Isothermal Quenching of Crusher Hammers

Diunggah oleh

Christian MavarezHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Isothermal Quenching of Crusher Hammers

Diunggah oleh

Christian MavarezHak Cipta:

Format Tersedia

ISOTHERMAL

G.K.

QUENCHING

OF

CRUSHER

HAMMERS

UDC 621.785.4:669.15' 74-194

Savinovskii

C r u s h e r h a m m e r s of steel 65G are quenched and t e m p e r e d to HRC 48-54 (GOST 8772-58) to increase

the s e r v i c e life.

Both in the l a b o r a t o r y bench tests and tests in the DKU-1.0A feed mill the h a m m e r s subjected to uninterrupted quenching with subsequent tempering in an e l e c t r i c furnace have repeatedly been found u n s a t i s f a c t o r y in their wear r e s i s t a n c e . The impact type of working conditions at a c i r c u l a r velocity of 56 m / s e e

often leads to cracking and spalling of the working f a c e s .

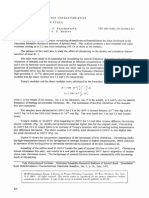

The investigation of the m e c h a n i c a l p r o p e r t i e s on samples of steel 65G subjected to uninterrupted off

quenching f r o m 820-830~ with subsequent tempering to HttC 48-54 and i s o t h e r m a l quenching in a bath at

270-290~ with holding 45 min showed that ~bend = 220-280 k g / m m 2 (samples 8 x 8 x 90 ram) and HRC = 4854 for both heat t r e a t m e n t s . The impact toughness (U type samples, GOST 9454-60) after i s o t h e r m a l quenching was 150% higher for unnotched samples and 30-40% higher for notched s a m p l e s (Fig. 1).

On the basis of the p r e l i m i n a r y experiments to determine the p o s sibility of increasing the durability of the h a m m e r s , an i s o t h e r m a l quenching line was set up (Fig. 2). Through a r e d u c e r 13, the e l e c t r i c m o t o r 1

drives the chain 12 and s p r o c k e t 10 on the shaft 11, the other end of which

has teeth. The toothed end of the shaft runs against the g e a r 3 on the

s a m e shaft with the s p r o c k e t 9, by the rotation of which the s p r o c k e t chain

4 with b r a c k e t s for,~he

h a m m e r s moves in pulses. In p a s s i n g through the

/

inductor 8, the working face of the h a m m e r s is heated to quenching t e m p e r a t u r e ; On leaving the inductor the h a m m e r s slide down the chute 6 into

the i s o t h e r m a l quenching bath 7, which has a basket to hold the p a r t s . The

inductor is powered by the L P Z - 6 7 high-frequency t r a n s f o r m e r 5. The

bath t e m p e r a t u r e is maintained automatically at 270-290~ the holding

time for the h a m m e r s is 45 rain.

an, kg-ra/cm~

Unnotched samples

1o,o?.

I

a

3'O~tched samples

1,008

51

b

54HRC

This automatic quenching line has an output of 330 p a r t s / h . The

p a r t s are not t e m p e r e d after i s o t h e r m a l quenching, since the t e m p e r a t u r e

and holding time are sufficient to reduce the internal s t r e s s e s and no i m p r o v e m e n t of the mechanical c h a r a c t e r i s t i c s is noted after temperIng.

Fig. i. Variation of impact

toughness with the hardness

of steel 65G: a) unnotched

s a m p l e s ; b) notched s a m pies.

,, ) I s o t h e r m a l l y

quenched; . . . .

) quenched

and t e m p e r e d .

This automatic quenching line has i n c r e a s e d the durability of the

h a m m e r s by 20-30% and the h a m m e r s operate without failure under impact loads and even under continuous production conditions.

4, 5_ F'--6

13 12 1110

Fig. 2. Line for i s o t h e r m a l quenching of h a m m e r s .

T r a n s l a t e d f r o m Metallovedenie t T e r m l c h e s k a y a Obrabotka Metallov, No. 2, p. 62, F e b r u a r y , 1969.

