Natural and Vulcanized Rubber

Diunggah oleh

Kamal KishoreHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Natural and Vulcanized Rubber

Diunggah oleh

Kamal KishoreHak Cipta:

Format Tersedia

NATURAL RUBBER

Rubber trees are grown in tropical and semitropical countries such as Indonesia, Malaysia, Sri

Lanka, South America and southern parts of India (Kerala, Tamil Nadu, Karnatka etc), etc. On making

a cut in the bark of the rubber tree, a white viscous fluid exudes which is known as latex. Latex is a

colloidal solution of rubber particles (30-40%). So, natural rubber can be obtained from latex by coagulation

process. For this we add some electrolyte solution to the latex. Commonly used coagulating agent is

dilute acetic acid. The solid obtained is pressed with the help of rollers to make rubber sheets.

Structure. In terms of chemistry natural rubber is a polymer of 2-methyl-1, 3-butadiene. The

monomer which is also known as isoprene undergoes 1,4-additon polymerization to give natural rubber.

The polymerization is shown below:

CH3

n CH2

CH3

CH

CH2

Polymerization

CH2

Isoprene

(2-Methyl-1,3-butadiene)

CH

CH2

Polyisoprene

(Natural rubber)

From the structure it is clear that the polymer contains double bonds capable of showing geometrical

isomerism. So, we can have more than one type of natural rubbers due to cis- or trans orientation across

the double bonds. Since each repeating unit in polyisoprene contains a double bond, it may have either all

cis or all trans or alternate cis and trans or randam cis and trans orientation. Natural rubber obtained

from rubber tree polyisoprene having cis-orientation across all double bonds. On the other hand

synthetically prepared polymer of isoprene has trans-orientation across all double bonds and is known as

gutta percha.

H2C

H3C

CH2

H

H3C

H3C

H

CH2

CH2

CH2

cisPolyisoprene

(Natural rubber)

H3C

H2C

H

C

CH2

CH2

H

transPolyisoprene

(Gutta Percha)

H2C

H3C

H2C

H3C

CH2

H

H

CH2

VULCANIZED RUBBER

Natural rubber is soft, elastic and tacky material. It has a coiled structure rather than having a

straight chain structure. On applying deforming force it gets streched like a spring and regains its

original structure when deforming forces are removed. This explains the elasticity of the natural rubber.

Other properties include a large water absorption capacity, low tensile strength, resistance to abrasion,

not-resistant to the action of organic solvents and attack by oxidising agents. The temperature range for

which it maintains its elasticity is 283-335 K. It can not be used for making articles below 283 K and

above 335 K. Because it becomes brittle below 283 K and becomes sticky above 335 K.

PDF Creator - PDF4Free v3.0

http://www.pdf4free.com

B.Sc. I (IInd Semester)

Absence of polar groups/substituents in natural rubber are responsible for lowers intermolecular

forces of attraction which are weak van dar Waals interactions. Since the orientation at each double

bond is cis, this means the molecules do not fit closely so the forces of interaction are further weakened.

On the basis of above properties we can easily see that natural rubber has limited uses. In order to

improve properties of natural rubber like elasticity, tensile strength etc. many attempts were made.

Charles Goodyear in 1839 added sulphur at 373 415 K to natural rubber which improved many of its

properties. This process of adding sulphur to natural rubber for improving its properties is called

vulcanization and the rubber obtained is called vulcanized rubber.

Added sulphur forms disulphide linkages (cross-links between polymeric chains) through their

reactive allylic positions as shown below.

S

S

S

Stretched

S

S

S

Relaxed

S

S

CH3

CH

CH2

S

CH

CH3

C

CH

CH

CH3

CH

CH2

CH2

CH

CH2

CH

CH2

S

CH

CH

CH2

CH

CH

CH

C

(A) In vulcanized rubber, the polymer chains are held together by polysulphide bridges or cross links,

(B) When the strecthing force is applied, the chains can straigthen out but they cannot slip past each

other because of polysulphide bridges. When the stretching force is withdrawn, the chains tend to coil

up again and the rubber returns to its original shape, (C) Sulphur cross links at reactive allylic sites.

