Performance Analysis of A Inverted Downdraft Biomass Wood Stove

Diunggah oleh

IAEME PublicationJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Performance Analysis of A Inverted Downdraft Biomass Wood Stove

Diunggah oleh

IAEME PublicationHak Cipta:

Format Tersedia

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 6, Issue 8, Aug 2015, pp. 144-155, Article ID: IJMET_06_08_014

Available online at

http://www.iaeme.com/IJMET/issues.asp?JTypeIJMET&VType=6&IType=8

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

IAEME Publication

________________________________________________________________________

PERFORMANCE ANALYSIS OF A

INVERTED DOWNDRAFT BIOMASS WOOD

STOVE

A. R. Sivaram

Assistant professor, Department of Mechanical Engineering,

AMET University, Chennai

Dr. K. Karuppasamy

Assistant Professor, Department of Mechanical Engineering,

Regional centre of Anna University Tirunelveli

Dr. R. Rajavel

Professor and HOD, Department of Mechanical Engineering,

AMET University, Chennai

C. Jagadesh Vikram,

Assistant Professor, Dept. of Automobile Engineering,

Bharath University, Chennai

ABSTRACT

Biomass is a syngas fuel which can be used as a fuel for furnaces, stoves

and vehicles in place of gasoline, diesel or other fuels. In the present

investigation, syngas is used as fuel for biomass wood stove to meet the energy

requirement for community and domestic level cooking applications. Water

boiling tests were conducted to evaluate the biomass performance with respect

to efficiency and fuel flexibility. The biomass wood stove was tested with Amla,

Calotropis, Juliflora, Neem wood and Cashew nut shell. The properties of the

biomasses were determined experimentally. It is seen from results that the

thermal efficiency of neem wood is 56% higher than the other biomasses.

Key words: Syngas, Water boiling tests, Amla, Calotropis, Juliflora, Neem

wood and Cashew nut shell.

Cite this Article: Sivaram, A. R., Dr. Karuppasamy, K., Dr. Rajavel, R. and

Jagadesh Vikram, C. Performance Analysis of a Inverted Downdraft Biomass

Wood Stove. International Journal of Mechanical Engineering and

Technology, 6(8), 2015, pp. 144-155.

http://www.iaeme.com/IJMET/issues.asp?JTypeIJMET&VType=6&IType=8

http://www.iaeme.com/IJMET/index.asp

144

editor@iaeme.com

Performance Analysis of a Inverted Downdraft Biomass Wood Stove

1. INTRODUCTION

In recent years the interest in bio fuels has been increasing, motivated on the one hand

by the need for reducing greenhouse gas emissions and on the other hand by t he

desire to improve energy security by reducing our dependence on imported fossil

fuels. Biomass energy production does not suffer from the generation intermittency of

solar and wind facilities. Biomass energy generation is effectively and can be utilized

as a stable, reliable, on-demand source of base-load power generation. Yung-Chang

Ko et al [1] have carried out a study which was aimed to assess the effects of changes

in gas composition on burner performance and to propose suitable design or

operational factors of domestic gas stoves burning natural gas with various heating

values. A single gas burner, originally designed for burning natural gas with low

heating value, is adopted to investigate the effects of variations in gas composition on

the burner performance.

Using natural gas with high heating value instead of natural gas with low heating

value results in a decrease in thermal efficiency (due to higher thermal input) and an

increase in CO emission (caused by incomplete combustion). Smith et al [2] have

investigated about the implications of changes in household stoves and fuel use.

Persson et al [3] have carried out a study which investigates how electrically heated

single- family houses can be converted to wood pellets- and solar heating using pellet

stoves and solar heating systems. Four different system concepts are presented and

system simulations in TRNSYS evaluate the thermal performance and the electrical

savings possible for two different electrically heated single-family houses.