145

Anda mungkin juga menyukai

- 7-Day Dial With 6 Ui/o CarryouerDokumen1 halaman7-Day Dial With 6 Ui/o CarryouerDika FradanaBelum ada peringkat

- Tig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsDari EverandTig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsPenilaian: 5 dari 5 bintang5/5 (1)

- Knowledge of Motor Duty - Key To Proper Planning of DrivesDokumen6 halamanKnowledge of Motor Duty - Key To Proper Planning of DrivesEric AndrésBelum ada peringkat

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentDari EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentBelum ada peringkat

- Full Text 11Dokumen3 halamanFull Text 11Shazana MisranBelum ada peringkat

- Ducol W30 MaterialDokumen21 halamanDucol W30 Materialshanker100% (1)

- Electric-Resistance-Welded and Carbonamanganere Boiler Tuôes'Dokumen3 halamanElectric-Resistance-Welded and Carbonamanganere Boiler Tuôes'Joao Osmar CorreaBelum ada peringkat

- How to prepare Welding Procedures for Oil & Gas PipelinesDari EverandHow to prepare Welding Procedures for Oil & Gas PipelinesPenilaian: 5 dari 5 bintang5/5 (1)

- Bohler Welding in Tool MakingDokumen24 halamanBohler Welding in Tool MakingcfcshakerBelum ada peringkat

- Electric Gas Lighting How to Install Electric Gas Ignition ApparatusDari EverandElectric Gas Lighting How to Install Electric Gas Ignition ApparatusBelum ada peringkat

- Nasa NiCrAlY TBC Application 19850018558 PDFDokumen17 halamanNasa NiCrAlY TBC Application 19850018558 PDFatfrost4638Belum ada peringkat

- E 1 - 6 3 8 8 - L o - / Y) - 7 - Zi : Corporation, StreetDokumen1 halamanE 1 - 6 3 8 8 - L o - / Y) - 7 - Zi : Corporation, StreetSinhrooBelum ada peringkat

- Fif FFT - FT Fi) : Aott L Rotat Of: of HM LrithDokumen2 halamanFif FFT - FT Fi) : Aott L Rotat Of: of HM LrithmybestfriendgrewalBelum ada peringkat

- Creep Behavior of Eutectic 80Au20Sn Solder Alloy PDFDokumen4 halamanCreep Behavior of Eutectic 80Au20Sn Solder Alloy PDFeid elsayedBelum ada peringkat

- STCL FF ServicingDokumen13 halamanSTCL FF Servicingratnakar cpwdBelum ada peringkat

- Piping, General Mech PDFDokumen8 halamanPiping, General Mech PDFAhmed Shaban KotbBelum ada peringkat

- PMO801N0615398Dokumen2 halamanPMO801N0615398Jose ExtremeraBelum ada peringkat

- ' LRNDTQ QR R$: Rubber and Plastics Hoses - Sub-Ambient Temperature Flexibility TestsDokumen7 halaman' LRNDTQ QR R$: Rubber and Plastics Hoses - Sub-Ambient Temperature Flexibility Teststmt_salesBelum ada peringkat

- IV 3 - Brochure MezDokumen12 halamanIV 3 - Brochure MezAsep DarojatBelum ada peringkat

- Example 3Dokumen1 halamanExample 3mhao49480Belum ada peringkat

- Astm-D1586-Pdf-Free 2Dokumen1 halamanAstm-D1586-Pdf-Free 2zeeshanBelum ada peringkat

- 1006 1009Dokumen4 halaman1006 1009SinhrooBelum ada peringkat

- Machine Design I 2014Dokumen8 halamanMachine Design I 201455511223344Belum ada peringkat

- 36 Nickel IronAlloyforLowTemperatureService 410Dokumen8 halaman36 Nickel IronAlloyforLowTemperatureService 410gigel1980Belum ada peringkat

- Regression Modeling of Macrohardness ofDokumen5 halamanRegression Modeling of Macrohardness ofabraham silva hernandezBelum ada peringkat

- Fracture Toughness of A516 Gr70Dokumen8 halamanFracture Toughness of A516 Gr70avisyoBelum ada peringkat

- ASTM A123 - Zinc Hot Dip Galvanised Coatings On Iron and Steel ProductsDokumen4 halamanASTM A123 - Zinc Hot Dip Galvanised Coatings On Iron and Steel ProductsPisut LeelalumlertBelum ada peringkat

- 1851Dokumen11 halaman1851Md Tajijul IslamBelum ada peringkat

- T" Ii M', N, I I Tlilltll: Isothermal Treatment OF AlloyDokumen3 halamanT" Ii M', N, I I Tlilltll: Isothermal Treatment OF AlloySinhro018Belum ada peringkat

- MIL-W-22759 Rev E - Part36Dokumen1 halamanMIL-W-22759 Rev E - Part36David WongBelum ada peringkat

- Manufacturing and Inspection Procedure For 3 Lpe Coating: PurposeDokumen6 halamanManufacturing and Inspection Procedure For 3 Lpe Coating: PurposeNitin Nahar100% (1)

