DIMENSION INSPECTION GUIDE

Diunggah oleh

Umesh SakhareliyaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

DIMENSION INSPECTION GUIDE

Diunggah oleh

Umesh SakhareliyaHak Cipta:

Format Tersedia

WORK INSTRUCTION FOR DIMENSION

INSPECTION

Doc. No.

WI-QC-21

Date/Rev No.

Page No.

20.06.2015/00

Page 1 of 3

1. Purpose and Scope:To inspect the casting geometrically and dimensionally as per approved

drawing.

All casting can check by dimension inspection.

2. Responsibilities:Q.C. Inspector is responsible for to do the inspection and records the data.

Q.C. In-Charge is final responsible for inspection.

3. Safety:Wear helmet, Safety shoes and Hand Gloves.

4. Procedure:Input

a) Drawing must have Control Copy stamp. If found without stamp

drawing then receive the stamped drawing from Q.A. Department.

b) Compare drawing no. & revision no. in drawing with ERP. If not

match then inform to Q.A. Department and receive the latest

drawing.

c) Check visually all shape of casting as per drawing. E.g. Boss

location, lug location, Pad location, Shape of each view, Part

waviness, over grinding on riser or any methoding area, Letter of

casting & extra metal on any location.

d) Shifting check visually.

e) Check instrument calibration, if instrument found due in calibration

than inform to Q.C. department for calibration.

f) Insect the casting dimensionally as per drawing and use

instruments as per control plan.

g) Length Dimension must check Top and Bottom on both sides for

checking shifting.

h) Casting tolerance understand as per below listed method.

Basic Dimension is 20.80 mm, Upper Limit is 20.80

0.040=20.84mm and Lower limit is 20.80 0.090 = 20.71mm.

So, Dimension accept between 20.71mm to 20.84mm.

i) If dont mansion tolerance in dimension then see the drawing title

box which have a mansion standard for tolerance or tolerance chart

and use this standard tolerance in particular dimension.

j) If no mansion standards of tolerance or tolerance chart in drawing

then ask to Q.C. department for tolerance.

WORK INSTRUCTION FOR DIMENSION

INSPECTION

Doc. No.

WI-QC-21

Date/Rev No.

Page No.

20.06.2015/00

Page 2 of 3

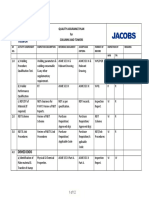

k) Geometry tolerance chart.

Symbol

Description

Symbol

Description

Tolerance

feature

indication

Datum

feature

indication

Datum

target

indication

Theoretically Exact

dimension

MD

Major Diameter

PD

Pitch Diameter

LE

Line Element

NC

Not Convex

Project

Tolerance

Zone

Maximum Material

Requirement

Least

material

Requirement

Free

State

Condition

(Non

Rigid part)

All around (Profile)

ACS

Any Cross Section

Angularity

Concentricity

Cylidricity

Flatness

Parallelism

CZ

Envelop

requirement

Common Zone

LD

Minor Diameter

Position

Profile

Straightness

Profile of a line

Symmetry

Circularity

Total Run out

Run Out

Tangent Plane

Diameter

Unilateral

Perpedicularity

l) ID and OD to be check on parting line and top- bottom point for

checking ovality.

Output:a) Fill the dimensions in report.

b) Check the variation of dimensions w.r.t. drawing, if dimension found

out-of tolerance then inform to Q.C. In-Charge.

5. Records & Cross Reference:-

Prepared By :

Approved By :

Issued By : M.R.

WORK INSTRUCTION FOR DIMENSION

INSPECTION

Doc. No.

WI-QC-21

Date/Rev No.

Page No.

20.06.2015/00

Page 3 of 3

Sign :

Sign :

Sign :

Date :18.06.2015

Date :

Date :

Casting Dimension Inspection Report

Dimension Inspection Control Plan

QC-FO-04

QC-FO-09

Anda mungkin juga menyukai

- DFT Measurement Worksheet: Paint InspectionDokumen1 halamanDFT Measurement Worksheet: Paint Inspectionjay nathBelum ada peringkat

- Al-Uqlah Central Processing Facility Water Level & Settlement TableDokumen12 halamanAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaBelum ada peringkat

- Samples Inspection ReportDokumen5 halamanSamples Inspection ReportArun GuptaBelum ada peringkat

- REPORT - Trial Mix Material Grout (Pumpable)Dokumen7 halamanREPORT - Trial Mix Material Grout (Pumpable)Triadi Bagus GumilarBelum ada peringkat

