Automatic coffee roaster with temperature control

Diunggah oleh

MohamadDanielBinYaacobDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Automatic coffee roaster with temperature control

Diunggah oleh

MohamadDanielBinYaacobHak Cipta:

Format Tersedia

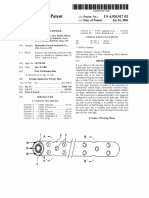

US 20080089986Al

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2008/0089986 A1

Song

(43) Pub. Date:

Apr. 17, 2008

(54)

COFFEE ROASTER AND CONTROLLING

METHOD OF SAME

Publication Classi?cation

(51)

Eugene Song, Seoul (KR)

(76) Inventor:

Correspondence Address:

FISH & ASSOCIATES, PC

(52)

ROBERT D. FISH

2603 Main Street, Suite 1050

(57)

Irvine, CA 92614-6232

Int. Cl.

A23N 12/12

A23F 5/04

A23N 12/08

(2006.01)

(2006.01)

(2006.01)

US. Cl. ........................... .. 426/466; 99/484; 99/486

ABSTRACT

Contemplated fully automated coiTee roaster have signi?

(21) Appl. No.:

11/608,025

cantly reduced energy demands, use electrical heat as a heat

source in a temperature-only driven program mode, and

(22) Filed:

Dec. 7, 2006

eliminate smoke and smell Within the roaster. Most prefer

ably, contemplated fully automated roasters Will consume

only about 10 percent of the energy as compared to known

(30)

Foreign Application Priority Data

devices on a per kilogram basis of beans and require no

Oct. 13, 2006

operator experience.

(KR) ...................... .. l0-2006-0099924

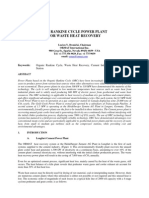

Temperature Control Processing Chart

Tsi Temp

Control bitterness

of Drum

ist Target

Drum Temp.

250 + a

.

Temp. of lnslde Drum

Preheotin9

Control body-?avour

[DTI]

_

2nd Temp

of Drum

[DT2]

250

roasting

'

Bean

3rd Temp.

(T2)

;: 1stBean

Temp

;2

(ll)

597m Color Select

2nd

Crack;2

[T3]

2nd Temp,

Tst

Load

Temp-

'

g o

Bean

Bean Temp. ;

I50

3rd

D11

Convert

Process

Time [Min_)

about B~l2

ETTaE

'

D72

Convert

Convert:

P

TZQ

9~l4

'

DT3

POW

Point

Crack I-

Crack

Green Beons

Classification

Automatic

Extin uisher

Setlln Tem.-3~ac _ _, -------- 235C

200

of Drum

(m3)

Stand-by

Preheating

3rd Temp

:

: SettinTem.-3~l5C I

T2u5

l0~l6

Dlschurgmg

roasted Beans

I

t

.

.

0 'Ist

2nd

3rd

water quenching

19 MAX I

Patent Application Publication

Apr. 17, 2008 Sheet 1 0f 18

Figure 1

US 2008/0089986 A1

Patent Application Publication

Apr. 17, 2008 Sheet 2 0f 18

Figure 2

US 2008/0089986 A1

Patent Application Publication

Apr. 17, 2008 Sheet 3 0f 18

Figure 3

US 2008/0089986 A1

Patent Application Publication

Apr. 17, 2008 Sheet 4 0f 18

Figure 4

US 2008/0089986 A1

Patent Application Publication

Apr. 17, 2008 Sheet 5 0f 18

Figure 5

US 2008/0089986 A1

Patent Application Publication

Apr. 17, 2008 Sheet 6 0f 18

Figure 6A

US 2008/0089986 A1

Patent Application Publication

Apr. 17, 2008 Sheet 7 0f 18

Figure 6B

US 2008/0089986 A1

Patent Application Publication

Apr. 17, 2008 Sheet 8 0f 18

US 2008/0089986 A1

Patent Application Publication

Apr. 17, 2008 Sheet 9 0f 18

Figure 8

Figure 9

US 2008/0089986 A1

Patent Application Publication

Apr. 17, 2008 Sheet 10 0f 18

Figure 10

Figure 11

US 2008/0089986 A1

Patent Application Publication

Apr. 17, 2008 Sheet 11 0f 18

Figure 12

US 2008/0089986 A1

Patent Application Publication

Apr. 17, 2008 Sheet 12 0f 18

Figure 13

x _ _ _ _ _ _ _ _ _ _ _ _ _ _.