- Welding Research: Development of A New Hot-Cracking Test-The SigmajigDokumen6 halamanWelding Research: Development of A New Hot-Cracking Test-The SigmajigElaine JohnsonBelum ada peringkat

- Creep Properties of Grade 91 Steam Generator Tube Steel at 923KDokumen8 halamanCreep Properties of Grade 91 Steam Generator Tube Steel at 923KD P RAO PALAPARTIBelum ada peringkat

- Technika 9-10 2014Dokumen76 halamanTechnika 9-10 2014technikaBelum ada peringkat

- FINAL BROCHURE Bowthorpe EMP 150802 PDFDokumen16 halamanFINAL BROCHURE Bowthorpe EMP 150802 PDFfernando romero sotoBelum ada peringkat

- P 91 Piping WeldingDokumen81 halamanP 91 Piping Weldingneelapu mahesh reddy100% (1)

- Heating IN AN Electrically Conducting Layer Carbon-Containing Particles OFDokumen4 halamanHeating IN AN Electrically Conducting Layer Carbon-Containing Particles OFSinhrooBelum ada peringkat

- Dry Arc Resistance TesterDokumen6 halamanDry Arc Resistance TesteranuBelum ada peringkat

- Heat Treatment PDFDokumen10 halamanHeat Treatment PDFSatwant SinghBelum ada peringkat

- Heat Treated Al-Zn-Cu-Mg: The Structure and Mechanical PropertiesDokumen6 halamanHeat Treated Al-Zn-Cu-Mg: The Structure and Mechanical PropertiesAna L G RodríguezBelum ada peringkat

- Manual de OperacionDokumen11 halamanManual de OperacionSalocinBelum ada peringkat

- Temper Bead Welding 36036664Dokumen9 halamanTemper Bead Welding 36036664sv1xv100% (1)

- MIL-W-22759 Rev E - Part34Dokumen1 halamanMIL-W-22759 Rev E - Part34David WongBelum ada peringkat

- Supertester 680 RDokumen39 halamanSupertester 680 Rdomingos.sanchezBelum ada peringkat

- Cigweld-Deposited Rates PDFDokumen7 halamanCigweld-Deposited Rates PDFNam_HitechBelum ada peringkat

- Sem 6 Papers 1 PDFDokumen11 halamanSem 6 Papers 1 PDFBhupesh GuptaBelum ada peringkat

- Project Report: On Analyze Submerged Arc Welding (SAW) With Respect To MIG Welding (GMAW)Dokumen32 halamanProject Report: On Analyze Submerged Arc Welding (SAW) With Respect To MIG Welding (GMAW)Rama Krishna Reddy DonthireddyBelum ada peringkat

- Data GRS PLTP Gunung Salak #3 PDFDokumen28 halamanData GRS PLTP Gunung Salak #3 PDFfirmantuakiaBelum ada peringkat

- Bathias Et Al - How and Why The Fatigue S-N Curve Does Not Approach A Horizontal AsymptoteDokumen9 halamanBathias Et Al - How and Why The Fatigue S-N Curve Does Not Approach A Horizontal AsymptoteHajatBelum ada peringkat

- Ijct 1 (5) 305-307 PDFDokumen3 halamanIjct 1 (5) 305-307 PDFAnonymous v5uipHBelum ada peringkat

- Astm B 233-97Dokumen4 halamanAstm B 233-97Faridi Mohamed BasriBelum ada peringkat

- Dissimilar Metal Welds - 001Dokumen1 halamanDissimilar Metal Welds - 001Bacha KarimBelum ada peringkat

- A Creep Life Assessment Method For Boiler Pipes Using Small Punch Creep TestDokumen6 halamanA Creep Life Assessment Method For Boiler Pipes Using Small Punch Creep TestAndrea CalderaBelum ada peringkat

- II.B.1.3 EnglezaDokumen16 halamanII.B.1.3 EnglezaPopa MirceaBelum ada peringkat

- Fire Terrace Booster Pump SpecificationDokumen11 halamanFire Terrace Booster Pump SpecificationRajkishore NayakBelum ada peringkat

- 510 Open ExamDokumen17 halaman510 Open Examariyamanjula2914100% (1)

- Astm d1586Dokumen9 halamanAstm d1586Franco PretellBelum ada peringkat

- Design and Fabricatino of Liquid Dispensing Machine Using Automatic Control For Engg IndustryDokumen7 halamanDesign and Fabricatino of Liquid Dispensing Machine Using Automatic Control For Engg IndustryChristian MavarezBelum ada peringkat