- E3 Sample NOI for HPU Type TestDokumen1 halamanE3 Sample NOI for HPU Type TestIsaac EdusahBelum ada peringkat

- FINAL Inspection Report PO#KL-3448 PDFDokumen21 halamanFINAL Inspection Report PO#KL-3448 PDFArslan HaiderBelum ada peringkat

- PMI Procedure for Verifying Alloy Elements in Metals by XRFDokumen2 halamanPMI Procedure for Verifying Alloy Elements in Metals by XRFMohamed NabilBelum ada peringkat

- Roundness Shell #1 - 1-Tank -012 BEFORE WELDDokumen2 halamanRoundness Shell #1 - 1-Tank -012 BEFORE WELDyuwantoniBelum ada peringkat

- Prevention Costs: Appraisal Costs: Internal Failure Costs: External Failure CostsDokumen35 halamanPrevention Costs: Appraisal Costs: Internal Failure Costs: External Failure CostsRaniaBelum ada peringkat

- Nig VT Spec QB S2 - Level IiDokumen12 halamanNig VT Spec QB S2 - Level Iikingston100% (1)

- Construction Organization Processes InteractionsDokumen1 halamanConstruction Organization Processes InteractionsfazalBelum ada peringkat

- Procedure For Vacuum Box TestingDokumen3 halamanProcedure For Vacuum Box TestingZakirUllahBelum ada peringkat

- Penetrant Test ReportDokumen1 halamanPenetrant Test Reportary rizki100% (1)

- ITP Final PLPS 82336-43 - ITP 150kV KENDARI ANDOOLO SECT 1 Rev1 Baruga PDFDokumen3 halamanITP Final PLPS 82336-43 - ITP 150kV KENDARI ANDOOLO SECT 1 Rev1 Baruga PDFMuhammad YahdimanBelum ada peringkat

- 17-05 Dimensional ControlDokumen1 halaman17-05 Dimensional ControlRyan GillespieBelum ada peringkat

- Inspection Plan NDTDokumen7 halamanInspection Plan NDTEdison WalitBelum ada peringkat

- Holiday Detection Test Report PDFDokumen1 halamanHoliday Detection Test Report PDFtonierlandaBelum ada peringkat

- Sop Welding RevisiDokumen12 halamanSop Welding RevisifandyBelum ada peringkat

- Material Receiving Inspection Report: Project TitleDokumen2 halamanMaterial Receiving Inspection Report: Project TitleGomathyselviBelum ada peringkat

- Magnesium Anode Test Quality Control and Inspection Report FormDokumen1 halamanMagnesium Anode Test Quality Control and Inspection Report FormsindalisindiBelum ada peringkat

- Handscan Mini MFL Tank Floor ScannerDokumen4 halamanHandscan Mini MFL Tank Floor ScannerBala Krishnan100% (1)

- General Specification For Visual TestingDokumen5 halamanGeneral Specification For Visual Testingsyukron_aBelum ada peringkat

- Jacking Procedurefor Construction of Tanks OLDDokumen10 halamanJacking Procedurefor Construction of Tanks OLDVikram RangasamyBelum ada peringkat

- 04 - Material Receiving Inspection Procedure - Asf-Qc-Mri-001Dokumen8 halaman04 - Material Receiving Inspection Procedure - Asf-Qc-Mri-001Sherif YehiaBelum ada peringkat

- Incoming Material FormatDokumen22 halamanIncoming Material Formattuan mai vanBelum ada peringkat

- Windals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportDokumen2 halamanWindals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportMurtza ArzaiBelum ada peringkat

- In-Situ Metallography Mett-Bio PDFDokumen3 halamanIn-Situ Metallography Mett-Bio PDFMettBioBelum ada peringkat

- Painting Report - FormatDokumen1 halamanPainting Report - FormatSenthil Kumaran100% (1)

- Daily Production Report For PrintDokumen24 halamanDaily Production Report For PrintnakultileBelum ada peringkat

- PMI Ferrite Measurement ProcedureDokumen7 halamanPMI Ferrite Measurement ProcedureAbd Rahman AliasBelum ada peringkat

- TWI CSWIP Training Plan - Dynaquest Energy LimitedDokumen2 halamanTWI CSWIP Training Plan - Dynaquest Energy LimitedAdeniyi100% (1)

- Factory Acceptance Test & SAT Site Acceptance TestDokumen3 halamanFactory Acceptance Test & SAT Site Acceptance TestMohamedBelum ada peringkat

