Cameron - Installation Procedures

Diunggah oleh

msu6383Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cameron - Installation Procedures

Diunggah oleh

msu6383Hak Cipta:

Format Tersedia

SD-018239-01

Section 2

Installation Procedures

Page 1 of 110 Rev. 01

SD-018239-01

This Page

Intentionally Left Blank

Page 2 of 110 Rev. 01

SD-018239-01

Section 2.1

Installation Procedures for Full Size Wells with 20"

Lower Casing Head Housing

Page 3 of 110 Rev. 01

SD-018239-01

This Page

Intentionally Left Blank

Page 4 of 110 Rev. 01

SD-018239-01

Sequence of Operations for Full Size Wells

Description

Page

Procedures for the installation of the bell nipple and

20" nom. lower casing head housing

Installation of 20" nom. riser adaptor

13

Running and retrieval of 20" nom. BOP test tool

17

Running and retrieval of 20" nom. wear bushing

21

Installation of 13.5/8" nom. 2 stage compact housing

25

Installation of 13.5/8" nom. riser adaptor

31

Running and retrieval of 13.5/8" nom. BOP test tool

35

Running and retrieval of 13.5/8" nom. lower wear bushing

43

Installation of 10.3/4" casing hanger

47

Washout of compact housing lower seal areas

51

Installation and testing of casing hanger seal assembly

55

Running and retrieval of 13.5/8" nom. BOP test tool

61

Running and retrieval of 13.5/8" nom. upper wear bushing

65

Washout of compact housing upper seal areas

69

Installation and testing of tubing hanger

73

Termination of control lines

79

Installation and testing of xmas tree

81

Page 5 of 110 Rev. 05

SD-018239-01

Description (continued)

Page

Removal of xmas tree and retrieval of tubing hanger

86

Installation of 20" nom. emergency lowermost housing

87

Installation of 13.3/8" emergency sliplock connector

91

Installation of 9.5/8" or 10.3/4" emergency slip bowl assembly

97

Installation and testing of 9.5/8" or 10.3/4" emergency seal assembly

101

Final A and B-annuli wellhead configuration and connection pressure

testing

106

Page 6 of 110 Rev. 07

SD-018239-01

Procedure for the installation of the bell nipple and 20" nom. lower casing

head housing

Bell nipple, 28" I/D x 38" O/D slotted flange, etc.

Customer supply

Equipment

One

20" nom. lower casing head housing,

Fastlock hub top x 18.5/8" pup joint

Part no. 2263490-01-12

One

20" nom. lower housing running tool,

21.25"-2 TPI LH stub acme x 20" buttress

Part no. 2125904-01

One

Crossover, 20" buttress x 18.5/8" buttress

Part no. 2205444-01

Page 7 of 110 Rev. 01

SD-018239-01

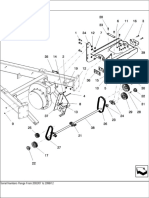

Conductor Base Plate

'I' beam

O/D

Conductor

pipe

3m

O/D

Flange

Slotted bolt holes for bell

nipple

12"

5"

Fig 1 I beams and flange arrangement

Page 8 of 110 Rev. 07

SD-018239-01

Rotary beams

Trolley beams

2.2m

1.9m

2.5m

Bell Nipple

7.65m

4 pad eyes to centralize and hold riser

tied to substructure (welded on site)

Ground Level

36 O/D x 1 flange rubber seal

1.22m

38 O/D x 1 flange

2.13m

Cellar Floor

O/D Conductor

Fig 2 Bell nipple stack up

Page 9 of 110 Rev. 07

SD-018239-01

Page 10 of 110 Rev. 07

SD-018239-01

Procedure for the installation of the bell nipple and 20" nom. lower

casing head housing

1.0

Install two 5" x 12" x 3m 'I' beams on the cellar as Fig 1 (see page 8). The

conductor pipe will be pre-installed by site construction contractor when

constructing the cellar.

2.0

Pick up 38" O/D x 1" flange with 4 slotted bolt holes and install over conductor

pipe until it rests on the 'I' beams.

