Appendix A

Diunggah oleh

Ali HassanDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Appendix A

Diunggah oleh

Ali HassanHak Cipta:

Format Tersedia

a

Working Drawing Problems

Beginning Level Problems

PROBLEM 1

Directions for Problem 1

Create the Plumb bob using 3D modeling techniques. Create detail drawings of the 2 objects

and an assembly drawing.

TWO PICTORIAL VIEWS OF

THE CAP ARE PROVIDED

FOR CLARITY

A1

A2

PROBLEM 2

Directions for Problem 2

Create a solids model and develop detail drawing for the parts of the hammer. The handle

section has 2 different styles; choose one style only for the project. A separate sheet will

have an assembly drawing created.

METRIC

Appendix A Working Drawing Problems

PROBLEM 3

Directions for Problem 3

Create solids model and generate a detail drawing of both the Caster and Wheel from the

freehand sketch. Additional design information is provided on the CAD drawing for the caster

support. Experiment with different wheel support designs for the caster keep the wheel in

the current measured position in any re-design.

A3

A4

PROBLEM 4

Directions for Problem 4

Create a solids model of the key ring assembly. Detail each part for production purposes,

create an assembly drawing including parts list.

Appendix A Working Drawing Problems

PROBLEM 5

Directions for Problem 5

Using the drawing, create the parts of the traffic barrier as a solid model. Create a drawing

as a 3D assembly view of a traffic barrier.

PROBLEM 6

Directions for Problem 6

Using the sketches, create solid models of each of the pieces of the metric scale clamp

assembly. Develop detail drawings of each piece. An assembly model and parts list of all the

pieces is also required.

A5

A6

Intermediate Level Drawings

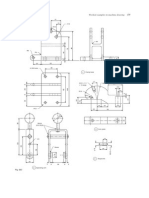

PROBLEM 7

Directions for Problem 7

Using the sketches create solid models of each of the pieces of the winch assembly. Develop detail

drawings of each piece. An assembly model and parts list of all the pieces is also required.

Appendix A Working Drawing Problems

A7

A8

PROBLEM 8

Directions for Problem 8

Create a solids model of the roller assembly; create detail drawings for each of the parts along

with an assembly view. The balloons indicate each separate part of the roller assembly.

1.688

1.38

2

2

.625

.06

FN-2

3.75

1.63

1.063

.75

1.25

FN-2

4

3.25

.25

RC-6

3.625

.375

.375

FN-1

LC-6

.375

.50

.88

.88

3.25

.25

1.50

.25

1.50

6

4.0

.25

Appendix A Working Drawing Problems

PROBLEM 9

Directions for Problem 9

Create a complete set of working drawings of the provided house plan. Develop the missing

elevational views (side and rear), a typical wall sectional view along with the foundation plan.

The foundation plan will have 8" wide concrete walls, 16" wide footers at a basement depth of

8' for the wall height. The garage and front and rear porches will have a footer depth of 3'.

A9

A10

Appendix A Working Drawing Problems

A11

A12

Advanced Level Drawings

PROBLEM 10

Directions for Problem 10

Using the provided drawing create pedestrian bridge as a 3D solid assembly.

Appendix A Working Drawing Problems

PROBLEM 11

Directions for Problem 11

Create the Mill Work Stop assembly as a series of solid model parts. The knobs are purchase

parts so their dimension will come from specifications sheets. These specifications sheets

are available through parts suppliers like Carr Lane Manufaturing and are available through

the Internet.

ITEM QTY NAME

DESCRIPTION

MATERIAL NOTES

VERTICAL MEMBER 3/4 X2 X 4

SAE 6061

BASE MEMBER

1 X 2 X 3.5

SAE 6061

RIB

1/4 PLATE

SAE 6061

ARM

3/8 X 1 X 5-1/2

SAE 1018

CLAMP

1/2 X 1 X 1-5/16

SAE 1018

TEE PLATE

5/16 X X1 X 1-1/4 SAE 1018

STOP ROD

5/16 X 6

WING NUT

1/4 - 28 X 1/2

BUSHING

1/2 X .31

10

TEE STUD

3/8-16 X 2 LG

ALL THREAD

11

CARRAIGE BOLT

5/16-18UNC-2

12

HAND KNOB

HK-4A

ALUMINUM

3/8-16UNC-2B

13

HAND KNOB

HK-2A

ALUMINUM

5/16-18UNC-2B

DRILL AND

TAP AT

CENTER FOR

5/16-18UNC-2

THREAD

SAE 303 SS

SAE 1018

A13

A14

Appendix A Working Drawing Problems

PROBLEM 12

Directions for Problem 12

Create as a solid model the parts that make up the ball valve. Each part will have a detail

drawing, and an overall assembly drawing of the ball valve will complete this project. Use the

dimensioned drawing and the parts list for sizing information.