- US2259748Dokumen3 halamanUS2259748Christian MavarezBelum ada peringkat

- Optimal Sizing of Counterflow Cooler For PelletsDokumen72 halamanOptimal Sizing of Counterflow Cooler For PelletsChristian MavarezBelum ada peringkat

- Investigating Limits in Naturally Cooled Systems Using FlothermDokumen6 halamanInvestigating Limits in Naturally Cooled Systems Using FlothermChristian MavarezBelum ada peringkat

- Mobile Crushing Plant: Rio Tinto Coal Australia Clermont Coal Mine (Australia) Turn-Key ProjectDokumen2 halamanMobile Crushing Plant: Rio Tinto Coal Australia Clermont Coal Mine (Australia) Turn-Key ProjectChristian MavarezBelum ada peringkat

- In-And Outlet For SU/SO/SUH/SAU: Data Sheet 605.30Dokumen1 halamanIn-And Outlet For SU/SO/SUH/SAU: Data Sheet 605.30Christian MavarezBelum ada peringkat

- 605 05 Industrial Screw ConveyorDokumen1 halaman605 05 Industrial Screw ConveyorChristian MavarezBelum ada peringkat

- Rock Crushing PlantsDokumen29 halamanRock Crushing PlantsChristian MavarezBelum ada peringkat

- Ds Asphalt THF 1214 EngDokumen2 halamanDs Asphalt THF 1214 EngChristian MavarezBelum ada peringkat

- Guidelines: The Feed Analysis Laboratory: Establishment and Quality ControlDokumen103 halamanGuidelines: The Feed Analysis Laboratory: Establishment and Quality ControlChristian MavarezBelum ada peringkat

- 04cDokumen29 halaman04cChristian MavarezBelum ada peringkat

- Gt125 Track Mounted Crushing PlantDokumen2 halamanGt125 Track Mounted Crushing PlantChristian MavarezBelum ada peringkat

- Heat Treatment: Unit - 2Dokumen75 halamanHeat Treatment: Unit - 2reza chamanfarBelum ada peringkat

- Eff Ect of Heat Treatment Parameters On Material Properties of AISI 4140 SteelDokumen3 halamanEff Ect of Heat Treatment Parameters On Material Properties of AISI 4140 SteelMatheus Paes PeçanhaBelum ada peringkat

- Alloy SteelDokumen4 halamanAlloy SteelDalibor CetojevicBelum ada peringkat

- Excelente Welding Inspection Qualifications Testing Procedures PDFDokumen117 halamanExcelente Welding Inspection Qualifications Testing Procedures PDFravi00098Belum ada peringkat

- HT Work Instruction Chart 23.03.2010 RevisedDokumen5 halamanHT Work Instruction Chart 23.03.2010 RevisedkvmoorthiBelum ada peringkat

- Heat Treatment of Aluminum AlloysDokumen9 halamanHeat Treatment of Aluminum AlloysUmar Shaukat100% (1)

- Standards and TablesDokumen7 halamanStandards and TablesDEIVASIHAMANI PERUMALBelum ada peringkat

- Hardenability of SteelDokumen59 halamanHardenability of SteelKhaula M RausyanBelum ada peringkat

- Index of Material Specs PDFDokumen6 halamanIndex of Material Specs PDFAndres Fitria FarrelBelum ada peringkat

- Amomax-10 - A Novel Ammonia Synthesis Catalyst: Norbert Ringer Dr. Marcus MichelDokumen6 halamanAmomax-10 - A Novel Ammonia Synthesis Catalyst: Norbert Ringer Dr. Marcus Michelsara bagheriBelum ada peringkat

- WWW - Learnengineering.In: Me8491 - Engineering Metallurgy Question BankDokumen21 halamanWWW - Learnengineering.In: Me8491 - Engineering Metallurgy Question BankDr.A.Maniram KumarBelum ada peringkat

- EMM 2312 - Fe-CDokumen53 halamanEMM 2312 - Fe-CCalebBelum ada peringkat

- THI Products CatalogueDokumen12 halamanTHI Products CatalogueAngelus129Belum ada peringkat

- BF02642758 1Dokumen9 halamanBF02642758 1Edgar LopezBelum ada peringkat

- Astm 194-2017 PDFDokumen13 halamanAstm 194-2017 PDFThiago CurvoBelum ada peringkat

- Distortion Mechanisms During Carburizing and Quenching in A Transmission ShaftDokumen12 halamanDistortion Mechanisms During Carburizing and Quenching in A Transmission Shaftnilesh_092Belum ada peringkat

