Quick Start Guide

Diunggah oleh

svic11Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Quick Start Guide

Diunggah oleh

svic11Hak Cipta:

Format Tersedia

http://www.titanjet.com.

cn

Three

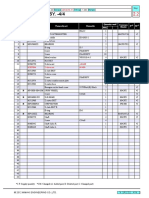

ThreeTool bar

Function of key from left to right :

AInput file

BReplacementPress it one timecarriage replace one time

CStart print

DStop print

EPause print

FContinue print

GParameter settingUsed to setting printing parameter,like stepping,direction,carriage speed and so on.

HRemove file in the list

IAdjust toolInk pump voltage adjust and wiper adjust

JPrinthead voltage adjustNormally this tool used by professional technician)

KPrinthead SituationUsed to check the printhead print quality,Printing bar doesn't breaking line,is good

situation,referance follow picture :

LExitExit control software

Four

FourPrinting information bar

Show the current printing work information.File name,condition,printing mode,file size,path and so on.

Five

FiveUnually parameter

AMargin

Margin

http://www.titanjet.com.cn

aZero to paper: User setting it according to material location.

bPaper MarginFrom the start of printing picture to the margin of material

BPrint Direction

Direction

aSingle direction printingWhen carriage out it print,when carriage back,it not print.

bDouble direction printingWhen carriage out it print

When carriage back,it also print.

CColor bar setting

setting

aColor bar LocationWhen printing you can choose did not put color barAlso can add color bar in both

side of picture.

bWidthUsed to adjust the width of the color bar when print

cDistance between color bar and picture

DFlush printing

printing Frequency

Frequency

When software open but did not printingCarriage will stop on original stationin order to avoid the printhead

get too dryYou can try choose flush printing frequency freedomly to make head nozzle wetkeep the printhead

in good condition.

EStepping setting

setting

aStepping numberThe distance of material move up after each 1 pass,Different pass have different stepping

number

the stepping number will be introduced below

bAfter feather function the software have the function of featherthis function used to avoide pass line.We

suggest customer use feather function when printing.

FApply

Applysave

save

After finish setting all the parameter,do remever press Apply to save it.

Six

SixStatus

About when start print the document,when finish printing,and information from main

board,software ,and feedback from the encoder sensor.

Introduce of Control software

Setting the parameter

parameter

Printhead parameter setting

http://www.titanjet.com.cn

1Same color printhead adjust,it has test and adjust when printer out from factory,didn't need customer to

adjust .

This item used to adjust the left and right printhead location when printing,for one head

printer,this item is "0".Printhead quantity choose "2",try to print 1 pass small picture,and if print resoult

same as picture 1 and picture 2,you need adjust the number in this item .And if print resoult like picture

3,the number is correct.

3Carriage speedSpeed of carriage have 3 models---model 1 ,model 2,model 3 (low speed,middle speed,fast

speed)

4Bidirection adjustNormally,when choose bidirection printing,this item need adjust.This item to adjust

the printhead print in the same place when go and back.Show as follow picture

When above picture totally march with picture below,put this picture number into the item.For example,now number

9 totally march,then put the number 9 into the item when bidrection printing.

Two

TwoPrinting adjust

adjust

1Check the printhead nozzle

Tool

barhas

2Printhead adjustOne head,X direction adjust

introduced

http://www.titanjet.com.cn

Press printhead adjustIf print bar shown above picture,that means printhead X way direction not correct.Need

to adjust the screw 3 (shown in follow picture) to reset.When adjust screw3,need firstly loose screw 1 and

2,Should noticeScrew 1 and 2 should not too long,when make the screw 1 and 2 tight,it can not withstand

printhead cable,it is very important,if printhead cable damage,when printer on,it will damage printhead !

Then to adjust the screw 3

Loose and tighten the screws to adjust the printhead,if print resoult same as follow picture,blue color line

in the same lever with red color,the adjust finish.

3Bidirection adjustinPrinthead parameter settinghas been introduced

4Stepping adjust

Press stepping adjust,the carriage will print 2 times,at first time,it will print 5 short line,when print

in second time,it will print one long line.If the long line 100% march the middle short line(same as picture

shown above),it means the stepping number is right.

If the second long like above the middle line,(same as follow picture)it meaning the stepping number should

increase.

