API 600 Overview - Steel Gate Valves - Flanged and Buttwelding Ends, Bolted Bonnets

Diunggah oleh

Nilesh MistryHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

API 600 Overview - Steel Gate Valves - Flanged and Buttwelding Ends, Bolted Bonnets

Diunggah oleh

Nilesh MistryHak Cipta:

Format Tersedia

API 600 - Overview

Sr. #

Particular

Details

Scope

Requirements for Heavy Duty Series of Steel Gate Valves Petroleum Refinery

and Related Applications where Corrosion, Erosion & Other Service Conditions

Would Indicate a need of Full Port Opening heavy wall sections and large stem

diameters

Covered Sizes

NPS 1 to NPS 42 (DN 25 to DN 1050)

Covered Class Ratings

150 to 2500

Bonnet Type

Bolted Bonnet

Type of Stem

Outside Screw & Yoke, Non Rising Stem

Types of Wedges

Single and Double Wedge & Parallel Seating

Available End

Connections

Flanged & Welding Ends

Body & Bonnet From ASME B16.34 Group 1 and Group 2

Applicable Materials

Trim Materials From Standard API Trims

Materials Other Than Trim Materials As specified in API 600

Design Standard API 600

Pressure Temperature Ratings ASME B16.34

Sizes API 600

Body Wall Thickness API 600

Bonnet Wall Thickness API 600

Face-to-Face & End-to-End Dimensions ASME B16.10 or ISO 5752

End Connections:

Flanged Ends ASME B16.5 (Up to NPS 24, except 22) , ASME B16.47 Series A or

Series B (Above NPS 26).

Chemical Composition for Carbon Steel Welding Ends API 600

Acceptance for Attachment Welding ASME B31.3 or ISO 15649

Reference

Specifications

Butt Welding Ends ASME B16.25 (Above NPS 2), API 602 (Up to NPS 2)

Inside Diameter ASME B16.34 (Up tp NPS 24), ASME B16.34 (Class 150 to 300,

NPS 26 to 30), API 600 (Class 150 to 300, NPS 32 to 42)

Body to Bonnet Joint ASME B16.5

Spot Facing or Back Facing Parallelism Requirement ASME B16.5

Minimum Stud Bolt Sizes for Body-to-Bonnet Joint API 600

Total Cross Sectional Area of Bolts in Bonnet Bolting ASME B16.34

Construction of Bonnet Joint Pressure Seal Bonnet Design MSS-SP-144 Style B

Stem Strength Calculation for Maximum Input Force from Handwheel or Gear

box MSS-SP-91

Stem Threads Trapezoidal Type Left Handed Threads from ASME B1.5 or

ASME B1.8

Direction of Handwheel for Closing Valve - Clockwise

Prepared By: Nilesh Mistry (mistrynilesh@icloud.com)

Page 1 of 2

Minimum Stem Diameter API 600

Maximum Stem Projection API 602

Permitted Undertolerance for Stem Diameter API 600

Fugitive Emission Type Test API 624

Bolting for Body-to-Bonnet Joint ASME B18.2.2 or ASME B18.2.6M

Threads for Studs in Gland Bolting ASME B1.12 or ASME B1.13M

Valve-to-Gear Box or Power Actuator Flange Mating Dimensions ISO 5210 or

MSS-SP-102

Bypass and Other Auxiliary Connections ASME B16.34

Testing & Inspection API 598

Marking ASME B16.34 and MSS-SP-25

Shipment & Packaging Requirements API 600

Body End Flanges and Bonnet Flanges Forged or Cast Integral With Body

Minimum Thickness of Any Facing Material 1.6 mm (0.06 in.)

Bonnet One Piece Casting or Forging

Body-to-Bonnet Joint:

Flat Face in joint flanges is only acceptable in Class 150

For Class 150 NPS 2-1/2 and smaller, Body-to-Body Joint shall be circular only.

Parallelism of Body and Bonnet Flange Nut Bearing Surfaces - 1

Surface finish of the area of stem in contact with packing 0.80 m (32 in.) or

smoother.

10

Other Specified

Requirements

Stem Straightness of Entire Length Max 0.001 mm/mm (0.001 in./in.)

Min. No of Packing Rings Five

Min. No of packing Rings when Lantern Ring is used 3 Above Lantern & 3

Below Lantern Ring

Surface Finish of Packing Box Are in Contact With Packing Material 4.5 m

(175 in.)

