Worked Example 1 - Composite Beam - Normal Design

Diunggah oleh

Tudor TudorDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Worked Example 1 - Composite Beam - Normal Design

Diunggah oleh

Tudor TudorHak Cipta:

Format Tersedia

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

FABSEC

Sheet

of

25

Rev

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

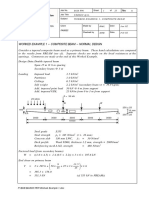

WORKED EXAMPLE 1 COMPOSITE BEAM NORMAL DESIGN

Consider a tapered composite beam used as a primary beam. These hand calculations are compared

to the results from FBEAM (see cf). Separate checks are made on the local resistances at the

openings. Comments are made at the end of this Worked Example.

Design Data: Double tapered beam

Span 15 m @ 6 m spacing

Secondary beams @ 3 m

Loading

3.5 kN/m2

1.0 kN/m2

0.5 kN/m2

2.2 kN/m2 (secondary beam wt = 39.9 kg/m)

50 kN @ 6 m from support

25 kN/m from 0 to 3 m from support

Imposed load

Partitions

Ceilings

Self weight

Add. imposed point load

Add. imposed UDL

P = 50 kN

25 kN/m

W

W

250 x 25

400

10 mm

web

250 x 25

800

3000

3000

3000

3000

3000

15000

Steel grade

S355

Steel strength

p y = 345 N/mm2 (t > 16 mm)

Concrete slab

130 mm LWC, fcu = 30 N/mm2

Deck profile

Ward FD60, thickness 1.2 mm, strength = 280N/mm 2

Reinforcing mesh A142, strength

= 460 N/mm 2

Factored load (from secondary beams)

W = ((1.6 4.5) + 1.4 (0.5 + 2.2)) 3 6 = 197.6 kN

End shear on primary beam

V

9

13 .5

= 2 197.6 + 50

+ 25 3

1 .6

15

15

= 395.3 + 156.0

= 551.3 kN

(cf 555 kN in FBEAM))

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

FABSEC

Sheet

of

25

Rev

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

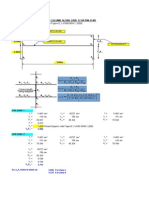

Maximum moment (occurs at 2 nd secondary beam from LH support in diagram)

3.0

M = 551.3 6.0 25 3 1.6 6.0

197.6 3.0

2

= 3308 540 593

= 2175 kNm

(cf 2178 kNm)

Mid-span moment (for completeness)

M = 551.3 7.5 25 3 1.6 6 197.6 4.5 197.6 1.5 50 1.6 1.5

= 4135 720 889 296 120

= 2110 kNm

(cf 2115 kNm)

Interaction of M - V at 3 m from support

M = 551.3 3 25 3 1.6 1.5

= 1474 kNm

V = 551.3 25 3 1.6 197.6

= 233 kN

(cf 1476 kNm)

(cf 237 kN)

Shear resistance of web

400 mm depth:

600 mm depth:

800 mm depth:

VRd =

=

VRd =

=

VRd =

=

0.6 345 10 350 10 -3

724 kN

(cf 725 kN)

-3

0.6 345 10 550 10

1138 kN

(cf 1139 kN)

-3

0.6 345 10 750 10

1552 kN

(cf 1283 kN)) (See Comment No. 1)

Shear Connector Layout

300

18 @ 150

20 @ 150

3900

3000

P:\BCB\Bcb896\PDF\Worked Example 1.doc

5200

3000

7500

10 @ 150

1500

CL

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

FABSEC

Sheet

of

Rev

25

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

Bending resistance of composite section (600 mm depth, 3 m from LH support)

Be

70

130

600

(See Comment No.2)

Resistance of concrete:

Rc

= 0.45 30 70 1500 10 3

= 1417 kN

Resistance of section:

Rs

= (250 25 2 + 550 10) 345 10 3

= 6210 kN

Resistance of shear connectors: No of studs (from layout) = 18

Stud resistance = 72 kN

Rq = 18 72 = 1296 kN

Resistance of flange:

Rf

Resistance of web:

Rw

=

=

=

=

250 25 345 10 3

2156 kN

550 10 345 10 3

1897 kN

Check position of PNA:

PNA lies in web if: Rq + Rf < R w + Rf

or 1296 + 2156 < 1895 + 2156

(correct)

Difference = 601 kN

Depth of web in compression

yw = 601/(10 345 2 10 3)

= 87 mm

P:\BCB\Bcb896\PDF\Worked Example 1.doc

(See Comment No. 3)

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

FABSEC

Sheet

of

Rev

25

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

Rq

Moment resistance

Mc = Rq (95 + 25 + 87) 10 3

+ Rf 575 10 3

95

25

y

Rf

+

=

=

87 2 463 2

10 345 10 6

+

2

2

268 + 1240 + 383

1890 kNm (cf 1895 kNm in FBEAM)

Rf

Unity Factor =

1476

= 0.78

1890

(cf 0.78)

Degree of shear connection (check at 6 m from LH support)

No.

Rq

Be

RC

of shear connectors

= 38

= 38 72 = 2736 kN

= 3000 mm

= 0.45 70 3000 30 10 3 = 2835 kN

Degree of shear connection =

2736

2835

= 0.97

(cf 0.69)

Min. degree of shear connection

for asymmetric section

N

= 0.25 + 0.03L = 0.7 < 0.97

Nf

So adequate shear connection is provided.

