Walker Jacs 2011

Diunggah oleh

Babu DharmarajHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Walker Jacs 2011

Diunggah oleh

Babu DharmarajHak Cipta:

Format Tersedia

Communication

pubs.acs.org/JACS

Reactive Silver Inks for Patterning High-Conductivity Features at

Mild Temperatures

S. Brett Walker and Jennifer A. Lewis*

Department of Materials Science and Engineering and the Frederick Seitz Materials Research Laboratory, University of Illinois at

Urbana-Champaign, Urbana, Illinois 61801, United States

S Supporting Information

*

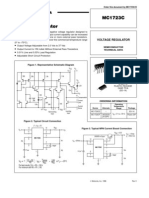

Scheme 1. Key Constituents in the Initial Solution, Ink, and

Printed Features

ABSTRACT: Reactive silver inks for printing highly

conductive features (>104 S/cm) at room temperature

have been created. These inks are stable, particle-free, and

suitable for a wide range of patterning techniques. Upon

annealing at 90 C, the printed electrodes exhibit an

electrical conductivity equivalent to that of bulk silver.

(middle), and the patterned silver features (right). The

chemical reactions occurring at each step are shown in the

Supporting Information (SI). Silver particles formed during

initial mixing and were removed by sedimentation over a period

of 12 h, yielding a stable, clear supernatant constituting the

reactive silver ink.

This modified Tollens process has several inherent

advantages. First, by using silver acetate in place of silver

nitrate, we are able to create a stable, nonexplosive silver

precursor ink. Second, the use of formic acid results in the

formation of carbon dioxide and water, leaving no residual

reducing agent.18 Third, by using excess ammonia in water, we

directly create the diamminesilver(I) complex without the need

for a silver oxide intermediate. The excess ammonia in solution

complexed preferentially with formic acid, leading to the in situ

synthesis of ammonium formate (see the SI). The resulting ink

is composed of 22 wt % silver, which is comparable to other

silver-precursor-based inks.14 When stored in a sealed vial, this

solution is stable for months under ambient conditions without

further precipitation. However, upon ink patterning and

evaporation, silver particles rapidly form.

The reactive silver ink is highly transparent and can be

printed through highly flexible, ultrafine nozzles (100 nm

diameter) via direct ink writing (Figure 1a,b; also see the movie

in the SI). This ink can also be inkjet-printed and airbrushsprayed upon the addition of 2,3-butanediol (10% by volume)

as a humectant and viscosifying aid (see the SI). The UVvis

absorption spectrum showed a lack of absorption in the 400

425 nm range typically associated with the presence of silver

particles (Figure 1c), thus confirming the ink to be particlefree.19 Thermogravimetric analysis (TGA) indicated that the

ink contains a solids loading of 26 wt % when dried at 23 C

and a final silver content of 22 wt % after annealing at 90 C for

15 min (Figure 1d). The maximum silver content is limited by

the solubility of the diamminesilver(I) cation in water.20 Under

rinted electronics constitute an emerging class of materials

with potential applications in photovoltaics,1 transistors,2,3

displays,4 batteries,5 antennas,6 and sensors.7 Recent efforts

have focused on the design of conductive inks for integration

on plastic,2,8 textile,9 and paper substrates.10,12 To date,

conductive polymer,2 carbon,5,9 and metallic nanoparticle

inks11,12 have been demonstrated. However, organic inks

typically exhibit low conductivity, whereas metallic nanoparticle

inks often require high annealing temperatures (>200 C) to

decompose stabilizing agents and other polymeric additives that

inhibit electrical conductivity.13

Recent exploration into silver precursor inks has yielded

promising results. For example, silver compounds with

carbamate or other relatively low molecular weight ligands

(compared to polymer stabilizers) have been synthesized that

decompose at temperatures near 150 C, yielding electrical

conductivities approaching that of bulk silver.14 Unfortunately,

even these temperatures render the ink incompatible with many

plastic15 and paper12,16 substrates used in flexible electronic and

biomedical devices. Hence, there is a need to develop particlefree silver inks that possess high conductivity under ambient

conditions.

