Von Ruden

Diunggah oleh

Neeraj SharmaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Von Ruden

Diunggah oleh

Neeraj SharmaHak Cipta:

Format Tersedia

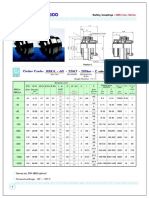

Bevel Gear Boxes

A GENERAL OVERVIEW

For Complete Specifications & Comprehensive Performance Data on All Bevel Gear Box Models

see www.vonruden.com.

11.05.C

Any discussion of Bevel Gear Boxes

must first clarify the definition of Beveled Gears.

A bevel gear is made in the shape of a cone. Deployed in pairs, they are used to

connect intersecting shafts. Normally they are mounted on shafts that are at 90

to each other (hence the term right angle bevel gears). However, they are not

restricted to 90 mounting.

Nomenclature of a Typical Bevel Gear Box.

End Cap

Case

Gear

Cross

Shaft

End Cap

Pinion Gear

Pinion Housing

Typical set of bevel

gears meshed at 90

Direction

of Rotation

Model

Maximum

Input speed

(rpm)

Maximum

Input

Horsepower

15

.625

3000

18

25

.75

3000

36

27

1.0

3000

32

33

1.0

3000

69

40

1.0

3000

69

90

1.25

2800

87

93

1.375

2500

149

110

1.5

1750

175

1750

202

113

1.75

(2.0 opt)

The primary purposes of bevel gear

boxes are illustrated here. Two or more

purposes are frequently accomplished

simultaneously. For example: To transmit power at 90 AND decrease

speed/increase torque.

Transmitting

Power At 90

OUT

Pinion Shaft

Von Ruden Standard Bevel Gear Box Overview

Pinion Shaft

Diameter

(inches)

Primary

Purposes:

Available Gear

Reduction

Ratios

1:1

1.5:1

2:1

1:1

1.5:1

2:1

1:1

1.5:1

2:1

3:1

1:1

1.5:1

2:1

1:1

1.5:1

2:1

1:1

1.5:1

2:1

1:1

1.5:1

2:1

1:1

1.5:1

2:1

1:1

1.5:1

2:1

3:1

Available

Speed UP

Ratios

Gear

Types

Available

1:1.5

1:2

Straight Cut

Spiral

1:1.5

1:2

Straight Cut

Spiral

1:1.5

1:2

1:3

Straight Cut

Spiral

1:1.5

1:2

1:1.5

1:2

1:1.5

1:2

1:1.5

1:2

1:3

1:1.5

1:2

1:3

Forged

Straight Cut

Spiral

Forged

Straight Cut

Spiral

Forged

Straight Cut

Spiral

Forged

Straight Cut

Spiral

Forged

Straight Cut

Spiral

IN

Splitting

Power

OUT

OUT

IN

Decreasing Speed &

Increasing Torque

IN: 200 rpm &

500 lb-inches

OUT: 100 rpm &

1000 lb-inches

2:1 Reduction

Increasing Speed &

Decreasing Torque

IN: 200 rpm &

500 lb-inches

OUT: 400 rpm &

250 lb-inches

1:2 Speed-Up

OUT

IN

OUT

IN

Functioning as a Power Take-off Device

with the Cross-shaft as a Common Input

IN

Forged

Straight Cut

Spiral

OUT

OUT

All information is subject to change without notice. Always confirm with us that you are working with the most current data.

Page 1 of 4

2003, Von Ruden Manufacturing, Inc. Buffalo, MN Fax 763.682.3954 Phone 763.682.3122

Bevel Gear Boxes

TYPICAL CONFIGURATIONS

For Complete Specifications & Comprehensive Performance Data on All Bevel Gear Box Models

see www.vonruden.com.

11.05.C

Cross Shaft Extensions

With Double

Extensions

With Single

Extension

Single Cross

Shaft Extension

Cross Shaft

Extensions (2)

Experience Leads to Innovation

Like this blade drive gearbox for

commercial outfront, zero-turn,

lawnmowers

Cross Shaft Direction of Rotation

Type A

Type D

Type B

Types A and D are the same gear box

turned over. Note the gear is next to the

cross shaft extension (causing CCW

rotation of the cross shaft).

Type C

Types B and C are the same gear box

turned over. Not the gear is opposite the

cross shaft extension (causing CW rotation of the cross shaft).