(See Comment No. 4)

(to EC4)

(See Comment No. 5)

Bending resistance of composite section (800 mm depth, 6 m from LH support)

800 mm depth:

Be =

6000

= 3000 mm

2

Resistance of concrete:

Rc =

=

0.45 30 70 3000 10 3

2835 kN

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

FABSEC

Sheet

of

25

Rev

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

Resistance of flange:

Rf

Resistance of web:

Rw =

=

2156 kN

750 10 345 10 3

2587 kN

(See Comment No. 6)

Resistance of shear connectors: No. of studs (from connector layout)

Rq = 38 72 = 2736 kN

Rq < Rc at mid span

Check position of PNA:

PNA lies in web if:

Rq + Rf < R w + Rf

2736 + 2156 < 2587 + 2516

Not satisfied, so PNA is in flange

Moment resistance

Mc =

+

+

=

=

Applied moment

Unity Factor

Rq (95 + 12.5) 10 3

Rf 775 10 3

775

Rw

10 3

2

294 + 1671 + 1002

2967 kNm

M =

2175 kNm

2175/2967

= 0.73

38

(See Comment No. 7)

(cf 2973 kNm)

(cf 0.73)

Longitudinal shear resistance check (at position of greatest bending/shear unity factor)

Maximum Moment utilisation factor

Longitudinal shear force

Concrete shear resistance

=

(effective ht of deck = 69 mm) =

Unity Factor

= 0.78 (at 3m from LH support)

0 .78 72

2 0 .15

= 187 kN/m

0.8 0.8 (130 69) 300.5 10

213.8 kN/m

187/214 =

0.87

-3

(cf 0.86)

Calculate amount of transverse reinforcement

187 = 0.7 fy Ar + 0.03 0.8 30 (130 69) 10 -3

187 = 0.322 Ar + 45

Ar = 441 mm2 /m (inc. mesh)

= 441 142

= 299 mm2 /m

(ex.mesh)

(cf 302 mm2/m)

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

FABSEC

Sheet

of

25

Rev

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

Weld design

Build-up of force in web

Compression force in top flange

= 25 250 345 10 3

= 2156 kN

Force/unit length

= 2156/3000

= 0.72 kN/mm

Force from shear connectors

= 72/150

= 0.48 kN/mm

Total

(See Comment No. 8)

1.29 kN/mm

Total force is reduced because of utilisation factor in bending at the critical location

Force/length

= 0.78 0.72 + 0.48

= 1.04 kN/m

3

1.04 10

0 .7 250 2

= 3.0 mm per side

(use 5 mm FW per side)

Weld size

(cf 1.25 kN/mm)

(double sided FW)

Local check at change points

w

Fw

3.81

Web buckling (at 6 m and 9 m from LH support)

Fw = 250 25 345 10 3 sin 3.81o

= 143.3 kN

Compressive stress

(at half depth)

w =

143 .4 10 3

10 400 2

Slenderness of web

(See Comment No. 9)

= 18 N/mm2

0.85 d

0 .85 750

= 221

10 / 12

t / 12

p c (strut curve c)

= 36 N/mm2

Buckling resistance, pw

= 10 800 36 10 3

= 288 kN

143

Unity Factor

=

= 0.50

(cf 0.39)

288

(Software Utilisation Factor = 0.73, 0.73 0.50 = 0.37)

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

FABSEC

Sheet

of

Rev

25

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

Properties of steel section at mid span (neglecting openings at this stage)

py

250 x 25

345 N/mm 2 (t > 16 mm)

275

345

d/t = 75 > 80

Web in Class 2

125

b/t =

25

750 x 10

= 0.893

= 71

= 5, i.e. Class 1

250 x 25

Plastic bending resistance

Mp =

=

250 25 775 + 750 10 345 10 6

2156 kNm

Second moment of area

775 2 750 3

+

10

2

12

(1877 + 315) 10 6

2192 106 mm4

Ixx = 250 25

=

=

(cf 2229 10 6 mm4 )

250 3

25

12

65.1 10 6 mm4

2

Iyy

=

(cf 65.17 10 6mm4 )

= 250 2 25 + 250 10 = 20 10 3 mm2

ryy

65 .1 10 3

= 57.1 mm

20

(cf 57 mm)

Construction stage LTB check

Slenderness of beam between secondary beams (between 6 m and 9 m from LH support)

3000

57 .1

= 52.5

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

FABSEC

Sheet

of

25

Rev

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

D/T = 800/25 = 32

LT =

=

=

pb =

uv

0.9 0.98 52.5

46.3

311 N/mm 2

Buckling resistance moment

Mb = Mp

Pb

311

= 2156

py

345

= 1944 kNm

Applied moment during construction

M

(1.6 0.5 + 1.4 2.2) 6

= 655 kNm

15 2

8

(cf 656 kNm)

655

1944

= 0.34

(cf 0.39)

(See Comment No. 10)

(The difference is due to the more accurate treatment of LTB in the software)

Unity Factor =

Elastic properties of composite section (deflections)

Consider properties at mid-span

B e = 3750

D s =130

D = 800

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Dp =60

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

FABSEC

Sheet

of

25

Rev

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

Icomp =

I xx +

A D + Ds + Dp

)2 (D s D p )3

+

4 (1 + e r )

where r c = A/(Ds Dp ) Be =

Icomp = 2192 106 +

+

12 e

Be

(See Comment No. 11)

20 10 3

= 0.076

( 130 60 ) 3750

20 10 3 ( 800 + 130 + 60 ) 2

4 (1 + 15 0 .076 )

70 3

3750

12 15

= 2192 106 + 2287 106 + 7.2 106

= (2192 + 2287 + 7) 106

= 4486 106 mm4

(cf 4795 10 6 mm4 )

(The difference is due to the additional concrete between the ribs which is included in the software,

but is not included here)

Effective stiffness of tapered section

h1

h0

h1 2

I

h0

2 I + 1 I h 1 for uniform loading

Ieff

(See Comment No. 12)

