Stucco Coating Investment Casting

Diunggah oleh

90gaurangJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Stucco Coating Investment Casting

Diunggah oleh

90gaurangHak Cipta:

Format Tersedia

US 20060086707Al

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2006/0086707 A1

Kou et al.

(54)

(43) Pub. Date:

ARC-ENHANCED FRICTION STIR

Apr. 27, 2006

Publication Classi?cation

WELDING

(51)

(76) Inventors: Sindo Kou, Madison, WI (US);

Guoping Cao, Madison, WI (US)

(52)

Int. Cl.

323K 9/00

323K 20/12

(2006.01)

(2006.01)

US. Cl. ................................. .. 219/137 R; 228/1121

Correspondence Address:

DEWITT ROSS & STEVENS, S.C.

Intellectual Property Department

(57)

ABSTRACT

Firstar Financial Centre

(21)

8000 Excelsior Drive suite 401

Friction stir welding is enhanced by preheating of the

Madison, WI 537174914 (Us)

10/970,058

workpiece with an electrical arc, such as an are applied by

a common gas-tungsten arc welding (GTAW) torch. As the

arc is moved about a path on the workpiece, it preheats or

Oct. 21, 2004

partially welds the path, with the friction stir welding head

following along the path to complete the weld.

Appl, No.1

(22) Filed:

20G

Patent Application Publication Apr. 27, 2006 Sheet 1 0f 3

FIG. I

US 2006/0086707 A1

Patent Application Publication Apr. 27, 2006 Sheet 2 0f 3

FIG. 2b

20+

v202

US 2006/0086707 A1

Patent Application Publication Apr. 27, 2006 Sheet 3 0f 3

F|6.3

US 2006/0086707 A1

Apr. 27, 2006

US 2006/0086707 A1

ARC-ENHANCED FRICTION STIR WELDING

method); US. Pat. No. 6,360,937 to De Koning (Friction

stir Welding); US. Pat. No. 6,354,483 to EZumi et al.

STATEMENT REGARDING FEDERALLY

SPONSORED RESEARCH

[0001] This invention Was made With United States gov

ernment support awarded by the National Science Founda

tion (NSF) in Grant No. 0098776. The United States has

certain rights in this invention.

FIELD OF THE INVENTION

[0002]

This document concerns an invention relating gen

erally to devices and methods for friction stir Welding, and

more speci?cally to devices and methods for reducing tool

Wear in (and enhancing the versatility of) friction stir

Welding.

6,302,315 to Thompson (Friction stir Welding machine and

method); US. Pat. No. 6,299,050 to Okamura et al. (Fric

tion stir Welding apparatus and method); US. Pat. No.

6,237,829 to Aota et al. (Friction stir Welding apparatus);

US. Pat. No. 6,053,391 to Heideman et al. (Friction stir

Welding tool); US. Pat. No. 5,813,592 to Midling et al.

(Friction stir Welding); and US. Pat. No. 5,794,835 to

Colligan et al. (Friction stir Welding).

[0004] While friction stir Welding is a valuable Welding

process, particularly for soft and/ or thin Workpieces, it tends

to suffer from the disadvantages that the friction stir Welding

heads rapidly Wear (particularly When harder materials are

BACKGROUND OF THE INVENTION

[0003]

(Friction stir Welding method); US. Pat. No. 6,315,187 to

Satou et al. (Friction stir Welding method); US. Pat. No.

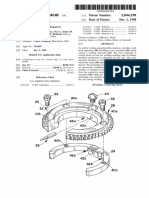

Friction stir Welding is a Welding process exem

being Welded). Additionally, it is often dif?cult to accom

plish friction stir Welding of materials With different melting

points or other physical properties.

pli?ed in the accompanying FIG. 1, Wherein a rotating

SUMMARY OF THE INVENTION

friction stir Welding tool 100 generally in the form of a

cylindrical head 102 extending from a larger-diameter cylin

drical shoulder 104 is rapidly rotated and contacted With a

Workpiece W to generate frictional heat and make the

Workpiece W plastic. The friction stir Welding head 102 is

plunged into the Workpiece W, usually until its shoulder 104

abuts the surface of the Workpiece W, to stir the area to be

Welded (generally a joint I betWeen tWo pieces of material

W1 and W2). The friction stir Welding head 102 may be held

in place to accomplish a spot Weld, or it may instead be

advanced along the joint I to form a linear Weld, as by

moving one or both of the friction stir Welding head 102 and

the Workpiece W. In the case Where the friction stir Welding

head 102 and the Workpiece W are moved relative to each

other, the head 102 is said to have an advancing side 106 (a

side Which moves in the same direction as the direction in

Which the head 102 moves relative to the Workpiece W), and

a retreating side (a side Which moves in the opposite

direction), Which is not visible in FIG. 1. Once the Weld is

complete, the friction stir Welding head 102 is removed from

the Workpiece W. Further details regarding friction stir

Welding can be found, for example, in US. Pat. No. 6,786,

388 to EZumi et al. (Friction stir Welding method); US.

Pat. No. 6,783,055 to EZumi et al. (Friction stir Welding

method and rotary tool); US. Pat. No. 6,780,525 to Lit

Winski (High strength friction stir Welding); US. Pat. No.

