VS200.V2 Sealey

Diunggah oleh

audioimagenHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

VS200.V2 Sealey

Diunggah oleh

audioimagenHak Cipta:

Format Tersedia

VS200.

V2,VS200D

Instructions for:

PETROL ENGINE COMPRESSION TEST KIT &

DELUXE TEST KIT

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

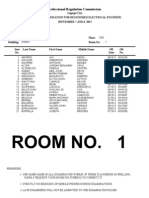

Item

1

Part Number

VS200D/01

VS200/A

2

3

4

--

VS200/5

VS200/6

VS200D/02

VS200D/84

Description

Compression Tester c/w 14mm/

18mm Thread Adaptor

12mm Thread Adaptor

10mm Thread Adaptor

Flexible Air Input Adaptor

c/w Airline Coupling

Long Reach 14mm Thread Adaptor

(VS200D ONLY)

Case + Insert

VS200D

1.

VS200.V2

INTRODUCTION & APPLICATIONS

PETROL ENGINES - Cylinder Compression testing incorporating Air Input Adaptor for valve seal/spring replacement.

1.1

VS200D Deluxe Kit

Includes Compression Tester VS200D/01 and a range of Adaptors for tests through 10mm, 12mm, 14mm & 18mm spark plug holes.

The VS200D Kit also incorporates VS200/A Long Reach Adaptor for deep seated 14mm spark plug holes in 16v. and V6 engines eg. Ford Zetec/Duratec, Vauxhall

Ecotec etc. and VS200D/02 Flexible Air Input Adaptor for valve seal and spring replacement applications.

VS200.V2 is as above but does not include VS200/A Long Reach Adaptor.

1.2

CONTENTS

VS200D/01 Petrol Engine Compression Tester comprises a quality dual scale pressure gauge (0-25 bar/0-350psi), re-test valve (pressure relief valve) and

flexible hose fitted with standard 14mm/18mm spark plug adaptor.

VS200/5 & VS200/6 Adaptors convert the 14/18mm adaptor of VS200D/01 Tester to cover 10mm and 12mm spark plug holes.

VS200/A Long Reach Adaptor (VS200D only) is used in conjunction with VS200D/01 Tester for tests on engines with very deep seated 14mm. long thread

spark plug holes, found on many 16v. and V6 engines.

VS200D/02 Air Input Adaptor assists valve seal/spring replacement by providing the connections to allow compressed air into the cylinder to maintain the valves

in closed position. Utilises the adaptors in the kit to allow use across a wide range of engines.

p

7

3

3

3

3

3

3

s

2.

SAFETY INSTRUCTIONS

WARNING! Ensure all Health & Safety, local authority and general workshop practice regulations are strictly adhered to when using tools.

DO NOT use equipment if damaged.

Maintain the equipment in good and clean condition for best and safest performance.

If required, ensure vehicle to be worked on is adequately supported with axle stands, ramps and chocks.

Wear approved eye protection. A full range of personal safety equipment is available from your Sealey dealer.

Wear suitable clothing to avoid snagging. Do not wear jewellery and tie back long hair.

Account for all tools and equipment being used and do not leave them in, on or near engine.

When not in use, place in protective case and store in a safe, dry, childproof area.

IMPORTANT: Always refer to the vehicle manufacturers service instructions, or a proprietary manual, to establish the current procedure and data. These

instructions are provided as a guide only.

VS200.V2 & VS200D - 1 - 151004

3.

INSTRUCTIONS

3.1

Performance Guide:Compression should build up quickly in a healthy engine.

A low compression on the first stroke, followed by gradually increasing pressure on successive strokes,

indicates worn piston rings.

A low compression reading on the first stroke, which does not build up during successive strokes, indicates

leaking valves or a faulty head gasket (a cracked head could also be the cause).

Deposits on the undersides of the valve heads can also cause low compression.

If the pressure in any cylinder is considerably lower than the others, introduce a small quantity of clean oil into

that cylinder through its spark plug hole, and repeat the test.

If the addition of oil temporarily improves the compression pressure, this indicates that bore or piston wear is

responsible for the pressure loss.

No improvement suggests that the leakage is past the valves, or a faulty head gasket may be to blame.

A low reading from two adjacent cylinders suggests a faulty head gasket between the two cylinders. The

presence of coolant in the engine oil will confirm this.

If the compression is unusually high, the combustion chambers are probably coated with carbon deposits. If

this is the case, the cylinder head should be removed and de-carbonised.