The vulcanization increases tensile strength, hardness, modulus of elasticity, reduces water absorption

tendency and increases resistant to the action of organic solvents and oxidising agents. The improvement

of properties depends the amount of sulphur added. For example, rubber, used for making tyres, has 5%

suphur, ebonite has 20-25% sulphur, and battery case rubber has 30% suphur. It should be noted that

vulcanization (direct addition of sulphur) is slow. Hence, now a days, we use substances like zinc oxide

(ZnO), 2-mercaptobenzothiazole, 2, 2'-dithiobisbenzothiazole, tetramethylthiuram disulphite etc. as

additives for vulcanization.

N

SH

2-mercaptobenzothiazole

n

2, 2'-dithiobisbenzothiazole

H3C

N

CH3

S

S

N

CH3

Tetramethylthiuram disulphite

PDF Creator - PDF4Free v3.0

http://www.pdf4free.com

CH3

Anda mungkin juga menyukai

- K01587 - 20190317173057 - Chapter 4 Processing RubberDokumen36 halamanK01587 - 20190317173057 - Chapter 4 Processing RubbernabilahBelum ada peringkat

- K01587 - 20200217124343 - Chapter 4 - Natural and Synthetic RubberDokumen27 halamanK01587 - 20200217124343 - Chapter 4 - Natural and Synthetic RubberAbdulRahim059Belum ada peringkat

- Topic 13 Natural Materials-Rubber: SynopsisDokumen7 halamanTopic 13 Natural Materials-Rubber: SynopsisKaynine KikoBelum ada peringkat

- Rubber Is A Unique Material, Which Can Be Extended Ten Times of Its Original LengthDokumen18 halamanRubber Is A Unique Material, Which Can Be Extended Ten Times of Its Original LengthShafin KhanBelum ada peringkat

- ELASTOMERSDokumen9 halamanELASTOMERSAmbar ShahBelum ada peringkat

- RubberDokumen44 halamanRubberlidabonnyBelum ada peringkat

- How To Devulcanize RubberDokumen12 halamanHow To Devulcanize RubberVijayaraghavan Gonuguntla100% (3)

- 8 Natural RubberDokumen18 halaman8 Natural RubberNazia BibiBelum ada peringkat

- 8 Natural RubberDokumen18 halaman8 Natural RubberMThana BalanBelum ada peringkat

- Properties and Uses of Polymeric MaterialsDokumen16 halamanProperties and Uses of Polymeric MaterialszaraBelum ada peringkat

- RubberDokumen55 halamanRubberAleem AhmedBelum ada peringkat

- 552 Shazia (Rubber)Dokumen22 halaman552 Shazia (Rubber)Anishah ChaudheryBelum ada peringkat

- Resins PDFDokumen11 halamanResins PDFZaib AdilBelum ada peringkat

- Rubber IndustryDokumen9 halamanRubber IndustryifounditBelum ada peringkat

- Rubber Compound Preparation For Conveyor BeltDokumen20 halamanRubber Compound Preparation For Conveyor BeltNEVIN67% (3)

- Types of Synthetic Rubber: Neoprene, Buna-S, Buna-N, Thiokol & Vulcanized RubberDokumen3 halamanTypes of Synthetic Rubber: Neoprene, Buna-S, Buna-N, Thiokol & Vulcanized RubberCh. Muhammad UsamaBelum ada peringkat

- Rubber Technology PDFDokumen20 halamanRubber Technology PDFVeeresh S Y50% (4)

- Recycling RubberDokumen8 halamanRecycling RubberJean Rechell Frias SultanBelum ada peringkat