If

the

long

line

below

the

middle

short

line,it

means

you

should

reduce

the

number

of

stepping.

User according it's own printing resoult to adjust,until printing picture same as picture 1,longing line

http://www.titanjet.com.cn

100% march the middle short line.

5Stepping parameter setting

InRoutine

setting

been introduced.

6Printing distance /length

InRoutine

setting

been introduced.

7Color choose

You can choose printing color when adjust.

Three

ThreeOther parameter setting

1Stepping speedThe speed of paper move up for each 1 pass when printing.

2Stepping paper move down speedWhen not print,the speed of paper move up and move down.

3Ending of printingAt end of printing,the length of the paper can move up and move down(Unit mm)

4Previel settingThe color of the control software shows

5Color for chooseDifferent color can be choose when printing

6Printer lengthThe width of printing plate is 1.83 meter,and maxima printing width is 1.8 meter,need to adjust

here to make printer printing maxima printing width.

Find out from the contral software this button,

Press it,then the carriage will move right and stop

automaticly.If you find the carriage move not in the maxima width,then you need increase the number of it until

it can print 1.8meter width.

7Printing setting

Jump blackIn the middle of 2 picture,printhead did not work ,only print on where it have picture.

Bugle AlertWhen start printing,the computer will have sound to alert it .

Print automaticallyChoose the file,Repeat printing it automatically.

8Printhead quantity

The printhead quantity,this model printer can install 2 Epson DX5 heads.

9Feather function

http://www.titanjet.com.cn

Feather function used to avoid pass line.We suggest customer use feather function.This function parameter is

confirmed,didn't need adjust by customer.

10

10More others--------others---------

---------

This items need code number,some items did not open to customer,only for the test by factory technical man.

******

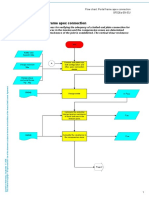

Eight

EightTest after adjust the control software

After completing the installation of the RIP software, switch on and open the RIP software

- control tool

, in turn test the function by make the wiper up,down,forward and back.

If it doesn't work well, please check your machine under the guidance of the agent

or manufacturer.

Click the cleaning button

, check whether the cartridge ,ink pump,wiper have completed

the cleaning action.

It is ---click

---click the cleaning button--button---the

---the ink pump revolve( pump all the waste ink out of the

damper)--damper)---the

---the cartridge return to the zero place ( press the damper tightly against the

nozzle)--nozzle)---the

---the ink pump keeps revolving to pump the ink from the print head( it needs about 10

seconds)--seconds)---When

---When the ink pump stop revolving , the cartridge will stay there for about

about 4

seconds--seconds---the

---the wiper move out--out---the

---the cartridge move slowly till all the cartridge passes the

wiper--wiper---the

---the wiper move back--back---the

---the cartridge move back( It inkjets strongly when the cartridge

is 1.5mm near the damper)---damper)----meanwhile

----meanwhile , the ink pump keep pump out the waste ink that jetted

out)

If you have any questions ,please contact the distributor or the manufacturer.

The wiper had better be 0.5mm0.5mm-1mm higher than the nozzle.

http://www.titanjet.com.cn

3. The distance between the print head of TaiTeng1604 photo machine and the printing material.

According to the different thickness of the printing material, we can adjust the height

of the cartridge. The idea printing distance between the print head and the printing material

is 1 mm. To avoid the touch between the print head and the printing material,which will destroy

the whole printing effect when we do the printing operation,we can adjust the flatness of

the printing material.But don't make it over 2.5mm. The method: revolve the adjusted plate

as showed down there, which can adjust the height of the cartridge.

( Attention: Before the installation of print head, first using the MainTop software to process

a photo with L*W:1.5m*1m ,to try to print first. When you make sure everything is ok with your

machine ,then you can instal the print head.)

4, The installation of ink of the TaiTeng machine.

Relevant precautions

1, Please put the ink out of the reach of Child.

2.Rinse with clean water after eye contact.

4,Pease clean the ink supply system with the cleaning liquid sent together

with the mahcine.

4. The best temperature for using the ink is between 18-30.

5, Please store the ink in cool place, avoid the direct exposure to high/low temperature or light.

6, When the bottle is opened , please use the ink timely. It not suitable for long-term storage.