3

3 h

0

but h1 /h0 = 0.5 and so Ieff

= 0.75 I where I = inertia of deepest section

Deflections

Deflections due to self wt (consider as udl)

s

5

2 .2 6 15 4 10 9

384 205 2229 10 6 0 .75

= 25.4 mm

Deflection due to imposed udl (composite section)

i

5

4.5 6 15 4 10 9

384 205 4795 10 6 0.75

= 24.1 mm

P:\BCB\Bcb896\PDF\Worked Example 1.doc

(See Comment No. 13)

(cf 24.6 mm)

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

FABSEC

Sheet

10

of

25

Rev

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

Deflection at mid -span due to imposed point load

3

3a

a

where a = 6 m and L = 15 m

L

L

PL3

48 EI

50 15 3 10 9

48 205 4795 0 .75 10 6

3

3 6

6

4

15

15

= 4.5 mm

Deflection at mid -span due to imposed partial udl

=

WL4

n2 [2 m3 6 m2 + m (4 + n2 ) n2 ]

24 aEI

where a = 3 m, n = 0.2 and m = 0.5

=

0.22 ]

25 3 15 4 10 12

0.2[2(0.5)3 6(0.5) 2 + 0.5 (4 + 0.2 2 )

24 3 10 3 205 4795 10 6 0.75

= 2.1 mm

Total imposed load deflection at mid -span at the composite stage (prior to allowing for partial shear

connection)

= 24.1 + 4.5 + 2.1

= 30.7 mm

Deflection due to imposed load (steel section)

s

= 30.7

4795

2229

66.0 mm

Additional deflection due to partial shear connection

add = 0.3 (1 0.69)(66.0 30.7)

= 3.3 mm

(See Comment No. 14)

Total imposed load deflection

= 30.7 + 3.3

Deflection due to ceiling and services

Total deflection

0.5

24.1 =

4.5

= 25.4 + 34.0 + 2.7 = 62.1 mm

P:\BCB\Bcb896\PDF\Worked Example 1.doc

34.0 mm

(cf 30.6 mm)

2.7 mm

(cf 57.8 mm) (See Comment No.15)

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

FABSEC

Sheet

11

of

25

Rev

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

Elastic properties of composite section (vibrations)

e

= 10 for dynamic calculations

Icomp = 2192 106 +

20 10 3 ( 800 + 130 + 60 ) 2

70 3

+

3750

4 ( 1 + 10 0 .076 )

12 10

= 2192 106 + 2781 106 + 10.8 10 6

= (2192 + 2781 + 11) 10 6

= 4984 106 mm4

(cf 5254 10 6 mm4 )

(See Comment No. 16)

Loading for natural frequency calculation

= wsw +wd + 0.1wi (excl. partitions)

= 2.2 + 0.5 + 0.35

= 3.05 kN/m2

(See Comment No. 17)

Deflection due to udl over 6 m width

5 3.05 6 15 4 10 9

384 205 4984 10 6 0 .75

= 15.7 mm

(cf 13.8 mm)

(The factor of 0.75 is due to the influence of the tapered section, as previously)

Natural frequenc y f

= 18 /

= 4.5 Hz

P:\BCB\Bcb896\PDF\Worked Example 1.doc

(cf 4.8 Hz)

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

FABSEC

Sheet

12

of

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

Checks at Rectangular Opening at Mid-span

130

25

210

t = 10 mm

140

25

900

Applied moment at mid -span

2115 kNm

Web classification

d eff =

d eff =

dt

40 t

1

275

= 0.89

345

40 10 0.89

210 1

900

= 192 mm

but limit is 9t

= 9 10 0.89 = 80 mm

d eff > limit, so section is Class 3

Use elastic properties of Tees

Shear stress is low at mid -span

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Rev

Made by

CALCULATION SHEET

400

25

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

FABSEC

Sheet

13

of

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

Properties of Top Tee

250

210

ye

10

ye

10 210 130 + 250 25 2 /2

250 25 + 210 10

351 .1 10 3

8.35 10 3

= 42.1 mm

Ixt

= 10 210 (130 42.1)2 + 250 25 (42.1 12.5)2 + 10 210 3/12

= 16.2 10 6 + 5.5 106 + 7.7 106

= 37.1 10 6 mm4

37.1 10 6

= 192.3 103 mm3

(235 42 .1)

Zxt =

Mt = 192.3 103 345 10 -6

= 66.3 kNm

At

= 25 250 + 10 210 = 8350 mm2

Properties of Bottom Tee

10

140

25

250

ye

10 140 95 + 250 25 2 2

250 25 + 140 10

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Rev

Made by

CALCULATION SHEET

25

25

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

FABSEC

Sheet

of

14

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

211 .1 10 3

= 27.6 mm

7.65 10 3

Ixb = 10 140 (95 27.6)2 + 250 25 (21.1 12.5)2 + 10 1003 /12

= 6.4 106 + 1.4 10 6 + 2.3 106

= 10.1 10 6 mm4

Zxb =

10.1 10 6

( 165 27 .6 )

73.3 10 3 mm3

Mb = 73.3 10 3 345 10 6

= 25.3 kNm

Ab = 10 140 + 25 250 = 7650 mm2

Composite bending resistance at opening

xc

R c or Rq

25

pna

py

210

400

140

25

Compressive resistance of slab

Rc

= 0.45 fcu (Ds Dp ) Be

= 0.45 30 (130 60)

15000

/ 10 3 = 3544 kN

4

Resistance of shear connectors

Rq = NPd =

48 72 =

3456 kN < R c

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Rev

Made by

CALCULATION SHEET

25

yp

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

FABSEC

Sheet

15

of

25

Rev

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

xc

Rq

Rc

(Ds Dp )