- Sources: Natural Rubber Is An Elastomer (An Elastic Hydrocarbon Polymer) That Was Originally DerivedDokumen4 halamanSources: Natural Rubber Is An Elastomer (An Elastic Hydrocarbon Polymer) That Was Originally DerivedzhensenBelum ada peringkat

- Rubber RecyclingDokumen9 halamanRubber RecyclingPoey ßongBelum ada peringkat

- SBR General Introduction: HistoryDokumen3 halamanSBR General Introduction: Historyanvesha raoBelum ada peringkat

- Unit-IV Thermoset Resins, Elastomers and Polyurethanes-IIDokumen77 halamanUnit-IV Thermoset Resins, Elastomers and Polyurethanes-IIMeghana SBelum ada peringkat

- Rubber Technology PDFDokumen18 halamanRubber Technology PDFCla ClauBelum ada peringkat

- RubberDokumen33 halamanRubberFadzilah Sakam100% (1)

- Introduction to Rubber Technology: Understanding Elastomers and Natural RubberDokumen274 halamanIntroduction to Rubber Technology: Understanding Elastomers and Natural RubberMahbuba ParvinBelum ada peringkat

- Introduction to Elastomer Manufacture, Processing and ApplicationsDokumen32 halamanIntroduction to Elastomer Manufacture, Processing and ApplicationsAnand DubeyBelum ada peringkat

- 31.5 Natural and Synthetic RubbersDokumen3 halaman31.5 Natural and Synthetic RubbersLakshmi PatreBelum ada peringkat

- Elastomer Tech - FSADokumen4 halamanElastomer Tech - FSASulaiman Kadher KBelum ada peringkat

- The Grades and Properties of Elastosil LR Liquid Silicone RubberDokumen44 halamanThe Grades and Properties of Elastosil LR Liquid Silicone RubberPablo Ariel BoverioBelum ada peringkat

- Rubber Materials and Processing TechnologyDokumen13 halamanRubber Materials and Processing Technologysmmehedih008Belum ada peringkat

- Resin FinishingDokumen30 halamanResin Finishingdchidembaram941967Belum ada peringkat

- Project On Natural PolymersDokumen24 halamanProject On Natural PolymersPrem Kumar74% (34)

- Nlsp-I Mid TermDokumen12 halamanNlsp-I Mid TermkhushiBelum ada peringkat

- Natural and Synthetic RubberDokumen23 halamanNatural and Synthetic RubberPrem ShankarBelum ada peringkat

- Chapter 2: Carbon Compounds: I. Natural RubberDokumen16 halamanChapter 2: Carbon Compounds: I. Natural RubberNirmala JosephineBelum ada peringkat

- Classes of Polymeric Materials ElastomersDokumen71 halamanClasses of Polymeric Materials ElastomersMehmet Gökhan YüzgeçBelum ada peringkat

- RUBBER COMPOUNDING: RAW MATERIALS AND APPLICATIONSDokumen16 halamanRUBBER COMPOUNDING: RAW MATERIALS AND APPLICATIONSMadan Saini100% (1)

- Polymeric Materials.Dokumen8 halamanPolymeric Materials.Harini BhumulaBelum ada peringkat

- ZG 31268271Dokumen4 halamanZG 31268271AJER JOURNALBelum ada peringkat

- Top 10 Bonding Agents for OrthodonticsDokumen137 halamanTop 10 Bonding Agents for OrthodonticsHarmeet BajwaBelum ada peringkat

- Rubber & Its PropertiesDokumen20 halamanRubber & Its PropertieskeshunaBelum ada peringkat

- Natural and Synthetic RubbersDokumen35 halamanNatural and Synthetic RubbersAnoop Kumar SainiBelum ada peringkat

- Silicon Rubber Laboratory Pre ReportDokumen9 halamanSilicon Rubber Laboratory Pre ReportAdrian Adalberto GarayBelum ada peringkat

- Effect of PbO Percent On Mechanical Prop PDFDokumen6 halamanEffect of PbO Percent On Mechanical Prop PDFFocuBelum ada peringkat