7, If you find the the ink freeze in the low temperature, just let it melt for several hours in the normal

temperature.

8.If the ink splash to your hands or cloths, please clean it with water as soon as possible.

9, Don't try to separate the ink tank.

10, Because ink belongs to chemicals, so please deal appropriately with the waste tank and ink.

Try to avoid the pollution as much as you can.

11, When you install the ink , please move the ink capsule as less as possible, to make the loss to the minimum.

12, Use the appointed ink of the machine , don't mix-use different brand of ink.

13, Don't shake the bottle of the ink when you add the ink to the ink tank. Add the ink when the printer stop

working. Please add ink slowly to the ink tank to avoid the bubble in the tank. Then put the ink tank on the

ink tank shelf.

Attention: The faucet of the ink tank should aim at the ink needle of the ink tank shelf. Don't forget to plug

in slowly to avoid the bending or breaking off of the needle.( the sequence of the ink tank is :

K1 K2 C2 M2 Y2

Y1 M1 C1

http://www.titanjet.com.cn

14.Use the syringe to pump out about 20ml ink from each ink tank to ink capsule. Each ink level of the ink

capsule should be at the same height.

5, The calibration of the damper ,the installation

installation of the print head and the

connection of the head cable.

Before you instal the print head , please calibrate the damper first.

1, Loosen the screw No.4, then loosen /tighten the screw No.5 with internal hexagonal wrench. Make the floor

plate hole of the cartridge point to the middle hole of the fixed plug base of the print head.Then tighten the wrench

softly.

2, Swith on the machine , when the cartridge gets back to its place, click the cleaning button of the control software,

then check whether the damper point right at the the hole of the fixed base of the print head.If it appeared to

be the following two situation , it should be adjusted, The concrete method is as follows:

If it appears the photo 1,you need to loosen the 4 screws a,b,c,d , and softly move forward and back the fixed plate

of the wiper,

If it appears the photo 2, you need to loosen the screws e,f,and softly move left and right the damper base.

Then charge in power and click the cleaning button of the software until it reach the situation of photo 3.

http://www.titanjet.com.cn

In turn , instal the print head.

A, Instal the print head cable at the print head side as showed in the photo.

(Attention : carefully plug in the cable to avoid the bending or breaking of the

head cable)

Each print head have 8 lines nozzles. Each line of nozzles have one specific ink mouth .Instal the print head to

the print head base. If you want to instal only one print head , put it into the left print head base. After putting

the print head evenly , tighten the screws No.1.2.3 ( Attention: Don't tighten the screws too tightly.

Because the out material of the printhead is made of plastic, it is easily to break). It is showed as follows:

B. There is 8 ink capsules in the print head of Tai Teng 1802 photo machine. It is Y1 M1 C1 K1 K2

C2 M2 Y2

from left to right. Switch the machine on, when the cartridge gets back to its place , click the

cleaning button

of the control software.At this moment , the machine will complete the cleaning action in

succession, and it needs about 30 seconds to 1 minute. During this process, you should see whether the ink pump

can pump out the ink from the print head. It is very important.If it can't , that is to say , you need make some

little adjustment of the relative place of the damper and the cartridge , until you can successfully pump out the

ink. This adjustment is very important , and it needs many time to do so. I have talked about how to adjust the

damper, so next I will introduce how to adjust the height of the damper: loosen the the screws No.A,B,C,D to adjust

the height of the damper:

http://www.titanjet.com.cn

C.When the ink pump can easily pump out the ink, switch the power off. ( The working voltage of the ink pump can

be adjusted form the Adjust Tool in the control software. Usually, 6V-8V is ok!). As showed in the below photo,

instal the other side the head cable to the cartridge board--the head board.

Make sure the connection of the head cable is totally right, then switch on the machine. Using the control software

to print test strip. It is the best situation that there is no bending or breaking line on the test strip.

If the test strip can not be printed so well, you need to cleaning the print head again and again,

until it can jet the pure and colorful ink smoothly.

When the test strip is good , you can process one picture with the RIP software then print it

out.