6,779,705 to EZumi et al. (Friction stir Welding method);

US. Pat. No. 6,742,696 to Thompson (Friction stir Welding

machine); US. Pat. No. 6,722,555 to EZumi et al. (Fric

tion stir Welding method); US. Pat. No. 6,715,664 to

Yamashita (Friction stir Welding method); US. Pat. No.

6,708,867 to Yoshinaga (Friction stir Welding method);

US. Pat. No. 6,676,004 to Trapp et al. (Tool for friction stir

Welding); US. Pat. No. 6,595,403 to Okamura et al.

(Friction stir Welding method); US. Pat. No. 6,554,175 to

Thompson (Friction stir Welding machine and method);

US. Pat. No. 6,536,651 to EZumi et al. (Friction stir

[0005] The invention involves Welding devices and meth

ods Which are intended to provide improved friction stir

Welding of at least some types of metals and Workpieces,

including Workpieces Wherein metals of different types are

to be joined. To give the reader a basic understanding of

some of the advantageous features of the invention, folloW

ing is a brief summary of preferred versions of the Welding

devices and methods, Which Will be described With reference

to the accompanying FIGS. 211-20 and 3. Since this is merely

a summary, it should be understood that more details regard

ing the preferred versions may be found in the Detailed

Description set forth elseWhere in this document. The claims

set forth at the end of this document then de?ne the various

versions of the invention in Which exclusive rights are

secured.

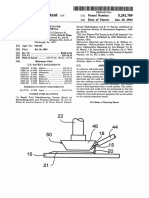

[0006]

In a preferred version of the invention exempli?ed

by FIGS. 2a-2c, a Welding device includes a torch 200 for

supplying an electrical arc 202 to a Workpiece W, and a

friction stir Welding head 204 Which frictionally stirs the

Workpiece W at the location(s) at Which the arc 202 is

applied. The Workpiece W may be a single piece of material

or several adjacently situated pieces (here W1 and W2)

spaced by joints J to be Welded, e.g., butt joints (Where the

edges of the pieces abut, as shoWn in FIGS. 2a-2c), lap

joints (Where the edges of the pieces overlap), or combina

tions of the tWo (e.g., tee joints, Wherein a butt joint is itself

abutted by an edge of another piece of material). The torch

200 and the friction stir Welding head 204 are movable With

respect to the Workpiece W, either by moving the Workpiece

W relative to the torch 200 and the friction stir Welding head

204 (as by situating the Workpiece W on a movable mount

ing bed, not shoWn), and/or by moving both the torch 200

and the friction stir Welding head 204 relative to the Work

piece W. The torch 200 and the friction stir Welding head 204

thereby travel about the Workpiece W to ?rst apply the arc

Welding method); US. Pat. No. 6,499,649 to Sayama et al.

202 to each location on the Workpiece W at Which a Weld is

(Friction stir Welding apparatus); US. Pat. No. 6,474,533

desired, and then apply frictional stirring. Such a location

to EZumi et al. (Friction stir Welding method); US. Pat.

No. 6,471,112 to Satou et al. (Friction stir Welding

method); US. Pat. No. 6,419,142 to Larson (Apparatus

for friction stir Welding); US. Pat. No. 6,367,681 to

Waldron et al. (Friction stir Welding apparatus and

may simply be a spot, or may instead be an extended line.

As an example, the torch 200 may be situated adjacent the

joint I of the Workpiece W to apply the arc 202, and may

then be moved along the joint I (as depicted in FIG. 2a). The

friction stir Welding head 204, Which may be movable With

Apr. 27, 2006

US 2006/0086707 A1

respect to the torch 200 and Which may be initially retracted

away from the workpiece W (as also depicted in FIG. 2a),

DETAILED DESCRIPTION OF PREFERRED

VERSIONS OF THE INVENTION

may then be moved into at least substantially the same plane

at Which the arc 202 Was initially located, and may then

the invention depicted in FIGS. 211-20 and 3 Will noW be

frictionally stir the Workpiece W along its joint I Where the

arc Was applied (as depicted in FIG. 2b). The friction stir

[0012] Further details regarding the exemplary versions of

provided, and the reader is encouraged to consult the fore

going Summary of the Invention if basic details are desired.

Welding head 204 may then folloW the torch 200 so that the

locations on the Workpiece W Which Were preheated by the

[0013] The invention is usefully implemented in auto

arc 202 are frictionally stirred, thereby completing the Weld

mated or substantially semi-automated form, With a robotic

(as depicted in FIG. 20). The arc 202 is preferably applied

at a voltage and current such that it does not melt the

Workpiece W, but rather plasticiZes it so that less energy

input is required by the friction stir Welding head 204 to

effect stirring. Alternatively, the arc 202 may melt the

Workpiece W, but in this case the arc 202 strength is

preferably such that by the time the friction stir Welding head

204 is applied to the arced location, the arced location Will

have at least partially solidi?ed.