Nominal Bore of Packing Box Sum of Stem Dia + 2(Nominal Width of Packing)

+ Clearance Factor

Class for Bolt Threads 2A (6g For Metric Threads)

Class for Nut Threads 2B (6H For Metric Threads)

Marking on Handwheel OPEN and Arrow Pointing Direction of Opening

Gate Position During Shipment Gate Closed

Prepared By: Nilesh Mistry (mistrynilesh@icloud.com)

Page 2 of 2

Anda mungkin juga menyukai

- Checklist of ISO 9001 2015 Mandatory Documentation enDokumen9 halamanChecklist of ISO 9001 2015 Mandatory Documentation enfcleong6988% (8)

- Asme B16.5Dokumen11 halamanAsme B16.5jacquesmayol100% (1)

- API6A Trim Material RatingsDokumen5 halamanAPI6A Trim Material RatingsAneez MhdBelum ada peringkat

- API Flange LeakageDokumen1 halamanAPI Flange Leakagegajanan_iitbBelum ada peringkat

- W-P-10-01 - Design Validation TestProcedure - BALL VALVE PR2 ANNEX FDokumen6 halamanW-P-10-01 - Design Validation TestProcedure - BALL VALVE PR2 ANNEX FPalkesh TrivediBelum ada peringkat

- W-P-10-01 - Design Validation TestProcedure - BALL VALVE PR2 ANNEX FDokumen6 halamanW-P-10-01 - Design Validation TestProcedure - BALL VALVE PR2 ANNEX FPalkesh TrivediBelum ada peringkat

- API 602 Forged Steel Gate, Globe & Check Valves (Vel-Sfv-Web) PDFDokumen22 halamanAPI 602 Forged Steel Gate, Globe & Check Valves (Vel-Sfv-Web) PDFThomasFrenchBelum ada peringkat

- Product Brochure: Manufacturers and Stockists of High Pressure Pipeline and Drilling EquipmentDokumen30 halamanProduct Brochure: Manufacturers and Stockists of High Pressure Pipeline and Drilling EquipmentSaravanan NatesanBelum ada peringkat

- Norsok Material Data Sheet (M-630r2)Dokumen77 halamanNorsok Material Data Sheet (M-630r2)karuna346Belum ada peringkat

- Stub Ends Ansi b16.9Dokumen1 halamanStub Ends Ansi b16.9hisaj4uBelum ada peringkat

- Codes & Standards For Natural GasDokumen13 halamanCodes & Standards For Natural Gasharikrishnanpd3327Belum ada peringkat

- Armatury CZ Trunnion Mounted Ball ValvesDokumen28 halamanArmatury CZ Trunnion Mounted Ball ValvesLuka BornaBelum ada peringkat

- Process & Piping Design Section Plug Valves Technical SpecificationDokumen14 halamanProcess & Piping Design Section Plug Valves Technical Specificationashish.mathur1100% (1)

- Critical Reading As ReasoningDokumen18 halamanCritical Reading As ReasoningKyle Velasquez100% (3)

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityDari EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityBelum ada peringkat

- Double Disc Gate Valve: Pressure Seal BonnetDokumen12 halamanDouble Disc Gate Valve: Pressure Seal BonnetMuhammadImaduddienSalamBelum ada peringkat

- EFCO Valve Repair ProductsDokumen20 halamanEFCO Valve Repair Productsjay_rajeshirkeBelum ada peringkat

- API 6A Valves Design, Construction and FeaturesDokumen12 halamanAPI 6A Valves Design, Construction and Featuresedo_tapia_ur100% (1)

- Summary of Choke Valve API 6A 21st EditionDokumen52 halamanSummary of Choke Valve API 6A 21st EditionInChy Rencarnation Poseidon100% (2)

- Oracle Service Procurement Advisory & ConsultingDokumen22 halamanOracle Service Procurement Advisory & ConsultingPrakashBelum ada peringkat

- Standards in The Valve IndustryDokumen2 halamanStandards in The Valve IndustryessnelsonBelum ada peringkat

- API 6D Overview - Pipeline & Piping ValvesDokumen3 halamanAPI 6D Overview - Pipeline & Piping ValvesNilesh MistryBelum ada peringkat

- API 6D Overview - Pipeline & Piping ValvesDokumen3 halamanAPI 6D Overview - Pipeline & Piping ValvesNilesh MistryBelum ada peringkat

