chamber via spool (C).

4. All oil flow acts on spool (A) in the pump control

vale, so that the force acting on spool (A) overcomes the spring force and the pressure acting on

the spring chamber through spool (C).

Therefore, the spool in the pump control valve

moves to the right.

5. As connecting port PC and port DR via the spool

notch, the pump control pressure which was

routed to the regulator is returned to the hydraulic

oil tank via port PC.

6. Thus, the pump control pressure is reduced so

that the regulator reduces the pump displacement

angle to the minimum, saving engine fuel consumption.

When a Control Lever is Operated:

1. When a control lever is operated, the control valve

spool is moved so that the control valve neutral

passage is restricted.

2. In response to the control valve spool, the oil flow

acted on spool (A) in the pump control valve is reduced.

3. When the force acting on spool (A) doesnt overcome the spring force and the pressure acting on

the spring chamber through spool (C), the spool in

the pump control valve is returned to the left.

4. Then, port PE is connected to port PC via the

spool notch. Thus, the pilot oil pressure is routed

from port PE to the regulator via port PC.

5. When the pump control pressure increases, the

regulator increases the pump displacement angle.

T3-3-12

COMPONENT OPERATION / Control Valve

Spool

Spring

DR

(A)

Spring Chamber

(B)

(C)

Hydraulic Oil Tank

PE

PC

T1HH-03-03-013

When All Control Lever are in Neutral:

(A)

Spool

(C)

Spring Chamber

Neutral Passage

(B)

To

PE

Hydraulic

Oil Tank

PC

DR

T1HH-03-03-011

When a Control Lever is Operated:

(A)

(C)

Spool

Spring Chamber

Neutral Passage

To Hydraulic PE

Oil Tank

PC

DR

T3-3-13

T1HH-03-03-012

COMPONENT OPERATION / Control Valve

MAIN RELIEF VALVE

The main relief valve prevents the main circuit pressure from increasing more than the designed pressure.

When the power boost switch is ON, the relief valve

set pressure is increased. (Refer to the Control System

group in the SYSTEM section.)

Neutral:

2

1 Oil Chamber

Orifice

SG

HP

LP

5 Passage B

Passage A

T1HH-03-03-014

1 - Main Poppet

2 - Pilot Poppet

3 - Spring B

Normal Relief Operation

1. The main circuit pressure in port HP acts on pilot

poppet (2) via the orifice in main poppet (1).

2. When pressure in port HP increases more than

the set force of spring B (3), pilot poppet (2) is unseated, allowing pressure oil to flow to hydraulic

oil tank port LP via passage A.

3. Then, pressure in the oil chamber is reduced, developing a pressure difference between port HP

and the oil chamber by the orifice in main poppet

(1). When the pressure difference increases more

than the set force of spring A (6), main poppet (1)

is unseated, allowing the pressure oil to flow from

port HP to port LP.

4 - Piston

5 - Sleeve

6 - Spring A

Normal Relief Operation:

3

1 Oil Chamber

Orifice

HP

LP

Passage A

T1HH-03-03-015

Orifice 1

Oil Chamber

HP

LP

6

T1HH-03-03-016

Relief Operation When Set-Pressure is Increased

1. When power boost switch is ON, the pilot pressure is routed in port SG.

2. The pilot pressure via passage B in sleeve (5) and

passage C in piston (4) pushes piston (4) to the

left.

3. Therefore, a higher pressure is required to open

pilot poppet (2) as the set force of spring B (3) increases. The relief set pressure increases more

than normal.

Relief Set-Pressure is Increased:

2

Passage C

SG

HP

LP

4

5 Passage B

T1HH-03-03-017

T3-3-14

COMPONENT OPERATION / Control Valve

OVERLOAD RELIF VALVE

Neutral:

The overload relief valve prevents the actuator circuit

pressure from increasing more than the designed

pressure. If the actuator pressure becomes negative,

the valve makes up the hydraulic oil from the hydraulic

oil tank.

Orifice

HP

LP

7

1234-

Relief Operation

1. Pressure in port HP (actuator circuit) acts on pilot

poppet (4) via the orifice in piston (1).

