WS36-01 DPPS

Diunggah oleh

Garcia C L AlbertoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

WS36-01 DPPS

Diunggah oleh

Garcia C L AlbertoHak Cipta:

Format Tersedia

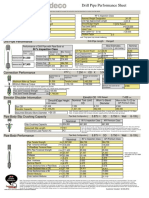

Drill Pipe Performance Sheet

Asset Number: WS36-01

Pipe Body:

Tubular Assembly:

Nominal

100% RBW

95% RBW

Ultra Class

90% RBW

Premium

80% RBW

2.875

0.362

2.151

2.839

0.344

2.151

2.803

0.326

2.151

2.730

0.290

2.151

Tensile Strength (lbs):

Torsional Strength (ft-lbs):

385,820

20,798

363,889

19,547

342,236

18,321

299,763

15,945

Burst Capacity (psi):

Collapse Capacity (psi):

29,747

29,716

32,297

28,746

30,597

27,739

27,197

25,602

OD (in):

Wall Thickness (in):

Nominal ID (in):

Size and Weight: 2.875'' 10.40 ppf 0.362'' wall EU

Grade: S-135

Range: 2

Tool Joint: 3.875'' x 2.156'' 2 7/8" AOH

Adjusted Weight (lbs/ft): 11.29

Approximate Length (ft): 31.3

Box TJ Length (in): 11

Pin TJ Length (in): 9

Upset Type: EU

Max Upset OD (in): 3.188

Drift Size (in): 2.031

Fluid Displacement (gal/ft): 0.17

Fluid Displacement (bblsl/ft): 0.0041

Fluid Capacity w/IPC (gal/ft): 0.18

Fluid Capacity w/IPC (bbls/ft): 0.0043

Fluid Capacity w/o IPC (gal/ft): 0.18

Fluid Capacity w/o IPC (bbls/ft): 0.0043

18

0

Notes: Body properties are calculated based on uniform OD and wall thickness.

Burst capacity for Nominal (100% RBW) based on 87.5% RBW per API.

Note: These are OEM values that may vary with actual values due to mill tolerances, IPC tolerances, OEM rounding, and other

factors. Pipe is purchased at a guaranteed 95% RBW. IPC is applied to a nominal thickness of 0.009''. Pipe will have an ID of

2.093'', which is smaller than pipe purchased at 87.5%.

Connection: 2 7/8" AOH

Elevator Shoulder:

TJ OD (in): 3.875

TJ ID (in): 2.156

MYS (ksi): 120

Maximum MUT (ft-lbs):

Tension at Shoulder Separation @ Max MUT (lbs):

Tension at Connection Yield @ Max MUT (lbs):

5,200

Tensile Limited

325,700

Minimum MUT (ft-lbs):

Tension at Shoulder Separation @ Min MUT (lbs):

Tension at Connection Yield @ Min MUT (lbs):

4,300

285,300

337,000

Smooth Edge Height (in): N/A

Smooth Edge OD (in): N/A

SE Elevator Shoulder Capacity (lbs): N/A

Nominal TJ OD (in): 3.875

Nominal TJ OD Elevator Shoulder Capacity (lbs): 367,400

Assumed Elevator Bore (in): 3.281

N/A

N/A

Tool Joint Torsional Strength (ft-lbs): 8,700

Tool Joint Tensile Strength (lbs): 337,000

Note: MUT values are based on a friction factor of 1.0. There is no published pressure rating for this connection.

Note: Elevator capacity based on assumed elevator bore, no wear factor, and contact stress of 110, 100 psi. An increased

elevator shoulder OD increases elevator capacity without affecting make-up torque.

The technical information containted herein, including the product performance sheet and other attached documents, has been extracted from information available from the manufacturer and is for reference only and not a recommendation. The user is fully responsible for the accuracy and suitability of use of the technical

information. Workstrings International cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various

inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operation limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices,

and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.workstringsinternational.com

Download the Workstrings International Pipe Specification App on the App Store or Google Play

09-Sep-15

Operational Limits of Drill Pipe

Connection

Pipe Body

2-7/8 AOH (2-7/8 OH)

80 % Inspection Class

Tool Joint OD

(in)

3.875

Tool Joint ID

Pipe Body OD

(in)

2.875

Wall Thickness (in) 0.362

(in)

Combined Loading for Drill Pipe at

Maximum Make-up Torque = 5,200

Operational Assembly

Torque

Max Tension

0

300

500

800

1,000

1,300

1,600

1,800

2,100

2,400

2,600

2,900

3,100

3,400

3,700

3,900

4,200

4,400

4,700

5,000

299,800

299,700

299,600

299,400

299,200

298,800

298,300

297,800

297,200

296,300

295,800

294,800

294,000

292,900

291,600

290,700

289,200

288,100

286,400

284,800

Operationa Assembly

l Torque

Max Tension

(ft-lbs)