Type E

Type G

Types E and G are also the same gear

box turned over. In some cases (for

higher reduction ratios) the cross shaft

extension nearest the gear will be smaller

in diameter than the other extension.

This is to accommodate gear installation.

Other Configuration Possibilities

Type F

Type H

Type I

Type J

Gear Reduction Ratio

The term gear reduction applies to

speed. A 2:1 reduction means that the

speed will be reduced by a factor of two,

or in other words, to 50%.

Obviously, if the the gear reduction

reduces speed by 50%, the resulting

torque will be doubled.

Example:

Gear Ratio

Input Speed

Output Speed

Input Torque

Output Torque

2:1

150 rpm

150/2 = 75 rpm

1000 lb.-inches

1000 x 2 = 2000 lb.-inches

In all current VonRuden bulletins, the

ratio is determined from the pinion shaft

to the cross shaft.

The cross shaft can be used as the input

shaft. In such cases the ratio would be

simply reversed. A 2:1 reducer would

become a 1:2 speed increaser.

All information is subject to change without notice. Always confirm with us that you are working with the most current data.

Page 2 of 4

2003, Von Ruden Manufacturing, Inc. Buffalo, MN Fax 763.682.3954 Phone 763.682.3122

Bevel Gear Boxes

WHY CHOOSE VON RUDEN?

For Complete Specifications & Comprehensive Performance Data on All Bevel Gear Box Models

see www.vonruden.com.

11.05.C

Tailored to the Needs of a Design Engineer.

Selection:

Models up to 200 hp.

Choices of gear types and ratios.

Speed reducing and increasing models.

Direction of rotation options.

Hydraulic motor input flange option.

Configuration options.

Extended Working Life

Custom Angle Boxes

Unique configurations are available

to meet your special needs and to

solve difficult problems. Contact your

factory representative -- were always

willing to work with you.

Press-fit gears and bearings for superior rigidity and

maximum performance.

Properly shimmed gears and bearings for consistent backlash.

No paper or plastic shims. Metal shims used throughout.

Tapered roller (not ball) bearings throughout.

Aluminum end caps and pinion housings on most models for improved heat dissipation.

High strength steel alloys gears cut from 8620 steel, the carburized and hardened.

Improved shaft seals spring loaded double lip design. One lip seals in the oil, the other seals out dirt.

All shafts are specially ground/burnished at the seal area for extended life.

Maintenance and Repair

End caps and piston housings remove easily. (No need for a special access cover.)

Only locking nuts or locking tab washers used internally. Threads are not staked.

Organized to Earn Your Confidence:

Every member of the VonRuden team works for you to provide a quality product, delivered on-time with

the best possible service both before and after the sale. This company-wide commitment assures you:

Very competitive prices.

Improved delivery via flexible production schedules.

Complete technical assistance from our global network of local representatives and

our own engineering department.

Direct support for your own customers when you request it.

Specials will always be considered and usually built.

Over a Half-Century of Expertise

For over 50 years, VonRuden manufacturing has built its reputation around quality products, designed

and built in modern, well-tooled facilities. Though our products and processes have certainly evolved

over the decades our 21st Century commitment to superior products, competitive prices, and

unexcelled service remains unchanged.

All information is subject to change without notice. Always confirm with us that you are working with the most current data.

Page 3 of 4

2003, Von Ruden Manufacturing, Inc. Buffalo, MN Fax 763.682.3954 Phone 763.682.3122

Bevel Gear Boxes

PROBLEM-SOLVING EXPERIENCE

For Complete Specifications & Comprehensive Performance Data on All Bevel Gear Box Models

see www.vonruden.com.

11.05.C

Because weve been producing bevel gear boxes for over 50 years, Von Ruden brings

substantial problem-solving experience to the table. Whether your goal is to blend,

blow or bottle you need to crank, cut or convey or the task is to press, propel or

raise, we welcome the opportunity to put our experience with all these industries to

work for you.