10

END CAP

BRASS

1DT1010

BALL

STAINLESS STEEL

1DT1009

WASHER

PLASTIC

1DT1008

VALVE

BODY

BRASS

1DT1007

PLASTIC

1DT1006

WASHER

STEM

WASHER

STAINLESS STEEL

1DT1004

5DT1003

O-RING

PARKER #2-008

HANDLE

HANDLE

NUT

5/16-24UNF-2

QTY

NAME

KEY

1DT1005

PLASTIC

DESCRIPTION

PARTS LIST

1DT1002

5DT1001

PART NO.

A15

A16

PROBLEM 13

Directions for Problem 13

Create a solid model of the pump house. Use the drawing provided to develop the exterior and

interior components of the building. Alternate project: Create a complete set of working drawings of the pump house using the details below. As an option a scale model could be built.

Appendix A Working Drawing Problems

PROBLEM 14

Directions for Problem 14

Using the drawing layout create the sections of pre-cast cement pipe that is used in the

standard gravity Manhole. The Pipe will be created as a 3D solid object. Include and inlet and

outlet openings in the pipe section. When completed create both detail and an assembly

drawing of the pre-cast concrete sections.

A17

A18

PROBLEM 15

Directions for Problem 15

Create each of the parts of the worm gear reducer as a solid model. Each part will have a

detail drawing, and an overall assembly drawing of the worm gear reducer will complete this

project. Use the dimensioned drawing and the parts list for sizing information.

Appendix A Working Drawing Problems

A19

A20

Appendix A Working Drawing Problems

A21

Anda mungkin juga menyukai

- Advanced AutoCAD® 2022 Exercise Workbook: For Windows®Dari EverandAdvanced AutoCAD® 2022 Exercise Workbook: For Windows®Belum ada peringkat

- Assembly Drawing ExercisesDokumen57 halamanAssembly Drawing ExercisesAli HassanBelum ada peringkat

- Workshop DIY PROJECTSDokumen75 halamanWorkshop DIY PROJECTSEmijo.A100% (1)

- Steel Plate 2Dokumen32 halamanSteel Plate 2Rollen de LeonBelum ada peringkat

- Transformer Sizing CalculationDokumen6 halamanTransformer Sizing CalculationAvijnan Mitra100% (3)

- Simply Gearbox DesignDokumen39 halamanSimply Gearbox DesignJean Pablo Valverde MoraBelum ada peringkat

- Machine Design Elements and AssembliesDari EverandMachine Design Elements and AssembliesPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- Excavation and TrenchingDokumen89 halamanExcavation and TrenchingAli HassanBelum ada peringkat

- Ergonomics Laboratory ChecklistDokumen11 halamanErgonomics Laboratory ChecklistAli HassanBelum ada peringkat

- Example of Gearbox CalculationDokumen9 halamanExample of Gearbox CalculationWassihun Amdie100% (1)

- LampDokumen8 halamanLampNabil RoufailBelum ada peringkat

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDari EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsBelum ada peringkat

- Ds - Concrete Mix DesignDokumen51 halamanDs - Concrete Mix DesignDarshan ShahBelum ada peringkat

- Analysis and Design of Residential Building Implementing Flat Slab Using Staad ProDokumen42 halamanAnalysis and Design of Residential Building Implementing Flat Slab Using Staad ProKarthik Naidu67% (6)

- Assembly DrawingDokumen2 halamanAssembly Drawingeuclidl75% (4)

- Chapter 12 Working DrawingDokumen63 halamanChapter 12 Working DrawingLhen Mediante AsuncionBelum ada peringkat

- CR 13045 PIER R00 Calculation ReportDokumen11 halamanCR 13045 PIER R00 Calculation Reportmusiomi2005Belum ada peringkat