v

\

\\

\\\\\\\\\\

\\

Figure 14

US 2008/0089986 A1

Patent Application Publication

Apr. 17, 2008 Sheet 13 0f 18

Eaamuing Emi. Pack

US 2008/0089986 A1

r.

saw menu

Diaplarymachim Ten-p. _

f

i;

Pl'edieiiting

._

I.

.Immm Rang; strtleadg v,

Start

Butttm

Figure 15

Buzzer.

Blinking Light I

Patent Application Publication

Apr. 17, 2008 Sheet 15 0f 18

US 2008/0089986 A1

"

I'?is'peiiv BlankIforM-anual um. 1;.

. .Fiiiin'the Blank

glnfmn'immt Start Ready 7 -

Hume!

Blinking Light

Dismay Emma!

Camam

Temp 4% Time

Fiqgast solm:

miin mil

t'lnuirt?cpwnl

a

n-

51mm

.9

ieiett Diagram} (K

LP

Figure 17

J'

Patent Application Publication

Apr. 17, 2008 Sheet 16 0f 18

~.

US 2008/0089986 A1

no

'

The temimatue

(1r 1M1 LQWTE}

3". which aimed

"3.

5241321v

Dmiwing?m farm:

?filmide Ilium

*1

I?

SUEI WMQLW

'

'

Water-Quenching

Figure 18

Patent Application Publication

Apr. 17, 2008 Sheet 18 0f 18

US 2008/0089986 A1

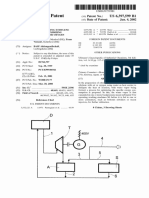

<CuScreen

Screen, 'louch Screen>

I

a

.u

Y

.w

r...

a

s

Module

for S eri at

LCD

<RS232 Scanner>

1.2.

Driving

Barcode Scanning

Unit

<MAX232>

r

*m"a

Chip of Signal

Converters

<Eepron1>

(LTRX Xport>

Memory saving unit

Web Associated

Support Unit

SSR

Control

C onverter

nit

Ampli ?e r

vileum-wing

Components

Heater, Smoke

Heater, Control Motor

Filter, Door, Cooling

Unit Etc

<PT1OO Thermal Sensor)

Figure 20

<Electric

Current Te sting

Sensor>

Apr. 17, 2008

US 2008/0089986 A1

COFFEE ROASTER AND CONTROLLING

METHOD OF SAME

[0007] Therefore, there is still a need to provide improved

colfee roasting devices that Will alloW fully automated

operation by an inexperienced user or even novice at sig

ni?cantly reduced poWer consumption.

[0001] This application claims priority to the Korean

national patent application With the serial number 10-2006

0099924, Which Was ?led Oct. 13, 2006.

FIELD OF THE INVENTION

[0002]

This invention relates to a coffee roaster and con

trolling methods of same, particularly, to a coffee roaster for

SUMMARY OF THE INVENTION

[0008]

It is, therefore, an object of the present invention to

provide a coffee roaster Which can e?iciently roast coffee

beans by using an electrical heater With very small poWer

consumption and eliminate smoke and smell generated When

roasting coffee beans, Whereby everyone can easily roast

economiZing in electric poWer only by using electrical heat

coffee beans in the optimum state While maintaining com

as a heat source When roasting coffee beans, eliminating

fortable circumstances in a room.