Anda mungkin juga menyukai

- Adobe Acrobat - How To Create PDF EbooksDokumen66 halamanAdobe Acrobat - How To Create PDF Ebooksrose166100% (1)

- Adobe Acrobat - How To Create PDF EbooksDokumen66 halamanAdobe Acrobat - How To Create PDF Ebooksrose166100% (1)

- SRX11838 Engineers Handbooks ACI AISC 16Dokumen194 halamanSRX11838 Engineers Handbooks ACI AISC 16AntonBelum ada peringkat

- Print Color Management ISO 12647-2: SystemserviceDokumen1 halamanPrint Color Management ISO 12647-2: SystemserviceAngel de LuzBelum ada peringkat

- MIG Welding Guide - Processes, Principles & Applications of GMAWDokumen23 halamanMIG Welding Guide - Processes, Principles & Applications of GMAWAsad Bin Ala Qatari50% (2)

- ItemDokumen604 halamanItemapi-263566460% (1)

- Keil Softwar1Dokumen5 halamanKeil Softwar1Bhargavi BodigeBelum ada peringkat

- 33& 11kv Terminations. KitsDokumen9 halaman33& 11kv Terminations. Kitsnvinodn06Belum ada peringkat

- Vortex FlowmeterDokumen16 halamanVortex FlowmeterBiswajit DebnathBelum ada peringkat

- Heat Exchangers: Efficient Product HeatingDokumen11 halamanHeat Exchangers: Efficient Product Heatingمصطفى- القرقعيBelum ada peringkat

- Tosun Digital (HS) Product Manual-USBDokumen45 halamanTosun Digital (HS) Product Manual-USBFerdinand CaluyaBelum ada peringkat

- 20110520101701Dokumen27 halaman20110520101701Arie Teckno100% (2)

- How To Install A Print Server: Important: Print Servers Do Not Work With "Multifunction" or "All in One" MachinesDokumen22 halamanHow To Install A Print Server: Important: Print Servers Do Not Work With "Multifunction" or "All in One" MachinesZubas TevesatBelum ada peringkat

- Printer Setup GuideDokumen12 halamanPrinter Setup Guidecosmin DarieBelum ada peringkat

- POS Printer Ethernet Interface Users ManualDokumen10 halamanPOS Printer Ethernet Interface Users ManualALEXANDRA GALINDEZBelum ada peringkat

- Epson Manual Installation GuideDokumen68 halamanEpson Manual Installation GuideLuis RangelBelum ada peringkat

- Instruction of UV-A1 v2Dokumen31 halamanInstruction of UV-A1 v2Alexis MesiasBelum ada peringkat

- Service Guide BookDokumen152 halamanService Guide BookSupport Biomed100% (1)

- PhotoPrint Dither TypesDokumen1 halamanPhotoPrint Dither Typesalexandarno1Belum ada peringkat

- Canon Service Tool GuideDokumen11 halamanCanon Service Tool GuideJames GonzagaBelum ada peringkat

- Assesment G7 PDFDokumen6 halamanAssesment G7 PDFSiddharth SaxenaBelum ada peringkat

- Https Digiprintsupplies - Zendesk.com Attachments Token 9zadretbiapxzss Name Troubleshooting+Print+Head+ (Nozzles) +problemsDokumen6 halamanHttps Digiprintsupplies - Zendesk.com Attachments Token 9zadretbiapxzss Name Troubleshooting+Print+Head+ (Nozzles) +problemsmehoBelum ada peringkat

- Experimental Thermal and Fluid Science: Gangtao Liang, Yali Guo, Xingsen Mu, Shengqiang ShenDokumen8 halamanExperimental Thermal and Fluid Science: Gangtao Liang, Yali Guo, Xingsen Mu, Shengqiang ShenhsemargBelum ada peringkat

- Request For Daily Care JV5Dokumen8 halamanRequest For Daily Care JV5Lalo GutierrezBelum ada peringkat

- Eagle RipDokumen4 halamanEagle RippedroaraoztBelum ada peringkat

- Study Density & Colour Measurement DevicesDokumen3 halamanStudy Density & Colour Measurement DevicesShraddha GhagBelum ada peringkat

- How Do I Connect To A Remote Front Panel That Is Hosted Behind A Remote RouterDokumen4 halamanHow Do I Connect To A Remote Front Panel That Is Hosted Behind A Remote RouterGomia DetuttiBelum ada peringkat