3456

70 = 68.2 mm

3544

Resistance of web

Rw = (210 + 140) 10 345 10 -3

= 1208 kN

Since Rq + Rf > Rw + Rf, pna lies in top flange

Rf

= 250 25 345 10 3 = 2156 kN

yp is given by

Rq + 250 yp 345 10 -3 = 250 (25 yp ) 345 10 -3 Rw + Rf

(2y p 25) =

yp

1208 + 2156 3456

250 345 10 3

= 12.0 mm

(cf 12 mm)

Composite bending resistance at opening (taking moments about top of top flange)

Mc =

[3456 (130 68/2) 2 12 250 345 10 3 12/2 + 2156 25/2

+ 210 10 345 10 3 (25 + 210/2) + 140 10 345 10 3 (800 25 140/2)

+ 2156 (800 25/2)] 10 3

= 331.8 12.4 + 27.0 +94.2 + 340.5 + 1712.3

= 2493 kNm

UF =

2115

2493

= 0.85

(cf 2479 kNm)

(cf 0.85)

Reduced Vierendeel bending resistance of steel section

= 2 (Mb + Mt ) (1 UF2 )

= 2 (25.3 + 66.3) (1 0.852 )

= 50.8 kNm

P:\BCB\Bcb896\PDF\Worked Example 1.doc

(cf 43 kNm)

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

FABSEC

Sheet

16

of

25

Rev

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

Vierendeel bending resistance due to composite action (7 studs over opening)

Mvc

Rq 1

a 1

Mvc

R a'

Total Vierendeel bending resistance

= 69.6 + 50.8 = 120.4 kNm

=

=

=

=

Rq 1a1

7 72 = 504 kN

130 68/2 + 42 = 138

69.6 kNm

(cf 86 kNm)

The difference is due to the more accurate interaction between bending and te nsion in the software.

Applied shear force at mid -span (due to asymmetric loads only)

1.15

6

= 25 3 1.6

+ 50 1.6

15

15

= 12 + 32 = 44 kN

cf 15% of max. shear as the minimum shear

= 0.15 551 = 82.6 kN > 44 kN

Min. shear controls.

Vierendeel bending moment

=

V = 82.6 0.9

Unity factor =

74 .3

119 .8

74.3 kNm

(cf 75.0 kNm)

0.62

(cf 0.87)

Check for vierendeel bending at construction stage

Moment at mid-span

15 2

8

(cf 656 kNm)

(1.6 0.5 + 1.4 2.2) 6

= 655 kNm

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

FABSEC

Sheet

17

of

25

Rev

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

Consider bottom Tee acting in tension

M

la

= 800 42.1 27.6

= 730.3 mm

M

655

=

la

0.73

= 897 kN

Rb = tensile resistance of bottom Tee

= 7650 345 10 3

T

=

Rb

897

2639

= 2639 kN

= 0.33

Reduced Vierendeel bending resistance of steel section

=

=

2 (Mt + Mb ) (1 0.33 2 )

2 (66.3 + 25.3) 0.89

= 163.2 kNm

(cf 141 kNm)

The difference is due to the more accurate interaction between tension and bending in the software.

Assume minimum applied shear force = 25% of end shear at the construction stage

V

= 0.25 2 (0.5 1.6 + 2.2 1.4) 6 3

= 34.9 kN

Vierendeel bending moment

= 34.9 0.9 = 31.5 kNm

Unity Factor =

31 .5

163 .2

= 0.19

P:\BCB\Bcb896\PDF\Worked Example 1.doc

(cf 33 kNm)

(cf 0.24)

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

FABSEC

Sheet

18

of

25

Rev

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

Web Post Buckling

Vt

= 3.5 d o

t

0.5 d o

Shear in top Tee =

210

82.6 = 50 kN

350

Compressive stress over 0.5d0

3.5 d o

t

From buckling curve (c)

pc

Slenderness of web

Shear resistance =

Unity Factor =

Vt

=

0 .5 d o t

c =

3.5 400

10

= 25 N/mm2

140

81 N/mm2

0.5d o t p c =

0.5 400 10 81 10 3

50

162

0.31

50 10 3

0 .5 400 10

= 162 kN

(cf 0.19)

The difference is due to the use of the actual shear rather than the minimum shear in the software.

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

FABSEC

Sheet

19

123.5

Date

Jan 02

Checked by

MSB

Date

Feb 02

=

=

5.2

400 + 400

6

747 mm

h = 5.2/6x400+400

= 747 mm

450

123.5

25

Applied moment at normal stage at x

M

= 5.2 m

= 551.3 5.2 25 3 1.6 (5.2 1.5) 197.6 (5.2 3.0)

= 1988 kNm

(cf 1993 kN)

Applied shear force

V

= 551.3 25 3 1.6 197.6

= 233.7 kN

(cf 233 kN)

Web classification

d eff =

dt

40 t

1

= 225 mm

= 0.5d o

d eff

40 10 0 .89

= 123.5 1

225

= 0.89

2

<0

So web is Class 2. Use plastic properties of Tee

Shear stress =

233 .7 10 3

=

247 10

95 N/mm2

Properties of Top Tee

250yp

500yp

yp

= 10 123.5 + 250 (25 yp )

= 7485

= 15.0 mm

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Rev

RML

Checks at circular opening at 5.2 m from support

h

25

Made by

CALCULATION SHEET

25

of

low shear

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

FABSEC

Sheet

20

of

25

Rev

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

2

2

10 123 .5 72 + 250 10 + 15 345 10 6

2

= 44.7 kNm

= 250 25 + 123.5 10

= 7485 mm2

Mt

At

Bottom Tee Same properties

Composite bending resistance at opening

Rq

R a ' = 110 mm

R b- Rq

a1

=

=

=

747 + 95 15

827 mm

95 + 15 = 110 mm

(See Comment No. 19)

R a = 827 mm

Rb

Tensile resistance of bottom Tee

Rb

= 7485 345 10 3

= 2582 kN

Longitudinal shear resistance

Rq = NPd

From shear connection layout,

N

5200 300

= 32.7, say 33 No.