3.0

Cut conductor pipe excess.

4.0

Weld 38" O/D x 1" flange to conductor pipe and tack weld to beams.

5.0

Install rubber seal on 38" O/D x 1" flange.

6.0

Nipple up riser bell nipple with pre-welded 36" O/D x 1" flange, 4 pad eyes, 4

bolts and hole for 13.3/8" flow line as Fig 2 (see page 9).

7.0

Install 13.3/8" flow line.

8.0

Drill for the 18.5/8" casing.

9.0

Nipple down riser bell nipple.

10.0

Run 18.5/8" casing. If casing becomes stuck and emergency lowermost is

required, refer to page 87.

11.0

Pick up 18.5/8" buttress pin x 18.5/8" RL4S pin casing joint.

12.0

Make up pre-assembled 20.3/4" nom. casing head housing (completed with

crossover adaptor 18.5/8" x 20" API buttress and 20" nom. lower casing head

housing running tool) to 18.5/8" landing joint.

13.0

Check that the outlet orientation conforms to site requirements.

14.0

Land casing head on 38" O/D x 1" flange at cellar level.

15.0

Remove running tool by right hand rotation (approx. 4.1/2 turns). Lift tool slowly

to ensure that the tool has disengaged.

16.0

Rig up to cement 18.5/8" casing.

Page 11 of 110 Rev. 07

SD-018239-01

This Page

Intentionally Left Blank

Page 12 of 110 Rev. 01

SD-018239-01

Installation of 20" nom. drilling adaptor

Equipment

One

20" nom. 3000 psi drilling adaptor, Fastlock

Connector bottom x 20.3/4" API 3000 psi

studded top

Part no. 2125907-01

One

'CF-21' gasket

Part no. 2034005-02-02

One

RX-74 gasket

Part no. 702002-07-42

One

Torque wrench and 1" A/F hex. socket

Service tools

Page 13 of 110 Rev. 01

SD-018239-01

Page 14 of 110 Rev. 07

SD-018239-01

Installation of 20" nom. drilling adaptor

1.0

Thoroughly clean 'CF-21' gasket prep on bottom of 20-3/4" 3,000 psi drilling riser

adaptor and top of lowermost housing.

Note: The drilling riser adaptor should already be connected to the rig BOP.

2.0

Ensure segments of fastlock connector are fully retracted prior to make-up to the

lowermost housing.

3.0

Lightly grease seal preps and gaskets.

4.0

Install 'CF-21' gasket into 20-3/4" lowermost housing hub and lower BOP with

drilling riser adaptor onto connection.

5.0

Make-up the fastlock connector by tightening each drive screw in sequence and to

the correct torque specification. The correct sequence is to tighten opposite screws

in pairs to 200 ft.lbf and work around the connector in a right hand or left hand

direction. A second application of torque at the correct torque specification should

be applied in the same sequence to ensure make-up. The torque for each drive

screw is 600 ft.lbf.

6.0

When the fastlock connector is fully made up, the ends of the drive screws should

be flush or just below flush with the end of the bushings.

7.0

If necessary, fill the area around the segments with a general purpose grease using

the fitting on the body. A vent fitting is located opposite the grease fitting to

release any trapped air. Fill the connector with grease until all the air is displaced

and grease begins coming out of the vent fitting.

Page 15 of 110 Rev. 01

SD-018239-01

This Page

Intentionally Left Blank

Page 16 of 110 Rev. 01

SD-018239-01

Running and retrieval of 20" nom. BOP test tool

Equipment

One

20" nom. combination tool, BOP tester and

wear bushing running tool, NC50 threads

top and bottom

Page 17 of 110 Rev. 01

Part no. 2125905-01

SD-018239-01

Page 18 of 110 Rev. 07

SD-018239-01

Running and retrieval of 20" nom. BOP test tool

1.0

Make up NC50 handling joint into combination tool with pins facing up (see

drawing).

Note: Do not tong on seal areas. Use minimum make up torque as the

handling joint will need to be backed out to test the blind rams. Make up

with chain tongs.