- ETINK UV DTF Printer User's ManualDokumen59 halamanETINK UV DTF Printer User's ManualVMLP OrMdo SecGenBelum ada peringkat

- Unveiling The Dynamics of Ultra High Velocity Droplet Impact On Solid SurfacesDokumen11 halamanUnveiling The Dynamics of Ultra High Velocity Droplet Impact On Solid Surfacesxu KBelum ada peringkat

- Pattern Recognition & Learning II: © UW CSE Vision FacultyDokumen47 halamanPattern Recognition & Learning II: © UW CSE Vision FacultyDuong TheBelum ada peringkat

- Encoder Board MACH3Dokumen12 halamanEncoder Board MACH3Minerva MartinezBelum ada peringkat

- Time Management MatrixDokumen1 halamanTime Management MatrixArRDM24Belum ada peringkat

- TCP/IP Troubleshooting ToolsDokumen10 halamanTCP/IP Troubleshooting ToolsLoredel Doria LueteBelum ada peringkat

- Printer Maintenance GuideDokumen19 halamanPrinter Maintenance GuideEDU0914100% (1)

- Embedded CDokumen60 halamanEmbedded CShamanthaka ManiBelum ada peringkat

- Inkjet Printing GuideDokumen26 halamanInkjet Printing Guidelydiem09100% (1)

- Encon Thermal Engineers: Answer To The Continued Need For Energy ConservationDokumen70 halamanEncon Thermal Engineers: Answer To The Continued Need For Energy ConservationAtul SaxenaBelum ada peringkat

- Ems Piezon Fs 367 ConnectionDokumen4 halamanEms Piezon Fs 367 Connectionshakil ahmadBelum ada peringkat

- Setup Standard TCP/IP Printer PortDokumen11 halamanSetup Standard TCP/IP Printer PortMallikarjun GMBelum ada peringkat

- EagleRIP User GuideDokumen181 halamanEagleRIP User GuideJavier Martinez CañalBelum ada peringkat

- Mathcad - Pulse WaveformDokumen4 halamanMathcad - Pulse WaveformNguyễn Sơn LâmBelum ada peringkat

- Eagle RIP OperatorGuide - ENGDokumen151 halamanEagle RIP OperatorGuide - ENGKingsley Gomes100% (1)

- Prinect StandardizationDokumen36 halamanPrinect StandardizationVesna DjurovicBelum ada peringkat

- TAIMES T7 Printermanager Software Manual PDFDokumen17 halamanTAIMES T7 Printermanager Software Manual PDFSyamsul Arifin Ipin50% (2)

- Cephalopod-inspired ultralow voltage dielectric elastomer iridophoresDokumen40 halamanCephalopod-inspired ultralow voltage dielectric elastomer iridophoresGeorge SBelum ada peringkat

- PrintExp Control Software InstructionDokumen21 halamanPrintExp Control Software InstructionEduardo RiveraBelum ada peringkat

- 980a0675 PDFDokumen43 halaman980a0675 PDFMichael DavenportBelum ada peringkat

- Boiler LogicsDokumen42 halamanBoiler LogicsSupratim Pal100% (1)

- DeviceLink Profiles Fundamentals and ApplicationsDokumen38 halamanDeviceLink Profiles Fundamentals and Applicationsomar tlebBelum ada peringkat

- Generate stepper motor speed profiles in real timeDokumen10 halamanGenerate stepper motor speed profiles in real timeSteven Pfeifenroth100% (1)

- EagleRIP Offset Presentation-InglesDokumen37 halamanEagleRIP Offset Presentation-InglesJavier Martinez CañalBelum ada peringkat

- 1225 Main Board 6890NDokumen6 halaman1225 Main Board 6890NMarine JolieBelum ada peringkat

- UltraPrint User Guide. by Alto Imaging TechnologiesDokumen94 halamanUltraPrint User Guide. by Alto Imaging TechnologiesLeopoldo MedinaBelum ada peringkat

- PT DHCP DNS HTTPDokumen5 halamanPT DHCP DNS HTTPPisarenco GrigoreBelum ada peringkat

- Christian Camilo Afanador Marín: Professional ChemistDokumen6 halamanChristian Camilo Afanador Marín: Professional ChemistJOANNE MICHELLE CASTIBLANCO FERNANDEZBelum ada peringkat