An optimal ink design would meet the following requirements. First, the ink synthesis procedure should be both simple

and high-yielding. Second, the ink should possess low viscosity

to make it compatible with a broad range of patterning

techniques, including direct ink writing, inkjet printing, and

airbrush spraying. Third, the patterned features should be

highly conductive at room temperature and achieve bulk

conductivity upon annealing at mild temperatures (<100 C).

Finally, the ink should remain stable at room temperature for

months without particle precipitation.

To meet the above criteria, we synthesized a reactive silver

ink by a modified Tollens process.17 Specifically, we first

dissolved silver acetate in aqueous ammonium hydroxide.

Formic acid was then titrated into the solution, which was

mixed thoroughly. Scheme 1 shows the key constituents

present in the initial solution (left), the reactive silver ink

XXXX American Chemical Society

Received: October 1, 2011

dx.doi.org/10.1021/ja209267c | J. Am. Chem.Soc. XXXX, XXX, XXXXXX

Journal of the American Chemical Society

Communication

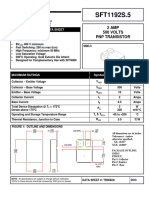

Figure 2. (a) Loglog plot of ink viscosity as a function of shear rate

and (b) semilog plot of electrical conductivity as a function of

temperature for the reactive silver ink (blue), the silver particle ink

developed for pen-on-paper printing (green), and the silver nanoparticle ink developed for omnidirectional (3D) printing (red).

are considerably larger than the nozzle size (Figure 1b). By

comparison, silver particle inks developed for omnidirectional

printing11 and pen-on-paper writing12 have apparent viscosities

roughly 35 orders of magnitude higher at low shear (Figure

2a). Because of the presence of silver particles, those inks

cannot be printed through nozzles that are less than 30 m

wide without intermittent clogging.

The electrical conductivity of printed features produced

using the reactive silver ink is shown in Figure 2b. For

comparison, data are also provided for electrodes produced

from silver particle inks developed for omnidirectional

printing11 and pen-on-paper writing.12 Upon drying at 23 C,

the electrical conductivity of electrodes printed from the

reactive silver ink exceeded 104 S/cm, which is 8 orders of

magnitude higher than that of electrodes produced from silver

nanoparticle inks formulated for omnidirectional printing,

which contain a polymer capping agent and a humectant to

enable in- and out-of-plane printing of self-supporting

filaments.11 Moreover, their conductivity was an order of

magnitude greater than that observed for the silver particle ink

developed for pen-on-paper writing.12 Upon annealing of the

electrodes printed from this reactive silver ink at 90 C for 15

min, their electrical conductivity was identical to that of bulk

silver (6.25 105 S/cm), while those produced from either of

the silver particle inks exhibited at least an order of magnitude

lower conductivity despite their substantially higher initial silver

contents (75 and 55 wt %, respectively). Importantly, the

reactive silver ink adheres very well to poly(ethylene

terephthalate) and polyimide substrates and moderately well

to other substrates such as glass and cellulose-based materials

(see the SI).

In conclusion, we have demonstrated a unique and facile

synthesis route for producing reactive silver inks that are

particle-free, low-viscosity, and highly conductive at room

temperature. These inks flow readily through ultrafine nozzles,

enabling patterning of conductive microelectrodes for flexible

electronics, displays, and photovoltaics. The ability to achieve

bulk silver conductivity upon annealing of the printed

electrodes at 90 C for several minutes opens new avenues

for integrating printed electronic devices on low-cost substrates

such as plastic, paper, and textiles.