smoke by burning the smoke generated When roasting coffee

computer of a control unit so that inexperienced users can

[0009] It is another object of the present invention to

provide a coffee roaster Which is provided With an equip

ment for removing the smell and cooling the green beans

instead of a separate large-siZed equipment so as to be

installed at any places and circumstances, and Which is

provided as a poWer saving automatic machine like home

easily roast coffee beans to an optimum state.

electronics so that everyone can easily use it.

beans Within the device itself and eliminating smell gener

ated When roasting coffee beans, and a method of controlling

the same, in Which an optimal method for roasting coffee

beans is selected in advance and then preset in a micro

BACKGROUND OF THE INVENTION

[0003] In general, When using electric poWer as a heat

source for roasting coffee beans, the heat source for roasting

1 kg of coffee beans needs 14 to 20 KW. Thus, if the Weight

of coffee beans to be roasted is 1 kg or more, gas heating (for

example, propane gas and LNG gas) is almost alWays used.

HoWever, gas heating typically requires an expert to pre

[0010] It is yet another object of the present invention to

provide a coffee roaster Which is made smaller for saving

electricity, in Which an electric heater is appropriately dis

posed so as to be capable of removing the smoke and

providing the additional heating, and in Which an open air

coil heater, a ceramic heater and sheath heater are disposed

at the outside of a rotating drum, and in Which a halogen

dictably roast coffee beans to an predetermined degree.

lamp heater for directly transferring heat to the beans is

installed Within the drum to increase thermal e?iciency.

[0011] It is yet another object of the present invention to

[0004]

provide a coffee roaster in Which a curved re?ector is

Further, an important knoW-hoW for roasting coffee

beans is to ?nd certain points When a ?rst crack sound is

installed at the upper side of the halogen lamp heater to

generated upon applying the heat to green beans, Wherein

the ?rst crack sound is failed by reducing the heat after a

protect the halogen lamp heater and to re?ect light doWn

While, and When the heat is further reduced after a second

crack sound is generated again so that the beans have a

desired color.

[0005] As described above, since the technique of roasting

coffee beans is largely depended upon the experts experi

ence and skill to ?nd the points of the ?rst, second, and third

crack sounds and requires increasing or reducing the heat

Wardly.

[0012]

It is yet another object of the present invention to

provide a coffee roaster provided With a multi-step smoke

eliminator assembly in Which a coil heater is Wound up in a

spiral shape Within a ceramic base through Which smoke

generated in the rotating drum is smoothly guided and then

completely burned at high temperature (about 700~l000o

C.) While passing along the heat coil.

While observing and heating the roasted coffee beans, it

[0013]

generally very dif?cult, if not even impossible for an inex

perienced user to predictably and reliably roast coffee beans

to a desired state. Even though neW machines for roasting

provide a coffee roaster in Which Water is injected into the

rotating drum so that steam is generated by the heat of the

coffee beans using hot air have been developed, resulting

roasted coffee is often not satisfactory for the general public.

Thus, the coffee roasting industry largely relies on expert

roasters.

[0006]

Further, When roasting the coffee beans, a consid

erable amount of smoke is generated, Which is in heretofore

knoWn devices typically discharged to the outside by install

ing a smoke pipe, or eliminated by installing a large smoke

collector (often 5 to 6 times larger as the roasting machine)

above the device in combination With an after-bumer for

burning the smoke collected in a smoke reserve tank (Which

is also six or more times as large as the roasting machine).

Therefore, a very large space is required to roast coffee

beans using heretofore knoWn devices. Moreover, a smoke

It is yet another object of the present invention to

rotating drum and the roasted beans, and the smoke is

pushed out by the steam and then completely removed by a

smoke eliminator and a deodoriZer (typically activated char

coal ?lter).