- EP802 Printer Driver Manual, Ver20220421Dokumen20 halamanEP802 Printer Driver Manual, Ver202204210d serviceBelum ada peringkat

- CISSDokumen4 halamanCISSAyari Supras NadhmiBelum ada peringkat

- CMYK GUIDE - Metamerism PDFDokumen6 halamanCMYK GUIDE - Metamerism PDFMario Daniel ConejoBelum ada peringkat

- Instructions For Updating The Printer Firmware in Chipless, Method 13Dokumen5 halamanInstructions For Updating The Printer Firmware in Chipless, Method 13Kevin Dispo MontajesBelum ada peringkat

- Ink Drop ExperimentDokumen3 halamanInk Drop Experimentprash_hingeBelum ada peringkat

- Color Offset: C/H M/H 6H5H4H3H2H1HDokumen1 halamanColor Offset: C/H M/H 6H5H4H3H2H1Hdes09Belum ada peringkat

- Dot Spread-Dot GainDokumen3 halamanDot Spread-Dot GainMansour SolimanBelum ada peringkat

- X Rite GregtagmacbethDokumen21 halamanX Rite GregtagmacbethdeepanairbalachandraBelum ada peringkat

- VigoEngraverL7 Installation GuideDokumen9 halamanVigoEngraverL7 Installation GuideJair ArmandoBelum ada peringkat

- Solder Paste Printer ManualDokumen14 halamanSolder Paste Printer ManualTrang ThuBelum ada peringkat

- VIGO ENGRAVER ManualDokumen9 halamanVIGO ENGRAVER ManualCarlos PessoaBelum ada peringkat

- Jam Tangan Casio PDFDokumen11 halamanJam Tangan Casio PDFsyukur1Belum ada peringkat

- Dfrobot Wireless Programming Module For Arduino: Versand Aus Deutschland, Shipping From GermanyDokumen2 halamanDfrobot Wireless Programming Module For Arduino: Versand Aus Deutschland, Shipping From Germanysvic11Belum ada peringkat

- Instructor Materials Chapter 2: Configure A Network Operating SystemDokumen19 halamanInstructor Materials Chapter 2: Configure A Network Operating SystemkaidiamarBelum ada peringkat

- Publicat Pe 5 Iul. 2016 Abonat (Ă) 21 K: EnglishenglezaDokumen2 halamanPublicat Pe 5 Iul. 2016 Abonat (Ă) 21 K: Englishenglezasvic11Belum ada peringkat

- Zigbee CommunicationDokumen4 halamanZigbee Communicationsvic11Belum ada peringkat

- UJF-3042HG - 6042 Replacement Page of Mechanical Drawing D500722 Ver.2.10ADokumen1 halamanUJF-3042HG - 6042 Replacement Page of Mechanical Drawing D500722 Ver.2.10Asvic11Belum ada peringkat

- Mimaki JV33-160A Printer: Ink Change GuideDokumen2 halamanMimaki JV33-160A Printer: Ink Change Guidesvic11Belum ada peringkat

- NetworkStartupGuide D202526-10NetworkStartupGuide D202526-10Dokumen44 halamanNetworkStartupGuide D202526-10NetworkStartupGuide D202526-10Manuel GarcianoBelum ada peringkat

- Opti MikDokumen94 halamanOpti Miksvic11Belum ada peringkat

- Summa 620Dokumen64 halamanSumma 620svic11100% (1)

- WebMin GuideDokumen315 halamanWebMin GuideshorvathBelum ada peringkat

- Arduino Nano Manual 23Dokumen5 halamanArduino Nano Manual 23Arthur de AbreuBelum ada peringkat

- Zigbee CommunicationDokumen4 halamanZigbee Communicationsvic11Belum ada peringkat

- WebMin GuideDokumen315 halamanWebMin GuideshorvathBelum ada peringkat

- WebMin GuideDokumen315 halamanWebMin GuideshorvathBelum ada peringkat

- 2008 Touring Bike GuideDokumen4 halaman2008 Touring Bike Guidesvic11Belum ada peringkat

- ICAO Abbreviations and Codes - 2007Dokumen74 halamanICAO Abbreviations and Codes - 2007svic11Belum ada peringkat