[0007] The frictional stirring may be applied by situating

Welding unit including both the torch 200/300 and the

friction stir Welding head 204/304, and With a computer or

other controller directing the relative motion of the Work

piece W versus the torch 200/300 and the friction stir

Welding head 204/ 3 04 (and also directing the relative motion

of the friction stir Welding head 204/304 versus the torch

200/300, if any such motion is used). It should be understood

that the invention may move the Workpiece W With respect

to the Welding unit (i.e., With respect to the torch 200/300

and the friction stir Welding head 204/304), and/or the

Welding unit may move relative to the Workpiece W.

the torch 200 and friction stir Welding head 204 spaced from

each other on the same side of the Workpiece W (as depicted

in FIGS. 211-20), and after the torch 200 supplies the arc 202

[0014]

to some location(s) on the Workpiece W, the friction stir

Welding head 204 may then be moved onto the location(s) to

Which the torch 200 supplied the arc 202. In this manner, the

friction stir Welding head 204 folloWs the torch 200 about

the path it travels across the Workpiece W to frictionally stir

the location(s) to Which the arc 202 Was just supplied.

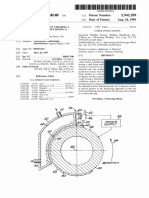

Alternatively, as shoWn in FIG. 3, the frictional stirring may

more of the folloWing functions. First, it holds the sections

be applied by situating the torch 300 and friction stir Welding

head 304 spaced from each other by the Workpiece W itself,

i.e., With the torch 300 and friction stir Welding head 304

being on opposite sides of the Workpiece W. In this case, the

friction stir Welding head 304 is preferably slightly spaced

from the torch 300 along the plane of the Workpiece W so

that the friction stir Welding head 304 is not directly opposite

the torch 300, and it again folloWs the torch 300 to friction

ally stir the location(s) to Which the arc (not shoWn) Was just

supplied.

While such an arrangement is not depicted in the

accompanying draWings, the Workpiece W is preferably

situated on a suitable mounting bed Which provides one or

W1 and W2 of the Workpiece W in place during Welding,

and positions the Workpiece W With respect to the Welding

unit, if the Workpiece W is to be moved. Second, it supports

the Workpiece W beneath the friction stir Welding head

204/304 so that the axial force of the head 204/304 onto the

Workpiece W is supported. Third, it serves to conduct

Welding current to or aWay from the Workpiece W for

effective application of the arc 202 (the arc not being shoWn

in FIG. 3). Such a mounting bed can take a Wide variety of

forms, and it need not necessarily take the form of an anvil

or other monolithic slab. As an example, it could simply take

the form of a roller (Which is preferably situated beneath the

Workpiece W to support the force exerted by the friction stir

Welding head 204/304), or some other structure Which only

supports the Workpiece W at selected points.

[0008] Further advantages, features, and objects of the

[0015] The invention may utiliZe any conventional means

for application of an arc 202 (i.e., any conventional torch

invention Will be apparent from the folloWing detailed

description of the invention in conjunction With the associ

Welding arrangement, With a common gas-tungsten arc

ated draWings.

BRIEF DESCRIPTION OF THE DRAWINGS

[0009]

FIG. 1 is a perspective vieW of a conventional

friction stir Welding arrangement.

[0010] FIGS. 2a-2c presents a perspective vieW of a ?rst

arc-enhanced friction stir Welding arrangement Which exem

pli?es the invention, Wherein the torch 200 applies an

electrical arc 202 to the joint I of the Workpiece W, With the

joint I subsequently being frictionally stirred by the friction

stir Welding head 204.

[0011]

FIG. 3 is a perspective vieW of a second arc

200/300) in conjunction With any conventional friction stir

Welding (GTAW) torch being a useful option. Inert gas

shielding of the arc 202 is recommended, though it may not

be necessary to have a gas supply project gas about the arc

202 if the electrode of the torch 200/300 and/or the Work

piece W are not susceptible to oxidation.

[0016]

As depicted in FIGS. 211-20 and 3, to reduce space

and to better alloW the torch 200/300 and friction stir

Welding head 204/304 to rest in close proximity, the torch

200/300 is preferably mounted at the end of an elongated

arm 206/306, With the arm 206/306 being oriented at an

angle of less than 45 degrees (and preferably nearly parallel)

to the plane of the portion of the Workpiece W over Which

the torch 200/300 rests, and With the torch 200/300 being

oriented at an angle of greater than 45 degrees (and prefer

enhanced friction stir Welding arrangement Which exempli

ably nearly perpendicular) With respect to the axis of the

?es the invention, Wherein the torch 300 applies an electrical

arc (not shoWn) to the joint I on one side of the Workpiece

elongated arm 206/306. In this manner, if the friction stir

Welding head 204/304 is oriented in a conventional manner

W, With the joint I also being frictionally stirred by the

With respect to the Workpiece W (i.e., perpendicular to the

friction stir Welding head 204 on the opposite side of the

Workpiece W or nearly so), the arm 206/306 of the torch

200/300 can rest closely nearby Without interfering With the

Workpiece W.

Apr. 27, 2006

US 2006/0086707 A1

friction stir Welding head 204/304, and/ or With any actuators

that advance and retract the friction stir Welding head

204/304 With respect to the workpiece W. GTAW torches

having short (approximately 0.5 inch) heads and 90-70

degree mountings, made for Welding in narroW/ small spaces,

are particularly useful.