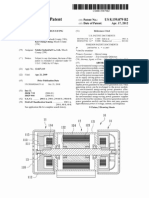

[0014] In order to accomplish these and other objects, a

coffee roaster according to the present invention comprises

a casing of a coffee roaster assembly; a rotating drum Which

is installed in the casing to roast beans; a drum shield for

surrounding an outer surface of the rotating drum; heating

elements, including a halogen lamp heater Which is installed

in the rotating drum to heat the rotating drum and beans, an

roasting operations, even When roasting a small amount

open air coil heater assembly Which is installed at an upper

part of the drum shield and a ceramic heater and a sheath

heater Which are respectively installed at the sides of the

drum shield; a ?rst sensor for bean temperature Which is

disposed at an inside of the rotating drum to measure a

temperature of the beans; a second sensor for drum tem

perature Which measures an inner temperature of the rotating

drum; a memory element for storing data values of tem

(several kilogram) of coffee beans.

peratures of the beans and the rotating drum, Which are

pipe is often essential to discharge the burned gas placing

further restriction to general use. Consequently, coffee bean

roasting is generally performed only in factories or smaller

Anda mungkin juga menyukai

- 10 Electricity Generation and CogenerationDokumen34 halaman10 Electricity Generation and CogenerationCristhian Garcia VillarroelBelum ada peringkat

- Double-Pipe Heat Exchanger ProjectionsDokumen10 halamanDouble-Pipe Heat Exchanger Projectionslambang wicaksonoBelum ada peringkat

- Microgeneration: Low energy strategies for larger buildingsDari EverandMicrogeneration: Low energy strategies for larger buildingsBelum ada peringkat

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersDari EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersBelum ada peringkat

- Styrene (Recovered)Dokumen7 halamanStyrene (Recovered)Mario VensfiseCrewBelum ada peringkat

- Gicc Us8631660Dokumen9 halamanGicc Us8631660Ricardo RamsesBelum ada peringkat

- Absorption Future PDFDokumen12 halamanAbsorption Future PDFVaidyanathan KS100% (1)

- Ethy Acetate Production US20140012037A1Dokumen41 halamanEthy Acetate Production US20140012037A1sariBelum ada peringkat

- United States Patent (10) Patent No.: US 6,397,599 B1: Theis Et Al. (45) Date of Patent: Jun. 4, 2002Dokumen6 halamanUnited States Patent (10) Patent No.: US 6,397,599 B1: Theis Et Al. (45) Date of Patent: Jun. 4, 2002Refi RahmanBelum ada peringkat

- Super Critical PresentationDokumen46 halamanSuper Critical PresentationSam100% (1)

- The Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattDari EverandThe Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattBelum ada peringkat

- Report On Steam Power PlantDokumen5 halamanReport On Steam Power PlantBabbu Mehra100% (1)

- United States Patent: SioliDokumen15 halamanUnited States Patent: SioliFebrian MermaliandiBelum ada peringkat

- Ulllted States Patent (10) Patent N0.: US 8,159,079 B2Dokumen9 halamanUlllted States Patent (10) Patent N0.: US 8,159,079 B2Victor Von DoomBelum ada peringkat

- BioEnergy VKKDokumen24 halamanBioEnergy VKKdane05Belum ada peringkat

- United States Patent: Megy Patent No.: Date of Patent: May 27, 2008Dokumen17 halamanUnited States Patent: Megy Patent No.: Date of Patent: May 27, 2008Bernie_Garcia__9886Belum ada peringkat

- Charcoal Stove ThesisDokumen5 halamanCharcoal Stove ThesisWriteMyBusinessPaperUK100% (1)

- FCC Baton Rouge Refinery Heat Exchangers and Columns SpecsDokumen8 halamanFCC Baton Rouge Refinery Heat Exchangers and Columns SpecsAlexBelum ada peringkat

- Ulllted States Patent (10) Patent N0.: US 7,935,254 B2Dokumen6 halamanUlllted States Patent (10) Patent N0.: US 7,935,254 B2Dejan CekovskiBelum ada peringkat