2.0

Check 'O' ring for damage and replace as necessary.

3.0

Lightly grease 'O' ring.

Note: Ensure the tiedown screws in the riser adaptor are fully retracted (4.00"

from O/D) and gland nuts are re-made tight before continuing with the

next stage.

4.0

Lower tool through BOP stack and riser and land on lowermost housing shoulder.

Note: Compare stick up above rotary table with that calculated to ensure at

correct depth.

5.0

Fill stack full of water and close pipe rams around handling joint. Open the valve

in the lowermost housing below the combination tool to monitor any fluid

passing.

6.0

Apply test pressure to BOP down the string with pressure entering BOP through

ported test joint to allow testing of lower rams for required hold period.

Note: Maximum test pressure is 3,000 psi or equal to the maximum working

pressure of the lowest rated item in the stack.

7.0

Release pressure and retract BOP rams.

Page 19 of 110 Rev. 01

SD-018239-01

Blind Ram Test

8.0

Back out handling joint from combination tool.

9.0

Fill stack full of water and close blind rams.

10.0

Apply test pressure to BOP through kill line for required hold period. Compare

volumes pumped with records from previous tests above.

Note: Maximum test pressure is 3,000 psi or equal to the maximum working

pressure of the lowest rated item in the stack.

11.0

Release pressure, ensure no check valve is in the kill line. Retract blind rams.

Close the valve in the lowermost housing below the combination tool. Retrieve

the combination tool.

Page 20 of 110 Rev. 01

SD-018239-01

Running and retrieval of 20" nom. wear bushing

Equipment

One

20" nom. wear bushing, 17.597" min. bore

Part no. 2055808-01

One

20" nom. combination tool, BOP tester and

wear bushing running tool, NC50 threads

top and bottom

Part no. 2125905-01

Page 21 of 110 Rev. 01

SD-018239-01

Page 22 of 110 Rev. 07

SD-018239-01

Running of wear bushing

1.0

Check that 'O' rings on wear bushing are in good condition. Replace as necessary.

Lightly grease 'O' rings.

2.0

Make up combination tool with pins down onto an NC50 handling joint, avoid

tonging on seal area.

3.0

Insert the combination tool into the wear bushing and rotate tool approx. 90 right

hand to fully latch into the wear bushing.

Note: Ensure the tiedown screws in the riser adaptor are fully retracted (4.00"

from O/D) and gland nuts are re-made tight before continuing with the

next stage.

4.0

Lower wear bushing through BOP stack and riser and land off on housing

shoulder.

Note: Compare stick up above rotary table with that calculated to ensure at

correct depth.

5.0

Lock wear bushing in place by engaging the two tiedown screws into the recess of

the wear bushing. To do this, the glands must be first loosened by turning left

hand with a 2-1/4" wrench approx. 2 turns. The tiedown screws can then be

rotated right hand with a 3/4" wrench until they come into contact with bushing

wall (approx 6 turns). Back off the tiedown screws 45 (1/8th turn) and re-tighten

the glands to 250 ft.lbf torque.

6.0

Rotate running tool left hand approx. 90 to disengage from 'Breech' connection

and retrieve tool.

Note: To ease rotation, some or all of the hang-off weight should be taken up

by the elevators.

7.0

Drill for the 13.3/8" casing.

Page 23 of 110 Rev. 07

SD-018239-01

Retrieval of wear bushing

8.0

Make up combination tool onto an NC50 handling joint.

9.0

Lower combination tool into lowermost housing and land on wear bushing.

Slowly rotate tool right hand to locate Breech connection until it drops 2.50".

Note: Compare stick up above rotary table with that calculated to ensure at

correct depth.

10.0

Continue rotating tool right hand approx 90 until it is fully engaged.

Note: Ensure the tiedown screws in the riser adaptor are fully retracted (4.00"

from O/D) and the gland nuts are re-made before continuing with the

next stage.

11.0

Retrieve wear bushing and running tool. Pick up slowly to ensure bushing is free.

Note: Overpull should not be required. Check tiedown screws if the wear

bushing does not come free.