Simulations show that the electricity savings using a wood pellet stove are greatly

affected by the level of comfort, the house plan, the system choice and if the internal

doors are open or closed. Installing a stove with a water-jacket connected to a radiator

system and a hot water store has the advantage that heat can be transferred to

domestic hot water and be distributed to other rooms. Pinar et al [4] have reviewed the

flue gas emissions of carbon monoxide (CO), nitrogen oxides (NO X), sulphur dioxide

(SO 2 ) and soot from an improved space-heating biomass stove and thermal efficiency

of the stove have been investigated. Rathore et al [5] have studied the wood gas stove

in meeting cooking energy requirement using biomass gasification. The stove works

on natural draft mode. The thermal efficiency of the stove was recorded at about

26.5% and it can be started, operated and stopped with very low emissions. Kariher et

al [6] have studied 14 solid-fuel household cook stove and fuel combinations,

including 10 stoves and four fuels, which were tested for performance and pollutant

emissions using a WBT (Water Boiling Test) protocol. Results from the testing

showed that some stoves currently used in the field have improved fuel efficiency and

lower pollutant emissions compared with traditional cooking methods. Rashid et al [7]

have carried out an experimental investigation using a multistage simple random

sampling design, to determine the structural characteristics of the traditional cooking

stoves, amount of wood fuel consumed. Kousksou et al [8] have carried out an

experimental investigation by incorpating a TE (thermoelectric) generator with a

multifunction wood stove. The TE generator has produced up to 9.5 W. Vigneswaran

et al [9] have evaluated three types of forced draft cook stoves using fuel wood [10]

and coconut shell. Carvalho et al [11] have carried out a field study investigating how

modern wood-burning stoves operated in modern single- family houses, which showed

that intermittent heat supply occasionally conflicted with the primary heating system

and that chimney exhaust occasionally conflicted with the ventilation system causing

overheating and particles in the indoor environment. On this background, it was

http://www.iaeme.com/IJMET/index.asp

145

editor@iaeme.com

A. R. Sivaram, Dr. K. Karuppasamy, Dr. R. Rajavel and C. Jagadesh Vikram

concluded that better combustion technology and automatics, controlling the interplay

between stove and house, can make wood-burning stoves suitable for low-carbon

dwellings and meet the remaining heat demand during the coldest period. Tonne et al

[12] have compared of fuel use between a low cost, improved wood stove and

traditional three-stone stove. The performances of a wood gas stove with different

biomasses such as Amla wood, juliflora, neem wood, calotropis, cashew nut shells

have been discussed in this paper.

2. DESIGN AND FABRICATION OF BIOMASS WOOD STOVE

One of the fibres selected for this biomass wood stove is coconut fibre. Based on the

properties of it, biomass wood stove was designed.

2.1. Energy needed

The amount of energy needed to cook food for a family of four members is estimated

energy needed which is given by equation 1,

Qn = m cp (T2 -T1 )

(1)

Where,

D - Reactor diameter (cm)

CP - specific heat (KJ/kg)

T1 - Initial temperature

T2 - Final temperature

2.2. Fuel Consumption Rate

Fuel consumption rate is given by equation 2 as

(2)

Where,

Q n - Energy Needed

cv - Calorific value of coconut fibre

g - Gasification efficiency

2.3. Reactor Diameter

(3)

Where,

FCR

SGR

- Fuel consumption rate (Kg/hr)

- Specific gasification rate (kgm-2 h-1 )

2.4. Height of the reactor:

(4)

Where,

T - Duty hour

- Density of coconut fibre (kg/m3 ).

http://www.iaeme.com/IJMET/index.asp

146

editor@iaeme.com

Performance Analysis of a Inverted Downdraft Biomass Wood Stove

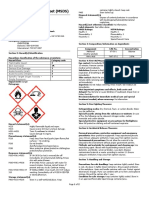

Inverted downdraft biomass wood stove of height 40 cm, diameter 29 cm and

thickness 3 mm as shown in Figure 1 has been fabricated using Mild steel in

cylindrical shape.

Figure 1 Photographic View of Biomass Wood Stove

3. FEED STOCK FOR WOOD STOVE

3.1. Prosopisjuliflora

Julliflora is a shrub or small tree in the Fabaceae family, a kind of mesquite. It is

native to Mexico, South America and the Caribbean. It has become established as an

invasive weed in Africa, Asia, Australia and elsewhere.

3.2. Cashew nuts shells

It is a tropical evergreen that produces the cashew nut and the cashew apple.