(lbs)

(ft-lbs)

Connection

Pipe Body

Max Tension Max Tension

(lbs)

(lbs)

(lbs)

299,800

325,700

285,300

299,800

285,300

299,700

325,700

200

285,300

299,700

285,300

299,600

325,700

400

285,300

299,700

285,300

299,400

325,700

600

285,300

299,600

285,300

299,200

325,700

900

285,300

299,300

285,300

285,300

299,000

285,300

285,300

298,800

285,300

285,300

298,400

285,300

285,300

298,100

285,300

285,300

297,600

285,300

285,300

298,800

298,300

297,800

297,200

296,300

295,800

294,800

294,000

292,900

291,600

290,700

289,200

288,100

286,400

284,800

S-135

Minimum Make-up Torque = 4,300

(ft-lbs)

(lbs)

Pipe Body Grade

Combined Loading for Drill Pipe at

Connection Max

Pipe Body

Max Tension Tension

(lbs)

(ft-lbs)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

2.156

1,100

325,700

1,300

325,700

1,500

325,700

1,700

325,700

1,900

325,700

325,700

2,100

285,300

297,200

325,700

2,400

285,300

296,300

285,300

325,700

2,600

285,300

295,800

285,300

325,700

2,800

285,300

295,100

285,300

325,700

3,000

285,300

294,400

285,300

325,700

3,200

285,300

293,700

285,300

325,700

3,400

285,300

292,900

285,300

325,700

3,600

285,300

292,000

285,300

325,700

3,900

285,300

290,700

285,300

325,700

4,100

285,300

289,800

285,300

Operational drilling torque is limited by the Make-up Torque.

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Max MUT

4,300

4,400

4,500

4,600

4,700

4,800

4,900

5,000

5,100

5,200

Connection Max

Tension

(lbs)

285,300

292,000

298,600

305,200

311,900

318,500

325,200

331,800

335,000

325,600

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

06-18-2015

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Drill Pipe Performance SheetDokumen3 halamanDrill Pipe Performance Sheetjinyuan74Belum ada peringkat

- Drill Pipe Performance SheetDokumen3 halamanDrill Pipe Performance Sheetjinyuan74Belum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Drill Pipe Performance SheetDokumen3 halamanDrill Pipe Performance SheetGarcia C L AlbertoBelum ada peringkat

- Drill Pipe Performance SheetDokumen3 halamanDrill Pipe Performance SheetGarcia C L AlbertoBelum ada peringkat

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDokumen3 halamanDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDokumen3 halamanDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Dokumen3 halamanDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoBelum ada peringkat

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Dokumen3 halamanDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoBelum ada peringkat

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Dokumen3 halamanDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoBelum ada peringkat

- Book Notes Covering: Andy Kirk's Book, Data Visualization - A Successful Design ProcessDokumen10 halamanBook Notes Covering: Andy Kirk's Book, Data Visualization - A Successful Design ProcessDataVersed100% (1)

- Cosare V BroadcomDokumen2 halamanCosare V BroadcomapbueraBelum ada peringkat

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokumen2 halamanPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoBelum ada peringkat

- 5 7/8" 23.4 PPF S135 Pipe SpecsDokumen2 halaman5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoBelum ada peringkat

- DPPS PDFDokumen2 halamanDPPS PDFStowartBelum ada peringkat

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokumen1 halamanPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoBelum ada peringkat

- DPPSDokumen2 halamanDPPSGarcia C L AlbertoBelum ada peringkat

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokumen2 halamanPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoBelum ada peringkat

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Dokumen3 halamanDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaBelum ada peringkat

- WS36-01 DPPSDokumen2 halamanWS36-01 DPPSGarcia C L AlbertoBelum ada peringkat

- 5 7/8" 23.4 PPF S135 Pipe SpecsDokumen2 halaman5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoBelum ada peringkat

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Dokumen3 halamanDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaBelum ada peringkat

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokumen2 halamanPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoBelum ada peringkat

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Dokumen3 halamanDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaBelum ada peringkat

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Dokumen3 halamanDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaBelum ada peringkat

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Dokumen3 halamanDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaBelum ada peringkat

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDokumen3 halaman3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDokumen3 halaman3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Dokumen3 halamanDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaBelum ada peringkat

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Dokumen3 halamanDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaBelum ada peringkat

- 3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BDokumen3 halaman3.5 In. 15.50# EU S-135 R2 XT39 (5.125 X 2.4375) - 10P.15BGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Dokumen3 halamanDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Garcia C L AlbertoBelum ada peringkat

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Dokumen3 halamanDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaBelum ada peringkat