- Us4716822 PDFDokumen10 halamanUs4716822 PDFpertmasterBelum ada peringkat

- US4232179Dokumen10 halamanUS423217931415Belum ada peringkat

- Art 3Dokumen7 halamanArt 3Adel KlkBelum ada peringkat

- Ormat Technologies Inc. - Ormat Energy Converters Proven Power From Cement Plant Waste Heat - 2013-05-09Dokumen7 halamanOrmat Technologies Inc. - Ormat Energy Converters Proven Power From Cement Plant Waste Heat - 2013-05-09Kiran VeerubhotlaBelum ada peringkat

- Uni AssignmentDokumen10 halamanUni AssignmentIt's MaharBelum ada peringkat

- YS150 Thermic CalculationsDokumen1 halamanYS150 Thermic CalculationsAmanda HansenBelum ada peringkat

- Waste Heat Recovery Power Plant - Cement PlantDokumen7 halamanWaste Heat Recovery Power Plant - Cement PlantknsaravanaBelum ada peringkat

- Organic Rankine Cycle Power PlantDokumen6 halamanOrganic Rankine Cycle Power PlantPower PowerBelum ada peringkat

- Kota Thermal Power Plant Report in Standered FormDokumen45 halamanKota Thermal Power Plant Report in Standered FormAbhishek Meena100% (2)

- Aquatec Bro 2Dokumen4 halamanAquatec Bro 2Thinh Pham VanBelum ada peringkat

- ORC Working Fluids Comparison ECOS PresentationDokumen16 halamanORC Working Fluids Comparison ECOS Presentationoverlord5555Belum ada peringkat

- Report of Electrical Wiring: Submitted To: Sir Urooj Uz ZafarDokumen21 halamanReport of Electrical Wiring: Submitted To: Sir Urooj Uz Zafarshrawan0908Belum ada peringkat

- Recovery Boiler Plant with Flue Gases Travelling in Two DirectionsDokumen8 halamanRecovery Boiler Plant with Flue Gases Travelling in Two DirectionspsychopassBelum ada peringkat

- T-MEET416FW GasTurbine PowerPlant Es MEE41Dokumen14 halamanT-MEET416FW GasTurbine PowerPlant Es MEE41Christian EscoberBelum ada peringkat

- ICES CM 2007/M:07 Design Concept For Low Energy Fishing VesselDokumen8 halamanICES CM 2007/M:07 Design Concept For Low Energy Fishing VesselSaatnya TersenyumBelum ada peringkat

- ORC Technology For Waste Heat Recovery Power Generation: DR Vijayakumar Kunche, M.Tech., PH.DDokumen45 halamanORC Technology For Waste Heat Recovery Power Generation: DR Vijayakumar Kunche, M.Tech., PH.Dandri.motoGBelum ada peringkat

- Cogen17 CDokumen2 halamanCogen17 CppfahdBelum ada peringkat

- Wienese 2001 Boilers and EfficiencyDokumen7 halamanWienese 2001 Boilers and EfficiencyjhkdhcvghBelum ada peringkat

- 1981 - Addison - Large Falling Film EvaporatorsDokumen3 halaman1981 - Addison - Large Falling Film EvaporatorsshondabagueBelum ada peringkat

- Analysis and Perspective On Heat Pump For IndustriDokumen27 halamanAnalysis and Perspective On Heat Pump For IndustriJianping TangBelum ada peringkat

- APV Evaporation HandbookDokumen68 halamanAPV Evaporation HandbookМаксим ХилоBelum ada peringkat

- United States Patent (10) Patent No.: US 8,482,920 B2Dokumen14 halamanUnited States Patent (10) Patent No.: US 8,482,920 B2truva_kissBelum ada peringkat

- Advanced Fire-Tube Boiler ProjectDokumen10 halamanAdvanced Fire-Tube Boiler ProjectRonnieldBelum ada peringkat

- United States Patent: (10) Patent No.: US 7,910,784 B2Dokumen5 halamanUnited States Patent: (10) Patent No.: US 7,910,784 B2Chandra AdityaBelum ada peringkat

- Spilling Steam EnginesDokumen23 halamanSpilling Steam EnginesSimEnzBelum ada peringkat