- Inspection RoleDokumen18 halamanInspection Rolesribd9128Belum ada peringkat

- Weld ShrinkageDokumen16 halamanWeld ShrinkageWeff JingBelum ada peringkat

- MD PV Asme v0.1Dokumen35 halamanMD PV Asme v0.1Kamlesh LuharBelum ada peringkat

- QA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsDokumen1 halamanQA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsvinothBelum ada peringkat

- Magnetic Particle Testing ReporDokumen2 halamanMagnetic Particle Testing ReporGabriela MotaBelum ada peringkat

- QC 64247-1 Contact Plate Inspection ReportDokumen2 halamanQC 64247-1 Contact Plate Inspection ReportSenthil KumarBelum ada peringkat

- 2.8.2. Indicative QAP - ColumnsDokumen12 halaman2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- Circularity Inspection Report: Shell Course (LW) CW CWDokumen14 halamanCircularity Inspection Report: Shell Course (LW) CW CWaszlizaBelum ada peringkat

- Painting RecordDokumen1 halamanPainting RecordHimawan SetyarsoBelum ada peringkat

- Inward Material Inspection Report: Project Name: Job Code: LocationDokumen2 halamanInward Material Inspection Report: Project Name: Job Code: LocationTarun GodiyalBelum ada peringkat

- MES - Construction Quality Manual - Rev - 0Dokumen55 halamanMES - Construction Quality Manual - Rev - 0Ishaan ThakerBelum ada peringkat

- Method Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Dokumen4 halamanMethod Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Nigin Parambath50% (2)

- Weld Cleaning MethodsDokumen7 halamanWeld Cleaning MethodsTrần Thùy LinhBelum ada peringkat

- Factory Test ReportDokumen11 halamanFactory Test Reportderabeas100% (1)

- SAIC-RT-2001 Revw of RT ProcedureDokumen1 halamanSAIC-RT-2001 Revw of RT ProcedureKirubhakarPooranamBelum ada peringkat

- Assessing linearity of phased array instrumentsDokumen20 halamanAssessing linearity of phased array instrumentsKevin HuangBelum ada peringkat

- RT ProcedureDokumen18 halamanRT Procedure1339979Belum ada peringkat

- Field inspection plan for structural steel erectionDokumen1 halamanField inspection plan for structural steel erectionDelta akathehusky100% (1)

- Non-Destructive Testing RequirementsDokumen7 halamanNon-Destructive Testing RequirementsWill SmithBelum ada peringkat

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Dokumen7 halamanPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaBelum ada peringkat

- Dockweiler Bpe DirectDokumen52 halamanDockweiler Bpe Directpradeep281001Belum ada peringkat

- GRP Inspection Report SummaryDokumen2 halamanGRP Inspection Report SummaryJoseph Perez100% (1)

- QapDokumen9 halamanQaprenjithv_4Belum ada peringkat

- Industrial radiography A Complete Guide - 2019 EditionDari EverandIndustrial radiography A Complete Guide - 2019 EditionBelum ada peringkat

- Geometrical Dimensioning and TolerancingDokumen59 halamanGeometrical Dimensioning and TolerancingMathai Ouseph100% (2)

- Checking Fixture STDDokumen12 halamanChecking Fixture STDSandip PatilBelum ada peringkat

- GD&T - Test Rev1Dokumen6 halamanGD&T - Test Rev1Lucian Mudura25% (4)

- Questionnaire On Geometric Dimensions and TolerancesDokumen5 halamanQuestionnaire On Geometric Dimensions and TolerancesPOOJA KUMARIBelum ada peringkat

- Risk Register Analysis FormatDokumen5 halamanRisk Register Analysis FormatUmesh SakhareliyaBelum ada peringkat

- Supplier Registrtion FormDokumen4 halamanSupplier Registrtion FormUmesh SakhareliyaBelum ada peringkat

- Product No Gross Weight Casting Weight % Yield Method Rev. No Gross Weight at 60% YieldDokumen12 halamanProduct No Gross Weight Casting Weight % Yield Method Rev. No Gross Weight at 60% YieldUmesh SakhareliyaBelum ada peringkat

- Heat Data Sheet - ACADokumen90 halamanHeat Data Sheet - ACAUmesh SakhareliyaBelum ada peringkat

- MPT Log SheetDokumen12 halamanMPT Log SheetUmesh SakhareliyaBelum ada peringkat

- Testing and Calibration Agency ContactDokumen6 halamanTesting and Calibration Agency ContactUmesh SakhareliyaBelum ada peringkat