- Rubber Lecture by Dr. Qahtan 08Dokumen7 halamanRubber Lecture by Dr. Qahtan 08Pranshu JainBelum ada peringkat

- Natural RubberDokumen28 halamanNatural RubberHafis PuzhakkalBelum ada peringkat

- Tyre ReportDokumen19 halamanTyre ReportZachary HuffmanBelum ada peringkat

- Chemistry Project On Natural Polymers: Jayash Yadav Xii - GDokumen23 halamanChemistry Project On Natural Polymers: Jayash Yadav Xii - GVisheshBelum ada peringkat

- Polymer Chemistry NotesDokumen23 halamanPolymer Chemistry Noteskunal200jeeBelum ada peringkat

- HCL Acid & RubberDokumen2 halamanHCL Acid & RubberEdgarDavidDiazCamposBelum ada peringkat

- Poly Sulphide Silicone RubberDokumen22 halamanPoly Sulphide Silicone RubberSuyash TrivediBelum ada peringkat

- Recycling of RubberDokumen37 halamanRecycling of Rubberdivya arya100% (1)

- Natural RubberDokumen7 halamanNatural RubberFrancis AdrianBelum ada peringkat

- Kamaruddin 2012 Effect Different Paraffin PDFDokumen12 halamanKamaruddin 2012 Effect Different Paraffin PDFRubber TeamBelum ada peringkat

- Introduction to Fibre Science and Rubber TechnologyDokumen33 halamanIntroduction to Fibre Science and Rubber TechnologyN.B.PBelum ada peringkat

- Manufacturing of Rubber Running Tracks From Recycled TyresDokumen13 halamanManufacturing of Rubber Running Tracks From Recycled TyresKelvin LimBelum ada peringkat

- Guide To Resin SystemsDokumen9 halamanGuide To Resin SystemsDaud Simon A100% (1)

- When Glass meets Pharma: Insights about glass as primary packaging materialDari EverandWhen Glass meets Pharma: Insights about glass as primary packaging materialBelum ada peringkat

- Essential Rubber Formulary: Formulas for PractitionersDari EverandEssential Rubber Formulary: Formulas for PractitionersPenilaian: 3 dari 5 bintang3/5 (1)

- Detailers Dictionary Volume 2: The Industry StandardDari EverandDetailers Dictionary Volume 2: The Industry StandardBelum ada peringkat

- Solutions DineshDokumen110 halamanSolutions DineshKamal KishoreBelum ada peringkat

- Solutions, Phase Equilibrium, Conductance, Electrochemistry & Functional Group Organic Chemistry-IiDokumen1 halamanSolutions, Phase Equilibrium, Conductance, Electrochemistry & Functional Group Organic Chemistry-IiKamal KishoreBelum ada peringkat

- OCR TextDokumen6 halamanOCR TextKamal KishoreBelum ada peringkat

- QuantumDokumen2 halamanQuantumKamal KishoreBelum ada peringkat

- Pectros 4Dokumen1 halamanPectros 4Kamal KishoreBelum ada peringkat

- Ii) A Six-Proton Singlet at The Highest Field (: C CH CHDokumen1 halamanIi) A Six-Proton Singlet at The Highest Field (: C CH CHKamal KishoreBelum ada peringkat

- Spectros 6Dokumen1 halamanSpectros 6Kamal KishoreBelum ada peringkat

- What Do We Mean by Black Body Radiation ?Dokumen2 halamanWhat Do We Mean by Black Body Radiation ?Kamal KishoreBelum ada peringkat

- Four Probe MethodDokumen1 halamanFour Probe MethodVita Efellina100% (3)

- Resistivity of Semiconductors by Four Probe MethodDokumen23 halamanResistivity of Semiconductors by Four Probe MethodK.H. TanBelum ada peringkat

- Polymer IntroductionDokumen1 halamanPolymer IntroductionKamal KishoreBelum ada peringkat