- VKC Group of Companies Industry ProfileDokumen5 halamanVKC Group of Companies Industry ProfilePavithraPramodBelum ada peringkat

- 2023-2024 Draft Benzie County Budget BookDokumen91 halaman2023-2024 Draft Benzie County Budget BookColin MerryBelum ada peringkat

- Inductive Grammar Chart (Unit 2, Page 16)Dokumen2 halamanInductive Grammar Chart (Unit 2, Page 16)Michael ZavalaBelum ada peringkat

- E Rpms Portfolio Design 3 1Dokumen52 halamanE Rpms Portfolio Design 3 1jebBelum ada peringkat

- Mitsubishi Forklift Fg30nm Service ManualDokumen22 halamanMitsubishi Forklift Fg30nm Service Manualbridgetsilva030690rqd100% (130)

- All About Ignition Coils: Technical InformationDokumen15 halamanAll About Ignition Coils: Technical InformationTrương Ngọc ThắngBelum ada peringkat

- Energia Eolica Nordex N90 2500 enDokumen20 halamanEnergia Eolica Nordex N90 2500 enNardo Antonio Llanos MatusBelum ada peringkat

- MIami Beach City Attorney's DenialDokumen7 halamanMIami Beach City Attorney's DenialDavid Arthur WaltersBelum ada peringkat

- Student Application Form BCIS - 2077Dokumen2 halamanStudent Application Form BCIS - 2077Raaz Key Run ChhatkuliBelum ada peringkat

- Joseph J. Fiumara v. Fireman's Fund Insurance Companies, 746 F.2d 87, 1st Cir. (1984)Dokumen7 halamanJoseph J. Fiumara v. Fireman's Fund Insurance Companies, 746 F.2d 87, 1st Cir. (1984)Scribd Government DocsBelum ada peringkat

- Subsistence and Travel FormsDokumen3 halamanSubsistence and Travel FormsAnonymous YRLhQY6G6jBelum ada peringkat

- System Requirements For Autodesk Revit 2018 ProductsDokumen8 halamanSystem Requirements For Autodesk Revit 2018 ProductsDaryobmsBelum ada peringkat

- Analysis and Design of Foundation of ROB at LC-9 Between Naroda and Dabhoda Station On Ahmedabad-Himmatnagar RoadDokumen10 halamanAnalysis and Design of Foundation of ROB at LC-9 Between Naroda and Dabhoda Station On Ahmedabad-Himmatnagar RoadmahakBelum ada peringkat

- 1.reasons For VariationsDokumen2 halaman1.reasons For Variationsscribd99190Belum ada peringkat

- Traffic Speed StudyDokumen55 halamanTraffic Speed StudyAnika Tabassum SarkarBelum ada peringkat

- Scout Activities On The Indian Railways - Original Order: MC No. SubjectDokumen4 halamanScout Activities On The Indian Railways - Original Order: MC No. SubjectVikasvijay SinghBelum ada peringkat

- Road To Recovery: Moving To A New NormalDokumen10 halamanRoad To Recovery: Moving To A New NormalFOX5 VegasBelum ada peringkat

- Non-Hazardous Areas Adjustable Pressure Switch: 6900P - Piston SensorDokumen2 halamanNon-Hazardous Areas Adjustable Pressure Switch: 6900P - Piston SensorDiana ArredondoBelum ada peringkat

- Statics: Vector Mechanics For EngineersDokumen25 halamanStatics: Vector Mechanics For EngineersProkopyo BalagbagBelum ada peringkat

- X606 PDFDokumen1 halamanX606 PDFDany OrioliBelum ada peringkat

- MGT 201 Midterm Exam, Version BDokumen8 halamanMGT 201 Midterm Exam, Version BCybelle TradBelum ada peringkat

- 032017Dokumen107 halaman032017Aditya MakwanaBelum ada peringkat

- IMS DB Interview Questions: Beginner LevelDokumen19 halamanIMS DB Interview Questions: Beginner LevelsudhakarcheedaraBelum ada peringkat

- Mobile Fire Extinguishers. Characteristics, Performance and Test MethodsDokumen28 halamanMobile Fire Extinguishers. Characteristics, Performance and Test MethodsSawita LertsupochavanichBelum ada peringkat

- Eastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateDokumen6 halamanEastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateTasheen MahabubBelum ada peringkat

- Psychological Attitude Towards SafetyDokumen17 halamanPsychological Attitude Towards SafetyAMOL RASTOGI 19BCM0012Belum ada peringkat

- Helsingborg EngDokumen8 halamanHelsingborg EngMassaCoBelum ada peringkat

- T53 L 13 Turboshaft EngineDokumen2 halamanT53 L 13 Turboshaft EngineEagle1968Belum ada peringkat