- Loan Amortization ScheduleDokumen9 halamanLoan Amortization ScheduleUmesh SakhareliyaBelum ada peringkat

- E-100-E-Questionnaire MM-Form1 (1) - Rev4Dokumen1 halamanE-100-E-Questionnaire MM-Form1 (1) - Rev4Umesh SakhareliyaBelum ada peringkat

- Job Profile: Degree CertificateDokumen4 halamanJob Profile: Degree CertificateUmesh SakhareliyaBelum ada peringkat

- E-100-E-Questionnaire MM-Form2-Rev3Dokumen1 halamanE-100-E-Questionnaire MM-Form2-Rev3Umesh SakhareliyaBelum ada peringkat

- CHALLANDokumen307 halamanCHALLANUmesh SakhareliyaBelum ada peringkat

- Customer Feedback FormDokumen1 halamanCustomer Feedback FormUmesh SakhareliyaBelum ada peringkat

- Hardness Conversion TableDokumen2 halamanHardness Conversion TableUmesh SakhareliyaBelum ada peringkat

- Steel Casing SolidificationDokumen1 halamanSteel Casing SolidificationUmesh SakhareliyaBelum ada peringkat

- A-Cast Foundry process sheet templateDokumen1 halamanA-Cast Foundry process sheet templateUmesh SakhareliyaBelum ada peringkat

- Machined Casting Sizes and Tolerances ChartDokumen2 halamanMachined Casting Sizes and Tolerances ChartUmesh Sakhareliya100% (1)

- WELDING INSTRUCTION FOR PROCESSDokumen8 halamanWELDING INSTRUCTION FOR PROCESSUmesh SakhareliyaBelum ada peringkat

- Steel Casing SolidificationDokumen1 halamanSteel Casing SolidificationUmesh SakhareliyaBelum ada peringkat

- Casting Defect and Its Cause For Fish BoneDokumen6 halamanCasting Defect and Its Cause For Fish BoneUmesh SakhareliyaBelum ada peringkat

- Equivalent GradesDokumen37 halamanEquivalent GradesUmesh SakhareliyaBelum ada peringkat

- Machined Casting Tolerance Chart: As Per IS: 2102 Tolerance (MM)Dokumen2 halamanMachined Casting Tolerance Chart: As Per IS: 2102 Tolerance (MM)Umesh SakhareliyaBelum ada peringkat

- PSI Tensile Mechanical Test ResultsDokumen8 halamanPSI Tensile Mechanical Test ResultsUmesh SakhareliyaBelum ada peringkat

- Geometric symbols and their descriptionsDokumen1 halamanGeometric symbols and their descriptionsUmesh SakhareliyaBelum ada peringkat

- COT Checklsist CrainDokumen1 halamanCOT Checklsist CrainUmesh SakhareliyaBelum ada peringkat

- Created By: Umesh Sakhareliya: Dimension Tolerance As Per ISO 8062Dokumen1 halamanCreated By: Umesh Sakhareliya: Dimension Tolerance As Per ISO 8062Umesh SakhareliyaBelum ada peringkat

- WPS & PQR FORMATE AS PER BPVC Sec-IX QW-482Dokumen6 halamanWPS & PQR FORMATE AS PER BPVC Sec-IX QW-482Umesh Sakhareliya100% (1)

- Date Product No Defect Root CauseDokumen2 halamanDate Product No Defect Root CauseUmesh SakhareliyaBelum ada peringkat

- 8062 Tolerance CalculationDokumen3 halaman8062 Tolerance CalculationUmesh SakhareliyaBelum ada peringkat

- Welding Data SheetDokumen12 halamanWelding Data SheetUmesh SakhareliyaBelum ada peringkat

- The Radical Axis of The Circumcircle and Incircle of A Bicentric QuadrilateralDokumen5 halamanThe Radical Axis of The Circumcircle and Incircle of A Bicentric QuadrilateralDũng Nguyễn TiếnBelum ada peringkat

- Solns 9Dokumen66 halamanSolns 9ramprakash_rampelliBelum ada peringkat

- Real Analysis Lecture SldiesDokumen16 halamanReal Analysis Lecture Sldiesruchi21july100% (1)

- Computer Science Important Question For Class 12 C++Dokumen24 halamanComputer Science Important Question For Class 12 C++Ravi singhBelum ada peringkat

- Theories of OrganizationsDokumen21 halamanTheories of Organizations1921 Pallav Pali100% (1)