2. When pressure in port HP increases more than

the set force of spring B (5), pilot poppet (4) is unseated so that the pressure oil flows to hydraulic

oil tank port LP via the passage.

3. Then, pressure in the oil chamber is reduced, developing a pressure difference between port HP

and the oil chamber by the orifice in piston (1).

When the pressure difference increases more

than the set force of spring A (3), piston (1) is

moved to the right and main poppet (2) is unseated, allowing the pressure oil to flow from port

HP to port LP.

Oil Chamber

Piston

Main Poppet

Spring A

Pilot Poppet

T1HH-03-03-018

Passage

5 - Spring B

6 - Spring C

7 - Sleeve

Relief Operation:

1

Orifice

HP

LP

Passage

Orifice

T1HH-03-03-019

HP

LP

Oil Chamber

Make-Up Operation

1. When pressure in port HP decreases lower than

port LP, sleeve (7) is moved to the right.

2. Then, the hydraulic oil flows from port LP to port

HP so that cavitation is prevented.

T1HH-03-03-020

Make-Up Operation:

HP

LP

T3-3-15

T1HH-03-03-021

COMPONENT OPERATION / Control Valve

ARM REGENERATIVE VALVE

The arm regenerative valve regulates the return oil

flow from the cylinder rod side when rolling the arm in.

Thereby, the arm roll-in speed is increased to improve

the arm controllability so that the arm hesitation is prevented.

When Arm Regenerative Valve is in Neutral:

Arm

Regenerative

Valve

1. In response to the signal from MC solenoid valve

unit (SC) acts, then the pilot pressure is routed to

the arm regenerative valve from solenoid valve

unit (SC). (Refer to SYSTEM / Control System

group)

2. The return oil from the arm cylinder flows into the

spool from hole A on the arm 2 spool.

To Hydraulic Oil

Tank.

Orifice A

Hole B

Hole A

Arm Regenerative Valve is in Neutral:

3. The pressure oil from hole A flows to the hydraulic

oil tank via orifice A and hole B.

Arm Regenerative Valve is Operated:

4. When the pilot pressure is supplied from port SC,

the arm regenerative valve is activated. Then, the

pressure oil flow from hole A is restricted by orifice

A and hole C, increasing the pressure in the

spool.

5. If the pressure in the arm cylinder bottom side circuit is lower than that of the spool inside, the

pressure in the spool opens the check valve via

orifice B and flows to the arm cylinder bottom side

circuit.

Orifice A, Hole B

Check Valve

Arm

Cylinder

From

4-Spool Section

Neutral Circuit

Arm

Regenerative

Valve

T1HH-03-03-022

When Arm Regenerative Valve is Operated:

Pilot Pressure from

Solenoid Valve Unit

(SC)

Hole B

From

4-Spool Side

Parallel Passage

Arm

Regenerative

Valve

To Hydraulic Oil

Tank.

Orifice A

SC

Arm 2 Spool

Hole A

Hole B

Hole C (Orifice )

Orifice B

Orifice A,

Hole C

To Hydraulic Oil

Tank

Hole A Orifice B

Check Valve

To Cylinder

Bottom Side

Circuit

T173-03-03-049

T1HH-03-03-023

T3-3-16

COMPONENT OPERATION / Control Valve

Arm Regenerative Valve

Arm Cylinder

Port SC

Hole B, Hole C

Tank Passage

Hole A

Check Valve

Cylinder

Bottom Side

Circuit

Arm 2 Spool

T1HH-03-03-024

T3-3-17

COMPONENT OPERATION / Control Valve

BOOM REGENERATIVE VALVE

The boom regenerative valve regulates the return oil

flow from the cylinder bottom side when the boom is

lowered. Thereby, the boom lower speed is increased

to improve the boom controllability so that cavitation is

prevented.

From

4-Spool Side

Parallel Passage

1. When the boom is lowered, the return oil from the

boom cylinder bottom side flows into the spool via

boom 1 spool hole A.

2. If the pressure in the boom cylinder rod side is

lower than the bottom side, the pressure (the

pressure oil in the bottom side) in the spool opens

the check valve 1 and flows into the boom cylinder

rod circuit via hole c.

3. When the pressure in the boom cylinder rod side

is higher than the bottom side during excavation

for example, check valve 2 is unseated so that all

oil flow is returned to the hydraulic oil tank via hole

B.