Industrial Applications

Mobile & Other Applications

Printing Presses

Plastic Extruders

Sewage Augers

Bonding Equipment

Metering Augers

Sewage Agitators

Newspaper Conveyors

Bottling Equipment

Material Handling

Web Finishing

Paper Conveying

Conveyors

Cardboard Box Equipment

Packaging

Antennas

Gate Valve Actuators

Business Form Presses

Feed Screw Drives

Sewage Conveyors

Collating Machinery

Mixing Equipment

Conveyor Drives

Film Processors

Pottle Packaging Equipment

Lifts/Hoists/Jacks

Food Processing

Robotics

Rubber Processing

Wrapping Machines

Solar Panels

Commercial Mowers

Street Sweepers

Dual Steering

Bulkhead Door Openers

Scissors Lifts

Pump Drives

Misc. Conveyors

Sand Spreaders

Residential Mowers

Car Wash Curtains

Snow Blowers

Fan/Blower Drives

Mining Equipment

Cranes

Hydraulic Motor Mounting Flange

Our Model 93 and Model 113 Bevel Gear

Boxes can be provided with SAE hydraulic

motor mounting flanges.

Specials

Yes, Von Ruden will manufacture

specials to satisfy unique customer

requirements. Different shaft lengths,

gear ratios and housing configurations

can all be provided. These are examples

of the hundreds of atypical configurations

weve provided in the past.

Agricultural Applications

Augers/Elevators

Grain Wagons

Harvesters

Forage Harvesters/Blowers

Manure Spreaders

Fertilizer Spreaders

Grain Bin Augers

Grinders/Mixers

Tillers

Fans

Feed Mills/Blenders

Hay Balers

Tub Grinders

Grain Dryers

Rotary Mowers/Cutters

Power Rakes

Rock Pickers

Food Handling

Indeed, we might already have produced

a custom design very similar to what you

need. Please contact your factory representative for data on existing Von Ruden

specials and a proposal for your

application.

All information is subject to change without notice. Always confirm with us that you are working with the most current data.

Page 4 of 4

2003, Von Ruden Manufacturing, Inc. Buffalo, MN Fax 763.682.3954 Phone 763.682.3122

Anda mungkin juga menyukai

- Rexroth-Hagglunds Drive SystemsDokumen28 halamanRexroth-Hagglunds Drive SystemsManuel Vizcarra100% (1)

- Gearflex Spanish EbrochureDokumen24 halamanGearflex Spanish EbrochureOscar CruzBelum ada peringkat

- Shaft CouplingsDokumen20 halamanShaft CouplingsLuis MenaBelum ada peringkat

- Brochure - Rigid Renold Page 40Dokumen76 halamanBrochure - Rigid Renold Page 40Carlos Gallardo LagosBelum ada peringkat

- FAG-Gearboxes Need Rolling BearingsDokumen10 halamanFAG-Gearboxes Need Rolling BearingsUMAMAHESWARAN03Belum ada peringkat

- Rotary TableDokumen12 halamanRotary TableNakul Devaiah50% (2)

- CD 728 PlansDokumen27 halamanCD 728 PlansPetar Petrovic100% (1)

- Guided Linear Motion Components & SystemsDokumen44 halamanGuided Linear Motion Components & SystemsVikram BorkhediyaBelum ada peringkat

- ELATHE-500 GearboxDokumen205 halamanELATHE-500 GearboxRC VilledaBelum ada peringkat

- DdmanualDokumen7 halamanDdmanualadriaan_villiersBelum ada peringkat

- Aerial & Die Mount CamsDokumen44 halamanAerial & Die Mount CamslelixBelum ada peringkat

- Idler EngrDimDokumen64 halamanIdler EngrDimJosé Eduardo Gaete DuarteBelum ada peringkat

- Single Toggle Jaw Crusher Manufacturers, Single Toggle Jaw Crusher For SaleDokumen3 halamanSingle Toggle Jaw Crusher Manufacturers, Single Toggle Jaw Crusher For SaleHashani Anuttara AbeygunasekaraBelum ada peringkat

- Wheel Loader ThesisDokumen5 halamanWheel Loader Thesisbkxk6fzf100% (2)

- Jaw Coupling PDFDokumen4 halamanJaw Coupling PDFhibhavuBelum ada peringkat

- Shaft Couplings and UJsDokumen48 halamanShaft Couplings and UJstahirabbasBelum ada peringkat

- Idler Catalog Complete Low Res For WebDokumen154 halamanIdler Catalog Complete Low Res For WebMauricio MpintoBelum ada peringkat

- Series H MetricDokumen123 halamanSeries H MetricJames Pacheco100% (1)