Figure 1. (a) Optical image of the reactive silver ink in a scintillation

vial. (b) 1D array of conductive silver lines (5 m wide) printed on a

silicon substrate via direct-write assembly using a 100 nm nozzle. (c)

UVvis spectrum of the reactive silver ink. (d) TGA curves for the

reactive silver ink held at 23 and 90 C in air. (e) XRD patterns of

films patterned from the reactive silver ink dried at 23 C for 24 h

(top) and annealed at 90 C for 15 min (bottom). Asterisks denote

peaks corresponding to silver acetate.

ambient conditions, residual acetate groups are present, which

are removed upon heating to 90 C. X-ray diffraction (XRD)

revealed the presence of both silver and silver acetate peaks in

drop-cast films produced from this ink and dried at 23 C for

24 h, while only silver peaks were observed when these films

are heated to 90 C for 15 min (Figure 1e). On the basis of

these data, we estimate that the dried ink is composed of

approximately 57 wt % silver and 43 wt % silver acetate.

Notably, diamminesilver(I) complexes exist only in solution,

reverting back to their constituent salts upon drying when the

complex is not reduced to metallic silver. Scanning electron

microscopy (SEM) images of the top surfaces of printed silver

electrodes dried at 23 C and annealed at 90 C for 15 min,

respectively, are provided in the SI. Unlike drop-cast films,

which required drying times of 24 h, the printed features dry

nearly instantaneously, yielding fine particles at 23 C and after

annealing at 90 C.

An important advantage of this reactive silver ink is that

particle formation occurs only after patterning, as evaporation

ensues. The ink possesses a low initial viscosity of 2 mPas

(Figure 2a), enabling it to flow through ultrafine nozzles.

However, it undergoes significant wetting and spreading on the

substrate, resulting in minimum feature widths (5 m) that

B

dx.doi.org/10.1021/ja209267c | J. Am. Chem.Soc. XXXX, XXX, XXXXXX

Journal of the American Chemical Society

Communication

ASSOCIATED CONTENT

S Supporting Information

*

Experimental methods for ink synthesis, assembly, and

characterization, a movie (MPG) showing direct ink writing,

and complete ref 15. This material is available free of charge via

the Internet at http://pubs.acs.org.

AUTHOR INFORMATION

Corresponding Author

jalewis@illinois.edu

ACKNOWLEDGMENTS

This material is based on work supported by the U.S.

Department of Energy, Materials Sciences and Engineering

Division, under Award DEFG-02-07ER46471 (ink synthesis)

and the NSF Center for Nanoscale Chemical-Electrical

Mechanical Manufacturing Systems (DMI-0328162) (ink

patterning). We gratefully acknowledge the Center for

Microanalysis of Materials in the Frederick Seitz Materials

Research Laboratory as well as Dr. Bok Ahn for experimental

assistance, Vania Petrova for SEM imaging, Scott McLaren for

AFM assistance, and the Murphy and Sottos groups for use of

their experimental facilities.

REFERENCES

(1) Li, L.; Coates, N.; Moses, D. J. Am. Chem. Soc. 2010, 132, 2223.

(2) Sirringhaus, H.; Kawase, T.; Friend, R.; Shimoda, T.; Inbasekaran,

M.; Wu, W.; Woo, E. Science 2000, 290, 21232126.

(3) Okimoto, H.; Takenobu, T.; Yanagi, K.; Miyata, Y.; Shimotani,

H.; Kataura, H.; Iwasa, Y. Adv. Mater. 2010, 22, 39813986.

(4) Comiskey, B.; Albert, J. D.; Yoshizawa, H.; Jacobson, J. Nature

1998, 394, 253255.

(5) Hu, L.; Choi, J.; Yang, Y.; Jeong, S.; Mantia, F.; Cui, L.; Cui, Y.

Proc. Natl. Acad. Sci. U.S.A. 2009, 106, 2149021494.

(6) Subramanian, V.; Frechet, J. M. J.; Chang, P. C.; Huang, D. C.;

Lee, J. B.; Molesa, S. E.; Murphy, A. R.; Redinger, D. R.; Volkman, S.

K. Proc. IEEE 2005, 93, 13301338.

(7) Lim, S.; Kemling, J.; Feng, L.; Suslick, K. Analyst 2009, 134,

24532457.

(8) Bok, A.; Lorang, D.; Lewis, J. Nanoscale 2011, 3, 27002702.