- Sea State CodeDokumen1 halamanSea State Codesvic11Belum ada peringkat

- SF026a-Flow Chart Portal Frame Apex ConnectionDokumen3 halamanSF026a-Flow Chart Portal Frame Apex ConnectiondvelchevBelum ada peringkat

- DrillingDokumen36 halamanDrillingMax LuxBelum ada peringkat

- Cepsa Fundicol Hfu: Lubricants For Industrial UseDokumen1 halamanCepsa Fundicol Hfu: Lubricants For Industrial UseVladislav TrempoletsBelum ada peringkat

- Astm B622Dokumen6 halamanAstm B622Ramón GarcíaBelum ada peringkat

- AISI S913-13 - SDokumen18 halamanAISI S913-13 - SEdison BecerraBelum ada peringkat

- Impact of Covid-19 On The Automotive Industry: By: Raman ATUL (19109029) RohitDokumen14 halamanImpact of Covid-19 On The Automotive Industry: By: Raman ATUL (19109029) RohitRaman BansalBelum ada peringkat

- FTIR Spectrometer AnalysisDokumen16 halamanFTIR Spectrometer AnalysisßraiñlĕsšȜĭnšteĭñBelum ada peringkat

- Disclaimer Document Supplier ListDokumen30 halamanDisclaimer Document Supplier ListAmin AzadBelum ada peringkat

- Datasheet IC L7107Dokumen16 halamanDatasheet IC L7107Michael HarveyBelum ada peringkat

- Technical Manual - EASICOOL - EZRE (Air Edale)Dokumen146 halamanTechnical Manual - EASICOOL - EZRE (Air Edale)Tong Hong LapBelum ada peringkat

- Report About: Classification of CompressorDokumen9 halamanReport About: Classification of Compressornabaz muhamadBelum ada peringkat

- 6063 Aluminium Alloy - WikipediaDokumen3 halaman6063 Aluminium Alloy - WikipediaNinad PawarBelum ada peringkat

- Welding Metallurgy and Weldability of Stainless SteelsDokumen6 halamanWelding Metallurgy and Weldability of Stainless SteelsoifhiudsnfBelum ada peringkat

- Product Data Sheet: Current Limiter, Tesys U / Tesys Gv2, 32A/690V, Activation 1ka, Iq 100Ka@440V, Din Rail MountingDokumen2 halamanProduct Data Sheet: Current Limiter, Tesys U / Tesys Gv2, 32A/690V, Activation 1ka, Iq 100Ka@440V, Din Rail MountingJorge MartinsBelum ada peringkat

- MyDokumen61 halamanMynvnrev0% (1)

- PTES Sample IR Scan ReportDokumen22 halamanPTES Sample IR Scan ReportAkshay GatkalBelum ada peringkat

- The Yuasa: Little Red ofDokumen19 halamanThe Yuasa: Little Red ofManjunatha RevanasiddappaBelum ada peringkat

- eCOMPRESSOR OIL PDFDokumen1 halamaneCOMPRESSOR OIL PDFKeshav Shrivastava KSBelum ada peringkat

- PET Resin Production and UsesDokumen13 halamanPET Resin Production and UsesA MahmoodBelum ada peringkat

- Venezuela Asfalto Modificado PDFDokumen12 halamanVenezuela Asfalto Modificado PDFkarenBelum ada peringkat

- Mini ProjectDokumen7 halamanMini ProjectSyakirin SpearsBelum ada peringkat

- 7.1 Cement MFG - R1617.1Dokumen22 halaman7.1 Cement MFG - R1617.1arsenic_94Belum ada peringkat

- Material Safety Data Sheet: Product Name: Mobil SHC Hydraulic Eal 68Dokumen11 halamanMaterial Safety Data Sheet: Product Name: Mobil SHC Hydraulic Eal 68Dheeraj Chowdary DhanekulaBelum ada peringkat

- Mil DTL 46027JDokumen23 halamanMil DTL 46027JmurphygtBelum ada peringkat

- Quiet Fan Heater FHW for Water Connection Offers Heating and VentilationDokumen20 halamanQuiet Fan Heater FHW for Water Connection Offers Heating and VentilationCrisTimBelum ada peringkat

- Ravi Sir DLC PresentationDokumen13 halamanRavi Sir DLC Presentationসৌগত রায় ঘটকBelum ada peringkat