3.2

When engine performance is down, or if misfiring occurs which cannot be attributed to ignition or fuel systems,

a compression test can provide diagnostic clues as to the engines condition.

As a guide engines having a compression pressure in excess of 6.9 bar (100psi), compression loss should not exceed 0.69 bar (10psi), on older engines with

lower compression pressure, loss should not exceed 0.35 bar (5psi).

3.3

3.3.1

3.3.2

3.3.3

3.3.4

OPERATION

Check engine oil is up to recommended level.

Remove the spark plugs.

Attach the required adaptor to VS200D/01 Tester and screw into the first spark plug port ensuring a good seal onto the O-ring.

Turn over the engine using the starter motor and observe the gauge, looking for a steady increase in the reading (see Performance Guide) and noting the

maximum reading obtained. Refer to the engine manufacturers workshop manual for compression data.

3.3.5 Depress the Re-test Valve (situated under the gauge) to release the pressure. The Re-test Valve allows the test to be repeated without disconnecting from the

cylinder.

WARNING! Always release pressure via the Re-test Valve BEFORE disconnecting the Tester. Press Re-test valve slowly to release pressure gradually.

p

3.3.6 Disconnect the compression tester and adaptor and install on the next cylinder.

Repeat the test for each of the remaining cylinders in turn.

NOTE: A variation in compression readings between cylinders is often a better indication of engine problems than the absolute values of compression.

3.4

3.4.1

3.4.2

s

VS200D/02 Air Input Adaptor - Valve Seal/Spring Replacement.

Remove the spark plugs and turn over the engine so that the piston of the cylinder being worked on is at TDC with all valves closed.

Select the appropriate spark plug thread adaptor and attach it to the VS200D/02 Air Input Adaptor.

IMPORTANT: If using the VS200/A Long Reach Adaptor, the non-return valve MUST BE REMOVED from the adaptor to allow free air flow.

3.4.3 Attach the airline coupling to the Air Input Adaptor.

3.4.4 Screw this assembled Air Input Adaptor into the spark plug hole and connect to the workshop compressed air supply which will pressurise the cylinder and

maintain the valves in the closed position facilitating work on seal/spring replacement.

VS200D/01 Petrol Engine Compression Tester Spares: -

VS200D/011 Gauge & Cover

VS200D/012 Hose Assembly

VS2042/012 Re-Test Valve Assembly

VS2042/014 Replacement Valve Assy for VS2042/012 Re-Test Valve

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

Sole UK Distributor,

Sealey Group,

Bury St. Edmunds, Suffolk.

01284 757500

01284 703534

sales@sealey.co.uk

Web

www.sealey.co.uk

VS200.V2 & VS200D - 1 - 151004

Anda mungkin juga menyukai

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Dari EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Penilaian: 1 dari 5 bintang1/5 (3)

- Foote-Jones 8000 Series Gear Reducer ManualDokumen20 halamanFoote-Jones 8000 Series Gear Reducer ManualbwelzBelum ada peringkat

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Dari EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Penilaian: 5 dari 5 bintang5/5 (1)

- Balcrank 1130-001 Tiger PumpDokumen8 halamanBalcrank 1130-001 Tiger PumpJoseph GeraciBelum ada peringkat

- Deutz TCD2012Dokumen96 halamanDeutz TCD2012MinaSaeed93% (14)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDari EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualBelum ada peringkat

- Gas AbsorptionDokumen93 halamanGas AbsorptionArgie Adduru73% (11)

- 3rd Quarter Examination in Hope 4Dokumen5 halaman3rd Quarter Examination in Hope 4Hazel Joan Tan100% (3)

- Patel, Anita - Super Indian Snack and Street Food Recipes PDFDokumen117 halamanPatel, Anita - Super Indian Snack and Street Food Recipes PDFBella ImèneBelum ada peringkat

- Top Mounted From MooriDokumen11 halamanTop Mounted From MooriBisoyiBelum ada peringkat

- Tf0628 Operating Instructions and Parts ManualDokumen12 halamanTf0628 Operating Instructions and Parts ManualJoe TorresBelum ada peringkat

- Aire Acondicionado ServicioDokumen6 halamanAire Acondicionado ServicioTEROBelum ada peringkat

- Cylinder Leakage Tester 2 - Gauge Vse2020.V3: 1. SafetyDokumen2 halamanCylinder Leakage Tester 2 - Gauge Vse2020.V3: 1. Safetyhotmaail4Belum ada peringkat