(9) Hu, L.; Pasta, M.; La Mantia, F.; Cui, L.; Jeong, S.; Deshazer, H.;

Choi, J.; Han, S.; Cui, Y. Nano Lett. 2010, 10, 708714.

(10) Dennuelin, A.; Blayo, A.; Neuman, C.; Bras, J. J. Nano. Res.

2011, 13, 38153823.

(11) Ahn, B.; Duoss, E.; Motala, M.; Guo, X.; Park, S.; Xiong, Y.;

Yoon, J.; Nuzzo, R.; Rogers, J.; Lewis, J. Science 2009, 323, 15901593.

(12) Russo, A.; Ahn, B.; Adams, J.; Duoss, E.; Bernhard, J.; Lewis, J.

Adv. Mater. 2011, 23, 34263430.

(13) Pan, H.; Ko, S.; Grigoropoulos, C. Appl. Phys. Lett. 2008, 93,

No. 234104.

(14) U.S. Patent Application 20090120800A1.

(15) Kim, D.; et al. Nat. Mater. 2010, 9, 511517.

(16) Martinez, A.; Phillips, S.; Butte, M.; Whitesides, G. Angew.

Chem., Int. Ed. 2007, 46, 13181320.

(17) Yin, Y.; Li, Z.; Zhong, Z.; Gates, B.; Xia, Y.; Venkateswaran, S. J.

Mater. Chem. 2002, 12, 522527.

(18) Lawson, A. J. Catal. 1968, 11, 295304.

(19) Kumbhar, A.; Kinnan, M.; Chumanov, G. J. Am. Chem. Soc.

2005, 127, 1244412445.

(20) Fox, B.; Beyer, M.; Bondybey, V. J. Am. Chem. Soc. 2002, 124,

1361313623.

dx.doi.org/10.1021/ja209267c | J. Am. Chem.Soc. XXXX, XXX, XXXXXX

Anda mungkin juga menyukai

- Variable Frequency DriveDokumen11 halamanVariable Frequency DriveNAYEEM100% (4)

- Conductive Ink Patent US2851380BerlinghofDokumen4 halamanConductive Ink Patent US2851380BerlinghofAndrea CalderaBelum ada peringkat

- 1985 Siliconix MOSPOWER Applications PDFDokumen512 halaman1985 Siliconix MOSPOWER Applications PDFGabrielitoBelum ada peringkat

- 6 Laws of Plant GrowthDokumen1 halaman6 Laws of Plant GrowthBabu DharmarajBelum ada peringkat

- Basic Silicone Chemistry P 1Dokumen21 halamanBasic Silicone Chemistry P 1Rahul Yadav100% (1)

- A Noobs Guide To UfopoliticsDokumen18 halamanA Noobs Guide To UfopoliticsPraveen240679Belum ada peringkat

- DHS Updated Network Hospital ListDokumen999 halamanDHS Updated Network Hospital ListBabu Dharmaraj50% (2)

- Characterization of Silver Flakes Utilized For Isotropic Conductive AdhesivesDokumen5 halamanCharacterization of Silver Flakes Utilized For Isotropic Conductive AdhesivesAndrea CalderaBelum ada peringkat

- Kumar 1980Dokumen14 halamanKumar 1980Anonymous 8zyIRTdBelum ada peringkat

- Stable Selective Coating "Black Nickel" For Solar Collector SurfacesDokumen4 halamanStable Selective Coating "Black Nickel" For Solar Collector SurfacesRojan PradhanBelum ada peringkat

- PaperDokumen4 halamanPaperTamilarasiBelum ada peringkat

- Enhancing Corrosion Resistance of Copper by Electrodeposition Mahmoud Abbas, Magdy KasemDokumen28 halamanEnhancing Corrosion Resistance of Copper by Electrodeposition Mahmoud Abbas, Magdy KasemMoeBelum ada peringkat

- Copper Post-CMP Brush CleaningDokumen3 halamanCopper Post-CMP Brush Cleaningfreebee12345Belum ada peringkat