- HT Howard - Cylinder Liner Fitting For Cars, Motorcycles, Vans, Classic and Modern EnginesDokumen3 halamanHT Howard - Cylinder Liner Fitting For Cars, Motorcycles, Vans, Classic and Modern EnginesAndrés Alejandro PereiraBelum ada peringkat

- Gam Spiral Bevel Gearbox CatalogDokumen75 halamanGam Spiral Bevel Gearbox CatalogServo2GoBelum ada peringkat

- Delux Bearings Ltd. Presentation Oct. 2013Dokumen52 halamanDelux Bearings Ltd. Presentation Oct. 2013AshwiniBelum ada peringkat

- Bomba de Vácuo Sotorbilt 4mrDokumen12 halamanBomba de Vácuo Sotorbilt 4mrWormInchBelum ada peringkat

- IndustrialDokumen204 halamanIndustrialrony adonay sandovalBelum ada peringkat

- Idler EngrDimDokumen64 halamanIdler EngrDimOrlando MelipillanBelum ada peringkat

- Power Curber 5700-D: #1 in The WorldDokumen20 halamanPower Curber 5700-D: #1 in The WorldMohamed MohamedBelum ada peringkat

- Chapter - I, Company ProfileDokumen12 halamanChapter - I, Company ProfileeswariBelum ada peringkat

- Falk Coupling SGDokumen16 halamanFalk Coupling SGJorge Ernesto PinzonBelum ada peringkat

- RENK MAAG Turbo Gearboxes 0413-1Dokumen24 halamanRENK MAAG Turbo Gearboxes 0413-1RCMBelum ada peringkat

- Melling 2018 Cylinder Sleeve Catalog PDFDokumen49 halamanMelling 2018 Cylinder Sleeve Catalog PDFfishhunter18100% (1)

- KVM 32 XL KVM 32 XG: The World's Best Design in Two ConfigurationsDokumen2 halamanKVM 32 XL KVM 32 XG: The World's Best Design in Two ConfigurationsMihnea-Bogdan Nicolaescu100% (1)

- SMS - 2003 For Web PDFDokumen96 halamanSMS - 2003 For Web PDFbatatahcBelum ada peringkat

- Renold Couplings - 7th EditionDokumen96 halamanRenold Couplings - 7th EditionGiancarlo MenachoBelum ada peringkat

- Flexible Couplings 2010Dokumen32 halamanFlexible Couplings 2010amekhzoumiBelum ada peringkat

- Hydrodinamic BearingsDokumen8 halamanHydrodinamic BearingsdigecaBelum ada peringkat

- TD Industrial Bro FinalDokumen5 halamanTD Industrial Bro FinalSekar KannanBelum ada peringkat

- 606EDokumen68 halaman606ELLBelum ada peringkat

- John Crane Engineered Bearings Service Solutions: Get The Engineering Edge For Your TurbomachineryDokumen8 halamanJohn Crane Engineered Bearings Service Solutions: Get The Engineering Edge For Your TurbomachineryAmet koko TaroBelum ada peringkat

- Crankshafts and Camshafts: Efficient Machining ofDokumen20 halamanCrankshafts and Camshafts: Efficient Machining ofAnees SheikhBelum ada peringkat

- Onvio Cycloidal CatalogDokumen22 halamanOnvio Cycloidal CatalogStefan IlicBelum ada peringkat

- Drive Coupling SKFDokumen19 halamanDrive Coupling SKFFrank MwafulirwaBelum ada peringkat

- AMC-SCHOU Cylindrical Grinders 0509Dokumen28 halamanAMC-SCHOU Cylindrical Grinders 0509m_najmanBelum ada peringkat

- rqvwuxfwlrq, Qgxvwuldo Dqg3HwurohxppowerDokumen19 halamanrqvwuxfwlrq, Qgxvwuldo Dqg3Hwurohxppower李春杰Belum ada peringkat

- Servomotores BaldorDokumen128 halamanServomotores BaldorBlAdE 12Belum ada peringkat

- KHD Tube MillDokumen2 halamanKHD Tube MillKeynes de SavaBelum ada peringkat

- SEW Eurodrive Industrial Gear UnitsDokumen15 halamanSEW Eurodrive Industrial Gear UnitsSteve IpBelum ada peringkat

- Motors: The New Platform For A Higher Degree of IndividualityDokumen10 halamanMotors: The New Platform For A Higher Degree of IndividualityssBelum ada peringkat

