QuickMount Dresser - 001-474

Diunggah oleh

Kar Gayee0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

51 tayangan3 halamanQuickMount Dresser

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniQuickMount Dresser

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

51 tayangan3 halamanQuickMount Dresser - 001-474

Diunggah oleh

Kar GayeeQuickMount Dresser

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 3

INSTRUCTIONS

QuickMount Dresser

FEED KNOB

#001-722

QuickMount

Dresser

FOR #001-724 QUICKMOUNT BASE

The QuickMount Wheel Dresser is

manufactured by Glendo for fast and accurate

front dressing of conventional vitrified grinding

wheels on bench grinders equipped with the

Glendo QuickMount system. YOU MUST USE

THIS QUICKMOUNT WHEEL DRESSER

WITH A QUICKMOUNT BASE.

USE ON STONE

(VITRIFIED)

WHEELS ONLY

DIAMOND

POINT

REPLACEMENT

#001-436

Mounting and Using the

QuickMount Wheel Dresser

NOTE: The QuickMount Base does NOT come

with the #001-722 Wheel Dresser. This base

comes with the Grind-R-Table. If you dont

have the required base(s), you MUST order

them separately using part # 001-724. Follow

instructions (#001-462) to install the base.

Once you have the necessary base(s) installed,

you are ready to use the Wheel Dresser.

First, make sure your grinder is OFF and

the wheel has STOPPED.

Now, retract the diamond point by turning the

feed knob counterclockwise, so it wont interfere

with the grinder wheel. Insert the locking shaft

into the front threaded hole. (NOTE: There are two

threaded holes for the locking shaft. Use the front

one until the grinding wheel wears to small for the

diamond point feed screw adjustment. Then

retract the diamond and switch the locking shaft to

the rear hole.) Set the Wheel Dresser down over

the QuickMount Base making sure the locking

shaft slides fully down into the machined slot in

the base. Make sure that the Wheel Dresser is

pushed down completely over the QuickMount

Base with the bottom of the Wheel Dresser even

with the bottom of the base. The diamond point

should NOT contact the grinding wheel yet.

Tighten the locking shaft firmly with a wrench.

LOCKING

SHAFT

QUICKMOUNT BASE

(NOT INCLUDED)

#001-724

The dresser works by sweeping the

mounted diamond point across the grinding

wheel face. Before you turn the grinder on,

check to make sure the diamond is

retracted far enough to clear the grinding

wheel. Now, turn the grinder on and let it

reach running speed. While holding the top

handle securely, advance the diamond feed

screw until it barely contacts the face of the

wheel. Next, hold the dresser to the left so

it clears the wheel and advance the

diamond about .010" (approx. 1/4 of a

turn). Now dress the wheel by smoothly

sweeping the diamond across the grinding

wheel face. It is important to sweep across

the wheel at the proper rate. Too fast

produces a rough finish and too slow clogs

the wheel which causes the tool to burn

during sharpening. Start with a 1 to 2

second sweep across a 3/4" wheel.

#001-474

TIPS FOR GOOD DRESSING

Try to dress in one sweep across the wheel

and retract the diamond so it doesnt drag across

the wheel when you return the dresser to its left

position. Dont try to dress too much in one sweep.

If the wheel is in especially poor shape, use

several .010" (approx. 1/4 of a turn) passes to true

it. A slow sweep will dress finer for better grinding

finishes but the wheel will cut slower with more

heat. Fast sweeping gives an open, aggressive

wheel surface for fast, cool cutting at the cost of a

rougher finish. Smoothness counts. A little practice

will make you a PRO.

A worn diamond that is too blunt can clog the

wheel and should be replaced with a new one

(Part # 001-436). A premium quality grinding wheel

can make a huge difference in tool grinding. Dont

skimp on the wheel, it does the work! After

dressing, carefully wipe the loose grit from your

grinder and attachments. Grit is the enemy of

shop equipment. Keep tools and sharpening

attachments away from the grinder or covered

while dressing your wheel.

Proper front wheel dressing can sometimes

improve the balance of the grinding wheels but

NOT in ALL cases. There are several ways to

improve wheel mounting and balance on bench

grinders. Be sure the large wheel-retaining flange

washers are true and deburred. If the arbor hole

in the wheel is big and sloppy, you may need to

shim for good concentricity. Often, just repositing

the wheel (loosen - rotate and tighten) can make

a difference. Some wheels come from the factory

with hidden density variations which make proper

balance almost impossible. If you suspect this, get

a new wheel...in the end youll be ahead. A small

percentage of grinders have bent shafts. No wheel

will run properly on a bent shaft.