Page 24 of 110 Rev. 07

SD-018239-01

Installation of 13.5/8" nom. 2 stage 'SSMC' compact housing

Equipment

One

13.5/8" nom. 'SSMC' 2 stage compact,

complete with annulus equipment

Part no. 2115330-16

One

Compact housing running tool

Part no. 2125909-01

Four

1.1/2" nom. outlet blanking plug

Part no. 268689-01

(Service tools)

Three

Control line outlet flush plug

2125647-01

(Service tools)

Four

Installation studs (1/2" UNC x 3" long

screwed bar) for hold down ring

Service tool

Page 25 of 110 Rev. 07

SD-018239-01

Page 26 of 110 Rev. 07

SD-018239-01

Installation of 13.5/8" nom. 2 stage compact housing

1.0

Run 13.3/8" casing to depth. If casing becomes stuck and the emergency sliplock

connector is required, refer to page 87.

2.0

Ensure the compact housing annulus equipment is removed and fit temporary

blanking plugs to all outlets.

3.0

Ensure that the compact housing is made up onto the housing running tool away

from rig floor before it is required, using 100 ft.lbf of torque maximum. Thread is

2 TPI left hand stub acme, approximately 3-1/2 turns anti-clockwise make up.

When fully made up tool shoulders out in recess of housing.

4.0

Make up the pre-assembled 13.5/8" nom. compact housing and running tool onto

the last joint of casing.

5.0

In order to confirm correct landing position of the compact housing, paint a 1/4"

wide band on the tonging neck of the compact housing. This band should be

positioned 1.38" below the shoulder of the housing.

6.0

Open valve and drain riser. If orientation of outlets is required, paint two vertical

white lines down the centre of the outlets and one horizontal line through the

lower outlets. The compact housing can then be observed through the drain valve.

7.0

Land compact housing on 45 shoulder inside the lowermost housing. Correct

landing of the housing can be viewed through the lowermost housing. The band

painted on the tonging neck should appear in the centre of the outlet.

8.0

Rig up to cement 13.3/8" casing. Cement through the landing string taking returns

through the 3" LP outlets in the lowermost housing.

Flow area of two off outlets = 16in

9.0

Retrieve running tool by rotating right hand approximately 3-1/2 turns and pulling

vertically. Lift slowly to ensure the tool has fully disengaged.

10.0

Nipple down riser.

11.0

Test between the compact seals through test port in the lowermost housing (see

drawing) to 3,000 psi for required hold period.

12.0

After successful test, release pressure and re-install fittings (see section 3.7).

13.0

Ensure threads on the 20" nom. lowermost housing are free of debris and greased.

Page 27 of 110 Rev. 01

SD-018239-01

Page 28 of 110 Rev. 07

SD-018239-01

14.0

Pass the hold down ring over the compact housing and thread into the 20" nom

lower housing by turning left hand using the 1/2" installation studs (approx. 3

turns) until it bottoms out on the shoulder of the compact housing body.

15.0

Install inner and outer 'O'-ring seals onto the hold down ring for debris protection.

16.0

Remove blanking plugs, clean out and re-install outlet equipment as required. For

the final A and B annuli outlet configuration and connection pressure testing see

page 106 to 109.

Note: If a pressure test is required on the annulus equipment, run a VR plug

into the outlet and pressure test against it. Alternatively this equipment can be

tested when conducting the BOP tests, see page 35.

17.0

Remove the temporary control line plugs and replace them with Control Line

Blind Flange part number 2715951-01. The Blind Flange connections will be

pressure tested when conducting the BOP tests, see page 35.

Page 29 of 110 Rev. 07

SD-018239-01

This Page

Intentionally Left Blank

Page 30 of 110 Rev. 01

SD-018239-01

Installation of 13.5/8" nom. riser adaptor

Equipment

One

13.5/8" nom. 5000 psi drilling adaptor,

Fastlock connector bottom x 13.5/8"

API 5000 psi studded top

Part no. 2205286-01

One

'CF-13' gasket

Part no. 2162890-01-01

One

BX-160 gasket

Part no. 702003-16-02

One

Torque wrench and 1" A/F hex. socket

Service tool

Page 31 of 110 Rev. 01

SD-018239-01

Page 32 of 110 Rev. 07

SD-018239-01

Installation of 13.5/8" nom. riser adaptor

1.0

Thoroughly clean 'CF-13' gasket prep on bottom of 13.5/8" 5,000 psi drilling riser

adaptor and top of compact housing.