- Electroless Ag PlatingDokumen4 halamanElectroless Ag PlatingozhedzojhBelum ada peringkat

- BCR - From Byproduct To Brick: Using Red Mud Waste As A Construction MaterialDokumen10 halamanBCR - From Byproduct To Brick: Using Red Mud Waste As A Construction Materiallamia97Belum ada peringkat

- Alternate Metal Finishes For Wire Bond and Soldering ApplicationsDokumen9 halamanAlternate Metal Finishes For Wire Bond and Soldering ApplicationsMuhd HasbulBelum ada peringkat

- Accepted Manuscript: Applied Surface ScienceDokumen15 halamanAccepted Manuscript: Applied Surface ScienceRASHI LAKHYANIBelum ada peringkat

- 2011 - Salerno Et Al. - Large-Scale Lithography-Free Fabrication of SERS Substrates by Gold Coating of Anodic Porous Alumina - 13th FotoDokumen5 halaman2011 - Salerno Et Al. - Large-Scale Lithography-Free Fabrication of SERS Substrates by Gold Coating of Anodic Porous Alumina - 13th FotoClaudio BiaginiBelum ada peringkat

- A New Sintering Additive For Silicon Carbide CeramicDokumen5 halamanA New Sintering Additive For Silicon Carbide CeramicyinxinshixianBelum ada peringkat

- Amm 543-547 3914-2Dokumen4 halamanAmm 543-547 3914-2Hao SuenBelum ada peringkat

- S.T. Kariyawasm, M.K.D.C.S. Meegoda, Dr. K.G.N Nanayakkara: Department of Civil Engineering, University of PeradeniyaDokumen1 halamanS.T. Kariyawasm, M.K.D.C.S. Meegoda, Dr. K.G.N Nanayakkara: Department of Civil Engineering, University of PeradeniyaSupun KariyawasamBelum ada peringkat

- One Nanometer Thin Carbon Nanosheets With Tunable Conductivity and StiffnessDokumen5 halamanOne Nanometer Thin Carbon Nanosheets With Tunable Conductivity and StiffnessManav SaxenaBelum ada peringkat

- Télé Star, Jun 2011Dokumen4 halamanTélé Star, Jun 2011emediageBelum ada peringkat

- Lead Dioxide 4Dokumen4 halamanLead Dioxide 4Khobaib HayatBelum ada peringkat

- Silver Paste For DSCC Solar CellDokumen30 halamanSilver Paste For DSCC Solar CellAkshay BhavsarBelum ada peringkat

- CeramographyDokumen6 halamanCeramographyRomer John DetubioBelum ada peringkat

- Solar EnergyDokumen6 halamanSolar EnergyDeyvisBelum ada peringkat

- ivy-AAO ExperimentDokumen9 halamanivy-AAO Experimentxiyu sunBelum ada peringkat

- Art:10 1007/BF00619084 PDFDokumen6 halamanArt:10 1007/BF00619084 PDFelectro242Belum ada peringkat

- Nanochemistry PDFDokumen60 halamanNanochemistry PDFRahool Doshi100% (2)

- ICP - AplhaDokumen5 halamanICP - AplhamaxmerschBelum ada peringkat

- A New Method For Preparing Hydrophobic Nano-Copper PowdersDokumen5 halamanA New Method For Preparing Hydrophobic Nano-Copper PowdersbacBelum ada peringkat

- Effects of Nano Pigments On The Corrosion Resistance of Alkyd CoatingDokumen8 halamanEffects of Nano Pigments On The Corrosion Resistance of Alkyd Coatingdvega1981Belum ada peringkat

- Physical and Electrochemical Properties of Cobalt Doped (Ti, Ru) O Electrode CoatingsDokumen8 halamanPhysical and Electrochemical Properties of Cobalt Doped (Ti, Ru) O Electrode CoatingsGrig31Belum ada peringkat