150

Rq = 33 72 = 2376 kN < Rb

Bending resistance

=

=

= Rb a (Rb Rq ) a1

2582 0.827 206 0.11

2113 kNm

Unity Factor = 1988/2113

= 0.94

P:\BCB\Bcb896\PDF\Worked Example 1.doc

(cf 0.93)

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

FABSEC

Sheet

21

Date

Jan 02

Checked by

MSB

Date

Feb 02

2Mt (1 0.942 )+ 2Mb (1 0.94 2 )

2 44.7 0.12 + 2 44.7 0.12

21.5 kNm

Vierendeel bending resistance due to composite action

By inspection,

N = 2

Rq = 2 72 = 144 kN

Mvc = 144 (15 + 95) 10 3

= 15.8 kNm

Total Vierendeel bending resistance

(cf 38 kNm)

Applied Vierendeel moment

M

= Vo

= 233.7 0.5 0.45

= 52.6 kNm

Unity Factor =

52.6

37 .3

(cf 52 kNm)

= 1.41

(cf 1.38)

Construction Stage

= (1.6 0.5 + 1.4 2.2) 6 3 (5.2 2 2.2)

= 573 kNm

(cf 576 kNm)

Moment

Shear force = (1.6 0.5 + 1.4 2.2) 6 3

= 69.8 kN

Consider bottom Tee acting in tension

T

T

=

Rb

M

=

l a l 1a

800

2582

573

0.11 )

(0.826

800 kN

= 0.31

Reduced Vierendeel bending resistance of steel section

= 2Mt (1 0.312 )+ 2Mb (1 0.31 2 )

= 2 2 44.7 0.90

= 161.6 kNm

(cf 159 kNm)

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Rev

RML

Reduced Vierendeel bending resistance of steel section

= 21.5 + 15.8

= 37.3 kNm

25

Made by

CALCULATION SHEET

=

=

=

of

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

FABSEC

Sheet

22

Date

Jan 02

Checked by

MSB

Date

Feb 02

(cf 16 kNm)

(cf 0.10)

Checks for Elongated Opening at 3.9 m from support

h

155

=

=

300

3.9

= 400 +400

6

660 mm

h = 3.9/6x400+400

= 660 mm

155

25

600

Applied moment at x = 3.9 m

M

= 551.3 3.9 197.6 0.9 25 3 1.6 2.4

= 2150 178 288

= 1684 kNm

(cf 1689 kNm)

Applied shear force

V

= 551.3 197.6 25 3 1.6

= 233.7 kN

(cf 235 kN)

Web classification

d eff =

40 t

dt 1

40 10 0 .89

155 1

450

= 94.8

Limiting

d eff

t

9t = 80

So web is Class 2. Use elastic section properties of Tee

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Rev

RML

Vierendeel moment

25

25

Made by

CALCULATION SHEET

Vo = 69.8 0.5 0.45

= 15.7 kNm

15 .7

Unity Factor =

= 0.10

161 .6

of

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

FABSEC

Sheet

23

of

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

250

25

155

10

ye

=

=

Ixf

10 155 102 .5 + 250 25 2 /2

250 25 + 10 155

237 .8

= 30.4 mm

7.8

= 10 155 (102.5 30.4) 2 + 250 25 (30.4 12.5)2 + 10 155 3 /12

= 8.1 106 + 2.0 10 6 +3.1 106

= 13.2 10 6 mm4

Zxf =

13.2 10 6

= 88.2 10 3 mm3

(180 30.4 )

Mt = 88.2 10 3 345 10 6

= 30.4 kNm

At

= 25 250 + 10 155 = 7800 mm2

Composite bending res istance at opening

Rq

R a ' = 128 mm

R q- R b

R a = 726 mm

Rb

P:\BCB\Bcb896\PDF\Worked Example 1.doc

=

=

1

a =

=

where

Rev

Made by

CALCULATION SHEET

Top Tee/

Bottom Tee

25

660 + 130 0.5x c 31

726 mm

130 0.5x c + 31 mm

128 mm

x c = 66 mm (see below)

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

FABSEC

Sheet

24

of

25

Rev

Made by

RML

Date

Jan 02

Checked by

MSB

Date

Feb 02

CALCULATION SHEET

= 7800 345

Tensile resistance of bottom Tee

Rb = 2691 kN

Rc

0.45fcu Be (Ds Dp )

= 0.45 30 (3900/2) (130 60)

= 1842 kN

Longitudinal shear resistance

3900 300

= 24

150

= 72 24 = 1728 kN < R c

Rq = NPd

Rq

where N =

Depth of concrete in compression, x c

Bending resistance

Rq

0 .45 f cu B e

1728 10 3

0.45 30 3900 / 2

= Rb a (Rb Rq ) a1

= 2691 0.726 (2691 1728) 0.128

= 1954 123

= 1831 kNm

Unity Factor =

1684

1831

(cf 1905 kNm)

= 0.91

(cf 0.89)

Reduced Vierendeel bending resistance of steel section

=

=

=

2Mt (1 0.912 )+ 2Mb (1 0.91 2 )

2 2 30.4 0.21

25.3 kNm

(cf 27 kNm)

Vierendeel bending resistance due to composite action

Mvc = NPd a 1where N =

= 3 72 128 10 -3

450

= 3

150

= 27.6 kNm

Total Vierendeel bending resistance

= 25.3 + 27.6

= 52.9 kNm

Applied Vierendeel moment

= Vo

where = 600 150

= 450

P:\BCB\Bcb896\PDF\Worked Example 1.doc

(cf 51 kNm)

= 66 mm

Silwood Park, Ascot, Berks SL5 7QN

Telephone: (01344) 623345

Fax: (01344) 622944

Job No.