- Installation, Operation and Maintenance Manual For Model WG-HLA Hydraulic ActuatorDokumen15 halamanInstallation, Operation and Maintenance Manual For Model WG-HLA Hydraulic ActuatorNeilton Junior100% (1)

- MB Csu 46bbrss1dDokumen18 halamanMB Csu 46bbrss1delver sanabriaBelum ada peringkat

- Spiraltec Non-Metallic FillersDokumen1 halamanSpiraltec Non-Metallic FillersJakir HossainBelum ada peringkat

- JIS Standard ValveDokumen8 halamanJIS Standard ValveJong JavaBelum ada peringkat

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionDari EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionBelum ada peringkat

- Piston ValveDokumen28 halamanPiston ValveDamien BouticourtBelum ada peringkat

- Tecumseh Service Repair Manual VH80 VH100 HH80 HH100 HH120 Oh120 Oh140 Oh160 Oh180 8HP Thru 18HP Cast Iron Engines 691462a PDFDokumen78 halamanTecumseh Service Repair Manual VH80 VH100 HH80 HH100 HH120 Oh120 Oh140 Oh160 Oh180 8HP Thru 18HP Cast Iron Engines 691462a PDFDan Clarke75% (4)

- Green Finance For Green GrowthDokumen24 halamanGreen Finance For Green GrowthSreejith BhattathiriBelum ada peringkat

- API 600 - Presentation - Steel Gate Valves - Flanged & Bulttwelding Ends, Bolted BonnetDokumen75 halamanAPI 600 - Presentation - Steel Gate Valves - Flanged & Bulttwelding Ends, Bolted BonnetNilesh Mistry100% (4)

- 04 Samss 002 PDFDokumen8 halaman04 Samss 002 PDFnadeem shaikhBelum ada peringkat

- Valve Standards ANSI BS APIDokumen6 halamanValve Standards ANSI BS APInaveenbaskaran1989Belum ada peringkat

- Triple-Offset Butterflyvalves PDFDokumen8 halamanTriple-Offset Butterflyvalves PDFDiwakar NigamBelum ada peringkat

- 01 Samss 035Dokumen28 halaman01 Samss 035Mohamed Ahmed MaherBelum ada peringkat

- Valvulas PDFDokumen32 halamanValvulas PDFMilena Lemus FonsecaBelum ada peringkat

- How to Size a Fire Pump and Understand Performance CurvesDokumen12 halamanHow to Size a Fire Pump and Understand Performance CurvesAmar kobitaBelum ada peringkat

- Basics of Valves Interview Questions & Answers: Directional Control ValveDokumen7 halamanBasics of Valves Interview Questions & Answers: Directional Control ValveJêmš NavikBelum ada peringkat

- 2014 68 Eu PDFDokumen96 halaman2014 68 Eu PDFAlienshow100% (1)

- En 12266-2Dokumen13 halamanEn 12266-2yashif ali100% (1)

- Technical notes on valvesDokumen29 halamanTechnical notes on valvesNilesh Mistry100% (2)

- Gold Series Dust Collector: Installation, Operation and MaintenanceDokumen85 halamanGold Series Dust Collector: Installation, Operation and MaintenanceDAVID ALFONSO CARABALLO PATIÑOBelum ada peringkat

- 10 Types of Valves and Their FunctionsDokumen7 halaman10 Types of Valves and Their FunctionsLamar TwitchBelum ada peringkat

- CQI IRCA ISO90012015 White PaperDokumen6 halamanCQI IRCA ISO90012015 White PaperHina KhurshidBelum ada peringkat

- Seal Ball ValvesDokumen45 halamanSeal Ball Valvesmetasoniko2014Belum ada peringkat

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDari EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryBelum ada peringkat

- Velan Ball Valve 1 PDFDokumen9 halamanVelan Ball Valve 1 PDFMilena Lemus FonsecaBelum ada peringkat

- Erreesse SRL - BrochureDokumen32 halamanErreesse SRL - BrochureEduardo VasquezBelum ada peringkat

- Two BallDokumen5 halamanTwo Ballchartwithsam0041653Belum ada peringkat

- Maverick Valves CatalogueDokumen84 halamanMaverick Valves Cataloguer4mms3sBelum ada peringkat

- ValveDokumen9 halamanValveAdhie_ginthinkBelum ada peringkat

- Globe Valve PresentationDokumen11 halamanGlobe Valve Presentationmayur22785Belum ada peringkat

- 5.3 CES-1002-F-Seat Leakage Testing PDFDokumen22 halaman5.3 CES-1002-F-Seat Leakage Testing PDFbowoBelum ada peringkat