- Elliott CompressorsDokumen7 halamanElliott CompressorsQuarkantBelum ada peringkat

- Machine Protection USA Web PDFDokumen84 halamanMachine Protection USA Web PDFEren GünerBelum ada peringkat

- Gear Box DesignDokumen8 halamanGear Box Designandiksribd100% (1)

- Excellence in HemmingDokumen12 halamanExcellence in Hemmingmlucian73Belum ada peringkat

- Disc TypeDokumen28 halamanDisc TypeamericolatinoBelum ada peringkat

- Schnorr Produktprospekt EnglDokumen44 halamanSchnorr Produktprospekt EnglIgor FelcBelum ada peringkat

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreDari EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MorePenilaian: 4.5 dari 5 bintang4.5/5 (11)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDari EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualPenilaian: 2.5 dari 5 bintang2.5/5 (2)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDari EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualBelum ada peringkat

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyDari EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyPenilaian: 5 dari 5 bintang5/5 (1)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Dari EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Penilaian: 5 dari 5 bintang5/5 (1)

- Alvania EP GreaseDokumen2 halamanAlvania EP GreaseNeeraj SharmaBelum ada peringkat

- With Inner Conical HubDokumen4 halamanWith Inner Conical HubNeeraj SharmaBelum ada peringkat

- Bevelgears: Screw Jacks Bevelgears Shafts/CouplingsDokumen2 halamanBevelgears: Screw Jacks Bevelgears Shafts/CouplingsNeeraj SharmaBelum ada peringkat

- Pulp and Paper Newsletter 11147EN - 5Dokumen8 halamanPulp and Paper Newsletter 11147EN - 5Neeraj SharmaBelum ada peringkat

- SR Programme Details Ocation Date Timings: Service Tax Will Be Extra 12.36%Dokumen2 halamanSR Programme Details Ocation Date Timings: Service Tax Will Be Extra 12.36%Neeraj SharmaBelum ada peringkat

- Reman - Guidelines For Sending MaterialDokumen2 halamanReman - Guidelines For Sending MaterialNeeraj SharmaBelum ada peringkat

- X-SSLIDE Seals Standard Dimensions CatalogueDokumen65 halamanX-SSLIDE Seals Standard Dimensions CatalogueNeeraj SharmaBelum ada peringkat

- I Text Sharp SingleDokumen2 halamanI Text Sharp SingleNeeraj SharmaBelum ada peringkat

- Mech Vibrations NotesDokumen32 halamanMech Vibrations Notesvgbharath33% (3)

- PC TrickesDokumen28 halamanPC TrickesNeeraj SharmaBelum ada peringkat

- Valve StemDokumen16 halamanValve StemNeeraj SharmaBelum ada peringkat

- LifeDokumen1 halamanLifeNeeraj SharmaBelum ada peringkat

- Engineers and GraduatesDokumen19 halamanEngineers and GraduatesNeeraj SharmaBelum ada peringkat

- Rankine CycleDokumen13 halamanRankine CycleAtul100% (5)

- TKSA20 Datasheet enDokumen2 halamanTKSA20 Datasheet enmcdermottrickBelum ada peringkat

- NozzlesDokumen5 halamanNozzlessreelu100% (1)

- LasersDokumen12 halamanLasersnnithinBelum ada peringkat

- Dislocation in Germanium CrystalDokumen4 halamanDislocation in Germanium CrystalNeeraj SharmaBelum ada peringkat

- What To After EnggDokumen8 halamanWhat To After EnggNeeraj SharmaBelum ada peringkat

- Astonishing Functions of Human Brain and Miracles of MindDokumen92 halamanAstonishing Functions of Human Brain and Miracles of MindNeeraj SharmaBelum ada peringkat

- Mudras and Bandhas Are Certain Postures of The Body by Which Kundalini Is Successfully AwakenedDokumen7 halamanMudras and Bandhas Are Certain Postures of The Body by Which Kundalini Is Successfully AwakenedNeeraj SharmaBelum ada peringkat

- Risk Management: Questions and AnswersDokumen5 halamanRisk Management: Questions and AnswersCentauri Business Group Inc.Belum ada peringkat

- Interceptor Specifications FinalDokumen7 halamanInterceptor Specifications FinalAchint VermaBelum ada peringkat

- Technology in Society: SciencedirectDokumen10 halamanTechnology in Society: SciencedirectVARGAS MEDINA ALEJANDRABelum ada peringkat