BCB 896

Job Title

FABSEC Q.A.

Subject

WORKED EXAMPLE 1 - COMPOSITE BEAM

Client

FABSEC

Sheet

Unity Factor

105

52.9

Jan 02

Checked by

MSB

Date

Feb 02

(cf 2.08)

Moment = (1.6 0.5 + 1.4 2.2) 6 3 (3.9 2 0.9)

= 482 kNm

(cf 503 kNm)

Shear force = (1.6 0.5 + 1.4 2.2) 6 3

V

= 69.8kN

(cf 74.0 kNm)

Consider bottom Tee acting in tension

T

T/Rb =

(l

M

a

l 1a

806

2691

482

(726 128 ) 10 3

806 kN

= 0.30

Reduce Vierendeel bending resistance of steel section

=

2Mt (1 0.302 )+ 2Mb (1 0.30 2 )

2 2 30.4 0.91

110.6 kNm

(cf 113 kNm)

Vierendeel moment

=

Vo = 69.8 0.45

= 31.4 kNm

Unity Factor =

31.4

110 .6

= 0.28

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Rev

Date

Construction Stage

25

RML

(cf 106 kNm)

= 1.98

of

Made by

CALCULATION SHEET

Mv = 233.7 0.45

= 105 kNm

25

(cf 33.2 kNm)

(cf 0.30)

Commentary on Worked Example 1

1.

At 800 mm depth, d/t = 75 > 63, so the shear resistance is based on a shear buckling

resistance in accordance with BS 5950-1:2000. Appendix H.

2.

Fbeam includes the concrete in the ribs of the decking which spans parallel to the beam,

which leads to a greater moment resistance.

3.

For simplicity, the hand calculation for Rw assumes no reduction due to web classification.

A check shows the web to be Class 3 at this cross-section, and Fbeam uses the effective

section of the web.

4.

The degree of shear connection in Fbeam is only 0.69 because the concrete in the ribs of the

decking is included (but not in the hand calculations).

5.

These simplified hand calculations show that the degree of shear connection is adequate,

but Fbeam requires one more shear connector.

6.

At 750 mm depth, d/t > 63, so the section resistance should be reduced for the effects of

shear buckling according to BS 5950-1: 2000 Annex H, but this is ignored for these hand

calculations.

7.

For simplicity, the plastic neutral axis is assumed to be in middle of the top flange.

8.

The increase in shear force is checked here over a 3 m length from the LH support, for

simplicity. Fbeam checks the increase between each successive pair of points at 1/50th of

the span along the beam.

9.

Fbeam reduces the applied force at the change point according to the Utilisation Factor (UF)

at that point.

10.

The software uses a more sophisticated m factor approach, as in BS 5950-1: 2000.

11.

This formula is obtained from publication SCI-P-078, Commentary on BS5950: Part 3:

Section 3.1 Composite beams, and neglects the concrete in the ribs.

12.

This formula is approximate, but Fbeam calculates the deflection by integrating the section

properties for the whole beam span.

13.

The value of the second moment of area, I, from the Fbeam output is used here.

14.

This formula uses the degree of shear connection from the Fbeam output at the position of

the maximum moment, which is not at mid-span.

15.

This difference in these values is due to the approximation of I in these hand calcs.

16.

The concrete in the ribs is neglected in calculating the composite stiffness.

17.

The additional loads are ignored in these hand calcs. Fbeam includes all loading in an

energy method for deflection calculations which divides the beam into 51 elements.

18.

The applied moment is the Fbeam output value.

19.

This force diagram is a simplification because it assumes that the forces are developed in the

concrete slab before forces are applied to the top Tee.

P:\BCB\Bcb896\PDF\Worked Example 1.doc

Anda mungkin juga menyukai

- Worked Example 1 - Composite Beam - Normal Design PDFDokumen26 halamanWorked Example 1 - Composite Beam - Normal Design PDFtudor2786Belum ada peringkat

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDari EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionBelum ada peringkat

- Corbel BS8110Dokumen3 halamanCorbel BS8110Nugraha BintangBelum ada peringkat

- Connessione A Taglio EC3 IngleseDokumen15 halamanConnessione A Taglio EC3 Inglesemihai_serban13Belum ada peringkat

- Deltabeam EngDokumen20 halamanDeltabeam EngAmir OmeraševićBelum ada peringkat

- Topic 2 Section PropertiesDokumen53 halamanTopic 2 Section PropertiesAmirul AshrafBelum ada peringkat

- Design of Column BasesDokumen9 halamanDesign of Column Basesdarshanakp100% (1)

- Composite ColumnDokumen73 halamanComposite ColumnraymondBelum ada peringkat

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDokumen56 halamanSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelBelum ada peringkat

- EN1994 4 HanswilleDokumen73 halamanEN1994 4 Hanswilleoluomo1Belum ada peringkat

- RC Corbel Design EC2Dokumen3 halamanRC Corbel Design EC2Tommaso PasconBelum ada peringkat

- Composite Beam ExampleDokumen7 halamanComposite Beam ExampleFong Pei TyngBelum ada peringkat

- Splice 03Dokumen15 halamanSplice 03LexBelum ada peringkat

- BS 5950-2000 Example 001Dokumen5 halamanBS 5950-2000 Example 001Anitha Hassan KabeerBelum ada peringkat