- Revised DraftDokumen45 halamanRevised DraftEva LloydBelum ada peringkat

- CHAPTER 4: Vacuum Pan BoilersDokumen4 halamanCHAPTER 4: Vacuum Pan BoilersArunaBuddhikaKumbukageBelum ada peringkat

- Technologies For High Performance and Reliability of Geothermal Power PlantDokumen4 halamanTechnologies For High Performance and Reliability of Geothermal Power Plantsum1else4Belum ada peringkat

- Energy Audit RER ProjectDokumen14 halamanEnergy Audit RER ProjectHamza HamidBelum ada peringkat

- Low Temp Flash Steam Power Generation Can Be EconomicalDokumen3 halamanLow Temp Flash Steam Power Generation Can Be EconomicalBogdanPBelum ada peringkat

- Spec BoilerDokumen9 halamanSpec BoilerAchmad MakmuriBelum ada peringkat

- Us6210562 PDFDokumen8 halamanUs6210562 PDFSyuhadah NoordinBelum ada peringkat

- A Large-Capacity Pressurized-Fluidized-Bed-Combustion-Boiler Combined-Cycle Power PlantDokumen5 halamanA Large-Capacity Pressurized-Fluidized-Bed-Combustion-Boiler Combined-Cycle Power PlantDhanasekaran RBelum ada peringkat

- Boiler Feed ManualDokumen30 halamanBoiler Feed Manualingrbarros100% (1)

- Ormat Technologies Inc. - Organic Rankine Cycle Power Plant For Waste Heat Recovery - 2013-05-09Dokumen5 halamanOrmat Technologies Inc. - Organic Rankine Cycle Power Plant For Waste Heat Recovery - 2013-05-09Anonymous Cxriyx9HIX100% (1)

- May 2017 Final Exams TimetableDokumen9 halamanMay 2017 Final Exams TimetableMohamadDanielBinYaacobBelum ada peringkat

- Environmental Laws in Malaysia - Bukit Merah Case StudyDokumen65 halamanEnvironmental Laws in Malaysia - Bukit Merah Case StudyMohamadDanielBinYaacobBelum ada peringkat

- Pomegenate Research PosterDokumen1 halamanPomegenate Research PosterMohamadDanielBinYaacobBelum ada peringkat

- Chemical substances data sheetDokumen8 halamanChemical substances data sheetMohamadDanielBinYaacobBelum ada peringkat

- Academic Year 2016-2017 Undergraduate and Postgraduate ProgrammesDokumen1 halamanAcademic Year 2016-2017 Undergraduate and Postgraduate ProgrammesMohamadDanielBinYaacobBelum ada peringkat

- List of MEP Research Projects (2016-17)Dokumen29 halamanList of MEP Research Projects (2016-17)MohamadDanielBinYaacobBelum ada peringkat

- P.U. (A) 149 - Radiation Protection (Licensing) Regulation 1986Dokumen59 halamanP.U. (A) 149 - Radiation Protection (Licensing) Regulation 1986MohamadDanielBinYaacobBelum ada peringkat

- WBM2017 ProdDraft 11 4.2.17Dokumen11 halamanWBM2017 ProdDraft 11 4.2.17Pim Tournaye100% (1)

- Regulatory Issues and Challenges (For New Reactor)Dokumen20 halamanRegulatory Issues and Challenges (For New Reactor)MohamadDanielBinYaacobBelum ada peringkat

- Case Study - Ben and Jerry SPCDokumen2 halamanCase Study - Ben and Jerry SPCMohamadDanielBinYaacobBelum ada peringkat

- Research Project ProposalDokumen7 halamanResearch Project ProposalMohamadDanielBinYaacobBelum ada peringkat

- Future Direction and Challenges of Malaysian Rare Earth Industry As A Potential Green Economy EngineDokumen21 halamanFuture Direction and Challenges of Malaysian Rare Earth Industry As A Potential Green Economy EngineMohamadDanielBinYaacobBelum ada peringkat