- Ahn SomDokumen19 halamanAhn SomEvan FanBelum ada peringkat

- Thermoplastic 3D Printing - An Additive Manufacturing Method For Producing Dense CeramicsDokumen6 halamanThermoplastic 3D Printing - An Additive Manufacturing Method For Producing Dense Ceramicsmzaq1Belum ada peringkat

- High-Quality Thin Graphene Films From Fast Electrochemical ExfoliationDokumen8 halamanHigh-Quality Thin Graphene Films From Fast Electrochemical ExfoliationelectroternalBelum ada peringkat

- Materials Letters: Radu Banica, Bogdan Taranu, Calin Ladasiu, Iosif Hulka, Petrica LinulDokumen4 halamanMaterials Letters: Radu Banica, Bogdan Taranu, Calin Ladasiu, Iosif Hulka, Petrica LinulSahin CoskunBelum ada peringkat

- The Effect of Current Density On The Grain Size of Electrodeposited Nanocrystalline Nickel Coatings (5 Pagini)Dokumen5 halamanThe Effect of Current Density On The Grain Size of Electrodeposited Nanocrystalline Nickel Coatings (5 Pagini)Asandulesa AndreeaBelum ada peringkat

- Tong Hop Ag Hat NanoDokumen2 halamanTong Hop Ag Hat NanoAnonymous cgKtuWzBelum ada peringkat

- Charecterization of Silver Particles Used For Low Temp Joining TechnDokumen5 halamanCharecterization of Silver Particles Used For Low Temp Joining TechnTecnoserv Ingenieros S.A:Belum ada peringkat

- Prabhakar 2020 Sb2S3 TiO2 - Heterojunction - Photocathodes (Accepted - Version)Dokumen23 halamanPrabhakar 2020 Sb2S3 TiO2 - Heterojunction - Photocathodes (Accepted - Version)ShrabaniPaulBelum ada peringkat

- Surface Modification of Edmed Surface With Powder Mixed FluidDokumen7 halamanSurface Modification of Edmed Surface With Powder Mixed FluidVishnu SrivastavaBelum ada peringkat

- Gold and Silver Micro-Wire Electrodes For Trace Analysis of MetalsDokumen9 halamanGold and Silver Micro-Wire Electrodes For Trace Analysis of Metalsmaster antares fernandezBelum ada peringkat

- Mahn Ke 2001Dokumen7 halamanMahn Ke 2001israelBelum ada peringkat

- Effect of Electrodeposition Parameters On Morphology of Copper Thin FilmsDokumen7 halamanEffect of Electrodeposition Parameters On Morphology of Copper Thin FilmsIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalBelum ada peringkat

- Seminar Report by AmanDokumen16 halamanSeminar Report by Amanpurushottam kharbeBelum ada peringkat

- Of Lustre Glazed CeramicDokumen11 halamanOf Lustre Glazed CeramicehsanBelum ada peringkat

- Investigation of Pd:Sno / Porous Silicon Structures For Gas SensingDokumen5 halamanInvestigation of Pd:Sno / Porous Silicon Structures For Gas SensingeditorijaiemBelum ada peringkat

- The Formation of Monodisperse Spherical Silver Particles: I.M. Yakutik, G.P. Shevchenko, S.K. RakhmanovDokumen5 halamanThe Formation of Monodisperse Spherical Silver Particles: I.M. Yakutik, G.P. Shevchenko, S.K. RakhmanovAlphaRaj MekapoguBelum ada peringkat

- Rautomead CC PDFDokumen13 halamanRautomead CC PDFDayanand SharmaBelum ada peringkat

- 2018 - Texturization of Multicrystalline DWS Wafers by HFHNO3 H2SO4 at Elevated TemperatureDokumen7 halaman2018 - Texturization of Multicrystalline DWS Wafers by HFHNO3 H2SO4 at Elevated TemperatureBeyza Nur AKBOLATBelum ada peringkat

- Inkjet Printing of Silver Nanowires On Flexible SuDokumen9 halamanInkjet Printing of Silver Nanowires On Flexible SuSuman DeviBelum ada peringkat