- Chapter 8: Screws, Fasteners and The Design of Nonpermanent JointsDokumen27 halamanChapter 8: Screws, Fasteners and The Design of Nonpermanent JointsSandeep KumarBelum ada peringkat

- Thesis Hill ResortDokumen8 halamanThesis Hill ResortShahid Afridi43% (7)

- Designing Parametric Bevel Gears With Catia V5: 1 Sources, Credits and LinksDokumen10 halamanDesigning Parametric Bevel Gears With Catia V5: 1 Sources, Credits and Linksimrans04Belum ada peringkat

- MPLS in Mobile BackhualDokumen88 halamanMPLS in Mobile Backhual万尼杨100% (1)

- Computer Aided Machine Drawing Laboratory: Lab ManualDokumen31 halamanComputer Aided Machine Drawing Laboratory: Lab ManualGiridharadhayalanBelum ada peringkat

- Assembly and Working DrawingDokumen63 halamanAssembly and Working Drawingtechnowilliams480Belum ada peringkat

- Week 6 - Problem Set Assignment PDFDokumen7 halamanWeek 6 - Problem Set Assignment PDFPaco JonesBelum ada peringkat

- Wheel Assembly Proj InfDokumen18 halamanWheel Assembly Proj InfJitaru Liviu MihaitaBelum ada peringkat

- m313 M Outline 2012 Winter v2Dokumen6 halamanm313 M Outline 2012 Winter v2Sepehr GhavamBelum ada peringkat

- Latihan Cad PartDokumen101 halamanLatihan Cad PartAvyadhanieBelum ada peringkat

- DCDokumen24 halamanDCnandhakumarmeBelum ada peringkat

- Assignment: 1 General InformationDokumen9 halamanAssignment: 1 General InformationCiro CordeiroBelum ada peringkat

- Inventor 2008 Sheet Metal Design: Student GuideDokumen22 halamanInventor 2008 Sheet Metal Design: Student GuideGraham MooreBelum ada peringkat

- Scissor Jack InputsDokumen39 halamanScissor Jack InputsPrasad Shenoy0% (1)

- OX Assembly ManualDokumen44 halamanOX Assembly ManualMati FernandezBelum ada peringkat

- Mechanical Draughting N4 QP Aug 2019Dokumen9 halamanMechanical Draughting N4 QP Aug 2019patel.ayushl2018Belum ada peringkat

- Final ReportDokumen24 halamanFinal Reportvarshasdm1987Belum ada peringkat

- Stan Eva Zvolen 2014Dokumen7 halamanStan Eva Zvolen 2014cristeadanielaBelum ada peringkat

- Cat 3176c Montagem Da Cabeça.Dokumen7 halamanCat 3176c Montagem Da Cabeça.César PérezBelum ada peringkat

- Autocad 3 FileDokumen37 halamanAutocad 3 Fileayariseifallah100% (2)

- BR G-7Dokumen37 halamanBR G-7Birhanu AsfawBelum ada peringkat

- Cylinder Head - Install: Disassembly and AssemblyDokumen8 halamanCylinder Head - Install: Disassembly and AssemblySaeed KazemiBelum ada peringkat

- Project 1.0 - 1Dokumen48 halamanProject 1.0 - 1dhanawatebhushanBelum ada peringkat

- Tecnolco Institute of Hvac Mep Nampally HYD.: Layout and Fabrication of Sheet-Metal and Fiber-Glass DuctDokumen40 halamanTecnolco Institute of Hvac Mep Nampally HYD.: Layout and Fabrication of Sheet-Metal and Fiber-Glass DuctAnkush NayarBelum ada peringkat

- Structural Design of Movenpick Hotel: An-Najah National University Civil Engineering DepartmentDokumen77 halamanStructural Design of Movenpick Hotel: An-Najah National University Civil Engineering Departmentlayaljamal2Belum ada peringkat

- Metalwork: University of Cambridge International Examinations General Certificate of Education Ordinary LevelDokumen12 halamanMetalwork: University of Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456Belum ada peringkat

- Ws13 SolidModel Ktjoint PDFDokumen8 halamanWs13 SolidModel Ktjoint PDFelgheryb_choukriBelum ada peringkat