- Sis 631 PRTDokumen15 halamanSis 631 PRTAshraf m aliBelum ada peringkat

- Diesel High Pressure Pump Test Kit: 1. SafetyDokumen4 halamanDiesel High Pressure Pump Test Kit: 1. SafetyVladimirAgeevBelum ada peringkat

- Comprecion Del MotorDokumen2 halamanComprecion Del Motoralex martinez coroBelum ada peringkat

- 45-200-D Catalogo GASTDokumen15 halaman45-200-D Catalogo GASTealcBelum ada peringkat

- Technical Note: 1.0 Maintenance ScheduleDokumen6 halamanTechnical Note: 1.0 Maintenance ScheduleJhan Carlos RamosBelum ada peringkat

- 35391B RevaDokumen234 halaman35391B RevaFelipe FloresBelum ada peringkat

- Catalytic Converter and Exhaust Back PressureDokumen2 halamanCatalytic Converter and Exhaust Back PressureeiochoaBelum ada peringkat

- SS815Dokumen24 halamanSS815Adel Ahmed100% (1)

- Brands Vilter Manual VMC 400 SeriesDokumen234 halamanBrands Vilter Manual VMC 400 SeriesJose Ricardo Prado SandovalBelum ada peringkat

- Air Springs Cab - ConvolutedDokumen98 halamanAir Springs Cab - ConvolutedСергей ЕгоровBelum ada peringkat

- Pump-Elite - Operating InstructionsDokumen12 halamanPump-Elite - Operating Instructionsbookslover1Belum ada peringkat

- 2 Installation Maintenance - FantechDokumen12 halaman2 Installation Maintenance - FantechLoi Chan TuBelum ada peringkat

- MD of 241 Vil Ter Compressor ManualDokumen234 halamanMD of 241 Vil Ter Compressor Manualsergiopaul100% (1)

- Instalación y Mantenimiento de Válvulas RotativasDokumen4 halamanInstalación y Mantenimiento de Válvulas RotativasGustavo León CarreraBelum ada peringkat

- Rotalube-Stewart Systems 4 Outlet PDU SystemDokumen21 halamanRotalube-Stewart Systems 4 Outlet PDU SystemĐất RồngBelum ada peringkat

- Manual Soldadura RidwellDokumen12 halamanManual Soldadura RidwellPablo MazalanBelum ada peringkat

- VSE2020.V2: Cylinder Leakage TesterDokumen2 halamanVSE2020.V2: Cylinder Leakage Testerwalson glen CrastaBelum ada peringkat

- High Pressure Instruction Manual (H2041)Dokumen26 halamanHigh Pressure Instruction Manual (H2041)Dario Morales100% (3)

- 06T Semihermetic Screw CompressorDokumen8 halaman06T Semihermetic Screw CompressorAbu Malak CiprianoBelum ada peringkat

- Ed 01 (EN)Dokumen36 halamanEd 01 (EN)Mesafint kassieBelum ada peringkat

- 8 15 Engine ManualDokumen24 halaman8 15 Engine ManualhainguyenbkvhvBelum ada peringkat

- Manual RLR 300 A 700 UKDokumen49 halamanManual RLR 300 A 700 UKLucyan Ionescu100% (1)

- 722.9 Tranny Oil Line FlushDokumen3 halaman722.9 Tranny Oil Line FlushAntonio da LuzBelum ada peringkat

- 2013Dokumen102 halaman2013ctorres_505746100% (1)

- Gate Valve MaintenanceDokumen8 halamanGate Valve Maintenancechar_lynBelum ada peringkat

- Ed 03 (EN)Dokumen38 halamanEd 03 (EN)Mesafint kassieBelum ada peringkat

- Partes y Piezas Compresor Schultz - MSI-2.6MLDokumen2 halamanPartes y Piezas Compresor Schultz - MSI-2.6MLWinca MantezBelum ada peringkat

- Orbital Motor Type RE Technical Manual DOC267980227406Dokumen40 halamanOrbital Motor Type RE Technical Manual DOC267980227406JustinBelum ada peringkat

- Installation and Maintenance Information: StartersDokumen32 halamanInstallation and Maintenance Information: StartersRicardoAguilarHidalgoBelum ada peringkat

- Ingersoll Rand SS815 Parts ManualDokumen36 halamanIngersoll Rand SS815 Parts ManualSergei KurpishBelum ada peringkat

- Installation and Repair Manual For Compressor G4481/G6204 Lincoln Air Vantage WelderDokumen23 halamanInstallation and Repair Manual For Compressor G4481/G6204 Lincoln Air Vantage WelderJamie RobertsBelum ada peringkat