Officially classed as Anacardium occidental, it can grow as high as 14 meters. The

cashew nut is served as a snack or used in recipes, like other nuts, although it is

actually a seed. The cashew apple is a fruit, whose pulp can be processed into a sweet,

astringent fruit drink or distilled into liqueur. The shell of the cashew nut yield

derivatives that can be used in many applications from lubricants to paints, and ot her

parts of the tree have traditionally been used for snake-bites and other folk remedies.

3.3. Calotropis

It is a large shrub growing to 4 m tall. It has clusters of waxy flowers that are either

white or lavender in colour. Each flower consists of five pointed petals and a small,

elegant "crown" rising from the centre, which holds the stamens. The plant has oval,

light green leaves and milky stem. The latex of Caltrops gigantean contains cardio

glycosides, volatile fatty acids and calcium oxalate.

3.4. Amla trees

The tree is small to medium in size, reaching 8 to 18 m in height, with a crooked trunk

and spreading branches. The branch lets are glabrous or finely pubescent, 1020 cm

long, usually deciduous; the leaves are simple, sub sessile and closely set along

branch lets, light green, resembling pinnate leaves. The flowers are greenish- yellow.

The fruit is nearly spherical, light greenish yellow, quite smooth and hard on

appearance, with six vertical stripes or furrow.

http://www.iaeme.com/IJMET/index.asp

147

editor@iaeme.com

A. R. Sivaram, Dr. K. Karuppasamy, Dr. R. Rajavel and C. Jagadesh Vikram

3.5. Neem tree

Neem is a fast-growing tree that can reach a height of 1520 metres, it is evergreen,

but in severe drought it may shed most or nearly all of its leaves. The branches are

wide and spreading. The fairly dense crown is roundish and may reach a diameter of

1520 metres in old, free-standing specimens.

4. ESTIMATION OF MOISTURE

Moisture content of the sample is determined by drying it in a hot oven at a

temperature of 102C to 105C for 5 hours. The hot oven is as shown in Figure 2.

Figure 2 Hot Ovens

5. ESTIMATION OF TOTAL VOLATILE MATTER

Volatile matter content of the sample is determined by placing it in a electric furnace

at a temperature of 550C for 5 hours and cooling it in a desiccator. By determining

the initial and final weight of the sample, the amount of volatile matter present in the

sample can be estimated. The photographic view of electric furnace is shown in

Figure 3.

6. ESTIMATION OF GROSS CALORIFIC VALUE:

Higher heating value (also called gross calorific value) is the theoretical maximum

amount of energy that can be extracted from the combustion of the moisture- free fuel

if it is completely combusted and the combustion products are cooled to room

temperature such that the water produced by the reaction of the fuel bound hydrogen

is condensed to the liquid phase. Gross calorific value is determined by using a bomb

calorimeter which is shown in Figure 4.

http://www.iaeme.com/IJMET/index.asp

148

editor@iaeme.com

Performance Analysis of a Inverted Downdraft Biomass Wood Stove

Figure 3 Electric Furnace

Figure 4 Bomb Calorimeter

7. WATER BOILING TEST

In the first phase, the cold-start in water, the tester begins with the stove at room

temperature and uses a pre-weighed bundle of wood or other fuel to boil a measured

quantity of water in a standard pot. The tester then replaces the boiled water with a

fresh pot of cold water to perform the second phase of the test. The second p hase, the

hot-start in water the test, follows immediately after the first test while stove is still

hot. Again, the tester uses a pre-weighed bundle of fuel to boil a measured quantity of

water in a standard pot. Repeating the test with a hot stove helps to identify

differences in performance between a stove when it is cold and when it is hot. The

third phase follows immediately from the second. Here, the tester determines the

amount of fuel required to simmer a measured amount of water at just below the

boiling point for a time span of 45 minutes.