Note: The drilling riser adaptor should already be connected to the rig BOP.

2.0

Ensure segments of fastlock connector are fully retracted prior to make-up to the

compact housing.

3.0

Lightly grease seal preps and gaskets.

4.0

Install 'CF-13' gasket into compact housing hub and lower BOP with drilling riser

adaptor onto connection.

5.0

Make-up the fastlock connector by tightening each drive screw in sequence and to

the correct torque specification. The correct sequence is to tighten opposite screws

in pairs to 200 ft.lbf and work around the connector in a right hand or left hand

direction. A second application of torque at the correct torque specification should

be applied in the same sequence to ensure make-up. The torque for each drive

screw is 600 ft.lbf.

6.0

When the fastlock connector is fully made up, the ends of the drive screws should

be flush or just below flush with the end of the bushings.

7.0

If necessary, fill the area around the segments with a general purpose grease using

the fitting on the body. A vent fitting is located opposite the grease fitting to

release any trapped air. Fill the connector with grease until all the air is displaced

and grease begins coming out of the vent fitting.

Page 33 of 110 Rev. 01

SD-018239-01

This Page

Intentionally Left Blank

Page 34 of 110 Rev. 01

SD-018239-01

Running and retrieval of 13.5/8" nom. BOP test tool

Test Connection (Gate Valves Annulus A & B + drilling Adapter +

BOP Rams)

Equipment

One

13-5/8 nom combination tool, BOP tester Part no. 2125910-04

and wear bushing running tool, with

NC50 (4-1/2 IFTJ) box thread top and bottom.

Page 35 of 110 Rev. 05

SD-018239-01

Page 36 of 110 Rev. 07

SD-018239-01

Running & retrieval of BOP test tool.

Test Connection (Gate Valves Annulus A & B + drilling Adapter + BOP

Rams)

Note: The test using this Combination Tool (P/N: 2125910-04) will test ALL

OUTLETS.

1.0

Check O-rings on BOP test tool for damage and replace if necessary. Oring

Part No. 718033.

Note: For this operation, only the lower Oring is required.

Pipe Plug NPT (P/N M103989) should be installed.

2.0

Make up NC50 handling joint into combination tool with pins facing up (see

drawing).

3.0

Lightly grease 'O' ring.

Note: Ensure the tiedown screws in the riser adaptor are fully retracted (4.25"

from O/D) and gland nuts are re-made tight before continuing with the

next stage.

Note: Installation of Combination Tool may require the use of two stands of

heavy weight drill pipe, hung from the underside of the Running Tool.

Note: Do NOT apply pressure below the BOP Test Tool.

Note: The pressure test must be performed by applying pressure through Choke

/ Kill Lines. Ensure upper side pipe plug is correctly installed.

4.0

Lower BOP Test Tool into Compact Housing, through BOP stack and Riser

Adapter and land on 45 shoulder in the Compact Housing. Close upper and

lower outlets.

Note: Compare stick up above rotary table with that calculated to ensure correct

landing position of the combination tool.

5.0

Fill the stack full of water and close the pipe rams around the handling joint.

6.0

Apply test pressure to the stack and hold for the required period. Monitor open

end of drill pipe for any leakage past the test plug.

Note: 1) Maximum test pressure equals maximum working pressure of the

lowest rated item in the stack. Pressure test to 5000 psi max.

Note: 2) Any leakage past the tester seal will be visible back up the drill string.

7.0

Bleed off pressure, retract pipe rams and retrieve the combination tool.