- Four Probe MethodDokumen1 halamanFour Probe MethodVita Efellina100% (3)

- Zoology Unitization Syllabus Guide BSC PapersDokumen5 halamanZoology Unitization Syllabus Guide BSC PapersKamal KishoreBelum ada peringkat

- Solutions, Phase Equilibrium, Conductance, Electrochemistry & Functional Group Organic Chemistry-IiDokumen1 halamanSolutions, Phase Equilibrium, Conductance, Electrochemistry & Functional Group Organic Chemistry-IiKamal KishoreBelum ada peringkat

- ElectrochemistryDokumen1 halamanElectrochemistryKamal KishoreBelum ada peringkat

- CN CH CH CL CH CH CoochDokumen1 halamanCN CH CH CL CH CH CoochKamal KishoreBelum ada peringkat

- B.Sc. IIDokumen252 halamanB.Sc. IIKamal KishoreBelum ada peringkat

- PaperDokumen2 halamanPaperKamal KishoreBelum ada peringkat

- Polymer Structure 1Dokumen1 halamanPolymer Structure 1Kamal KishoreBelum ada peringkat

- Natural RubberDokumen1 halamanNatural RubberKamal KishoreBelum ada peringkat

- V K AhluwaliaDokumen19 halamanV K AhluwaliaKamal KishoreBelum ada peringkat

- Two Problems NMRDokumen1 halamanTwo Problems NMRKamal KishoreBelum ada peringkat

- Amino Acids and Proteins IntroductionDokumen1 halamanAmino Acids and Proteins IntroductionKamal KishoreBelum ada peringkat

- Graphic1 PDFDokumen1 halamanGraphic1 PDFKamal KishoreBelum ada peringkat

- Types of Synthetic RubbersDokumen3 halamanTypes of Synthetic RubbersKamal KishoreBelum ada peringkat

- Synthesis, Characterization, and Catalytic Applications of Porous Transition-Metal Oxide Systems For The Conversion of BiomassDokumen38 halamanSynthesis, Characterization, and Catalytic Applications of Porous Transition-Metal Oxide Systems For The Conversion of BiomassKamal KishoreBelum ada peringkat

- Cyclo Al KanesDokumen1 halamanCyclo Al KanesKamal KishoreBelum ada peringkat

- Requirements For NDokumen1 halamanRequirements For NKamal KishoreBelum ada peringkat

- Date Relaxation For Attending Orientation and Refresher CoursesDokumen4 halamanDate Relaxation For Attending Orientation and Refresher CoursesKamal Kishore100% (2)

- JEE Time Saver Course Planner FinalDokumen24 halamanJEE Time Saver Course Planner FinalSadhak JainBelum ada peringkat

- Chapter 4 BDokumen5 halamanChapter 4 BAndy LêBelum ada peringkat

- POLYMER MW CALCULATIONSDokumen19 halamanPOLYMER MW CALCULATIONSks kBelum ada peringkat

- Deposition by Thermal Evaporation of Thin Films of Titanium and Zirconium For Tritium TargetsDokumen4 halamanDeposition by Thermal Evaporation of Thin Films of Titanium and Zirconium For Tritium Targetsnandza99Belum ada peringkat

- Unit 9 Star FormationDokumen76 halamanUnit 9 Star FormationManishBelum ada peringkat

- Handbook of Heterogeneous Catalysis, G. Ertl, H. Közinger, J. WeitkampDokumen40 halamanHandbook of Heterogeneous Catalysis, G. Ertl, H. Közinger, J. WeitkampFederico BogettiBelum ada peringkat

- Measuring temperature with alcohol thermometersDokumen3 halamanMeasuring temperature with alcohol thermometersLow Ban HengBelum ada peringkat

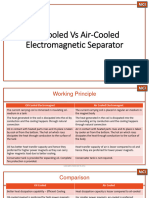

- MCI-Air Cooled Vs Oil Cooled Comparison-Rev1Dokumen4 halamanMCI-Air Cooled Vs Oil Cooled Comparison-Rev1mkbhat17kBelum ada peringkat