8. FORMULAE USED FOR WATER BOILING TEST

8.1. Specific Fuel Consumption (SFC)for Water Boiling Test:

SFC =

http://www.iaeme.com/IJMET/index.asp

(5)

149

editor@iaeme.com

A. R. Sivaram, Dr. K. Karuppasamy, Dr. R. Rajavel and C. Jagadesh Vikram

8.2. Mass Of Fuel Wood Used To Evaporate Water:

(6)

Where,

Masschar - mass of the remaining charcoal after conducting WBT

Massfwe - mass of fuel wood used to evaporate water

Massmwr - mass of water remaining in the pot at the end of the test

Massmw - mass of the moist wood

Mc -mass of fraction moisture content of the fuel on the dry.

NOx

- oxides of nitrogen

Tboil

- the local boiling temperature

Troom

- the air temperature in the room.

Tstart

- starting temperature of the water.

9. RESULTS AND DISCUSSION

9.1. Analysis of Properties of the Biomasses

From Figures 5, it is observed that the percentage of dry matter is higher for cashew

nutshells, followed by amla wood, juliflora, and neem wood. Percentage of dry matter

is very low for calotropis.

From Figure 6, it is can be seen that moisture content is low for cashew nutshells

and is very high for calotropis. Since calotropis has very low percentage of dry matter,

it has high moisture content. Cashew nut shells have higher percentage of dry matter,

so it has lower moisture content. This shows that if the percentage of dry matter is

high, then the moisture content will be low.

From Figure 7, it is clear that the percentage of ash content is maximum for

calotropis and minimum for cashew nutshells. This is due to the reason that calotropis

has high moisture content and cashew nutshells have low moisture content. This

shows that if moisture content is high then ash content will also be high.

100

% of Dry matter

90

80

70

60

50

40

30

20

10

0

Amla wood

Cashew

nutshells

Calotropis

Juliflora

Neem wood

Biomass

Figure 5 Comparison of Percentage of Dry Matter for Various Biomasses

http://www.iaeme.com/IJMET/index.asp

150

editor@iaeme.com

Performance Analysis of a Inverted Downdraft Biomass Wood Stove

90

80

% of moisture

70

60

50

40

30

20

10

0

Amla wood

Cashew

nutshells

Calotropis

Juliflora

Neem wood

Biomass

Figure 6 Comparison of Percentage of Moisture Content for Various Biomasses

14

12

% of ash

10

8

6

4

2

0

Amla wood

Cashew

nutshells

Calotropis

Juliflora

Neem wood

Biomass

Figure 7 Comparison of Percentage of Ash Content for Various Biomasses

http://www.iaeme.com/IJMET/index.asp

151

editor@iaeme.com

A. R. Sivaram, Dr. K. Karuppasamy, Dr. R. Rajavel and C. Jagadesh Vikram

100

98

% of volatile matter

96

94

92

90

88

86

84

82

Amla wood

Cashew

nutshells

Calotropis

Juliflora

Neem wood

Biomass

Figure 8 Comparison of Percentage of Volatile Matter for Various Biomasses

From Figure 8, it can be observed that the percentage of volatile matter is high for

cashew nutshells and is very low for calotropis. This shows that if moisture content is

high, then percentage of volatile matter of the biomass will a lso be high.

1000

Density(kg/m^3)

900

800

700

600

500

400

300

200

100

0

Amla wood

Cashew

nutshells

Calotropis

Juliflora

Neem wood

Biomass

Figure 9 Comparison of Density for Various Biomasses

http://www.iaeme.com/IJMET/index.asp

152

editor@iaeme.com

Performance Analysis of a Inverted Downdraft Biomass Wood Stove

6000

Calorific value(Kcal/g)

5000

4000

3000

2000

1000

0

Amla wood

Cashew

nutshells

Calotropis

Juliflora

Neem wood

Biomass

Figure 10 Comparison of Calorific Value for Various Biomasses

From Figure 9, it can be seen that the density is maximum for neem wood

followed by calotropis, juliflora, amla wood and cashew nutshells.