Page 37 of 110 Rev. 06

SD-018239-01

This Page

Intentionally Left Blank

Page 38 of 110 Rev. 05

SD-018239-01

Blind Ram Test

Equipment

One

13.5/8" nom. combination tool, BOP tester and

wear bushing running tool, NC50 threads top

and bottom

Page 39 of 110 Rev. 05

Part no. 2125910-01

SD-018239-01

Page 40 of 110 Rev. 07

SD-018239-01

Blind Ram Test

1.0

Make up NC50 handling joint into combination tool with pins facing up (see

drawing).

Note: Do not tong on seal areas. Use minimum make up torque as the

handling joint will need to be backed out to test the blind rams. Make up

with chain tongs.

2.0

Check 'O' rings for damage and replace as necessary.

3.0

Lightly grease 'O' rings.

Note: Ensure the tiedown screws in the riser adaptor are fully retracted (4.25"

from O/D) and gland nuts are re-made tight before continuing with the

next stage.

4.0

Lower tool through BOP stack and riser and land on compact housing shoulder.

Note: Compare stick up above rotary table with that calculated to ensure at

correct depth.

5.0

Back out handling joint from combination tool.

6.0

Close upper outlet valve and open lower outlet valve. Fill stack full of water and

close blind rams.

7.0

Apply test pressure to BOP through kill line for required hold period. Monitor

open lower outlet valve for any leakage past the test plug.

Note: Maximum test pressure is 5,000 psi or equal to the maximum working

pressure of the lowest rated item in the stack.

8.0

Release pressure, ensure no check valve is in the kill line. Retract blind rams.

Close the lower valves on the compact housing. Retrieve the combination tool.

Page 41 of 110 Rev. 07

SD-018239-01

This Page

Intentionally Left Blank

Page 42 of 110 Rev. 07

SD-018239-01

Running and retrieval of 13.5/8" nom. lower wear bushing

Equipment

One

13.5/8" nom. lower wear bushing,

12.300" min. bore

Part no. 2125911-01

One

13.5/8" nom. combination tool, BOP tester

and wear bushing running tool, NC50

threads top and bottom

Part no. 2125910-01

Page 43 of 110 Rev. 01

SD-018239-01

Page 44 of 110 Rev. 07

SD-018239-01

Running of wear bushing

1.0

Check that 'O' rings on wear bushing are in good condition. Replace as necessary.

Lightly grease 'O' rings.

2.0

Make up combination tool with pins down onto an NC50 handling joint, avoid

tonging on seal area.

3.0

Insert the combination tool into the wear bushing and rotate tool approx 90 right

hand to fully latch into the wear bushing.

Note: Ensure the tiedown screws in the riser adaptor are fully retracted (4.25"

from O/D) and gland nuts are re-made tight before continuing with the

next stage.

4.0

Lower wear bushing through BOP stack and riser into the compact housing and

land off on 45 shoulder.

Note: Compare stick up above rotary table with that calculated to ensure at

correct depth.

5.0

Lock wear bushing in place by engaging the two tiedown screws into the recess of

the wear bushing. To do this, the glands must be first loosened by turning left

hand with a 2-1/4" wrench approx. 2 turns. The tiedown screws can then be

rotated right hand with a 3/4" wrench until they come into contact with bushing

wall (approx 6 turns). Back off the tiedown screws 45 (1/8th turn) and re-tighten

the glands to 250 ft.lbf.

6.0

Rotate running tool left hand approx. 90 to disengage from Breech connection

and retrieve tool.

Note: To ease rotation, some or all of the hang-off weight should be taken up

by the elevators.

7.0

Drill out for 10.3/4" casing.

Page 45 of 110 Rev. 01

SD-018239-01

Retrieval of wear bushing

8.0

Make up combination tool onto an NC50 handling joint.

9.0

Lower combination tool into compact housing and land on wear bushing. Slowly

rotate tool right hand to locate Breech connection until it drops 2.50".

Note: Compare stick up above rotary table with that calculated to ensure at

correct depth.

10.0

Continue rotating tool right hand approx 90 until it is fully engaged.

Note: Ensure the tiedown screws in the riser adaptor are fully retracted (4.25"

from O/D) and the gland nuts are re-made before continuing with the

next stage.