- Vse952 DFC0166998Dokumen2 halamanVse952 DFC0166998ابوفاطمةاليساريBelum ada peringkat

- Chicago Pneumatic - Air Compressor - Instruction and Maintenance Manual - 6758900 - 01 PDFDokumen38 halamanChicago Pneumatic - Air Compressor - Instruction and Maintenance Manual - 6758900 - 01 PDFDelcinei Valentim MauricioBelum ada peringkat

- QGS 10 - 15 Instruction ManualDokumen38 halamanQGS 10 - 15 Instruction ManualGustavo GamarraBelum ada peringkat

- AlupDokumen38 halamanAlupALEXANDER GAMEZBelum ada peringkat

- Air Compressor OperationDokumen13 halamanAir Compressor OperationRomie HarieBelum ada peringkat

- Orbital Motors: Type WSDokumen48 halamanOrbital Motors: Type WSSouvik MukherjeeBelum ada peringkat

- SA英文使用手册NEWDokumen49 halamanSA英文使用手册NEWBernad Orlando0% (1)

- Operating and Maintenance Instructions PDFDokumen13 halamanOperating and Maintenance Instructions PDFshihabBelum ada peringkat

- Instruction Manual Air Compressor HL2/140Dokumen12 halamanInstruction Manual Air Compressor HL2/140juanpabloizuBelum ada peringkat

- Manual Compresor Amico MateoDokumen20 halamanManual Compresor Amico MateoSanchez HenriquezBelum ada peringkat

- Moocoowooodoo 987Dokumen32 halamanMoocoowooodoo 987scribbedd55Belum ada peringkat

- General Instructions For Safe Operation of High Pressure CompressorsDokumen6 halamanGeneral Instructions For Safe Operation of High Pressure CompressorsTansu MavunacıBelum ada peringkat

- Senator LSV Series With Mam-660 ControllerDokumen64 halamanSenator LSV Series With Mam-660 ControllerRomanCHubaBelum ada peringkat

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- Diesel Engine Care and Repair: A Captain's Quick GuideDari EverandDiesel Engine Care and Repair: A Captain's Quick GuidePenilaian: 5 dari 5 bintang5/5 (1)

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Dari EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Penilaian: 3 dari 5 bintang3/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDari EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceBelum ada peringkat

- Service Station Manual: Vespa LX - S 125 3V Ie 150 3V Ie (2012)Dokumen251 halamanService Station Manual: Vespa LX - S 125 3V Ie 150 3V Ie (2012)audioimagenBelum ada peringkat

- Instruction Manual: Safety PrecautionsDokumen2 halamanInstruction Manual: Safety PrecautionsaudioimagenBelum ada peringkat

- BMW Vehicle Communication Software Manual: August 2009Dokumen131 halamanBMW Vehicle Communication Software Manual: August 2009celiesBelum ada peringkat

- BMWEnginesDokumen3 halamanBMWEnginesJuan G. Gonzalez F.100% (1)

- VS200.V2 SealeyDokumen2 halamanVS200.V2 SealeyaudioimagenBelum ada peringkat

- Pistola Estroboscópica SAMDokumen16 halamanPistola Estroboscópica SAMaudioimagenBelum ada peringkat

- SAC Clutch Alignment ToolDokumen2 halamanSAC Clutch Alignment ToolaudioimagenBelum ada peringkat

- Compresor de Muelles SEALEYDokumen2 halamanCompresor de Muelles SEALEYaudioimagenBelum ada peringkat

- Later Style ATE Brake Servo: O-RingDokumen2 halamanLater Style ATE Brake Servo: O-RingaudioimagenBelum ada peringkat

- Brake Booster RebuildDokumen32 halamanBrake Booster RebuildaudioimagenBelum ada peringkat

- Ajuste Tensor Distribución M70Dokumen2 halamanAjuste Tensor Distribución M70audioimagenBelum ada peringkat

- Brake Booster RebuildDokumen32 halamanBrake Booster RebuildaudioimagenBelum ada peringkat

- Ajuste Tensor Distribución M70Dokumen2 halamanAjuste Tensor Distribución M70audioimagenBelum ada peringkat

- BMW Car - August 2020Dokumen86 halamanBMW Car - August 2020audioimagenBelum ada peringkat

- BMWEnginesDokumen3 halamanBMWEnginesJuan G. Gonzalez F.100% (1)

- BMW - Introduction To Coding & ProgrammingDokumen9 halamanBMW - Introduction To Coding & ProgrammingPaul JohnBelum ada peringkat