SEE TIPS AT

LEFT FOR

SWEEP

DETAILS

IMPORTANT:

SAFETY IS YOUR RESPONSIBILITY

WEAR SAFETY GLASSES. Always use the

safety guards. Observe and follow all safety

instructions that come with your grinder.

NEVER REMOVE, INSTALL, OR ADJUST

YOUR WHEEL DRESSER OR ANY

ATTACHMENTS UNTIL THE WHEEL HAS

STOPPED. Grinding wheels can break if

defective or abused - use them accordingly.

DIAMOND REPLACEMENT PART

#001-436

Mounted Diamond for

QuickMount Wheel Dresser

EXTRA BASE

#001-724

QuickMount Base

To Order Call: 1-800-835-3519

Glendo Corporation

900 Overlander Road

Emporia, KS 66801 USA

Fax: 620-343-9640 Tel: 620-343-1084

e-mail: glendo@glendo.com

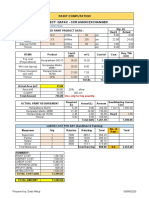

QuickMount Wheel Dresser #001-722

002-252

001-437

002-369

002-498

001-440

002-399

002-065

002-065 (6 required)

001-436

001-438

001-439

001-397

002-447

002-462 (2 required)

Anda mungkin juga menyukai

- MMPI-2 Validity and Clinical Scales ProfileDokumen6 halamanMMPI-2 Validity and Clinical Scales ProfileKar Gayee0% (5)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsDari EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsPenilaian: 5 dari 5 bintang5/5 (1)

- Military SociologyDokumen4 halamanMilitary SociologyJacobin Parcelle100% (2)

- The Electrical Engineering HandbookDokumen24 halamanThe Electrical Engineering HandbookKar GayeeBelum ada peringkat

- Steering and Wheel Alignment DiagnosisDokumen23 halamanSteering and Wheel Alignment DiagnosismohamedashrafsayedBelum ada peringkat

- Klingspor's Woodworking Shop Vol 122 Catalog.Dokumen92 halamanKlingspor's Woodworking Shop Vol 122 Catalog.Klingspor's Woodworking Shop100% (1)

- Shimano Brake ManualDokumen1 halamanShimano Brake ManualscozansBelum ada peringkat

- HoningDokumen4 halamanHoningmiso_mallard5123Belum ada peringkat

- The Dysfunctional Attitudes ScaleDokumen2 halamanThe Dysfunctional Attitudes ScaleKar GayeeBelum ada peringkat

- GRINDING MACHINE: A GUIDE TO GRINDING PROCESSES AND MACHINESDokumen54 halamanGRINDING MACHINE: A GUIDE TO GRINDING PROCESSES AND MACHINESravi upadhyay100% (4)

- Balancing Grinder WheelsDokumen8 halamanBalancing Grinder WheelsmountaineerjpBelum ada peringkat

- MMPI2RF Interpretive ReportDokumen10 halamanMMPI2RF Interpretive ReportKar GayeeBelum ada peringkat

- Grinding Wheel Safety Grinding Wheel Safety PDFDokumen6 halamanGrinding Wheel Safety Grinding Wheel Safety PDFWirote DewilaiBelum ada peringkat

- Clinical implications of Brief Psychiatric Rating Scale scoresDokumen7 halamanClinical implications of Brief Psychiatric Rating Scale scoresKar Gayee100% (1)

- Shimano MTB Rear Deraileur Dealer Manual PDFDokumen24 halamanShimano MTB Rear Deraileur Dealer Manual PDFJose Luis GutierrezBelum ada peringkat

- Boq - Paint CalculationDokumen8 halamanBoq - Paint CalculationDiosdado Mingi Jr.Belum ada peringkat

- Haas AlarmsDokumen46 halamanHaas AlarmsKar GayeeBelum ada peringkat

- Glazing, Loading and Chattering of Grinding Wheel GlazingDokumen5 halamanGlazing, Loading and Chattering of Grinding Wheel GlazingRenjith RajendraprasadBelum ada peringkat

- MCMI-III - Clinical Application and Updates WebinarDokumen14 halamanMCMI-III - Clinical Application and Updates WebinarKar Gayee100% (1)

- LPG Installation ManualDokumen42 halamanLPG Installation ManualAleksandar NikolovskiBelum ada peringkat

- Wheel RunoutDokumen12 halamanWheel Runoutsainandha100% (1)