- 2012-Reduction Synthesis of Tin Nanoparticles Using Various Precursors and Melting BehaviourDokumen7 halaman2012-Reduction Synthesis of Tin Nanoparticles Using Various Precursors and Melting BehaviourLili LilithBelum ada peringkat

- Microfluidization of Graphite and Formulation of Graphene-Based Conductive InksDokumen14 halamanMicrofluidization of Graphite and Formulation of Graphene-Based Conductive InkshijerBelum ada peringkat

- Surface Finish LineDokumen4 halamanSurface Finish LineNaveen GuptaBelum ada peringkat

- Stress in Electrodeposited Rhodium: by HillDokumen5 halamanStress in Electrodeposited Rhodium: by HillRaviIdhayachanderBelum ada peringkat

- Introduction To Sputtering, Targets and Utilization PDFDokumen4 halamanIntroduction To Sputtering, Targets and Utilization PDFanon_876950641Belum ada peringkat

- 02.02 Jui-Chin Chen Wen-T English PDFDokumen8 halaman02.02 Jui-Chin Chen Wen-T English PDFMaged AbbasBelum ada peringkat

- Microstructure and Cavitation Erosion Behavior of WC-Co-Cr Coating On 1Cr18Ni9Ti Stainless Steel by HVOF Thermal Spraying 2012 International Journal of Refractory MetalsDokumen6 halamanMicrostructure and Cavitation Erosion Behavior of WC-Co-Cr Coating On 1Cr18Ni9Ti Stainless Steel by HVOF Thermal Spraying 2012 International Journal of Refractory MetalsastronotusBelum ada peringkat

- Effect of Addition of TiO2 Nanoparticles On The Microstructure, Microhardness (Sn-3.4Ag-X) PDFDokumen8 halamanEffect of Addition of TiO2 Nanoparticles On The Microstructure, Microhardness (Sn-3.4Ag-X) PDFeid elsayedBelum ada peringkat

- Innovative High Throw Copper Electrolytic ProcessDokumen6 halamanInnovative High Throw Copper Electrolytic Processyonathan fausaBelum ada peringkat

- Perelaer 2008 3Dokumen7 halamanPerelaer 2008 3m.s.oryloveBelum ada peringkat

- Comparative Tribological Study of Air Plasma Sprayed WC-12%Co Coating Versus Conventional Hard Chromium Electrodeposit 2010 Tribology InternationalDokumen5 halamanComparative Tribological Study of Air Plasma Sprayed WC-12%Co Coating Versus Conventional Hard Chromium Electrodeposit 2010 Tribology InternationalastronotusBelum ada peringkat

- How To Measure ProductsDokumen4 halamanHow To Measure ProductsBabu DharmarajBelum ada peringkat

- No Objection Certificate: P.BamaDokumen1 halamanNo Objection Certificate: P.BamaBabu DharmarajBelum ada peringkat

- Diamond NozzlellllDokumen1 halamanDiamond NozzlellllBabu DharmarajBelum ada peringkat

- TAZ BOM Version3.1Dokumen15 halamanTAZ BOM Version3.1Babu DharmarajBelum ada peringkat

- Readme JJJJJJDokumen1 halamanReadme JJJJJJBabu DharmarajBelum ada peringkat

- LCD Menu Tree For Marlin FirmwareDokumen1 halamanLCD Menu Tree For Marlin FirmwarecharuatreBelum ada peringkat

- X-Carve Bill of MaterialsDokumen3 halamanX-Carve Bill of MaterialsBabu DharmarajBelum ada peringkat

- Witbox2 LOMDokumen12 halamanWitbox2 LOMBabu DharmarajBelum ada peringkat

- GIFT Tilapia Culture 15Dokumen11 halamanGIFT Tilapia Culture 15Babu DharmarajBelum ada peringkat

- Tds Ugray GrapheneDokumen5 halamanTds Ugray GrapheneBabu Dharmaraj100% (1)