From Figure 10, it can be observed that the calorific value is maximum for

juliflora, and is minimum for calotropis. It is also figured that amla wood, cashew

nutshells and neem wood also has higher calorific values

9.2. Performance Analysis of Various Biomasses

0.9

0.8

0.7

0.6

SFC( kJ/kg)

0.5

0.4

0.3

0.2

0.1

0

amla wood

neem wood

calotropsis

juli flora

cashew nut

shells

Biomass

Figure 11 Comparison of Specific Fuel Consumption Of Various Biomasses

http://www.iaeme.com/IJMET/index.asp

153

editor@iaeme.com

A. R. Sivaram, Dr. K. Karuppasamy, Dr. R. Rajavel and C. Jagadesh Vikram

From Figure 11, it can be seen that, calotropis has higher specific fuel

consumption due to its low calorific value and other biomasses have an specific fuel

consumption of above 0.5. This shows that, if the calorific value is low, then the

specific fuel consumption will be high.

60

Thermal Efficiency (%)

50

40

30

20

10

0

amula wood

neem wood

calotropsis

juli flora

cashew nut

shells

Biomass

Figure 12 Comparision of Thermal Efficiency of Various Biomasses

From Figure 12, it can be observed that, the thermal efficiency is very low for

calotropis due to its lower calorific value and other biomasses have an efficiency

value greater than 50%.

10. CONCLUSION

The properties analysis of the biomasses shows that, the percentage of dry matter is

higher for cashew nutshells, moisture content is low for cashew nutshells and is very

high for calotropis. The percentage of ash content is maximum for calotropis and

minimum for cashew nutshells. The percentage of volatile matter is high for cashew

nutshells and is very low for calotropis. The calorific value is maximum for juliflora,

and is minimum for calotropis. The performance analysis of the inverted downdraft

biomass wood stove shows that calotropis has higher specific fuel consumption due to

its low calorific value and other biomasses have an specific fuel consumption of

above 0.5. This shows that, if the calorific value is low, then the specific fuel

consumption will be high. The thermal efficiency is very low for calotropis due to its

lower calorific value and other biomasses have a n efficiency value greater than 50%.

This inverted downdraft biomass wood stove can meet the energy requirement for

community and domestic level cooking applications.

REFERENCES

[1]

Ko, Y.-C. and Lin, T.-H. Emissions and efficiency of a domestic gas stove

burning natural gases with various compositions. Energy Conversion and

Management, 44, 2003, pp.30013014.

http://www.iaeme.com/IJMET/index.asp

154

editor@iaeme.com

Performance Analysis of a Inverted Downdraft Biomass Wood Stove

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

Edwards, R. D. Smith, K. R., Zhang, J. and Ma, Y. Implications of changes in

household stoves and fuel use in China. Energy policy, 32, 2004, pp. 395411.

Persson, T., Nordlander, S. and Ronnelid, M. Electrical savings by use of wood

pellet stoves and solar heating systems in electrically heated single-family

houses. Energy and Buildings, 27, 2005, pp. 920929.

Koyuncu, T. and Pinar, Y. The emissions from a space-heating biomass stove.

Biomass and Bioenergy, 31, 2007, pp. 7379.

Panwar, N. L. and Rathore, N. S. Design and performance evaluation 5 kW of a

producer gas stove. Biomass and Bioenergy, 32, 2008, pp. 13491352.

Jetter, J. J. and Kariher, P. Solid-fuel household cook stoves Characterization of

performance and emissions. Biomass and Bioenergy, 33, 2009, pp. 294305.

Miaha, M. D., Rashid, H. A. and Shina, M. Y. Wood fuel use in the traditional

cooking stoves in the rural flood plain areas of Bangladesh A socio-environment

all perspective. Biomass and Bioenergy, 33, 2009, pp. 7078

Champier, D., Bdcarrats, J. P., Kousksou, T., Rivaletto, M., Strub, F. and

Pignolet, P. Study of a TE (thermoelectric) generator incorporated in a

multifunction wood stove. Energy, 36, 2011, pp. 15181526.

Raman, P., Murali, J., Sakthivadivel, D. and Vigneswaran, V. S. Performance

evaluation of three types of forced draft cook stoves using fuel wood and coconut

shell. Biomass and Bioenergy, 49, 2013, pp. 333340.

Chopra, A. and Pullagura, G. Performance Optimization and Emission Reduction

of a Diesel Gen-Set Using Dual Fuel Diesel-LPG Controller. International

Journal of Mechanical Engineering and Technology, 3(2), 2012, pp. 817828.