- Environ Movement in MalaysiaDokumen24 halamanEnviron Movement in MalaysiaMohamadDanielBinYaacobBelum ada peringkat

- Research Rev A04Dokumen9 halamanResearch Rev A04MohamadDanielBinYaacobBelum ada peringkat

- Case Study - Nestle QC PDFDokumen8 halamanCase Study - Nestle QC PDFMohamadDanielBinYaacobBelum ada peringkat

- Roasting TerminologyDokumen8 halamanRoasting TerminologyMohamadDanielBinYaacobBelum ada peringkat

- YR01. Introductory GeologyDokumen38 halamanYR01. Introductory GeologyMohamadDanielBinYaacobBelum ada peringkat

- Env Isssues - Emission and SafetyDokumen10 halamanEnv Isssues - Emission and SafetyMohamadDanielBinYaacobBelum ada peringkat

- Cocoa Natural DistillatesDokumen27 halamanCocoa Natural DistillatesMohamadDanielBinYaacobBelum ada peringkat

- Future Direction and Challenges of Malaysian Rare Earth Industry As A Potential Green Economy EngineDokumen21 halamanFuture Direction and Challenges of Malaysian Rare Earth Industry As A Potential Green Economy EngineMohamadDanielBinYaacobBelum ada peringkat

- Draw Calendar (Sketch / Digital) : Jan / JulDokumen1 halamanDraw Calendar (Sketch / Digital) : Jan / JulMohamadDanielBinYaacobBelum ada peringkat

- Maxon Ovenpak 400 BroDokumen4 halamanMaxon Ovenpak 400 Bromaximus64Belum ada peringkat

- Reaction RatesDokumen1 halamanReaction RatesMohamadDanielBinYaacobBelum ada peringkat

- 3 PPM Cost Estimating GuideDokumen42 halaman3 PPM Cost Estimating GuideMohamadDanielBinYaacobBelum ada peringkat

- Cocoa Design Project BriefDokumen1 halamanCocoa Design Project BriefMohamadDanielBinYaacobBelum ada peringkat

- Flotation Control and OptimisationDokumen11 halamanFlotation Control and OptimisationAmalia PănescuBelum ada peringkat

- If You Can Come Along Earlier We'd Really Like Your Help in Setting Up For The Fair!Dokumen6 halamanIf You Can Come Along Earlier We'd Really Like Your Help in Setting Up For The Fair!MohamadDanielBinYaacobBelum ada peringkat

- Recommendation of Process Routes For The Production of PotashDokumen9 halamanRecommendation of Process Routes For The Production of PotashMohamadDanielBinYaacobBelum ada peringkat

- Unit 1 2marksDokumen5 halamanUnit 1 2marksLokesh SrmBelum ada peringkat

- Bernardo Corporation Statement of Financial Position As of Year 2019 AssetsDokumen3 halamanBernardo Corporation Statement of Financial Position As of Year 2019 AssetsJean Marie DelgadoBelum ada peringkat

- EDI810Dokumen11 halamanEDI810ramcheran2020Belum ada peringkat

- Department Order No 05-92Dokumen3 halamanDepartment Order No 05-92NinaBelum ada peringkat

- (Free Scores - Com) - Stumpf Werner Drive Blues en Mi Pour La Guitare 40562 PDFDokumen2 halaman(Free Scores - Com) - Stumpf Werner Drive Blues en Mi Pour La Guitare 40562 PDFAntonio FresiBelum ada peringkat

- RTL8316C GR RealtekDokumen93 halamanRTL8316C GR RealtekMaugrys CastilloBelum ada peringkat

- APM Terminals Safety Policy SummaryDokumen1 halamanAPM Terminals Safety Policy SummaryVaviBelum ada peringkat

- Model S-20 High Performance Pressure Transmitter For General Industrial ApplicationsDokumen15 halamanModel S-20 High Performance Pressure Transmitter For General Industrial ApplicationsIndra PutraBelum ada peringkat