- Heat Treatment DefectsDokumen13 halamanHeat Treatment DefectsAbu HurairaBelum ada peringkat

- Heat Treatment PPTDokumen70 halamanHeat Treatment PPTJhonrey QuejadaBelum ada peringkat

- GBT3077-2015 enDokumen29 halamanGBT3077-2015 enSinan Chen100% (1)

- Capili Jefferson 11Dokumen16 halamanCapili Jefferson 11Christian Al EncarnacionBelum ada peringkat

- Heat TreatmentDokumen44 halamanHeat TreatmentMastram HatheshBelum ada peringkat

- Heat Treatment Lab ReportDokumen12 halamanHeat Treatment Lab ReportCarl Behlmer100% (5)

- The Heat Treatment of Al AlloysDokumen11 halamanThe Heat Treatment of Al AlloysartBelum ada peringkat

- Project Report On NBCDokumen49 halamanProject Report On NBCamaramar511Belum ada peringkat

- 220801bnejs3963 Cdfex0 33Dokumen33 halaman220801bnejs3963 Cdfex0 33tskmechBelum ada peringkat

- ASHOKADokumen40 halamanASHOKAManish PatilBelum ada peringkat

- Continuous Gas Carburising FurnaceDokumen2 halamanContinuous Gas Carburising FurnaceEmba MadrasBelum ada peringkat

- Bs-En 10052 1994Dokumen34 halamanBs-En 10052 1994Tufan ÜnalBelum ada peringkat

- Jominy TestDokumen5 halamanJominy TestAhmet Ozan Basar100% (1)

- Steel Bars, Alloy, Hot-Wrought or Cold-Finished, Quenched and TemperedDokumen3 halamanSteel Bars, Alloy, Hot-Wrought or Cold-Finished, Quenched and TemperedDarwin Darmawan100% (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyDari EverandSodium Bicarbonate: Nature's Unique First Aid RemedyPenilaian: 5 dari 5 bintang5/5 (21)

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EDari EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EPenilaian: 3 dari 5 bintang3/5 (6)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemDari EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemBelum ada peringkat

- Process Plant Equipment: Operation, Control, and ReliabilityDari EverandProcess Plant Equipment: Operation, Control, and ReliabilityPenilaian: 5 dari 5 bintang5/5 (1)

- An Applied Guide to Water and Effluent Treatment Plant DesignDari EverandAn Applied Guide to Water and Effluent Treatment Plant DesignPenilaian: 5 dari 5 bintang5/5 (4)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisDari EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisPenilaian: 5 dari 5 bintang5/5 (1)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersDari EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Piping Engineering Leadership for Process Plant ProjectsDari EverandPiping Engineering Leadership for Process Plant ProjectsPenilaian: 5 dari 5 bintang5/5 (1)

- Guidelines for Chemical Process Quantitative Risk AnalysisDari EverandGuidelines for Chemical Process Quantitative Risk AnalysisPenilaian: 5 dari 5 bintang5/5 (1)

- Well Control for Completions and InterventionsDari EverandWell Control for Completions and InterventionsPenilaian: 4 dari 5 bintang4/5 (10)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersDari EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersBelum ada peringkat

- A Complete Guide to Safety Officer Interview Questions and AnswersDari EverandA Complete Guide to Safety Officer Interview Questions and AnswersPenilaian: 4 dari 5 bintang4/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsDari EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsPenilaian: 4 dari 5 bintang4/5 (11)

- Workbook to Accompany Maintenance & Reliability Best PracticesDari EverandWorkbook to Accompany Maintenance & Reliability Best PracticesPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesDari EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesBelum ada peringkat

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDari EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsBelum ada peringkat

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlDari EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlPenilaian: 4 dari 5 bintang4/5 (4)

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksDari EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksBelum ada peringkat

- The Perfumed Pages of History: A Textbook on Fragrance CreationDari EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationPenilaian: 4 dari 5 bintang4/5 (1)

- Water-Based Paint Formulations, Vol. 3Dari EverandWater-Based Paint Formulations, Vol. 3Penilaian: 4.5 dari 5 bintang4.5/5 (6)

- Fun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksDari EverandFun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksBelum ada peringkat

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsDari EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottPenilaian: 4 dari 5 bintang4/5 (6)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsDari EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsBelum ada peringkat

- A New Approach to HAZOP of Complex Chemical ProcessesDari EverandA New Approach to HAZOP of Complex Chemical ProcessesBelum ada peringkat