Carvalho, R. L., Jensen, O. M., Afshari, A. and Bergsoe, N. C. Wood-burning

stoves in low-carbon dwellings. Enegy and Buildings, 59, 2013, pp. 244251.

Ochieng, C. A., Tonne, C. and Vardoulakis, S. A comparison of fuel use between

a low cost, improved wood stove and traditional three-stone stove in rural Kenya.

Biomass and Bioenergy, 58, 2013, pp. 258266.

http://www.iaeme.com/IJMET/index.asp

155

editor@iaeme.com

Anda mungkin juga menyukai

- Broad Unexposed Skills of Transgender EntrepreneursDokumen8 halamanBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationBelum ada peringkat

- Determinants Affecting The User's Intention To Use Mobile Banking ApplicationsDokumen8 halamanDeterminants Affecting The User's Intention To Use Mobile Banking ApplicationsIAEME PublicationBelum ada peringkat

- A Study On The Reasons For Transgender To Become EntrepreneursDokumen7 halamanA Study On The Reasons For Transgender To Become EntrepreneursIAEME PublicationBelum ada peringkat

- Analyse The User Predilection On Gpay and Phonepe For Digital TransactionsDokumen7 halamanAnalyse The User Predilection On Gpay and Phonepe For Digital TransactionsIAEME PublicationBelum ada peringkat

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDokumen10 halamanImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationBelum ada peringkat

- Voice Based Atm For Visually Impaired Using ArduinoDokumen7 halamanVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationBelum ada peringkat

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDokumen14 halamanModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationBelum ada peringkat

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDokumen15 halamanAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationBelum ada peringkat

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDokumen10 halamanA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationBelum ada peringkat

- Gandhi On Non-Violent PoliceDokumen8 halamanGandhi On Non-Violent PoliceIAEME PublicationBelum ada peringkat

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDokumen16 halamanInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationBelum ada peringkat

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDokumen7 halamanA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationBelum ada peringkat

- Visualising Aging Parents & Their Close Carers Life Journey in Aging EconomyDokumen4 halamanVisualising Aging Parents & Their Close Carers Life Journey in Aging EconomyIAEME PublicationBelum ada peringkat

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDokumen16 halamanA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationBelum ada peringkat

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDokumen9 halamanA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationBelum ada peringkat

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDokumen9 halamanEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationBelum ada peringkat

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDokumen18 halamanRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationBelum ada peringkat

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDokumen19 halamanApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationBelum ada peringkat

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDokumen13 halamanA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationBelum ada peringkat

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDokumen13 halamanAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationBelum ada peringkat

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDokumen13 halamanOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationBelum ada peringkat

- Various Fuzzy Numbers and Their Various Ranking ApproachesDokumen10 halamanVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationBelum ada peringkat

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDokumen8 halamanDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationBelum ada peringkat

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDokumen13 halamanPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationBelum ada peringkat

- A Review of Particle Swarm Optimization (Pso) AlgorithmDokumen26 halamanA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationBelum ada peringkat

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDokumen9 halamanFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationBelum ada peringkat

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDokumen8 halamanKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationBelum ada peringkat

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDokumen7 halamanModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationBelum ada peringkat

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDokumen7 halamanQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationBelum ada peringkat

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDokumen9 halamanAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Unit 8 NotesDokumen2 halamanUnit 8 NotesRahna AzaamBelum ada peringkat

- Faizal Bux, Yusuf Chisti Eds. Algae Biotechnology Products and ProcessesDokumen344 halamanFaizal Bux, Yusuf Chisti Eds. Algae Biotechnology Products and ProcessesHAMED100% (4)

- Ashrae 90.1 Tabelas e ComentáriosDokumen12 halamanAshrae 90.1 Tabelas e ComentáriosEmerson Borges SantanaBelum ada peringkat

- Organic Nomenclature IbDokumen2 halamanOrganic Nomenclature Ibubaid_nedianBelum ada peringkat