11.0

Retrieve wear bushing and running tool. Pick up slowly to ensure bushing is free.

Note: Overpull should not be required. Check tiedown screws if the wear

bushing does not come free.

Page 46 of 110 Rev. 01

SD-018239-01

Installation of 10.3/4" casing hanger

Equipment

One

13.5/8" nom x 10.3/4" casing hanger

Part no. 2125537-04

One

10.3/4" casing hanger running tool

Part no. 2125913-01

One

Crossover adapter, 9.5/8" New Vam

x 10.3/4" buttress

Part no. 2205445-01

Page 47 of 110 Rev. 01

SD-018239-01

Page 48 of 110 Rev. 07

SD-018239-01

Installation of 10.3/4" casing hanger

1.0

Run casing to depth. If casing becomes stuck and the emergency equipment is

required, refer to page 93.

2.0

Make up the pre-assembled 10.3/4" casing hanger, with running tool, onto the last

joint of casing. Ensure casing is hanging central.

3.0

Run hanger through B.O.P stack and riser into compact housing and land on 45

shoulder.

Note 1. Care should be taken when lowering hanger through BOP and

housing. Hanger should be run slowly to avoid damage to the housing

bore.

Note 2. In order to confirm correct landing position for the casing hanger,

prior to running, paint the running tool with a 1/4" wide band at a

height of 2.17" from the running thread end. On installation, the

band can be viewed through the lower outlet valve on the compact

housing (see page 44).

4.0

Rig up to cement 10.3/4" casing.

5.0

Remove running tool by right hand rotation, (approx. 6 turns) and retrieve slowly

to ensure tool has fully disengaged.

Page 49 of 110 Rev. 01

SD-018239-01

This Page

Intentionally Left Blank

Page 50 of 110 Rev. 01

SD-018239-01

Washout of compact housing lower seal areas

Equipment

One

Wash out tool, NC50 box thread

Page 51 of 110 Rev. 01

Part no. 2125914-01

SD-018239-01

Page 52 of 110 Rev. 07

SD-018239-01

Washout of compact housing lower seal areas

1.0

Make-up wash tool onto handling joint and connect to a clean water supply.

2.0

Open lower outlets in the compact housing

3.0

Lower tool through rotary and slowly begin washing at the top of BOP stack,

using a flowrate of approximately 900 litres/min. Washout tool should be slowly

rotated to achieve full circumferential washing effect.

Note: Ensure the tiedown screws in the riser adaptor are fully retracted (4.25"

from O/D) and gland nuts are re-made tight before continuing with the

next stage.

4.0

Lower wash tool slowly, continuing to wash housing bore and seal areas of casing

hanger.

Note: As tool approaches fully landed position on casing hanger, the volume

of water passing through the tool may have to be reduced to reduce back

pressure build up.

5.0

Continue to jet water until water flowing out of the compact housing outlets is

clean.

6.0

Stop water jet and retrieve tool.

Note: DO NOT jet water and clean on retrieval of tool back up the stack, as

this may wash any remaining debris that could be lodged in the ram

cavities/annular, back down hole.

Page 53 of 110 Rev. 01

SD-018239-01

This Page

Intentionally Left Blank

Page 54 of 110 Rev. 01

SD-018239-01

Installation and testing of casing hanger seal assembly

Equipment

One

13.5/8" nom. seal assembly, to suit

10.3/4" casing hanger

Part no. 2205123-01

One

Seal assembly running tool, NC50

threads top and bottom

Part no. 2095627-01

One

Installation tool for split lockdown ring

Part no. 2230761-02

(Service tool)

Page 55 of 110 Rev. 04

SD-018239-01

Page 56 of 110 Rev. 05

SD-018239-01

Installation and testing of casing hanger seal assembly

Note: Ensure the riser is drained prior to running the seal assembly.

1.0

Inspect seal assembly for damage, paying particular attention to the 'LS' and 'NS'

seals. Replace as necessary.

2.0

Make up the running tool onto NC50 handling joint.

Note: A minimum weight of 10,000 lbf is required to install the seal assembly.