T3-3-18

To Hydraulic Oil

Tank

Boom 1

Spool

Check Valve 1

Boom

Cylinder

T1HH-03-03-045

COMPONENT OPERATION / Control Valve

Boom 1 Spool

Hole B

Check Valve 2

Boom Cylinder

Hole A

Hole C

Check Valve 1

T1HH-03-03-025

T3-3-19

COMPONENT OPERATION / Control Valve

BUCKET REGENERATIVE VALVE

The bucket regenerative valve controls the return oil

from the cylinder rod side when operating the bucket

roll-in. This makes the bucket roll-in operation more

controllable and the occurrence cavitation is prevented.

1. If operating the bucket roll-in at the most retracted

position of the arm cylinder, the pressure in the

bottom side circuit of the bucket cylinder is lower

than that in the rod side because of its own

weight.

2. The return oil from the bucket cylinder rod side is

separated in the bucket spool. One flows back to

the hydraulic oil tank.

The other flows into the spool through hole A on

the spool.

3. The pressure oil (in the rod side) into the spool

opens the check valve and flows to the bucket cylinder bottom side circuit via hole B on the spool.

Thereby the cavitation is prevented.

From Flow

Combiner

Valve

Check Valve

To Hydraulic

Oil Tank

Bucket

Spool

Bucket

Cylinder

Hole B

T3-3-20

Hole A

T1HH-03-03-027

COMPONENT OPERATION / Control Valve

Check Valve

Hole B

Hole A

T1HH-03-03-026

T3-3-21

COMPONENT OPERATION / Control Valve

ARM ANTI-DRIFT VALVE (BOTTOM SIDE)

The arm anti-drift valve is provided to reduce cylinder

drift.

Port A6B

X

When the control lever is in neutral: Holding Operation

1. The pressure in the arm cylinder bottom side is

routed to port A6B.

2. The pressure in port A6B is routed to spring

chamber A via the spool.

3. Then, the check valve is pushed downward, closing the oil circuit from the cylinder bottom to the

spool.

4. Thereby, the cylinder drift is reduced.

Spool

Arm

Cylinder

T173-03-03-028

Cross Section X-X

Check Valve

Check Valve

Spring Chamber A

Port A6B

Port A6B

Spool

T173-03-03-024

Spool

T1HH-03-03-028

T3-3-22

COMPONENT OPERATION / Control Valve

When the control lever is operated : Deactivated

When Arm is Rolled-In:

1. When the arm is rolled in, the pressure oil from

the arm spool opens the check valve and flows to

the cylinder from port A6B.

Check Valve

2. When the arm is rolled out, the pilot pressure is

supplied to ports PL so that the spool is shifted after moving the piston.

3. Port D is connected to spring chamber A and the

hydraulic oil tank so that the pressure in spring

chamber A is reduced.

4. Then, the return oil from the arm cylinder bottom

Port A6B

side opens the check valve and flows back to the

arm spool.

Arm

Cylinder

Check Valve

Port A6B

To Arm

Spool

Port

Pilot Pressure PL

From Arm Spool

T1HH-03-03-030

Port D

Spool

Piston

Hydraulic Oil Tank

T173-03-03-026

Y

Check Valve

Section Y-Y

Spring Chamber A

Pilot Pressure

When Arm is Rolled-Out:

Port PL

Port D

Port A6B

Y

Drain

Port D

Spool

Spool

Piston

T1HH-03-03-029

To Arm Spool

T3-3-23

T1HH-03-03-031

COMPONENT OPERATION / Control Valve

When the control lever is in neutral: Overload

Prevention

1. When the control lever is in neutral, if the presCheck Valve

sure in the arm cylinder bottom side is increased

by an external force, hydraulic components may

be damaged.

2. The pressure in port A6B on the arm cylinder bottom side is routed to spring chamber A through

the spool as when the arm is in the holding position.

3. Then, when the pressure increases more than the

set pressure, the poppet is unseated, allowing the Port A6B

pressure oil to flow into chamber C.

4. Therefore, the piston is pushed downward, the

spool is shifted, allowing the pressure oil in port D

to flow back to the hydraulic oil tank.