- CatalogDokumen34 halamanCatalogccvvbbnnBelum ada peringkat

- 0620 w10 QP 32Dokumen16 halaman0620 w10 QP 32AhmadOsamaBelum ada peringkat

- TPCA8A11-H Datasheet en 20140220Dokumen9 halamanTPCA8A11-H Datasheet en 20140220luis alberto perez monteroBelum ada peringkat

- Embedded System ReportDokumen38 halamanEmbedded System ReportAmit Jain100% (1)

- MC1723 PDFDokumen9 halamanMC1723 PDFOsman KoçakBelum ada peringkat

- ECE20L-2 E05-ACT-5 DelaCruz JamesDokumen10 halamanECE20L-2 E05-ACT-5 DelaCruz JamesKim SolimanBelum ada peringkat

- Nmos 128K (16K X 8) Uv Eprom: Figure 1. Logic Diagram DescriptionDokumen11 halamanNmos 128K (16K X 8) Uv Eprom: Figure 1. Logic Diagram DescriptionJosepe Franco GerentBelum ada peringkat

- EL1021L Ohms Law Basic Electrical Fundamental - WK3Dokumen27 halamanEL1021L Ohms Law Basic Electrical Fundamental - WK3Dexrey John QuizanBelum ada peringkat

- Lecture13 Chapter4 BoostandBuckBoost CCM Analysis-1Dokumen22 halamanLecture13 Chapter4 BoostandBuckBoost CCM Analysis-1Buridi JahnaviBelum ada peringkat

- T2159en MVD500-4701Dokumen18 halamanT2159en MVD500-4701J KeigBelum ada peringkat

- STK416-090-E: 3-Channel Power Switching Audio Power IC, 80W+80W+80WDokumen12 halamanSTK416-090-E: 3-Channel Power Switching Audio Power IC, 80W+80W+80WendersonBelum ada peringkat

- Exam Questions-Section 1Dokumen38 halamanExam Questions-Section 1Gecca VergaraBelum ada peringkat

- SFT1192S.5: Solid State Devices, IncDokumen2 halamanSFT1192S.5: Solid State Devices, IncIPUNK PURNOMOBelum ada peringkat

- M140 DatasheetDokumen10 halamanM140 DatasheetBozo ThaClownBelum ada peringkat

- (Final)Dokumen16 halaman(Final)saurabhBelum ada peringkat

- Another Simple MK484 RadioDokumen2 halamanAnother Simple MK484 Radiorftek100% (2)

- LM2937 500-Ma Low Dropout Regulator: 1 Features 3 DescriptionDokumen31 halamanLM2937 500-Ma Low Dropout Regulator: 1 Features 3 DescriptionElectronica Mecatronica RasmusBelum ada peringkat

- Chapter 15 ElectromagneticDokumen35 halamanChapter 15 Electromagneticosama100% (1)

- Photocatalytic Decolorization of Bismarck Brown RDokumen170 halamanPhotocatalytic Decolorization of Bismarck Brown Rgeorge.ejaam8975Belum ada peringkat

- Dual Operational Amplifier: General DescriptionDokumen3 halamanDual Operational Amplifier: General DescriptionFrancisco MadridBelum ada peringkat

- Ee491 - Design Document FinalDokumen22 halamanEe491 - Design Document Finalapi-527919034Belum ada peringkat

- Lab ManualDokumen45 halamanLab ManualChaitanya SingumahantiBelum ada peringkat

- BMD101 PDFDokumen14 halamanBMD101 PDFrajBelum ada peringkat

- An Introduction To Telephone Line Interfacing Using The PIC Micro ControllerDokumen46 halamanAn Introduction To Telephone Line Interfacing Using The PIC Micro Controllerayaz_shiraziBelum ada peringkat

- LOGIC-GATES, DIGITAL-ELECTRONICS, CH-3, DLD-1, On Bio-Medical Engineering (BME)Dokumen24 halamanLOGIC-GATES, DIGITAL-ELECTRONICS, CH-3, DLD-1, On Bio-Medical Engineering (BME)GUIDE ON BIO-MEDICAL ENGINEERING UNDERGRADUATE PROGRAM:Belum ada peringkat