- Lectures TheoryofStructures1 Chapter1 PDFDokumen27 halamanLectures TheoryofStructures1 Chapter1 PDFMikoy TicmonBelum ada peringkat

- Assessment of Water Quality Using GISDokumen8 halamanAssessment of Water Quality Using GISSudharsananPRSBelum ada peringkat

- En 50216-10Dokumen16 halamanEn 50216-10Mahmoud ShaheenBelum ada peringkat

- Prria MemoDokumen4 halamanPrria MemoRebecca C. LewisBelum ada peringkat

- Chapter-1 Ishida2011Dokumen79 halamanChapter-1 Ishida2011sasidharkanthetiBelum ada peringkat

- CCWDokumen2 halamanCCWspearboraBelum ada peringkat

- Book of Abstracts - NIMACON 2020Dokumen53 halamanBook of Abstracts - NIMACON 2020Nwigwe UzomaBelum ada peringkat

- MS DirectPhD Sample PDFDokumen4 halamanMS DirectPhD Sample PDFArunKumarBelum ada peringkat

- EHV Cables Laying MethodDokumen22 halamanEHV Cables Laying MethodSudharsanan Sitrarasu100% (2)

- METALS Structured Questions and Worked SolutionsDokumen9 halamanMETALS Structured Questions and Worked SolutionsYoviBelum ada peringkat

- Nital EtchDokumen2 halamanNital EtchJohn GeddesBelum ada peringkat

- CHEM 20024 General Chemistry Practice Exam #2Dokumen7 halamanCHEM 20024 General Chemistry Practice Exam #2Yhana Ruth PajitaBelum ada peringkat

- Exotic TarantulasDokumen82 halamanExotic TarantulasThiago MartinsBelum ada peringkat

- WoundVite®, The #1 Most Comprehensive Wound, Scar and Post-Surgical Repair Formula Receives Amazon's Choice High RatingsDokumen3 halamanWoundVite®, The #1 Most Comprehensive Wound, Scar and Post-Surgical Repair Formula Receives Amazon's Choice High RatingsPR.comBelum ada peringkat

- Masterflow 647R Repair Grout: Technical Data GuideDokumen2 halamanMasterflow 647R Repair Grout: Technical Data Guidegazwang478Belum ada peringkat

- The Calorific Value of A Fuel Is TheDokumen4 halamanThe Calorific Value of A Fuel Is TheRana PrathapBelum ada peringkat

- Windsor Spirit Manual-PartsDokumen18 halamanWindsor Spirit Manual-PartsNestor Marquez-Diaz100% (1)

- BM 12 Uc Usa 2011 08Dokumen44 halamanBM 12 Uc Usa 2011 08dangomezvBelum ada peringkat

- Profile Sections and Molded Parts Made From Elastomers (EPDM) in The Body AreaDokumen13 halamanProfile Sections and Molded Parts Made From Elastomers (EPDM) in The Body AreaNagarajan DS100% (1)

- SDS PLS2Dokumen8 halamanSDS PLS2Đinh Quốc LiêmBelum ada peringkat

- 13 - Chapter 3Dokumen32 halaman13 - Chapter 3Wahab Al-QaisiBelum ada peringkat

- IPPP II (Cosmetics)Dokumen46 halamanIPPP II (Cosmetics)Tinsaye HayileBelum ada peringkat

- Composite Materials: Cris Arnold Materials Research Centre J.c.arnold@swansea - Ac.ukDokumen30 halamanComposite Materials: Cris Arnold Materials Research Centre J.c.arnold@swansea - Ac.ukMazin MohammedBelum ada peringkat

- Threshold Limit Values (TLV)Dokumen7 halamanThreshold Limit Values (TLV)chem_taBelum ada peringkat

- Laboratory Title: Determination of Ash Date of Experiment: 11/11/2019 Laboratory Group: MondayDokumen5 halamanLaboratory Title: Determination of Ash Date of Experiment: 11/11/2019 Laboratory Group: MondayCtBelum ada peringkat

- Barbicide MsdsDokumen3 halamanBarbicide MsdstudorcerneaBelum ada peringkat