5. Port D is connected to spring chamber A and the

hydraulic oil tank so that the pressure in spring

chamber A is reduced.

6. Then, the check valve is unseated, the pressure

oil in port A6B on the arm cylinder bottom side

flows to the arm spool and opens the overload relief valve.

7. This makes the pressure in the arm cylinder bottom prevent from increasing abnormally.

Poppet

Spring

Chamber A

Spool

T1HH-03-03-032

Y

Section Y-Y

Check Valve

Spring

Chamber A

Poppet

Port D

Port A6B

Drain

Y

Port D

Spool

Piston

Spool

Chamber C

T1HH-03-03-033

To Arm Spool

T3-3-24

T1HH-03-03-031

COMPONENT OPERATION / Control Valve

ARM ANTI-DRIFT VALVE (Rod Side) /

BOOM ANTI-DRIFT VALVE

Holding Operation:

The anti-drift valves (on the arm cylinder rod side and

boom cylinder bottom side) are provided to reduce

cylinder drift.

Spool

Arm Spool

Boom Spool

NOTE: The construction of the arm anti-drift valve

is identical to the boom anti-drift valve.

When the control valve is in neutral: Holding Operation

1. The oil pressure in the arm cylinder rod side (the

boom cylinder bottom side) is routed to port B6

(B3).

2. Then, the pressure in port B6 (B3) is routed to oil

chamber A through the spool.

3. Thereby, the check valve is pushed to block the oil

flow from the cylinder to the spool so that the cylinder drift is reduced.

Oil Chamber

A

Check Valve

Port B6 (B3)

T1HH-03-03-035

Deactivation (Arm Roll-In, Boom Lower):

When the control valve is operated: Deactivation

1. When the arm is rolled in (the boom is lowered),

the pressure oil from the arm (boom) spool opens

the check valve so that the pressure oil flows to

the cylinder via port B6 (B3).

2. When the arm is rolled out (the boom is raised),

the pilot oil pressure moves the spool.

3. The oil in oil chamber A flows back to the hydraulic oil tank through the spool, reducing pressure in

oil chamber A.

4. Then, the return oil from the arm cylinder rod side

(the boom cylinder bottom side) passes port B6

(B3), opens the check valve, and flows to the arm

spool (the boom spool).

Arm Spool

Boom Spool

Check Valve

Port B6 (B3)

T1HH-03-03-037

Deactivation (Arm Roll-Out, Boom Raise):

Spool

To Arm Cylinder

To Boom Cylinder

Arm Spool

Boom Spool

Spool

To Hydraulic Oil

Tank.

Pilot Pressure

Arm Roll-Out Pilot Pressure

Boom Raise Pilot Pressure

Check Valve

To Arm Spool.

To Boom Spool.

Oil Chamber A

T1HH-03-03-034

Check Valve

T3-3-25

Port B6 (B3)

T1HH-03-03-036

COMPONENT OPERATION / Control Valve

BUCKET FLOW RATE CONTROL VALVE

When Bucket is Single-Operated:

The bucket flow rate control valve consists of the poppet valve, switch valve A, and switch valve B.

The bucket flow rate control valve restricts the bucket

oil flow to give priority to the boom raise operation

when the bucket, arm roll-in, and boom raise functions

are simultaneously operated.

Check Valve

Poppet Valve

Switch Valve B

1. The pressure oil from the neutral passage flows to

the poppet valve.

Bucket Cylinder

When the Bucket is Single-Operated:

2. Normally, the pressure oil opens the check valve

in the poppet valve and flows to port A2 from

chamber A.

3. Both the check valve and poppet in the poppet

valve are supported by the same spring. Therefore, when the check valve is opened, the poppet

valve is also opened, allowing the pressure oil

from the neutral circuit to directly flow to the

bucket spool.

When the bucket, the arm roll-in and the boom

raise are combined-operated:

4. When operating the arm roll-in, the arm roll-in pilot

pressure shifts the spool in switch valve A.

5. Therefore, the boom raise pilot pressure through

switch valve A shifts the Spool in switch valve B.

6. But, when switch valve B spool is moved to restrict the pressure oil flow from chamber A to port

A2, pressure in chamber A increases.