- Quantum Mechanics of the Hydrogen AtomDokumen9 halamanQuantum Mechanics of the Hydrogen AtomAbdullah AlghamdiBelum ada peringkat

- DifusionDokumen5 halamanDifusionDiego Ignacio Valderrama SotoBelum ada peringkat

- Practical Physical Chemistry (II) Laboratory ManualDokumen25 halamanPractical Physical Chemistry (II) Laboratory Manualabdu30esBelum ada peringkat

- Bayer Test, Dan Bromine TestDokumen18 halamanBayer Test, Dan Bromine TestBa'ist KhaerulBelum ada peringkat

- Ice Load For This Floor 1.0Kn/M2: M/L DWG No. H-11400-1360-1209Dokumen1 halamanIce Load For This Floor 1.0Kn/M2: M/L DWG No. H-11400-1360-1209Chiều TànBelum ada peringkat

- Heterogeneous Reaction Kinetics: Determining the Rate-Controlling StepDokumen35 halamanHeterogeneous Reaction Kinetics: Determining the Rate-Controlling StepDaniel OmolewaBelum ada peringkat

- Van't Hoff FactorDokumen17 halamanVan't Hoff FactorRaymond Godfrey Dagwasi100% (1)

- LAB - 6 - Factors That Affect Enzyme ActivityDokumen2 halamanLAB - 6 - Factors That Affect Enzyme ActivityRaqsBelum ada peringkat

- Periodic Table Unit TestDokumen4 halamanPeriodic Table Unit Testapi-303120399Belum ada peringkat

- Cbse Class XI Chemistry Sample Paper - 3 Solution Section ADokumen13 halamanCbse Class XI Chemistry Sample Paper - 3 Solution Section ABhabaniBelum ada peringkat

- Photochromatic LensDokumen38 halamanPhotochromatic LensSrinivas DonBelum ada peringkat

- Chemistry Calculations DDokumen7 halamanChemistry Calculations DKasunDilshanBelum ada peringkat

- PHET Rutherfords Scattering - 1769974724Dokumen3 halamanPHET Rutherfords Scattering - 1769974724Robert ColemanBelum ada peringkat

- Unit 6 - Week 03: Mass Transfer Coefficient and Interface Mass TransferDokumen3 halamanUnit 6 - Week 03: Mass Transfer Coefficient and Interface Mass TransferSandra GilbertBelum ada peringkat

- 2006 Keiyo District Paper 1Dokumen4 halaman2006 Keiyo District Paper 1dkavitiBelum ada peringkat

- Conformaations Chairs Energy ProfilingDokumen24 halamanConformaations Chairs Energy ProfilingMaxi MaBelum ada peringkat

- Thomson Atom Model: Physics NotesDokumen13 halamanThomson Atom Model: Physics NotesEs EBelum ada peringkat

- Kompedium FrosioDokumen126 halamanKompedium Frosioprotein100% (5)

- Aes SpyrosDokumen29 halamanAes SpyrosbondanBelum ada peringkat

- GT2011-46380 Implementation of A Multi Zone Radiation Method in A Low Nox Gas Turbine Combustion Chamber Conceptual SimulatorDokumen10 halamanGT2011-46380 Implementation of A Multi Zone Radiation Method in A Low Nox Gas Turbine Combustion Chamber Conceptual SimulatorMarcos Noboru ArimaBelum ada peringkat

- Let V Velocity of The Ith Species Relative To Stationary Coordinate AxisDokumen6 halamanLet V Velocity of The Ith Species Relative To Stationary Coordinate AxisDozdiBelum ada peringkat

- Absorption Cooling and On - Energy Dynamics LimitedDokumen122 halamanAbsorption Cooling and On - Energy Dynamics Limitedjamesbrown100100% (2)