[0017] To effectively Weld a given Workpiece W, one of

the primary parameters that must be determined is the

desired arc heat input per unit length of the Weld (Which can

[0020] As the friction stir Welding head 204/304 folloWs

the path of the torch 200/300, the stirred area preferably

overlaps With, but need not be centered about, the path of the

arc 202 applied by the torch 200/300. As an example, if a

Workpiece W includes tWo materials W1 and W2 having

different melting points, the arc 202 may be applied to only

the material With the higher melting point, on one side of the

joint I, With the friction stir Welding head 204/304 then

stirring both sides of the joint I. Most preferably, the friction

stir Welding head 204/304 has its retreating side (rather than

voltage, and V the Welding speed). These parameters are

its advancing side) situated over the location at Which the arc

202 Was applied, since this arrangement has been found to

preferably selected such that the applied arc 202 Will heat a

often result in less ?ash formation from the resulting Weld.

location on the Workpiece W to such an extent that the arced

[0021] FIG. 3 depicts the arrangement Wherein the arc

(not shoWn) of the torch 300 preheats one side of the

Workpiece W and frictionally stirs the Workpiece W on its

other side. This arrangement can more effectively preheat

the Workpiece W throughout its entire thickness: the arc

preheats one side of the Workpiece W, Whereas the other side

be expressed as IE/V, Wherein I is the arc current, E the arc

location Will be partially plastic (but not liquid) When

encountered by the friction stir Welding head 204/3 04. Thus,

the torch 200/300 need not melt the Workpiece W, and it may

simply heat the Workpiece W such that it softens and alloWs

a reduction in the axial load and torque applied by the

friction stir Welding head 204/3 04. This in turn reduces Wear

on the head 204/304 and alloWs an increase in Welding

speed. In essence, the torch 200/300 applies an arc 202 to

simply preheat the Workpiece (or at most perform partial

of the Workpiece W is effectively preheated by the rubbing

of the shoulder 308 as the friction stir Welding head 304

advances onto the arc-heated area. Since both sides of the

Workpiece W are preheated, the Workpiece W is better

Welding), With the friction stir Welding head 204/304 then

completing the Weld. A GTAW torch carrying up to about

plasticiZed throughout its entire thickness, thereby further

150 A With an arc voltage of approximately 20 volts (and

W.

thus approximately 3,000 W of preheating) has been found

to be generally su?icient.

[0018] Another parameter of importance is the distance (if

any) by Which the torch 200/300 precedes the friction stir

Welding head 204/304. This affects the amount of cooling

that the arced location Will experience before it is friction

ally stirred. In general, it is suf?cient to have the torch

200/300 precede the friction stir Welding head 204/304 by a

distance approximately equal to the diameter of the tool

shoulder 208/308. Workpieces W formed of materials that

have relatively loW thermal conductivity, such as steel,

stainless steel, and titanium, have a greater tendency to have

localiZed areas melt beneath the arc 202 before the heat

conducts to broader areas. In these cases, it is useful to

increase the distance betWeen the torch 200/300 and the

friction stir Welding head 204/304 to alloW more time for the

heat to diffuse through the Workpiece W, and alloW the arced

area of the Workpiece W to solidify, before the Workpiece W

is frictionally stirred at these areas.

[0019]

Other factors that in?uence heating are arc polarity

and arc oscillation (i.e., Whether the arc 202 is oscillated in

some direction, such as perpendicular to the joint I, as the

arc 202 is moved along the joint). Regarding arc polarity,

DC electronegative (DCEN) Welds, Which are commonly

used With GTAW of steels, tend to be narroW and deep With

Weld surfaces covered With oxide ?lms. With DC electrop

ositive (DCEP) Welds, the Welds tend to be Wide and shalloW

With Weld surfaces free of oxide ?lms. AC Welds, Which are

commonly used in GTAW of aluminum, tend to have

easing the frictional stirring of the material of the Workpiece

[0022] The arrangement of FIG. 3 might be modi?ed such

that the friction stir Welding head 304 is directly opposite the

torch 300 (or nearly so), such that the arc and the frictional

stirring are effectively applied to the same locations on the

Workpiece W at the same time. HoWever, this arrangement

is not preferred since the position of the torch 300 makes it

dif?cult to situate a support directly opposite the friction stir

Welding head 304 to counterbalance the forces it exerts

(though adjacent supports may be possible). Additionally,

the heat generated by the arc Will in this case usually not

have time to suf?ciently disperse that the entire areas being

approached by the friction stir Welding head 304 Will

plasticiZe. As a result, the friction stir Welding head 304 may

encounter more resistance in the Workpiece W. Further, the

friction stir Welding head 304 Will overheat and rapidly Wear

unless the arc heating is loW.

[0023]

The invention is not intended to be limited to the

preferred versions described above, but rather is intended to

be limited only by the claims set out beloW. Thus, the

invention encompasses all different versions that fall liter

ally or equivalently Within the scope of these claims.

1. A Welding device for Welding a Workpiece, the device

including:

a. a torch applying an electrical arc directly to the Work

piece, the torch lacking any means for supply meltable

material to the Workpiece,

b. a friction stir Welding head spaced from the torch, the

friction stir Welding bead frictionally stirring the Work

intermediate Width, penetration and surface cleanliness.

Thus, in corresponding fashion, Where the torch 200/300 is

piece,

a GTAW torch, it is preferred that DCEN be used to Weld

steels and that AC be used to Weld aluminum. Regarding arc

Wherein:

oscillation, this can usefully be implemented (particularly

(l) at least one of:

With the aforementioned materials of loW thermal conduc

tivity) to spread arc heating over a larger area on the

Workpiece W to plasticiZe it Without melting.

