MNT en File 4.1 Introduction Clean Service

Diunggah oleh

edsonleviHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

MNT en File 4.1 Introduction Clean Service

Diunggah oleh

edsonleviHak Cipta:

Format Tersedia

LESER Information Document

LID_EN 1003.03

Maintenance Handbook for

LESER Product Group Clean Service

Seite 1/6

MAINTENANCE

public

Maintenance Handbook for

LESER Product Group

Clean Service Series 48X

disclosure cat.:

author:

resp. depart.:

released by:

PM

published date:

revision No.:

doc. type:

LID

LESER Information Document

LID_EN 1003.03

Maintenance Handbook for

LESER Product Group Clean Service

Seite 2/6

Introduction

About MAINTENANCE

MAINTENANCE provides a collection of documents for repairing or maintaining LESER

safety valves. The following topics are covered:

Maintenance Fundamentals of LESER safety valves (terminology, design elements

relevant for valve operation)

Repair process

Suggested equipment for assembling, disassembling and rework of critical parts

Disassembly, including sectional drawings

Rework of critical parts including an overview of critical dimensions

Assembly, including options

Spring charts

Testing procedures (set pressure and leak tests)

Spare parts lists

Guidelines for inspection, storage and transport

Trouble shooting

disclosure cat.:

author:

resp. depart.:

released by:

PM

published date:

revision No.:

public

doc. type:

LID

LESER Information Document

LID_EN 1003.03

Maintenance Handbook for

LESER Product Group Clean Service

Seite 3/6

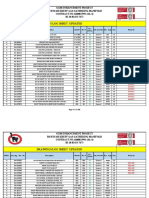

Contents

Chapter

Content

Sources

1.1 Introduction

Introduction and table of contents

LID 1003.03

Introduction

1.2 Maintenance

Fundamentals

Terminology:

LID 1002.00

Maintenance

Fundamentals

- Parts

- Set pressure

- Overpressure & blowdown

Critical parts:

- Nozzle & disc

public

- Spring

- Adjusting ring

- Parts providing alignment

- Lifting devices

1.3 Repair process

-Process of Safety Valves to Repair

-Repair Traveller

LGS 4111

Process for Safety

Valves to Repair

LGS 4112

Repair Traveller

1.4 Suggested equipment

Equipment for disassembly and

lapping

- Required equipment with technical

information

- Order numbers of LESER

equipment

1.5 Disassembly and

Cleaning

LGS 4459

Clean Service_Tool-Kit

Specifications

LGS 4456

Standard Tool

Specification

- Equipment and materials

LGS 4116

Operating materials

and supplies for

repaired valves

Disassembly instruction:

LGS 4108

Dismantling

instructions for types

483, 484, 485, 488

- Step-by-step instruction for

disassembly

Cleaning instructions

disclosure cat.:

author:

resp. depart.:

released by:

PM

published date:

revision No.:

doc. type:

LID

Chapter

LESER Information Document

LID_EN 1003.03

Maintenance Handbook for

LESER Product Group Clean Service

Seite 4/6

Content

Sources

LGS 4105

Dismantling

instructions for types

437, 438, 439, 481

LGS 4115

Cleaning repaired

valves

1.6 Rework of critical parts

1.7 Assembly

The rework of critical

parts like seat and disc

does not apply to the

Clean Service Series,

because all Types have

a soft seat disc.

Assembly instruction:

LGS 4100

Assembly instructions

for types 437, 438, 439,

481

Torques:

- Assembly torques for body-bonnet

connection, caps, test gags, O-ring

discs and bellows

After Assembly:

- Color finishing and painting

- Component plate

LGS 3323

Torques for screw,

nuts and caps H2 /

lifting devices

LGS 3325

Torques ranges for

O-ring-disc

LGS 4114

Paint touch-up and

painting repaired

valves

LGS 4118

Component plates

1.8 Spring charts

Spring charts:

- Overview of spring ranges for set

pressure adjustments and spring

selection in bar and psi

disclosure cat.:

author:

resp. depart.:

released by:

PM

published date:

revision No.:

LGS 3620

Spring charts type

481

doc. type:

LID

public

- Step-by-step instruction for

assembly

LGS 4103

Assembly instructions

for types 483, 484, 485,

488

Chapter

LESER Information Document

LID_EN 1003.03

Maintenance Handbook for

LESER Product Group Clean Service

Seite 5/6

Content

Sources

LGS 3621

Spring charts type

483

LGS 3622

Spring charts type

484

LGS 3623

Spring charts type

485

LGS 3624

Spring charts type

488

1.9 Testing Procedures

Testing set pressure:

Leak testing:

- Procedures and equipment for

testing functional tightness (discnozzle connection)

LGS 4434

Performing Leak

Tests

- Procedures and equipment for

testing shell tightness (nozzle, cap)

Tightness requirements:

- Seat tightness

LGS 0201

Tightness Test

- Shell tightness

- Back seat tightness

1.10 Spare parts

Last visual check up

LGS 4117

Final visual inspection

of repaired valves

Spare parts list

LWN 483.01

Spare parts type 481

LWN 483.01

Spare parts type 483

LWN 483.01

Spare parts type 484

disclosure cat.:

author:

resp. depart.:

released by:

PM

published date:

revision No.:

doc. type:

LID

public

- Procedures and equipment for

setting and testing the cold

differential test pressure, including

tolerances

LDeS 1001.69

CDTP-Cold differential

test pressure

Chapter

LESER Information Document

LID_EN 1003.03

Maintenance Handbook for

LESER Product Group Clean Service

Seite 6/6

Content

Sources

LWN 483.01

Spare parts type 485

LWN 483.01

Spare parts type 488

1.11 Installation & storage

Testing and inspection before

installation:

- visual inspection of the valve

- hydraulic pressure test

disclosure cat.:

author:

Inspection intervals

Extract from LWN

753.00

Recommendation for

Testing and Inspection

during Operation

Storage and transport

Extract from LWN

753.00 Storage and

Handling of Safety

Valves

Typical errors

Extract from LWN

765.01 Typical

Mistakes as a Result of

Unauthorized Repair

resp. depart.:

released by:

PM

published date:

revision No.:

doc. type:

LID

public

1.12 Trouble shooting

Extract from LWN

753.00 Testing and

Inspection of Safety

Valves before

Installation

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Company Profile - PetrominDokumen26 halamanCompany Profile - Petrominapi-306897329100% (2)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- 07P Operating Manual Vc999Dokumen74 halaman07P Operating Manual Vc999yeraslash100% (4)

- Coast Aluminum Catalog, 2019Dokumen200 halamanCoast Aluminum Catalog, 2019roberto silvaBelum ada peringkat

- KPMG Global Automotive Retail Market StudyDokumen28 halamanKPMG Global Automotive Retail Market StudydeepakkkeniBelum ada peringkat

- Strategic Study Greener 2017 2018 PDFDokumen75 halamanStrategic Study Greener 2017 2018 PDFedsonleviBelum ada peringkat

- Replacement Parts for Fette Tablet PressesDokumen84 halamanReplacement Parts for Fette Tablet Pressesedsonlevi100% (1)

- Schneider Electric Utility Scale Brochure PDFDokumen24 halamanSchneider Electric Utility Scale Brochure PDFedsonleviBelum ada peringkat

- Eu 1 - QMSDokumen5 halamanEu 1 - QMSapi-3859063Belum ada peringkat

- First Solar Series 3 Black Plus Module: User GuideDokumen15 halamanFirst Solar Series 3 Black Plus Module: User GuideedsonleviBelum ada peringkat

- Bill of Materials Type 481 enDokumen2 halamanBill of Materials Type 481 enedsonleviBelum ada peringkat

- DS ACPowerBlock A4Dokumen2 halamanDS ACPowerBlock A4edsonleviBelum ada peringkat

- Series 4 User Guide PDFDokumen18 halamanSeries 4 User Guide PDFedsonleviBelum ada peringkat

- CATALOG 2015 / 2016: Make The Most of Your EnergyDokumen65 halamanCATALOG 2015 / 2016: Make The Most of Your EnergyedsonleviBelum ada peringkat

- Sampling of starting and packaging materialsDokumen2 halamanSampling of starting and packaging materialsGautam KumarBelum ada peringkat

- MNT en File 4.1 Introduction Clean ServiceDokumen6 halamanMNT en File 4.1 Introduction Clean ServiceedsonleviBelum ada peringkat

- EHB en 3-TerminologyDokumen32 halamanEHB en 3-TerminologyedsonleviBelum ada peringkat

- Handling Reports of Suspected Quality Defects in Medicinal ProductsDokumen7 halamanHandling Reports of Suspected Quality Defects in Medicinal ProductsedsonleviBelum ada peringkat

- Compilation of Community Procedures On Inspections and Exchange of InformationDokumen9 halamanCompilation of Community Procedures On Inspections and Exchange of InformationedsonleviBelum ada peringkat

- Isolator ISPE Study 2008Dokumen51 halamanIsolator ISPE Study 2008edsonleviBelum ada peringkat

- FDA Sterile Product Manufacturing GuidelinesDokumen63 halamanFDA Sterile Product Manufacturing GuidelinesSmartishag Bediako100% (2)

- Mylan Engineering GuideDokumen9 halamanMylan Engineering GuideedsonleviBelum ada peringkat

- RABS DefinitionDokumen0 halamanRABS DefinitionAbdan ShidqiBelum ada peringkat

- Glove Box BrochureDokumen21 halamanGlove Box BrochureedsonleviBelum ada peringkat