- 01 Rock Shox Judy Owners ManualDokumen7 halaman01 Rock Shox Judy Owners ManualakjasonBelum ada peringkat

- Cut-off Wheel Dangers of Side GrindingDokumen2 halamanCut-off Wheel Dangers of Side Grindingmark_59Belum ada peringkat

- Worksheet Grinding DJF3012Dokumen8 halamanWorksheet Grinding DJF3012suhaizyra0% (1)

- PorteusDokumen12 halamanPorteusKar GayeeBelum ada peringkat

- The Buss-Durkee Scale of AggressionDokumen4 halamanThe Buss-Durkee Scale of AggressionKar GayeeBelum ada peringkat

- Bench GrinderDokumen6 halamanBench GrinderGaurav KhamkarBelum ada peringkat

- Deborah Harkness - Fiul TimpuluiDokumen482 halamanDeborah Harkness - Fiul TimpuluiKar GayeeBelum ada peringkat

- GridingDokumen12 halamanGridingYam BlackBelum ada peringkat

- Shimano WH R 600Dokumen1 halamanShimano WH R 600AHSetiawanBelum ada peringkat

- Installing Brakes Shimano Deore BRM 596Dokumen1 halamanInstalling Brakes Shimano Deore BRM 596František SvobodaBelum ada peringkat

- Manitou Suspension Fork User ManualDokumen73 halamanManitou Suspension Fork User ManualYaksá HiperbólicoBelum ada peringkat

- ROAD Wheel Set: Dealer's ManualDokumen34 halamanROAD Wheel Set: Dealer's Manualmarcio.mrrsBelum ada peringkat

- ROAD Wheel Set: Dealer's ManualDokumen38 halamanROAD Wheel Set: Dealer's ManualJorgeBelum ada peringkat

- Wheels and Tires: Look at E-Mail From John Under Inbox Tab, Brakes Class FolderDokumen100 halamanWheels and Tires: Look at E-Mail From John Under Inbox Tab, Brakes Class Foldereizz88Belum ada peringkat

- VDL Service ManualDokumen13 halamanVDL Service ManualSergio Martín BrionesBelum ada peringkat

- Xtra10 Ride PPS ShockDokumen25 halamanXtra10 Ride PPS ShockKen DyckBelum ada peringkat

- MTB Wheel Set: Dealer's ManualDokumen39 halamanMTB Wheel Set: Dealer's ManualJONAS OPLASBelum ada peringkat

- SprocketDokumen6 halamanSprocketArefin ProttashaBelum ada peringkat

- Disc Brake System: General Safety InformationDokumen9 halamanDisc Brake System: General Safety InformationAdi AntonescuBelum ada peringkat

- Wheel Bearing InspectionDokumen44 halamanWheel Bearing InspectionJuan RenteriaBelum ada peringkat

- TRAINING REPORT ON ESCORT INDIA PVT. LTDDokumen34 halamanTRAINING REPORT ON ESCORT INDIA PVT. LTDVarun AggarwalBelum ada peringkat

- Bleeding XT755Dokumen1 halamanBleeding XT755Braggi BambergerBelum ada peringkat

- YZ 250-02-10 Flywheel Weight Installation InstructionsDokumen2 halamanYZ 250-02-10 Flywheel Weight Installation InstructionsJoe ScaliaBelum ada peringkat

- Sidekick AssemblyDokumen5 halamanSidekick AssemblyFrancisco Fernández BernardoBelum ada peringkat

- Shimano Disk BrakeDokumen1 halamanShimano Disk Brakehayleymorris24Belum ada peringkat

- Ball Bearing Disc Brake: Installation and Setup GuideDokumen14 halamanBall Bearing Disc Brake: Installation and Setup GuideAKILI PSIBelum ada peringkat

- DM Radbr10 03 EngDokumen92 halamanDM Radbr10 03 EngsamBelum ada peringkat

- DM BR0007 04 FreDokumen19 halamanDM BR0007 04 FreKarounga MakalouBelum ada peringkat

- Grinding SafetyDokumen21 halamanGrinding SafetySahil SheikhBelum ada peringkat

- Mechanical Disc Brakes: Dealer's ManualDokumen19 halamanMechanical Disc Brakes: Dealer's ManualDwika YanuariBelum ada peringkat

- Shimano Disc ManualDokumen0 halamanShimano Disc ManualnubirunBelum ada peringkat

- Wheel Alignment ParametersDokumen22 halamanWheel Alignment Parameterssyed wahid aliBelum ada peringkat

- Hilliard Flame Clutch InstallationDokumen4 halamanHilliard Flame Clutch InstallationDavid CarsonBelum ada peringkat