(a) the torch and friction stir Welding bead, and

(b) the Workpiece,

Apr. 27, 2006

US 2006/0086707 A1

is movable With respect to the other, whereby the torch

and friction stir Welding head travel about the Work

piece;

(2) the torch preheats the Workpiece Without supplying

any meltable material thereon; and

(3) the friction stir Welding head folloWs the path of the

torch about the Workpiece.

2. The Welding device of claim 1 Wherein the friction stir

Welding head is movable With respect to the torch, Whereby

the friction stir Welding bead may be moved into engage

ment With the Workpiece after the torch has applied the

electrical arc to the Workpiece.

3. The Welding device of claim 1 Wherein the friction stir

Welding head stirs an area of the Workpiece overlapping

With, but not centered about, the path of the torch.

4. The Welding device of claim 3 Wherein:

a. the friction stir Welding head rotates With respect to the

Workpiece, the friction stir Welding head thereby hav

ing:

(1) an advancing side moving in the direction of the

path along Which the friction stir Welding head

moves along the Workpiece, and

(2) a retreating side moving opposite to the direction of

the path along Which the friction stir Welding head

moves along the Workpiece; and

11. The method of claim 10 Wherein the frictional stirring

is applied to the Workpiece after the arc is initially applied.

12. The method of claim 10 Wherein the frictional stirring

is applied to an area of the Workpiece larger than the area of

the Workpiece upon Which the arc is applied.

13. The method of claim 10 Wherein the frictional stirring

is applied to an area of the Workpiece overlapping With, but

not centered about, the path of the torch.

14. The method of claim 10 Wherein:

a. the Workpiece includes at least a pair of objects to be

joined, the objects being adjacently situated along a

juncture, and

b. the electrical arc is applied along one side of the

juncture; and

c. the Workpiece is frictionally stirred along both sides of

the juncture, Whereby the objects on the opposing sides

of the juncture are both stirred.

15. (canceled)

16. A Welding device for Welding a Workpiece, the device

including a Welder having:

a. a torch connected to an electrical poWer supply,

Whereby the torch can generate an electrical arc; and

b. a rotatable friction stir Welding head spaced from the

torch,

b. the path of the torch is situated closer to the retreating

side of the friction stir Welding head than the retreating

side.

5. The Welding device of claim 1 Wherein:

Wherein:

a. the torch is mounted at or near the end of an elongated

arm, and

(2) at least one of the torch and the friction stir Welding

head is movable into at least substantially the same

plane as the other, and

b. the torch is oriented at an angle of greater than 45

degrees With respect to the axis of the elongated arm.

6. The Welding device of claim 1 Wherein:

a. the torch is mounted at or near the end of an elongated

arm, and

b. the arm is oriented at an angle of less than 45 degrees

With respect to the surface of the Workpiece.

7. The Welding device of claim 1 Wherein the torch and

the friction stir Welding head are situated on opposite sides

of the Workpiece.

(l) the Welder lacks any means for supplying meltable

material to the Workpiece:

(3) at least one of the Welder and the Workpiece is

movable With respect to the other, Whereby the Welder

may be moved along a path de?ned on the Workpiece.

17. The Welding device of claim 16 Wherein the torch and

the friction stir Welding head are situated on opposite sides

of the Workpiece.

18. (canceled)

19. A method for Welding a Workpiece, the method

including:

8. The Welding device of claim 1 Wherein the device

a. applying an electrical arc to a ?rst location situated on

contacts discrete points spaced about the Workpiece, With

the friction stir Welding head frictionally stirring each point

the Workpiece Without melting the Workpiece or any

material thereon;

at Which the torch applies its electrical arc.

9. The Welding device of claim 1 Wherein the device

contacts a length of the Workpiece, With the friction stir

b. removing the electrical arc from the ?rst location, and

Welding head frictionally stirring the length along Which the

?rst location.

20. The method of claim 19 Wherein:

torch applies its electrical arc.

10. A method for Welding a Workpiece, the method

including:

a. applying an electrical arc directly to the Workpiece

Without supplying any meltable material thereon,

b. frictionally stirring the Workpiece at a location spaced

from the arc,

Wherein the arc and the frictional stirring are applied

along a path on the Workpiece, With the frictional

stirring folloWing the arc along the path.

a. subsequently frictionally stirring the Workpiece at the

a. the step of removing the electrical arc from the ?rst

location is performed by moving at least one of the arc

and the Workpiece to apply the arc to a second location

situated on the Workpiece; and

b. the Workpiece is frictionally stirred at the locations at

Which the arc is applied.

21. The method of claim 20 Wherein the electrical arc is

continuously applied along the Workpiece from the ?rst

location to the second location.

US 2006/0086707 A1

Apr. 27, 2006

5

22. The method of claim 20 wherein the electrical arc is

not applied to the workpiece betWeen the ?rst location and

the second location.

23. The method of claim 10 Wherein the electrical arc does

not melt the Workpiece.

24. The method of claim 19 Wherein no meltable material

is added to the Workpiece at the ?rst location prior to or

during application of the electrical arc.