- Unit Test Study Gulie: I Il-/ - ':: JDokumen6 halamanUnit Test Study Gulie: I Il-/ - ':: JPaulina TorresBelum ada peringkat

- NI ELVIS II Lab Exercises for Analog and Digital CircuitsDokumen150 halamanNI ELVIS II Lab Exercises for Analog and Digital Circuitszohas13Belum ada peringkat

- Dbms OutlineDokumen6 halamanDbms OutlineGeorge Mbiriri MuindiBelum ada peringkat

- Data Science Lab: Numpy: Numerical PythonDokumen71 halamanData Science Lab: Numpy: Numerical PythonPhamThi ThietBelum ada peringkat

- Survey or Review On Soft Set Theory and DevelopmentDokumen8 halamanSurvey or Review On Soft Set Theory and DevelopmentthesijBelum ada peringkat

- Thermodynamics Experiment Number 3 Radiation Correction Sarthak PDFDokumen9 halamanThermodynamics Experiment Number 3 Radiation Correction Sarthak PDFSarthak JainBelum ada peringkat

- ML 2 (Mainly KNN)Dokumen12 halamanML 2 (Mainly KNN)utpal100% (1)

- Transmission of DNA Genetic Information Into Water by Means of Electromagnetic Fields of Extremely-Low FrequenciesDokumen6 halamanTransmission of DNA Genetic Information Into Water by Means of Electromagnetic Fields of Extremely-Low FrequenciesFran De AquinoBelum ada peringkat

- C++ Binary Tree FunctionsDokumen5 halamanC++ Binary Tree FunctionsFahmi Rusdi Al IslamiBelum ada peringkat

- Recall The Innis Investments Problem Chapter 2 Problem 39 Letting S Units Purchased in The PDFDokumen4 halamanRecall The Innis Investments Problem Chapter 2 Problem 39 Letting S Units Purchased in The PDFCharlotte0% (1)

- Program To Multiply Two Sparse Matrices Using C Language: Course Code:-Mcs 021 Course Name:-Ds Q.1 AnsDokumen17 halamanProgram To Multiply Two Sparse Matrices Using C Language: Course Code:-Mcs 021 Course Name:-Ds Q.1 AnsAbinash MishraBelum ada peringkat

- Panjaitan & Sarah (2023) - Adaptasi Career Adapt-Abilities - Short Form Ke Versi Indonesia PDFDokumen11 halamanPanjaitan & Sarah (2023) - Adaptasi Career Adapt-Abilities - Short Form Ke Versi Indonesia PDFEliasFundiceBelum ada peringkat

- Experiment 1 Calorimetry - Hess's LawDokumen14 halamanExperiment 1 Calorimetry - Hess's Lawenieynaz100% (3)

- The Numbers Have An End: Mohamed Ababou Strengthens His Proof of a Finite Digit TheoryDokumen15 halamanThe Numbers Have An End: Mohamed Ababou Strengthens His Proof of a Finite Digit TheoryFredBelum ada peringkat

- Istanbul Aydin University: Chapter 4: Probability DistributionsDokumen12 halamanIstanbul Aydin University: Chapter 4: Probability Distributionsxxnameless 97Belum ada peringkat

- MY NOTES Linear RegressionDokumen6 halamanMY NOTES Linear RegressionbveshpsuBelum ada peringkat

- Ca PDFDokumen27 halamanCa PDFYousef MohamedBelum ada peringkat

- System Design and Analysis of Main Landing Gear StrutDokumen7 halamanSystem Design and Analysis of Main Landing Gear StrutjeffinBelum ada peringkat

- NAVY DSSC Exam Past Questions and AnswersDokumen7 halamanNAVY DSSC Exam Past Questions and AnswersEmmanuel AdegokeBelum ada peringkat

- Lai 474 LessonplanDokumen9 halamanLai 474 Lessonplanapi-272790316Belum ada peringkat

- Assignment & Tutorials 02Dokumen1 halamanAssignment & Tutorials 02priya shashikumarBelum ada peringkat

- UMATDokumen6 halamanUMATshahriar_B100% (2)

- Quantitative Finance: 1 Probability and StatisticsDokumen2 halamanQuantitative Finance: 1 Probability and StatisticsVidaup40Belum ada peringkat

- Ontology Reasoning With Deep Neural NetworksDokumen38 halamanOntology Reasoning With Deep Neural NetworksYamine KliouiBelum ada peringkat

- Fried BergDokumen3 halamanFried BergneedmyscribdBelum ada peringkat