- Example of Gearbox Calculation.: Input ConditionsDokumen5 halamanExample of Gearbox Calculation.: Input Conditionsoman1148100% (1)

- Mechanical Engineering Design - Cad Module 2 - Day 2 Mechanical Fabrication - 3 HoursDokumen4 halamanMechanical Engineering Design - Cad Module 2 - Day 2 Mechanical Fabrication - 3 HoursMuhamad Eko FebriansyahBelum ada peringkat

- COMPUTER AIDED AUTOMOBILE COMPONENTS DESIGN Lab ManualDokumen17 halamanCOMPUTER AIDED AUTOMOBILE COMPONENTS DESIGN Lab ManualRuban MurugesanBelum ada peringkat

- SYS Bolt ManualDokumen64 halamanSYS Bolt ManualNoppolNorasriBelum ada peringkat

- MT 8711 Cad Lab Univ QP Set 1Dokumen9 halamanMT 8711 Cad Lab Univ QP Set 1Gopinath NBelum ada peringkat

- Project 3 2014Dokumen9 halamanProject 3 2014Daimen WilliamsBelum ada peringkat

- Air Compressor Screw Pair Profiling Based On An Advanced Envelope MethodDokumen8 halamanAir Compressor Screw Pair Profiling Based On An Advanced Envelope MethodTJPRC PublicationsBelum ada peringkat

- Design and Fabrication of Toggle JackDokumen30 halamanDesign and Fabrication of Toggle JackJitendra Rout0% (1)

- m313 13w M Outline v3Dokumen6 halamanm313 13w M Outline v3h_gholoumBelum ada peringkat

- Ejercicios Modelado y Ensamblaje BasicoDokumen14 halamanEjercicios Modelado y Ensamblaje BasicoNanii Vasquez PerekeBelum ada peringkat

- Eyelet DrawingDokumen49 halamanEyelet DrawingPra Vee33% (3)

- F.E. (Semester - I) Examination, 2012 Engineering Graphics (2008 Pattern)Dokumen16 halamanF.E. (Semester - I) Examination, 2012 Engineering Graphics (2008 Pattern)Rajeev RaiBelum ada peringkat

- Din 1480 2005Dokumen6 halamanDin 1480 2005PacoBelum ada peringkat

- TransformerDokumen20 halamanTransformerKarthikeyanKarunBelum ada peringkat

- Exp 9 Introduction To MachinesDokumen11 halamanExp 9 Introduction To MachinesMuhammad AwaisBelum ada peringkat

- 3D-Dynamic Design For Reinforced Versus Prestress Concrete For Al-Huriya BuildingDokumen36 halaman3D-Dynamic Design For Reinforced Versus Prestress Concrete For Al-Huriya BuildingCahyadi SetiawanBelum ada peringkat

- Designing Parametric Bevel ...Dokumen10 halamanDesigning Parametric Bevel ...ankit kumarBelum ada peringkat

- Metalwork: PAPER 1 Theory, Drawing and DesignDokumen12 halamanMetalwork: PAPER 1 Theory, Drawing and Designmstudy123456Belum ada peringkat

- Design and Analysis of Connecting Rod With Different Geometries Using FeaDokumen46 halamanDesign and Analysis of Connecting Rod With Different Geometries Using FeaLalu kumarBelum ada peringkat

- MECH4400 Assignment 2 2019Dokumen2 halamanMECH4400 Assignment 2 2019AliMalik0% (1)

- MC, Ce, El, Es, GL, GM, 156 - Engineering Drawing 2021 (Srid)Dokumen5 halamanMC, Ce, El, Es, GL, GM, 156 - Engineering Drawing 2021 (Srid)michaelx976Belum ada peringkat

- Cambridge International AS & A Level: Psychology For Examination From 2020Dokumen16 halamanCambridge International AS & A Level: Psychology For Examination From 2020Ali HassanBelum ada peringkat

- VW Case Fall Summer2016Dokumen6 halamanVW Case Fall Summer2016Ali HassanBelum ada peringkat

- Mil STD 105eDokumen76 halamanMil STD 105eAli HassanBelum ada peringkat

- Mil STD 105eDokumen76 halamanMil STD 105eAli HassanBelum ada peringkat

- FmeaDokumen45 halamanFmeaAli HassanBelum ada peringkat

- Six Sigma DMAIC MeasureDokumen16 halamanSix Sigma DMAIC MeasureRaul Hoan DauBelum ada peringkat