- E-Series Flanged Ball Valves: ANSI 150 and 300 Regular and Full-PortDokumen16 halamanE-Series Flanged Ball Valves: ANSI 150 and 300 Regular and Full-PortAhmed RashiedBelum ada peringkat

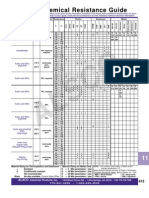

- Alsco: Chemical Resistance GuideDokumen55 halamanAlsco: Chemical Resistance GuidejcndBelum ada peringkat

- Api Spec 6D: API - The American Petroleum InstituteDokumen3 halamanApi Spec 6D: API - The American Petroleum Institutenrd9771100% (1)

- DIN 11864-1 Aseptic FittingsDokumen7 halamanDIN 11864-1 Aseptic FittingsChandhu Kurian ThampiBelum ada peringkat

- API vs. Asme-AnsiDokumen2 halamanAPI vs. Asme-Ansinaruto256Belum ada peringkat

- GSL Actuator Sizing CalculationDokumen0 halamanGSL Actuator Sizing CalculationAnonymous yQ7SQrBelum ada peringkat

- PBV Unibody and Two-Piece Flanged Floating Ball Valves: Smart Solutions. Powerful ProductsDokumen28 halamanPBV Unibody and Two-Piece Flanged Floating Ball Valves: Smart Solutions. Powerful ProductsSunil BajpaiBelum ada peringkat

- Understanding Australian Flange Standards and Pressure RatingsDokumen6 halamanUnderstanding Australian Flange Standards and Pressure Ratingsharikrishnanpd33270% (1)

- Dual-Plate Lug Check Valves - Face To Face Dimensions - API Standard 594Dokumen2 halamanDual-Plate Lug Check Valves - Face To Face Dimensions - API Standard 594unknownBelum ada peringkat

- Valves Shell Design StrengthDokumen10 halamanValves Shell Design Strengthمحمد عبدالدايمBelum ada peringkat

- Face To Face Valve Dimensions En-558-1 - ValviasDokumen3 halamanFace To Face Valve Dimensions En-558-1 - ValviasAntonio CeiBelum ada peringkat

- The A To Z of Valve MaterialsDokumen4 halamanThe A To Z of Valve Materialscool47guy09Belum ada peringkat

- Anti Blow Out StemDokumen48 halamanAnti Blow Out StemimthiyazmuhammedBelum ada peringkat

- SWI Products MetalDokumen21 halamanSWI Products MetalPrasanth PrasadBelum ada peringkat

- FCA Nozzle Non-Slam Check Valve CatalogueDokumen16 halamanFCA Nozzle Non-Slam Check Valve CataloguePatricio AcuñaBelum ada peringkat

- EfcoDokumen16 halamanEfcoBisoyiBelum ada peringkat

- Difference Between WRC 107 and WRC 297Dokumen2 halamanDifference Between WRC 107 and WRC 297kuselanmlBelum ada peringkat

- Sealing CatalogueDokumen160 halamanSealing Cataloguenata18040Belum ada peringkat

- Swagelok Flange AdaptersDokumen6 halamanSwagelok Flange AdapterstotcsabBelum ada peringkat

- Howco Global BrochureDokumen17 halamanHowco Global BrochureGuido FloresBelum ada peringkat

- Quality Manual Rev 11 No NamesDokumen27 halamanQuality Manual Rev 11 No NamesNilesh MistryBelum ada peringkat

- ANSI standards pipe specificationsDokumen2 halamanANSI standards pipe specificationsAhmed Jameel100% (1)

- Chapter 3: Navigating DrawingDokumen1 halamanChapter 3: Navigating DrawingNilesh MistryBelum ada peringkat

- DNV Standard1-2 PDFDokumen13 halamanDNV Standard1-2 PDFSteve MorrisonBelum ada peringkat

- Steelmaking and Semi Finished Products Intend-Ed For Further Processing by Rolling or Forg - INGDokumen6 halamanSteelmaking and Semi Finished Products Intend-Ed For Further Processing by Rolling or Forg - INGNilesh MistryBelum ada peringkat

- AXENMS0045Dokumen72 halamanAXENMS0045shareyhouBelum ada peringkat

- DNV - CN7 Non-Destructive TestingDokumen1 halamanDNV - CN7 Non-Destructive TestingNilesh MistryBelum ada peringkat