*

Anda mungkin juga menyukai

- D3 5-93PVDokumen8 halamanD3 5-93PVBirdyTheoBelum ada peringkat

- APPLIED MECHANICAL ENGINEERING PROBLEM SOLVINGDokumen4 halamanAPPLIED MECHANICAL ENGINEERING PROBLEM SOLVINGKyle LoveBelum ada peringkat

- PATENT - Axial Flux Motor AssemblyDokumen13 halamanPATENT - Axial Flux Motor Assemblyrakeshee2007Belum ada peringkat

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysDari EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysBelum ada peringkat

- Report Text About RainbowDokumen2 halamanReport Text About RainbowCornelia Ayu Trisna67% (3)

- Calculation of Steel Weldability and Weld Metal PropertyDokumen7 halamanCalculation of Steel Weldability and Weld Metal PropertyJohn Metaxas100% (1)

- Aggregate Impact Value TestDokumen6 halamanAggregate Impact Value Testnadz_fynazBelum ada peringkat

- FEECO Rotary Dryers Coolers PDFDokumen13 halamanFEECO Rotary Dryers Coolers PDFFernando MilmanBelum ada peringkat

- Chemical Engineering - 2010-04 (April)Dokumen100 halamanChemical Engineering - 2010-04 (April)Staszek BanachBelum ada peringkat

- Welding Technology Course Covers Procedures and VariablesDokumen35 halamanWelding Technology Course Covers Procedures and VariablesKrishnamoorthi Venkatesan100% (1)

- Study On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelDokumen8 halamanStudy On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelIJMERBelum ada peringkat

- Flash Butt Welding Method for Rail Steel with Controlled Heat-Affected ZoneDokumen20 halamanFlash Butt Welding Method for Rail Steel with Controlled Heat-Affected ZoneRakesh SrivastavaBelum ada peringkat

- Centrifugal Pump Piping Design LayoutDokumen16 halamanCentrifugal Pump Piping Design Layoutzizitro-1Belum ada peringkat

- Us 20040158969Dokumen5 halamanUs 20040158969dgfhjsdg hfsdhyjBelum ada peringkat

- Ulllted States Patent (19) (11) Patent Number: 6,075,224: de Coster (45) Date of Patent: Jun. 13, 2000Dokumen9 halamanUlllted States Patent (19) (11) Patent Number: 6,075,224: de Coster (45) Date of Patent: Jun. 13, 2000KrozeBelum ada peringkat

- Orbital Welding Rotor Assembly Reduces ArcingDokumen9 halamanOrbital Welding Rotor Assembly Reduces ArcingAngel GutierrezBelum ada peringkat

- United States Patent (191: Merz Et A1. Date of PatentDokumen13 halamanUnited States Patent (191: Merz Et A1. Date of Patentbonmarche28Belum ada peringkat

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0108418 A1Dokumen5 halamanUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0108418 A1shamsBelum ada peringkat

- US6581308Dokumen5 halamanUS6581308PUVAN TSTBelum ada peringkat

- Patent Application for a Directional Drilling Machine ViseDokumen11 halamanPatent Application for a Directional Drilling Machine ViseCường Nguyễn QuốcBelum ada peringkat

- Warm Forming PatentDokumen27 halamanWarm Forming PatentAndy HuffBelum ada peringkat

- FSW Lab - Complete ManualDokumen15 halamanFSW Lab - Complete ManualKrishnaKishoreReddyBelum ada peringkat

- CH 48Dokumen32 halamanCH 48islammonirBelum ada peringkat

- Friction Stir Welding-Process Developmentannd VariantDokumen21 halamanFriction Stir Welding-Process Developmentannd VariantrobertalhaBelum ada peringkat

- United States: (12) Patent Application Publication (10) Pub. No.: US 2003/0019100 A1Dokumen10 halamanUnited States: (12) Patent Application Publication (10) Pub. No.: US 2003/0019100 A1amd mhmBelum ada peringkat

- The Simultaneous Use of Two or More Friction Stir Welding ToolsDokumen6 halamanThe Simultaneous Use of Two or More Friction Stir Welding ToolsrobertalhaBelum ada peringkat

- Archery Bow Vibration Dampener Device Reduces ShockDokumen10 halamanArchery Bow Vibration Dampener Device Reduces Shockemnm30Belum ada peringkat

- Centri Cobra TattooDokumen9 halamanCentri Cobra TattooJeremy BloodBelum ada peringkat

- Types of Welding JointDokumen6 halamanTypes of Welding JointTesema TeshomeBelum ada peringkat

- Connecting Rod Cracker: Rigid Support and Floating Die Crack Connecting RodsDokumen12 halamanConnecting Rod Cracker: Rigid Support and Floating Die Crack Connecting RodsOkta Pariantoro Budi SetiawanBelum ada peringkat

- Chapter 6 - WeldingDokumen20 halamanChapter 6 - WeldingDipayan DasBelum ada peringkat

- Bending of Hollow Structural Sections - 03.12.18Dokumen6 halamanBending of Hollow Structural Sections - 03.12.18David ArndtBelum ada peringkat

- Smooth Surface WP PatentDokumen9 halamanSmooth Surface WP Patentprabhatkumar_6657012Belum ada peringkat

- Cutting Machine Using Wire SawDokumen10 halamanCutting Machine Using Wire SawMohammad FareedBelum ada peringkat

- United States Patent: Noveske (10) Patent N0.: (45) Date of PatentDokumen9 halamanUnited States Patent: Noveske (10) Patent N0.: (45) Date of Patentduffy5555Belum ada peringkat