- All About History History of Communism - 4th Edition 2022Dokumen148 halamanAll About History History of Communism - 4th Edition 2022Duke100% (1)

- CMS156Dokumen64 halamanCMS156Andres RaymondBelum ada peringkat

- Idoc - Pub - Pokemon Liquid Crystal PokedexDokumen19 halamanIdoc - Pub - Pokemon Liquid Crystal PokedexPerfect SlaNaaCBelum ada peringkat

- Excel Lesson 5 QuizDokumen5 halamanExcel Lesson 5 Quizdeep72Belum ada peringkat

- 3 HVDC Converter Control PDFDokumen78 halaman3 HVDC Converter Control PDFJanaki BonigalaBelum ada peringkat

- Duties and Responsibilities - Filipino DepartmentDokumen2 halamanDuties and Responsibilities - Filipino DepartmentEder Aguirre Capangpangan100% (2)

- Video ObservationDokumen8 halamanVideo Observationapi-532202065Belum ada peringkat

- Appsc Aee Mains 2019 Electrical Engineering Paper III 1fcbb2c9Dokumen12 halamanAppsc Aee Mains 2019 Electrical Engineering Paper III 1fcbb2c9SURYA PRAKASHBelum ada peringkat

- List of Practicals Class Xii 2022 23Dokumen1 halamanList of Practicals Class Xii 2022 23Night FuryBelum ada peringkat

- Buku BaruDokumen51 halamanBuku BaruFirdaus HoBelum ada peringkat

- 7540 Physics Question Paper 1 Jan 2011Dokumen20 halaman7540 Physics Question Paper 1 Jan 2011abdulhadii0% (1)

- Week 1-2 Module 1 Chapter 1 Action RseearchDokumen18 halamanWeek 1-2 Module 1 Chapter 1 Action RseearchJustine Kyle BasilanBelum ada peringkat

- Dr. Babasaheb Ambedkar Technological UniversityDokumen3 halamanDr. Babasaheb Ambedkar Technological UniversityalfajBelum ada peringkat

- Discrete Random Variables: 4.1 Definition, Mean and VarianceDokumen15 halamanDiscrete Random Variables: 4.1 Definition, Mean and VariancejordyswannBelum ada peringkat

- Installation, Operation & Maintenance Manual - Original VersionDokumen11 halamanInstallation, Operation & Maintenance Manual - Original VersionAli AafaaqBelum ada peringkat

- SST Vs BBTDokumen7 halamanSST Vs BBTFlaxkikare100% (1)

- Uxc01387a PDFDokumen16 halamanUxc01387a PDFmahesh123Belum ada peringkat

- Quadratic SDokumen20 halamanQuadratic SAnubastBelum ada peringkat

- LhiannanDokumen6 halamanLhiannanGreybornBelum ada peringkat

- Self-Efficacy and Academic Stressors in University StudentsDokumen9 halamanSelf-Efficacy and Academic Stressors in University StudentskskkakleirBelum ada peringkat

- (Biophysical Techniques Series) Iain D. Campbell, Raymond A. Dwek-Biological Spectroscopy - Benjamin-Cummings Publishing Company (1984)Dokumen192 halaman(Biophysical Techniques Series) Iain D. Campbell, Raymond A. Dwek-Biological Spectroscopy - Benjamin-Cummings Publishing Company (1984)BrunoRamosdeLima100% (1)

- Piston Master PumpsDokumen14 halamanPiston Master PumpsMauricio Ariel H. OrellanaBelum ada peringkat

- JLPT Application Form Method-December 2023Dokumen3 halamanJLPT Application Form Method-December 2023Sajiri KamatBelum ada peringkat

- ARHAM FINTRADE LLP - Company, Directors and Contact Details Zauba CorpDokumen1 halamanARHAM FINTRADE LLP - Company, Directors and Contact Details Zauba CorpArun SonejiBelum ada peringkat

- Pepsi Mix Max Mox ExperimentDokumen2 halamanPepsi Mix Max Mox Experimentanon_192325873Belum ada peringkat

- ZyLAB EDiscovery 3.11 What's New ManualDokumen32 halamanZyLAB EDiscovery 3.11 What's New ManualyawahabBelum ada peringkat

- GSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserDokumen13 halamanGSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserSanatana RoutBelum ada peringkat