- Civil Rate Analysis 0 72-73 Kathmandu To Be UpdatedDokumen697 halamanCivil Rate Analysis 0 72-73 Kathmandu To Be UpdatedAnonymous 3fQZqsGIu79% (62)

- AJPDokumen35 halamanAJPAnonymous g5Xzu4V8Belum ada peringkat

- Turfpave HDDokumen2 halamanTurfpave HDAnonymous 1uGSx8bBelum ada peringkat

- Effect of Stirrups (PARTE 01) PDFDokumen18 halamanEffect of Stirrups (PARTE 01) PDFDanBelum ada peringkat

- Configuring Dynamic Multiple CCCH V900R014C00 - 12 20171115103522Dokumen6 halamanConfiguring Dynamic Multiple CCCH V900R014C00 - 12 20171115103522brunoBelum ada peringkat

- Embedded Pentium Processor Family: December 1998Dokumen330 halamanEmbedded Pentium Processor Family: December 1998MarioKunditBelum ada peringkat

- Go MBW5000 WLP510Dokumen2 halamanGo MBW5000 WLP510WERMERMBelum ada peringkat

- Vidhan BhavanDokumen10 halamanVidhan Bhavanaastha545Belum ada peringkat

- STAS 12313-85 Test On Stand of Concrete Prefabricated Components (En)Dokumen16 halamanSTAS 12313-85 Test On Stand of Concrete Prefabricated Components (En)Gelu-Razvan GimigaBelum ada peringkat

- Damiano Bertoli: Continuous Moment, Hot August Knife - by Jason BealeDokumen3 halamanDamiano Bertoli: Continuous Moment, Hot August Knife - by Jason BealeJason BealeBelum ada peringkat

- Chapter 12 BennetDokumen29 halamanChapter 12 BennetpapipapiiBelum ada peringkat

- Mechanical PermitDokumen2 halamanMechanical PermitjbonvierBelum ada peringkat

- SBOP PC 10 M AdminDokumen102 halamanSBOP PC 10 M Admintririna2002Belum ada peringkat

- RC17 Column1Dokumen20 halamanRC17 Column1lavyBelum ada peringkat

- System Product Catalog: Commercial VRF HVAC Systems Water CooledDokumen25 halamanSystem Product Catalog: Commercial VRF HVAC Systems Water CooledHeber de LunaBelum ada peringkat

- IRAS E-Tax Guide: Machinery and Plant: Section 19/19A of The Income Tax ActDokumen12 halamanIRAS E-Tax Guide: Machinery and Plant: Section 19/19A of The Income Tax ActYuni SartikaBelum ada peringkat

- ThesisDokumen95 halamanThesisAper ZavaBelum ada peringkat

- HTTP://WWW Scribd com/doc/32362187/Workshop-ManualDokumen7 halamanHTTP://WWW Scribd com/doc/32362187/Workshop-Manualmous734Belum ada peringkat

- Al Furjan Villas (+971544050522)Dokumen6 halamanAl Furjan Villas (+971544050522)Aarti Bablani AroraBelum ada peringkat

- User Manual Zosi ZND311 SeriesDokumen12 halamanUser Manual Zosi ZND311 SeriesRobert Smith100% (1)

- Resume Tamer Elshayal October 2012Dokumen2 halamanResume Tamer Elshayal October 2012Tamer ElshayalBelum ada peringkat

- Key Management Interoperability ProtocolDokumen64 halamanKey Management Interoperability ProtocolKiran Kumar KuppaBelum ada peringkat

- Step by Step Process To Configure SLD, MOPZ & EWA in Solution Manager 7.1 SP 8Dokumen5 halamanStep by Step Process To Configure SLD, MOPZ & EWA in Solution Manager 7.1 SP 8debsankhaghosh100% (1)

- Inside The Social Network's (Datacenter) NetworkDokumen49 halamanInside The Social Network's (Datacenter) NetworkVamsi Krishna PatchamatlaBelum ada peringkat

- (2018) SGHC 254 MCST 940 V Lim Florence MajorieDokumen27 halaman(2018) SGHC 254 MCST 940 V Lim Florence MajorieterencebctanBelum ada peringkat