- Gilbert-Time-Dependent Stiffness of Cracked Reinforced & Composite Concrete SlabsDokumen16 halamanGilbert-Time-Dependent Stiffness of Cracked Reinforced & Composite Concrete SlabsjausingchiBelum ada peringkat

- 3 EC4-2 Background Gerhard HanswilleDokumen67 halaman3 EC4-2 Background Gerhard Hanswilleantonio111aBelum ada peringkat

- 2.design of Shallow Foundation Using EC 7 - DR NavarathnarajaDokumen20 halaman2.design of Shallow Foundation Using EC 7 - DR NavarathnarajaefackopaBelum ada peringkat

- Tying Resistance of A Fin Plate ConnectionDokumen9 halamanTying Resistance of A Fin Plate ConnectionSam Samoura0% (1)

- Engg/10/s4 Reinforced Concrete Design To Bs 8110: Contract RefDokumen3 halamanEngg/10/s4 Reinforced Concrete Design To Bs 8110: Contract RefGodfrey James MachotaBelum ada peringkat

- Foundation Calculation Sheet: Title DescriptionDokumen26 halamanFoundation Calculation Sheet: Title Descriptionsalman alfarisyBelum ada peringkat

- Splice Connection Beam Wide FlangeDokumen2 halamanSplice Connection Beam Wide Flangejoneru 04Belum ada peringkat

- Advantages CFSTDokumen14 halamanAdvantages CFSTprajjwal patidarBelum ada peringkat

- Truss DesignDokumen16 halamanTruss DesignRabindraUpretiBelum ada peringkat

- An Introduction To The Network ArchDokumen29 halamanAn Introduction To The Network ArchSzabolcs Attila KöllőBelum ada peringkat

- Common Rafters: Job No: Job Name: Date: Drawing Ref: Prepared By: Checked By: Site Ref: OtherDokumen8 halamanCommon Rafters: Job No: Job Name: Date: Drawing Ref: Prepared By: Checked By: Site Ref: Otherstarsplesh100% (1)

- Procedure - Equivalent Diagonal StrutDokumen5 halamanProcedure - Equivalent Diagonal StrutHemant SonawadekarBelum ada peringkat

- Steel Composite 1 VERY GOOD MahfuzDokumen5 halamanSteel Composite 1 VERY GOOD MahfuzEdson NhabetseBelum ada peringkat

- Good Flat Slab Example Acc To EC2 (The Concrete Centre)Dokumen14 halamanGood Flat Slab Example Acc To EC2 (The Concrete Centre)Nitish Ramdawor100% (4)

- 41-Pile FoundationDokumen56 halaman41-Pile Foundationsharif uddinBelum ada peringkat

- RC Design I ColumnsDokumen32 halamanRC Design I Columnseph100% (1)

- Circular Tube End Plate Calculation PDFDokumen4 halamanCircular Tube End Plate Calculation PDFALPHYL BALASABASBelum ada peringkat

- Strap Footing Foundation FinalDokumen3 halamanStrap Footing Foundation FinalMesfinBelum ada peringkat

- Design of Flat Slabs For PunchingDokumen8 halamanDesign of Flat Slabs For PunchingAli Alskeif100% (1)

- Example Calculation of Alpha-Cr PDFDokumen9 halamanExample Calculation of Alpha-Cr PDFHerdean RemusBelum ada peringkat

- Two Dimensional Analysis of Frame StructuresDokumen54 halamanTwo Dimensional Analysis of Frame StructuresFrank PuchiBelum ada peringkat

- Anker Vrska KompletDokumen4 halamanAnker Vrska KompletstojanovalidijaBelum ada peringkat

- IAT-IV Question Paper With Solution of 18CV72 Design of RC and Steel Structural Elements Feb-2022-Sreelakshmi GopalakrishnanDokumen29 halamanIAT-IV Question Paper With Solution of 18CV72 Design of RC and Steel Structural Elements Feb-2022-Sreelakshmi GopalakrishnanSrikanth ReddyBelum ada peringkat

- Steady Flow in Pipes: BTB 323/ Cse 352 Hydraulics Edwin K. Kanda, PHDDokumen19 halamanSteady Flow in Pipes: BTB 323/ Cse 352 Hydraulics Edwin K. Kanda, PHDErick WanduBelum ada peringkat

- Ec3 Kolon HesabıDokumen5 halamanEc3 Kolon HesabınaimalimliBelum ada peringkat

- RCCe11 Element DesignDokumen8 halamanRCCe11 Element DesignZayyan RomjonBelum ada peringkat

- SX019a-Example Column Base Connection Under Axial Compression PDFDokumen5 halamanSX019a-Example Column Base Connection Under Axial Compression PDFdvelchev100% (1)

- End Plates - Worked Examples With Partial Depth End Plate - Example 5Dokumen1 halamanEnd Plates - Worked Examples With Partial Depth End Plate - Example 5Kimutai Kirui AlphonceBelum ada peringkat

- Reinforcement of A Basement WallDokumen8 halamanReinforcement of A Basement WallZein FarahBelum ada peringkat

- Pile Cap DesignDokumen2 halamanPile Cap DesignUtaya Kumar VeelmuruganBelum ada peringkat

- 8 - Beam Column ConnectionDokumen13 halaman8 - Beam Column Connectionhari1008108Belum ada peringkat

- CRACKED BEAM-Prestressed Concrete Bridge Girder Structural Analysis ProgramDokumen3 halamanCRACKED BEAM-Prestressed Concrete Bridge Girder Structural Analysis ProgramNurLelyHardiantiZendratoBelum ada peringkat

- STR ReportDokumen10 halamanSTR ReportJagmohan Vijay JandhyalaBelum ada peringkat