- IT Hypalon Glove SpecDokumen2 halamanIT Hypalon Glove SpecedsonleviBelum ada peringkat

- Catalogue 20MCC 20 - EnglishDokumen154 halamanCatalogue 20MCC 20 - EnglishedsonleviBelum ada peringkat

- 2013 Symposiums SYMP003-2 Optimizing Ventilation Calculations 3-25-2013Dokumen25 halaman2013 Symposiums SYMP003-2 Optimizing Ventilation Calculations 3-25-2013edsonleviBelum ada peringkat

- Ultra BrochureDokumen4 halamanUltra BrochureedsonleviBelum ada peringkat

- CAT992Dokumen24 halamanCAT992Miriam Ruiz Cabellos100% (1)

- The Future Scenario of Marketing CommunicationDokumen6 halamanThe Future Scenario of Marketing Communicationlambanaveen123Belum ada peringkat

- 03 Sheet Metal FormingDokumen38 halaman03 Sheet Metal FormingPanBelum ada peringkat

- Bleriot XIDokumen8 halamanBleriot XIAlejandro M. Bianchi100% (1)

- Toyo CatalogDokumen196 halamanToyo CatalogAnand SinghBelum ada peringkat

- Brochure - FTTH Drop Cabinet For 48f & 96f Customer ConnectionsDokumen8 halamanBrochure - FTTH Drop Cabinet For 48f & 96f Customer ConnectionskmalBelum ada peringkat

- 2016 en PSDHandbook 2016 ScreenDokumen241 halaman2016 en PSDHandbook 2016 ScreenpreydisBelum ada peringkat

- Instruction Manual: SpecificationsDokumen16 halamanInstruction Manual: SpecificationsJorge L. ContrerasBelum ada peringkat

- Pass RulesDokumen40 halamanPass Ruleslvsaru50% (2)

- Turbomachinery For Ammonia Plants: Man TurboDokumen20 halamanTurbomachinery For Ammonia Plants: Man TurboavwnashBelum ada peringkat

- OSS ReferenceDokumen336 halamanOSS ReferenceMonish R Nath50% (2)

- Assam & Nagaland 1Dokumen218 halamanAssam & Nagaland 1Ahmer KhanBelum ada peringkat

- Up 11-22Dokumen91 halamanUp 11-22Tamjid Kabir100% (2)

- Tecnotion Torque Motor Brochure Ver 10120150120Dokumen16 halamanTecnotion Torque Motor Brochure Ver 10120150120ElectromateBelum ada peringkat

- Torneado del peón: Procesos de manufactura en el laboratorioDokumen14 halamanTorneado del peón: Procesos de manufactura en el laboratorioDanny Urtecho Ponte100% (1)

- GGM Enhancement Project Drawings Log Sheet UpdatedDokumen198 halamanGGM Enhancement Project Drawings Log Sheet UpdatedJohn BuntalesBelum ada peringkat

- Mechanical Engineer Resume For FresherDokumen5 halamanMechanical Engineer Resume For FresherIrfan Sayeem SultanBelum ada peringkat

- Maintenance Technician Job OpeningDokumen1 halamanMaintenance Technician Job OpeningRizky NafandyBelum ada peringkat

- Industrial Training: Muhammad Amiruddin Bin Hassan 161382895 Ry44 - Integrated Electronic Alps Electric (M) SDN BHDDokumen17 halamanIndustrial Training: Muhammad Amiruddin Bin Hassan 161382895 Ry44 - Integrated Electronic Alps Electric (M) SDN BHDAmiruddin HassanBelum ada peringkat

- Ut Calibration Blocks DetailsDokumen44 halamanUt Calibration Blocks Detailsmdsajidalam100% (4)

- Chapter 3 Master SchedulingDokumen5 halamanChapter 3 Master SchedulingKamble AbhijitBelum ada peringkat

- Quotations FormatDokumen3 halamanQuotations FormatRakeshBelum ada peringkat

- Brochure Al Osais International Holding CompanyDokumen4 halamanBrochure Al Osais International Holding CompanyhafezasadBelum ada peringkat

- OSA-06-Vibration Fatigue Analysis of Sheet Metal Mahindra2wheelerDokumen11 halamanOSA-06-Vibration Fatigue Analysis of Sheet Metal Mahindra2wheelerikramishereBelum ada peringkat

- Service Bulletin: Product Update: Drive Belt Auto-Tensioner Pivot Bolt ReplacementDokumen4 halamanService Bulletin: Product Update: Drive Belt Auto-Tensioner Pivot Bolt ReplacementJeffrey TuasonBelum ada peringkat

- 1 - SAP BPC NW 10.0 Script Logic Implementation Guide V18Dokumen84 halaman1 - SAP BPC NW 10.0 Script Logic Implementation Guide V18Angel Ammulu100% (1)