- SI 6PZRA 003 ENG - v1 - m56577569830677284Dokumen1 halamanSI 6PZRA 003 ENG - v1 - m56577569830677284lirch5Belum ada peringkat

- DM HB0005 05 Eng PDFDokumen13 halamanDM HB0005 05 Eng PDFHarri SivonenBelum ada peringkat

- Bench Grinding MachinesDokumen2 halamanBench Grinding Machinesశ్రీ వాసు. అవని0% (1)

- Front Hub/Freehub (Disc Brake) : Dealer's ManualDokumen15 halamanFront Hub/Freehub (Disc Brake) : Dealer's ManuallizukyBelum ada peringkat

- STEERING SYSTEM NotesDokumen15 halamanSTEERING SYSTEM Notesvictorkelly368Belum ada peringkat

- LSD Manual PDFDokumen13 halamanLSD Manual PDFDaniel CanalesBelum ada peringkat

- LSD Manual PDFDokumen13 halamanLSD Manual PDFHector Muñoz SepulvedaBelum ada peringkat

- DM BR0005 11 EngDokumen37 halamanDM BR0005 11 EngSpeedyChixBelum ada peringkat

- Demystifying The Mysterious Task of Wheel Truing Made EasyDokumen1 halamanDemystifying The Mysterious Task of Wheel Truing Made EasyNavyBelum ada peringkat

- Final DriveDokumen34 halamanFinal DriveArnold ChafewaBelum ada peringkat

- Um 3000H 003 00 EngDokumen1 halamanUm 3000H 003 00 EnglogonwheelerBelum ada peringkat

- Surface Grinding MachineDokumen26 halamanSurface Grinding MachinejohnBelum ada peringkat

- LegendDokumen1 halamanLegendbuilttorideBelum ada peringkat

- Ss2862d Wheel Alignment Tri FoldDokumen2 halamanSs2862d Wheel Alignment Tri Foldnuwan_nishaBelum ada peringkat

- 204-04 Wheel and TireDokumen13 halaman204-04 Wheel and TirePor PenglengBelum ada peringkat

- 3 Upravljanje ProjektimaDokumen24 halaman3 Upravljanje ProjektimaVulebg VukoicBelum ada peringkat

- GrinderDokumen3 halamanGrinderTool Room CIPET GHYBelum ada peringkat

- DM GN0001 08 EngDokumen118 halamanDM GN0001 08 EngMichael MorrowBelum ada peringkat

- BLACK City Trail OwnersManual FINALDokumen14 halamanBLACK City Trail OwnersManual FINALDrAlessanderArmondBelum ada peringkat

- Truing, Dressing & Balancing Grinding Wheels for Precision FinishingDokumen13 halamanTruing, Dressing & Balancing Grinding Wheels for Precision FinishingKrishnamani TiwariBelum ada peringkat

- PlatypusDokumen1 halamanPlatypusKar GayeeBelum ada peringkat

- Aptitudinile Si Evaluarea LorDokumen122 halamanAptitudinile Si Evaluarea LorKar GayeeBelum ada peringkat

- Anton Pann - Povestea VorbiiDokumen2 halamanAnton Pann - Povestea VorbiiKar GayeeBelum ada peringkat

- The Rotter Internal - External Locus of ControlDokumen5 halamanThe Rotter Internal - External Locus of ControlKar GayeeBelum ada peringkat

- ENG - Installation Manual For Sequential LPG-CNG (May 2005)Dokumen77 halamanENG - Installation Manual For Sequential LPG-CNG (May 2005)Kar Gayee100% (1)

- Orientarea Profesională A TinerilorDokumen79 halamanOrientarea Profesională A TinerilorKar GayeeBelum ada peringkat

- The Social Readjustment Rating ScaleDokumen3 halamanThe Social Readjustment Rating ScaleKar GayeeBelum ada peringkat

- Rulment Biax 2Dokumen1 halamanRulment Biax 2Kar GayeeBelum ada peringkat

- X X X X X XDokumen16 halamanX X X X X XKar GayeeBelum ada peringkat

- Rulment Biax 2Dokumen1 halamanRulment Biax 2Kar GayeeBelum ada peringkat

- Manual Coping Strategies InventoryDokumen2 halamanManual Coping Strategies InventoryKar GayeeBelum ada peringkat

- X X X X X XDokumen16 halamanX X X X X XKar GayeeBelum ada peringkat

- Manual Coping Strategies InventoryDokumen2 halamanManual Coping Strategies InventoryKar GayeeBelum ada peringkat