- RV Design of Column Base PlateDokumen2 halamanRV Design of Column Base Plateapi-190618655Belum ada peringkat

- Effective Length For Moment FrameDokumen5 halamanEffective Length For Moment FramenhulugallaBelum ada peringkat

- Eurocode - Load Combinations For Steel Structures - R1Dokumen26 halamanEurocode - Load Combinations For Steel Structures - R1anil97232Belum ada peringkat

- Design of Reinforced Concrete Deep BeamsDokumen45 halamanDesign of Reinforced Concrete Deep BeamsVivek Thakur SujanianBelum ada peringkat

- Design of Steel Base Plate On Existing Plain ConcreteDokumen5 halamanDesign of Steel Base Plate On Existing Plain ConcreteHayman AhmedBelum ada peringkat

- Slab Design Full Report: Material and Design DataDokumen22 halamanSlab Design Full Report: Material and Design DataazwanBelum ada peringkat

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionDari EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionBelum ada peringkat

- Difference Beetween Is 800-2007 & Is 800-1984Dokumen96 halamanDifference Beetween Is 800-2007 & Is 800-1984ayazmadBelum ada peringkat

- Philosophy of Limit State Design and Classification of SectionsDokumen96 halamanPhilosophy of Limit State Design and Classification of Sectionsybm987100% (1)

- All Pentek HousingsDokumen8 halamanAll Pentek HousingsRomankoBelum ada peringkat

- ASTM F1554 - Portland BoltDokumen1 halamanASTM F1554 - Portland BoltjacquesmayolBelum ada peringkat

- Shear Wall - Wikipedia, The Free EncyclopediaDokumen2 halamanShear Wall - Wikipedia, The Free EncyclopediazidaaanBelum ada peringkat

- Proceedings of Spie: High-Field Electrostriction of Elastomeric Polymer Dielectrics For ActuationDokumen14 halamanProceedings of Spie: High-Field Electrostriction of Elastomeric Polymer Dielectrics For ActuationrajainrushBelum ada peringkat

- Tables SaturationDokumen9 halamanTables SaturationGuilmar Moncayo PonceBelum ada peringkat

- Time Schedule RIIMDokumen4 halamanTime Schedule RIIMBayu KurniawanBelum ada peringkat

- Basic Calculations PDFDokumen1 halamanBasic Calculations PDFSanthosh Kumar100% (1)

- Slab Bridge DesignDokumen73 halamanSlab Bridge DesignAmy MengistuBelum ada peringkat

- Anexo 3 Seleccion Equipos Volumen Variable de RefrigeranteDokumen41 halamanAnexo 3 Seleccion Equipos Volumen Variable de RefrigerantepabloabelgilsotoBelum ada peringkat

- HW4Dokumen23 halamanHW4AliceAlormenu0% (1)

- Bill of Materials Quantity and Cost Estimate Sample 2017Dokumen4 halamanBill of Materials Quantity and Cost Estimate Sample 2017Frances Irish MarasiganBelum ada peringkat

- Mastic Asphalt Design (Without Ca)Dokumen30 halamanMastic Asphalt Design (Without Ca)Soundar PachiappanBelum ada peringkat

- GET Wear SystemsDokumen19 halamanGET Wear SystemsIvanBelum ada peringkat

- Tuboscope Drill PipeDokumen6 halamanTuboscope Drill PipeOscar CarrascoBelum ada peringkat

- BhavikattiDokumen7 halamanBhavikattiRakeshKrBelum ada peringkat

- Ventrimeter Lab ReportDokumen13 halamanVentrimeter Lab ReportMajak MarialBelum ada peringkat

- Thermo Scientific Gilmont: Accucal FlowmetersDokumen2 halamanThermo Scientific Gilmont: Accucal FlowmetersJulio David Vilca PizarroBelum ada peringkat

- Compliance SheetDokumen1 halamanCompliance SheetM DHAYAN VIVEKBelum ada peringkat

- Sonotube CatalogoDokumen2 halamanSonotube Catalogorodrigo2aguilarBelum ada peringkat

- Principle of Metal Magnetic Memory MethodDokumen6 halamanPrinciple of Metal Magnetic Memory MethodZIA ULLAHBelum ada peringkat

- Specification - Civil WorkDokumen61 halamanSpecification - Civil WorkdhanabalBelum ada peringkat

- BOQ SampleDokumen72 halamanBOQ SampleLakmal Jayashantha100% (1)

- Tong Hop BuiddingDokumen122 halamanTong Hop BuiddingTrần ViệtBelum ada peringkat

- Design of Bunkers and SilosDokumen15 halamanDesign of Bunkers and SilosSagarKasarla100% (1)

- Structural Steel Design (BS Code) - MORRIS & PulmDokumen174 halamanStructural Steel Design (BS Code) - MORRIS & Pulm1016101683% (6)

- F2162 01 (Reapproved 2008)Dokumen5 halamanF2162 01 (Reapproved 2008)krishna1401Belum ada peringkat

- TA-COMPACT-P EN LowDokumen8 halamanTA-COMPACT-P EN Lowjgv001Belum ada peringkat

- 2012.11.14 - How To Read and Understand A Geotechnical Report (Part 2)Dokumen24 halaman2012.11.14 - How To Read and Understand A Geotechnical Report (Part 2)UALU333Belum ada peringkat

- SIMULATION PROFESSIONAL ModDokumen101 halamanSIMULATION PROFESSIONAL Modhod meBelum ada peringkat

- Numerical Modelling of The Seismic Behaviour of Adobe BuildingsDokumen268 halamanNumerical Modelling of The Seismic Behaviour of Adobe BuildingsNicola Tarque100% (2)