- Tap1 401 1Dokumen1 halamanTap1 401 1Nilesh MistryBelum ada peringkat

- Oxygen Pressure Reducing Station AssemblyDokumen1 halamanOxygen Pressure Reducing Station AssemblyNilesh MistryBelum ada peringkat

- Erosion and Corrosion in Piping Systems For Sea Water: GuidelinesDokumen9 halamanErosion and Corrosion in Piping Systems For Sea Water: GuidelinesAston MartinBelum ada peringkat

- MSS and ASME valve standards guideDokumen2 halamanMSS and ASME valve standards guideNilesh MistryBelum ada peringkat

- Usage Reporting Dashboard - TechstreetDokumen2 halamanUsage Reporting Dashboard - TechstreetNilesh MistryBelum ada peringkat

- 10 Guidance Notes - 0Dokumen23 halaman10 Guidance Notes - 0Nilesh MistryBelum ada peringkat

- Valve Testing GuidelinesDokumen4 halamanValve Testing GuidelinesNilesh MistryBelum ada peringkat

- Lets Play BingoDokumen17 halamanLets Play BingoRosana SanchezBelum ada peringkat

- F. M. 1Dokumen3 halamanF. M. 1Aashish PardeshiBelum ada peringkat

- Abstract Substructure Conc - Frame Westgate RealDokumen4 halamanAbstract Substructure Conc - Frame Westgate RealTashamiswa MajachaniBelum ada peringkat

- Kurzweil MicropianoDokumen24 halamanKurzweil Micropianoestereo8Belum ada peringkat

- Fluid Mechanics-I: by Dr. Fayaz A Khan Assistant Professor, UET Bannu CampusDokumen22 halamanFluid Mechanics-I: by Dr. Fayaz A Khan Assistant Professor, UET Bannu CampusAsim WazirBelum ada peringkat

- Or & LPPDokumen14 halamanOr & LPPAjay Kumar Sharma100% (1)

- Service Manual Sony MHC-V5Dokumen122 halamanService Manual Sony MHC-V5Enya Andrea Ribba HernandezBelum ada peringkat

- Nitya Parayana Slokas MalayalamDokumen3 halamanNitya Parayana Slokas MalayalamGopakumar NairBelum ada peringkat

- Understanding Operating Systems Fifth Edition: Memory Management: Virtual MemoryDokumen21 halamanUnderstanding Operating Systems Fifth Edition: Memory Management: Virtual MemoryRidzuan DolahBelum ada peringkat

- Machine TimeDokumen11 halamanMachine TimeFRANCIS THOMASBelum ada peringkat

- I2C Bus ManualDokumen51 halamanI2C Bus Manualapi-26349602100% (6)

- Videojet 3140: Laser Marking SystemDokumen2 halamanVideojet 3140: Laser Marking SystemSudiptoBelum ada peringkat

- 2008-07-31 074935 04 CelicaDokumen10 halaman2008-07-31 074935 04 CelicaCesar Alarcón Solis100% (1)

- Torque ValuesDokumen1 halamanTorque ValuesfadhlidzilBelum ada peringkat

- Specialized Epic EVO 2021Dokumen3 halamanSpecialized Epic EVO 2021MTB-VCOBelum ada peringkat

- 2007 Output Stops RemovedDokumen45 halaman2007 Output Stops RemovedAisyah DzulqaidahBelum ada peringkat

- SKFDokumen26 halamanSKFRahul ParikhBelum ada peringkat

- 220 KV GSS, HeerapuraDokumen56 halaman220 KV GSS, Heerapurapikeshjain33% (3)

- Aqm Mallcom ReportDokumen12 halamanAqm Mallcom ReportHarshita TiwariBelum ada peringkat

- Sch40 80 ASTM A53Dokumen2 halamanSch40 80 ASTM A53Keshia Murillo PinnockBelum ada peringkat

- Me 2403 Power Plant Engineering - Short Question and AnswersDokumen16 halamanMe 2403 Power Plant Engineering - Short Question and AnswersBIBIN CHIDAMBARANATHANBelum ada peringkat

- Awardees List - 11th VKA 2019 (Final)Dokumen14 halamanAwardees List - 11th VKA 2019 (Final)ANKIT DWIVEDIBelum ada peringkat

- KQ2H M1 InchDokumen5 halamanKQ2H M1 Inch林林爸爸Belum ada peringkat

- MMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDDokumen6 halamanMMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDHenry Jose OlavarrietaBelum ada peringkat