- Method for Repairing Castings by Pouring Melted Filler MaterialDokumen10 halamanMethod for Repairing Castings by Pouring Melted Filler Materialtyhello21Belum ada peringkat

- Improved Tesla Turbine DesignDokumen12 halamanImproved Tesla Turbine DesignNemanja StojanovicBelum ada peringkat

- March 3, 1970 C. D. Weiss 3,497,942: Method of Welding Tungsten Carbide Materials To SteelDokumen4 halamanMarch 3, 1970 C. D. Weiss 3,497,942: Method of Welding Tungsten Carbide Materials To SteelPonce MrlnBelum ada peringkat

- Buttres ThreadDokumen3 halamanButtres ThreadjojoBelum ada peringkat

- US6435783 - Variable Radius Notching MachineDokumen48 halamanUS6435783 - Variable Radius Notching MachineJackie SongBelum ada peringkat

- United States Patent: (10) Patent N0.: (45) Date of PatentDokumen16 halamanUnited States Patent: (10) Patent N0.: (45) Date of PatentSelvaraji MuthuBelum ada peringkat

- United States Patent (19) : Park Et Al. (11) Patent NumberDokumen10 halamanUnited States Patent (19) : Park Et Al. (11) Patent NumberCarlos ArenasBelum ada peringkat

- Fundamentals of Friction Stir Welding, Its Application, and AdvancementsDokumen50 halamanFundamentals of Friction Stir Welding, Its Application, and Advancementsjose ramirez cruzBelum ada peringkat

- Patent Application Publication (10) Pub. No.: US 2002/0153034 A1Dokumen25 halamanPatent Application Publication (10) Pub. No.: US 2002/0153034 A1Paballo MontleBelum ada peringkat

- United States Patent 1191 1111 3,956,085: Haas (45) May 11, 1976Dokumen4 halamanUnited States Patent 1191 1111 3,956,085: Haas (45) May 11, 1976Alejandro Saravia AlcócerBelum ada peringkat

- US20100059503 Pulse Electrothermal Deicing (PETD) of Complex Shapes Application (IceMakers)Dokumen9 halamanUS20100059503 Pulse Electrothermal Deicing (PETD) of Complex Shapes Application (IceMakers)PolarStarBelum ada peringkat

- Tài liệu5Dokumen12 halamanTài liệu5Hoàng ĐứcBelum ada peringkat

- US7743601Dokumen4 halamanUS7743601Alien GmpBelum ada peringkat

- Heat Plat ApplicationDokumen6 halamanHeat Plat ApplicationJDC - Export ManagerBelum ada peringkat

- Method of Increasing Strength of Welded Slat Assembly for Inflatable PackersDokumen6 halamanMethod of Increasing Strength of Welded Slat Assembly for Inflatable Packersmohammadreza91Belum ada peringkat

- United States Patent: IP IPDokumen11 halamanUnited States Patent: IP IPAdriana Daniela SanduBelum ada peringkat

- Friction WeldingDokumen25 halamanFriction WeldingBHAVESH JOSHI0% (1)

- 336D2 L Excavator ZCT00001-UP (MACHINE) POWERED BY C9 Engine (SEBP6532 - 27) - Documentation PDFDokumen11 halaman336D2 L Excavator ZCT00001-UP (MACHINE) POWERED BY C9 Engine (SEBP6532 - 27) - Documentation PDFGeovanny SanjuanBelum ada peringkat

- General Welding GuidelinesDokumen13 halamanGeneral Welding GuidelinesSamir669Belum ada peringkat

- United States Patent (10) Patent No.: US 6,237,387 B1: Yoshizawa Et Al. (45) Date of Patent: May 29, 2001Dokumen7 halamanUnited States Patent (10) Patent No.: US 6,237,387 B1: Yoshizawa Et Al. (45) Date of Patent: May 29, 2001tajshah283Belum ada peringkat

- Study of Friction WeldingDokumen49 halamanStudy of Friction Weldingouterrace100% (1)

- Friction Based Welding Technology For Aluminium (July 2002) - TWI (BACKING NEEDED)Dokumen11 halamanFriction Based Welding Technology For Aluminium (July 2002) - TWI (BACKING NEEDED)Amar DJEDIDBelum ada peringkat

- WeldingDokumen27 halamanWeldingCleo Elveña100% (1)

- The Everyday Pocket Handbook On Welded Joint DetailsDokumen30 halamanThe Everyday Pocket Handbook On Welded Joint Detailsaqeel5Belum ada peringkat

- US20030006538A1Dokumen15 halamanUS20030006538A1Nqobane MakhobaBelum ada peringkat

- United States Patent (19) : (54) Multi-Torch Interface AssemblyDokumen12 halamanUnited States Patent (19) : (54) Multi-Torch Interface AssemblyKrozeBelum ada peringkat

- United States Patent: (10) Patent No.: (45) Date of PatentDokumen10 halamanUnited States Patent: (10) Patent No.: (45) Date of PatentPriyankaBelum ada peringkat

- 2 Classification of Welding PDFDokumen31 halaman2 Classification of Welding PDFSiva Narendra100% (2)