- BMW E31 8 Series - Roof RackDokumen10 halamanBMW E31 8 Series - Roof RackaudioimagenBelum ada peringkat

- General Introduction Manual: ©jephis Technology LTDDokumen5 halamanGeneral Introduction Manual: ©jephis Technology LTDaudioimagen100% (1)

- Jurnal Praktikum Dasar-Dasar Pemisahan Kimia Pembuatan Membran Polysulfon (PSF)Dokumen9 halamanJurnal Praktikum Dasar-Dasar Pemisahan Kimia Pembuatan Membran Polysulfon (PSF)Rizki AuBelum ada peringkat

- Boiler Sizing Guide PDFDokumen1 halamanBoiler Sizing Guide PDFfmkhan21100% (1)

- Evolution of Indian TolucaDokumen28 halamanEvolution of Indian TolucaAlberto Duran IniestraBelum ada peringkat

- Quiz13 130630200754 Phpapp02Dokumen10 halamanQuiz13 130630200754 Phpapp02anukrititiwaBelum ada peringkat

- 4mb/01r-Que-2023 Jun Edexcel PastpaperDokumen24 halaman4mb/01r-Que-2023 Jun Edexcel Pastpaperaugust.shwanBelum ada peringkat

- Interzinc 2280 Product BrochureDokumen4 halamanInterzinc 2280 Product BrochureAshish Raul CIEBelum ada peringkat

- DuranDuran OrdinaryWorldDokumen1 halamanDuranDuran OrdinaryWorldEduardo LuzBelum ada peringkat

- D 5431 - 93 Rdu0mzetotmDokumen4 halamanD 5431 - 93 Rdu0mzetotmJuanBelum ada peringkat

- 06 Brakes PDFDokumen6 halaman06 Brakes PDFAKILI PSIBelum ada peringkat

- Bruker d8 XRD TutoriallDokumen16 halamanBruker d8 XRD TutoriallravarBelum ada peringkat

- Estimating Crack Widths in Steel Fibre-Reinforced ConcreteDokumen12 halamanEstimating Crack Widths in Steel Fibre-Reinforced ConcreteRm1262Belum ada peringkat

- Research Paper On TurbojetDokumen6 halamanResearch Paper On Turbojetqptwukrif100% (1)

- Perbedaan Fermentasi Dan Respirasi Anaerob (Campbell Biology 12th Ed.)Dokumen4 halamanPerbedaan Fermentasi Dan Respirasi Anaerob (Campbell Biology 12th Ed.)Oppof7 OppoBelum ada peringkat

- REE0913ra LegazpiDokumen6 halamanREE0913ra LegazpiScoopBoyBelum ada peringkat

- EN 301.908-2 Ver 3.2.1Dokumen37 halamanEN 301.908-2 Ver 3.2.1DHDIDIDBelum ada peringkat

- Tubular Flow ReactorDokumen24 halamanTubular Flow ReactorluismiguelmmercadoBelum ada peringkat

- G 10 ICT WorkSheetc 2.2 English MDokumen8 halamanG 10 ICT WorkSheetc 2.2 English MMohamaad SihatthBelum ada peringkat

- SBB Product NoteDokumen3 halamanSBB Product NoteFilipe MartinsBelum ada peringkat

- Textile and ClothingDokumen12 halamanTextile and ClothingAstra CloeBelum ada peringkat

- The Tenth House in AstrologyDokumen6 halamanThe Tenth House in AstrologytratakBelum ada peringkat

- Use of Information Technology in The Flight Catering ServicesDokumen32 halamanUse of Information Technology in The Flight Catering ServicesAbhiroop SenBelum ada peringkat

- Lymphoid OrganDokumen23 halamanLymphoid OrganSwetha RameshBelum ada peringkat

- All About CupcakesDokumen4 halamanAll About CupcakesRevtech RevalbosBelum ada peringkat

- What Makes A Cup of NESCAFÉ So Special? The Best Coffee Beans andDokumen4 halamanWhat Makes A Cup of NESCAFÉ So Special? The Best Coffee Beans andYenny YanyanBelum ada peringkat

- Slides Arrays Two Dimensional ArraysDokumen12 halamanSlides Arrays Two Dimensional ArraysPratham MishraBelum ada peringkat

- Enzymes MCQsDokumen2 halamanEnzymes MCQsNobody's PerfectBelum ada peringkat

- Baluarte BridgeDokumen1 halamanBaluarte BridgeIndra MishraBelum ada peringkat

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)