- DiagnosingA MAF TechTipDokumen1 halamanDiagnosingA MAF TechTipKar GayeeBelum ada peringkat

- TA01Z004 Man SequentFast enDokumen19 halamanTA01Z004 Man SequentFast enKar GayeeBelum ada peringkat

- CameraCalibPaperCheck20A4 ModelDokumen1 halamanCameraCalibPaperCheck20A4 ModelKar GayeeBelum ada peringkat

- Diamond Files and Wheels MSDS SummaryDokumen8 halamanDiamond Files and Wheels MSDS SummaryKar GayeeBelum ada peringkat

- Grinding Processes and Machine TypesDokumen17 halamanGrinding Processes and Machine TypesTHEOPHILUS ATO FLETCHERBelum ada peringkat

- Jadual Pembahagian WIM - GrindingDokumen4 halamanJadual Pembahagian WIM - Grindingmuhammad fakhrin shamsudin0% (1)

- Pencil SharpenerDokumen7 halamanPencil SharpenerT NgBelum ada peringkat

- Iso 8503-2 (1988) - eDokumen6 halamanIso 8503-2 (1988) - eRICARDO SANTOSBelum ada peringkat

- Sandpaper Grit ChartDokumen2 halamanSandpaper Grit ChartDale FirmBelum ada peringkat

- Ch-10 Grinding and FinishingDokumen121 halamanCh-10 Grinding and FinishingMANJEET KUMARBelum ada peringkat

- Grit Comparison Chart PDFDokumen3 halamanGrit Comparison Chart PDFdanyBelum ada peringkat

- SharpeningDokumen6 halamanSharpeningMatt OrtizBelum ada peringkat

- Maharaja Full Range Coffee Grinder 01-2018aDokumen6 halamanMaharaja Full Range Coffee Grinder 01-2018aharris fadhillahBelum ada peringkat

- Assignment 4Dokumen3 halamanAssignment 4Abhishek VishwakarmaBelum ada peringkat

- Daftar Ukuran Dan Type AmplasDokumen2 halamanDaftar Ukuran Dan Type AmplasRnD Guitar SejinBelum ada peringkat

- Foley 314 Grinder - 20454Dokumen4 halamanFoley 314 Grinder - 20454batesscribdBelum ada peringkat

- Superfinishing Processes: HoningDokumen5 halamanSuperfinishing Processes: HoningAyman HussienBelum ada peringkat

- Machining Process Guide to Honing OperationsDokumen6 halamanMachining Process Guide to Honing OperationsAnonymous 5AmJ13mLkBelum ada peringkat

- Comec Depliant RV516Dokumen4 halamanComec Depliant RV516Yeam_90Belum ada peringkat

- VSM Cylindrical Grinding Brochure ENDokumen6 halamanVSM Cylindrical Grinding Brochure ENforough sardarzadehBelum ada peringkat

- DiamutStoneList Rel. 9.6 HySDokumen128 halamanDiamutStoneList Rel. 9.6 HyShectorBelum ada peringkat

- Ferm BGM1003Dokumen80 halamanFerm BGM1003Cristian BujorBelum ada peringkat

- Electroless Nickel Plating On Abs Plastic by Using Environmentally Friendly Chemicals (#350219) - 379925Dokumen8 halamanElectroless Nickel Plating On Abs Plastic by Using Environmentally Friendly Chemicals (#350219) - 379925miguelin9169Belum ada peringkat

- Finishing Processes and Grinding MachinesDokumen21 halamanFinishing Processes and Grinding MachinesAnonymous GEHeEQlajbBelum ada peringkat

- Grinding Technology GMO 0252Dokumen88 halamanGrinding Technology GMO 0252hudarusliBelum ada peringkat

- Part List (5 Set) : Date: Quote Number: No. Item Spec, Size Qty Note Item UnitDokumen2 halamanPart List (5 Set) : Date: Quote Number: No. Item Spec, Size Qty Note Item UnitgonzaBelum ada peringkat

- Sandpaper Grit Scales PDFDokumen1 halamanSandpaper Grit Scales PDFDGWBelum ada peringkat

- Sand Box With BuiltDokumen3 halamanSand Box With BuiltPamfil Raluca ElenaBelum ada peringkat

- Norton Tool Room Grinding ManualDokumen5 halamanNorton Tool Room Grinding ManualjuliansimonBelum ada peringkat

- Cylindrical GrinderDokumen4 halamanCylindrical GrinderyudhishtherBelum ada peringkat