- A1010 WeldingDokumen20 halamanA1010 WeldingCurious RajBelum ada peringkat

- SMST-Tubes Boiler Brochure 2009Dokumen12 halamanSMST-Tubes Boiler Brochure 2009ghostinshellBelum ada peringkat

- Properties of GasesDokumen51 halamanProperties of Gases90gaurangBelum ada peringkat

- Attendence of Mc-A and MC-B From HDT (Maths)Dokumen13 halamanAttendence of Mc-A and MC-B From HDT (Maths)90gaurangBelum ada peringkat

- CS1999Dokumen15 halamanCS1999inaylakBelum ada peringkat

- CONTRACT SHEET EVENT PAYMENTDokumen1 halamanCONTRACT SHEET EVENT PAYMENT90gaurangBelum ada peringkat

- Experiment No 10Dokumen7 halamanExperiment No 1090gaurangBelum ada peringkat

- Experiment No: 11: Aim: To Study About Critical Path Method and Program Evaluation Review Technique Critical Path MethodDokumen20 halamanExperiment No: 11: Aim: To Study About Critical Path Method and Program Evaluation Review Technique Critical Path Method90gaurangBelum ada peringkat

- How To Implement Lean ManufacturingDokumen2 halamanHow To Implement Lean Manufacturing90gaurangBelum ada peringkat

- Ex No 7Dokumen11 halamanEx No 790gaurangBelum ada peringkat

- Experiment No 9Dokumen10 halamanExperiment No 990gaurangBelum ada peringkat

- Ex No 8Dokumen12 halamanEx No 890gaurangBelum ada peringkat

- Ex No 6Dokumen9 halamanEx No 690gaurangBelum ada peringkat

- Experiment No. 5: AIM: To Study About Gantt ChartDokumen11 halamanExperiment No. 5: AIM: To Study About Gantt Chart90gaurangBelum ada peringkat

- Ex No 4Dokumen9 halamanEx No 490gaurangBelum ada peringkat

- Ex No 1Dokumen6 halamanEx No 190gaurangBelum ada peringkat

- Resins Word DocumentDokumen8 halamanResins Word DocumentHarish KakraniBelum ada peringkat

- Motion Canada - Bearing CatalogDokumen212 halamanMotion Canada - Bearing CatalogEric Lafrance100% (1)

- Ancient Cementitious MaterialsDokumen17 halamanAncient Cementitious Materialsenea3000Belum ada peringkat

- Phytochemical, Proximate and Nutrient Analysis of Cassia Tora SeedsDokumen3 halamanPhytochemical, Proximate and Nutrient Analysis of Cassia Tora SeedsinventionjournalsBelum ada peringkat

- Properties of SoilDokumen18 halamanProperties of Soiltouqeer AbroBelum ada peringkat

- b28113433 PDFDokumen202 halamanb28113433 PDFJuthika GogoiBelum ada peringkat

- TDS Energrease MP-MG 2 InfoDokumen9 halamanTDS Energrease MP-MG 2 InfoLucian IftemieBelum ada peringkat

- Iso 8502 - 6Dokumen1 halamanIso 8502 - 6Ahmad BadriBelum ada peringkat

- UST Organic Chemistry Lab Separates Malunggay CompoundsDokumen6 halamanUST Organic Chemistry Lab Separates Malunggay CompoundsAnonymouscatBelum ada peringkat

- CX 21Dokumen25 halamanCX 21OmariniYepezBelum ada peringkat

- Black SandDokumen2 halamanBlack SandMinato100% (1)

- Epsilon Echos 2 BDokumen40 halamanEpsilon Echos 2 BDaniel JoseBelum ada peringkat

- 2DoorCatalogue 2012-0Dokumen15 halaman2DoorCatalogue 2012-0Akanksha GuptaBelum ada peringkat

- Unit 2 Welding III HazDokumen9 halamanUnit 2 Welding III HazHada NanuBelum ada peringkat

- Session 6 - Analytical Chem - Complexation and Precipitation Part 2Dokumen22 halamanSession 6 - Analytical Chem - Complexation and Precipitation Part 2MehdiBelum ada peringkat

- SITI SOLEHAH BINTI OMAR (2015834112) /EH224 7A1 Heuristics of ReactorDokumen2 halamanSITI SOLEHAH BINTI OMAR (2015834112) /EH224 7A1 Heuristics of ReactorSolehah OmarBelum ada peringkat

- Scaffold in Tissue EngDokumen13 halamanScaffold in Tissue EngOluwasegun ModupeBelum ada peringkat

- Megtron 6Dokumen3 halamanMegtron 6rfduh100% (1)

- Hydrogen-Enriched Compressed Natural Gas As A Fuel For EnginesDokumen26 halamanHydrogen-Enriched Compressed Natural Gas As A Fuel For EnginesRahul AroraBelum ada peringkat

- MSc Surveying and Water Resources TopicsDokumen3 halamanMSc Surveying and Water Resources TopicsNirjhor KabirBelum ada peringkat

- Third Order Elastic ConstantsDokumen3 halamanThird Order Elastic ConstantsElango PaulchamyBelum ada peringkat

- Sheet 1Dokumen10 halamanSheet 1lawanBelum ada peringkat

- Etruscan CeramicDokumen18 halamanEtruscan Ceramicapi-3850604100% (1)

- Aiats PDFDokumen2 halamanAiats PDFAbhishek Kumar SinghBelum ada peringkat