7. Then, the poppet is raised to reduce the pressure

oil flow from the neutral passage to the bucket

spool.

8. Accordingly, the pressure oil has precedence to

flow to boom 1 spool via the parallel passage so

that the boom is raised.

Bucket Spool

T1HH-03-03-038

When Bucket the Arm Roll-In and Boom Raise are

Combined-Operated:

Check Valve

Poppet Valve

Switch Valve B

Bucket Cylinder

Bucket Spool

Arm Roll-In Pilot

Pressure

Switch Valve A

Boom Raise

Pilot Pressure

T3-3-26

T1HH-03-03-039

COMPONENT OPERATION / Control Valve

When Bucket is Single-Operated:

Neutral Passage

Check Valve

A2

Poppet Valve

B2

Chamber A

Spring

T1HH-03-03-040

When Bucket, Arm Roll-In and Boom Raise are Combined-Operated:

Neutral Passage

Poppet Valve

A2

B2

Chamber A

Switch Valve B

Spool

Boom Raise Pilot Pressure

From Switch Valve A

T3-3-27

T1HH-03-03-041

COMPONENT OPERATION / Control Valve

TRAVEL FLOW RATE CONTROL VALVE

When the travel and boom raise combined operation is

performed, the flow combiner valve is opened so that

the pressure oil from pump 1 flows to both right and left

travel motors and the pressure oil from pump 2 flows

to boom 2 spool.

When traveling on a flat or down slope surface, the

travel motor load pressure becomes lower than the

boom cylinder. Accordingly, the pressure oil from pump

2 is routed to the lower pressure side of the travel (left)

spool via parallel passage P2, reducing the oil flow to

the high pressure side of the boom 2 spool.

The travel flow control valve restricts the passage to

the travel (left) spool from parallel passage P2 in such

cases and secures oil flow to raise the boom.

Travel (Left) Spool

Piston

Poppet

To Hydraulic Oil Tank

From Flow

Combiner

Valve

Boom Raise

Pilot Pressure

1. When the boom is raised, the boom raise pilot

pressure is supplied to the travel flow control

valve, pushing piston to the right to increase the

spring force.

2. Then, the poppet is pushed to the right harder.

3. Therefore, even if the pressure in the travel (left)

neutral passage P2 is reduced lower than the

parallel passage P2, the poppet does not unseat.

4. Thereby, the pressure oil from pump 2 does not

flow to the travel (left) spool but flows to the boom

2 spool, ensuring boom raise operation.

T3-3-28

Neutral Passage P2

Parallel Passage P2

Spring

T173-03-03-043

COMPONENT OPERATION / Control Valve

Travel (Left)

Travel (Right)

Parallel Passage

P2

Piston

Boom Raise

Pilot Pressure

Poppet

Neutral Passage

P2

T1HH-03-03-042

T3-3-29

COMPONENT OPERATION / Control Valve

BYPASS SHUT-OUT VALVE

The bypass shut-out valve is provided in the neutral

passage of the 4-spool section control valve. The bypass shut-out valve allows the pressure oil from pump

1 to join into the pressure oil from pump 2 when an

attachment is operated by the auxiliary spool in the 5spool section control valve.

1. When the attachment is operated, the pilot pressure is routed to port PBC.

2. Then, the bypass shut-out valve spool is moved to

the right, closing the passage from the neutral circuit to port T2.

3. Accordingly, the pressure oil from pump 1 flows

from the neutral passage to port A4 and is routed

further to the point just before the auxiliary spool

in the 5-spool section control valve where the

pressure oil joins into the pressure oil flow from

pump 2.

Port PBC

Pilot Pressure

Neutral Circuit in 4-Spool

Section Control Valve

To Attachment

Spool

Port A4

Port T2

Spool

T1HH-03-03-043

T3-3-30

COMPONENT OPERATION / Control Valve

To Attachment

Auxiliary

Spool

Bypass

Shut-Out Valve

To 5-Spool Side

Control Valve

To 4-Spool Side

Control Valve

Pilot Pressure

Pump 2

Pump 1

T173-03-03-044

T3-3-31

COMPONENT OPERATION / Control Valve

NEEDLE VALVE

Port DR2

The needle valve is provided for emergencies in order

to lower the boom, in case stopping the engine is necessary.