- Portable dual-input thermometer with RS232 connectivityDokumen2 halamanPortable dual-input thermometer with RS232 connectivityTaha OpedBelum ada peringkat

- Laundry & Home Care: Key Financials 1Dokumen1 halamanLaundry & Home Care: Key Financials 1Catrinoiu PetreBelum ada peringkat

- ECON Value of The FirmDokumen4 halamanECON Value of The FirmDomsBelum ada peringkat

- ASME Y14.6-2001 (R2007), Screw Thread RepresentationDokumen27 halamanASME Y14.6-2001 (R2007), Screw Thread RepresentationDerekBelum ada peringkat

- Mapping Groundwater Recharge Potential Using GIS-Based Evidential Belief Function ModelDokumen31 halamanMapping Groundwater Recharge Potential Using GIS-Based Evidential Belief Function Modeljorge “the jordovo” davidBelum ada peringkat

- Overhead Door Closers and Hardware GuideDokumen2 halamanOverhead Door Closers and Hardware GuideAndrea Joyce AngelesBelum ada peringkat

- Information Pack For Indonesian Candidate 23.06.2023Dokumen6 halamanInformation Pack For Indonesian Candidate 23.06.2023Serevinna DewitaBelum ada peringkat

- Geneva IntrotoBankDebt172Dokumen66 halamanGeneva IntrotoBankDebt172satishlad1288Belum ada peringkat

- Arizona Supreme CT Order Dismisses Special ActionDokumen3 halamanArizona Supreme CT Order Dismisses Special Actionpaul weichBelum ada peringkat

- Mayor Byron Brown's 2019 State of The City SpeechDokumen19 halamanMayor Byron Brown's 2019 State of The City SpeechMichael McAndrewBelum ada peringkat

- Okuma Osp5000Dokumen2 halamanOkuma Osp5000Zoran VujadinovicBelum ada peringkat

- Single Wall Fuel Tank: FP 2.7 A-C Fire Pump SystemsDokumen1 halamanSingle Wall Fuel Tank: FP 2.7 A-C Fire Pump Systemsricardo cardosoBelum ada peringkat

- BA 9000 - NIJ CTP Body Armor Quality Management System RequirementsDokumen6 halamanBA 9000 - NIJ CTP Body Armor Quality Management System RequirementsAlberto GarciaBelum ada peringkat

- New Installation Procedures - 2Dokumen156 halamanNew Installation Procedures - 2w00kkk100% (2)

- Peter Wilkinson CV 1Dokumen3 halamanPeter Wilkinson CV 1larry3108Belum ada peringkat

- Instrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1ZDokumen24 halamanInstrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1Zmicmarley2012Belum ada peringkat

- Globalisation - Theories of Digital CommunicationDokumen12 halamanGlobalisation - Theories of Digital CommunicationDiya Patel-10SBelum ada peringkat

- Top Brand Story Bar Supervisor Jobs Chennai Apply Now Latest Fresher Experienced Bar Supervisor Jobs in Various Location July 18 2021Dokumen1 halamanTop Brand Story Bar Supervisor Jobs Chennai Apply Now Latest Fresher Experienced Bar Supervisor Jobs in Various Location July 18 2021Surya JamesBelum ada peringkat

- Open Compute Project AMD Motherboard Roadrunner 2.1 PDFDokumen36 halamanOpen Compute Project AMD Motherboard Roadrunner 2.1 PDFakok22Belum ada peringkat

- De Thi Chuyen Hai Duong 2014 2015 Tieng AnhDokumen4 halamanDe Thi Chuyen Hai Duong 2014 2015 Tieng AnhHuong NguyenBelum ada peringkat

- CASE DigeSTDokumen2 halamanCASE DigeSTZepht BadillaBelum ada peringkat

- As 1769-1975 Welded Stainless Steel Tubes For Plumbing ApplicationsDokumen6 halamanAs 1769-1975 Welded Stainless Steel Tubes For Plumbing ApplicationsSAI Global - APACBelum ada peringkat