Needle Valve

Boom AntiDrift Valve

(Switch Valve)

1. The pressure oil in the boom cylinder bottom side

is routed to port B3 and blocked by the boom antidrift valve. (Refer to T3-3-25.)

2. Port B3 is connected to the needle valve through

the inner passages. When the needle valve is

loosen, the pressure oil in port B3 flows to port

DR2 through the needle valve.

3. Consequently, the boom cylinder is retracted and

the boom is lowered because of its own weight.

Boom

Anti-Drift

Valve

(Check Valve)

Port B3

T1HH-03-03-044

Boom

Cylinder

Boom Anti-Drift

Valve

(Switch Valve)

Boom Anti-Drift

Valve

(Check Valve)

Needle Valve

T173-03-03-046

T3-3-32

COMPONENT OPERATION / Pilot Valve

OUTLINE

The pilot valve controls pilot pressure oil to move the

control valve spools. There are two types of pilot

valves. One is for front attachment / swing operation;

the other is for travel operation. Both have four oil ports

as standard. An optional two-port type is available. The

construction of the reducing valves in both the front

attachment / swing and travel pilot valves are identical

except for the pusher cams.

Front Attachment / Swing Pilot Valve

Right

Valve

Left

Valve

Port

No.

1

2

3

4

1

2

3

4

ISO Control Pattern

1

2

3

4

Hitachi Pattern

Arm Roll-In

Right Swing

Arm Roll-Out

Left Swing

Bucket Roll-Out

Boom Lower

Bucket Roll-In

Boom Raise

Right Swing

Arm Roll-Out

Left Swing

Arm Roll-In

P

Hydraulic

Diagram

Symbol

Travel Pilot Valve

Right Travel Reverse

Right Travel Forward

Left Travel Forward

Left Travel Reverse

T

Hydraulic

Diagram

Symbol

T105-02-07-020

T105-02-07-020

T

P

T

4

2

P

T178-03-04-001

T178-03-04-002

T3-4-1

COMPONENT OPERATION / Pilot Valve

OPERATION

Spool (6) head comes in contact with the upper face of

spring guide (3) which is kept raised by return spring

(5).

Neutral (Output Diagram: A to B):

1. When neutral, spool (6) totally blocks pressure oil

port P (from the pilot pump).The output port is

opened to port T (hydraulic oil tank) through the

passage in spool (6). Therefore, oil pressure in

the output port (to the control valve) is equal to

that in port T.

2. When the control lever is slightly tilted, cam (1) is

tilted, moving pusher (2) downward. Then, pusher

(2) compress return spring (5) along with spring

guide (3). At this time, as oil pressure in the output

port is equal to that in port T, spool (6) moves

downward while keeping the under face of the

spool head in contact with spring guide (3).

3. This status continues until hole (7) on spool (6) is

opened to port P.

T3-4-2

D

Pilot

Pressure

Lever Stroke

T522-02-05-001

COMPONENT OPERATION / Pilot Valve

Front Attachment / Swing Pilot Valve

6

Port T

7

Port P

Output Port

Port T

Port T

Port P

Output Port

Port P

Output Port

T178-03-04-005

T178-03-04-007

Travel Pilot Valve

1

Port T

7

3

Output Port

Port P

Port T

Port T

6

Port P

Output Port

1 - Cam

2 - Pusher

Port P

Output Port

T178-03-04-006

3 - Spring Guide

4 - Balance Spring

5 - Return Spring

6 - Spool

T3-4-3

7 - Hole

T178-03-04-011

COMPONENT OPERATION / Pilot Valve

During Metering or Decompressing (Output

Diagram: C to D)

1. When the control lever is further tilted to move

pusher (2) downward more, hole (7) on spool (6)

is opened to port P, allowing pressure oil in port P

to flow into the output port.

2. Oil pressure in the output port acts on the bottom

face of spool (6) so that spool (6) is pushed

upward.

3. However, until upward force acting on the bottom

face of spool (6) overcomes balance spring (4)

force, balance spring (4) is not compressed. Then,

spool (6) is not raised, allowing oil pressure in the

output port to increase.

4. As oil pressure in the output port increases, force