This may require the use of heavy weight drill collars hung from the

NC50 box thread below the running tool to supplement total hangoff

weight.

3.0

Partially screw seal assembly left hand onto running tool until tool contacts

tapered portion of split lockdown ring. Approximately 4 turns are required to

contact split lockdown ring, note number of turns.

4.0

Adjust bolt on the installation tool to compress the split lockdown ring.

5.0

As ring is compressed, screw the seal assembly further onto the running tool.

6.0

Repeat 4.0 and 5.0 until O/D of split lockdown ring is flush with or just below the

O/D of the seal assembly body. Approximately 4 further turns are required to

fully compress the split lockdown ring. Note number of turns.

7.0

With the running tool fully engaged on split lockdown ring, adjust bolt on the

installation tool and remove tool.

Note: After removal of the installation tool, split lockdown ring must be flush

with or just below the O/D of the seal assembly. If required, replace

installation tool and repeat from 4.0.

8.0

Clean seal assembly and lubricate all seals with valve grease.

9.0

Open lower outlets in the compact housing.

10.0

Slowly lower seal assembly through BOP stack and riser into housing.

Note. An increase in resistance will be felt as the I/D seals engage onto the

casing hanger.

11.0

Compare stick up above rotary table with that calculated to ensure at correct

depth.

Page 57 of 110 Rev. 01

SD-018239-01

Page 58 of 110 Rev. 05

SD-018239-01

Installation and testing of casing hanger seal assembly (continued)

12.0

13.0

Mark angular datum on handling joint and back out running tool 4 turns right

hand to allow split lockdown ring to expand into its groove in the housing.

Note 1.

Initial rotation right hand will locate the four anti-rotation spring

loaded pins of the seal assembly into the casing hanger. This will be

achieved within 90. A revised angular datum should then be marked

at this point.

Note 2.

If confirmation of ring expansion is required, an overpull of 20,000

lbf can be applied to the running tool at this stage.

Ensure lower outlets are open on housing, do not retrieve running tool at this

stage.

Pressure testing of seal assembly

Note: The split lockdown ring must be expanded into the lockdown groove

before pressure testing commences. Failure to do this can result in

damage to the seal assembly.

14.0

Remove autoclave plug and gland from test port 1 (see page 54) in housing.

15.0

Connect pressure test pump into the test port and apply pressure while bleeding

air from the opposite port. Test pressure is to be 5,000 psi max. Lock in for

required hold period.

16.0

After successful test, release pressure, and re-install plug and gland (see manual

section 3.7).

17.0

Fully back out running tool by right hand rotation, approximately 4 further turns

(see 3.0) and retrieve. Lift slowly to ensure that the tool has fully disengaged.

Page 59 of 110 Rev. 01

SD-018239-01

Installation and testing of casing hanger seal assembly (continued)

Retrieval of seal assembly

Note: In the unlikely event that a successful pressure test is not obtained on

the seal assembly, it may be necessary to retrieve the seal assembly and

investigate the problem.

1.0

If the running tool is still engaged on the seal assembly down hole, proceed to 5.0.

2.0

Make up running tool onto NC50 handling joint. Lubricate threads and inner lip

of tool.

3.0

Slowly lower running tool through BOP and riser into the compact housing

landing out on top of the seal assembly.

4.0

Rotate left hand to engage tool onto seal assembly thread.

5.0

Continue rotation approximately 8 turns (see 3.0 and 6.0 on page 53) until tool is

fully engaged on thread and a firm stop is encountered. The torque required will

increase as the running tool approaches 7 turns and the 8th turn should be achieved

within 5000 ft.lbf of make-up torque. DO NOT exceed 7,000 ft.lbf of make-up

torque as the seal assembly latch pins may be sheared. Back off from this point a

maximum of 45 (1/8th of a turn) right hand.

6.0

Retrieve seal assembly by overpull.

Note: An overpull of 15,000 lbf should be satisfactory to retrieve the assembly,

DO NOT exceed 25,000 lbf.

7.0

To remove seal assembly from running tool, replace the installation tool and

adjust bolt to fully compress the ring. Unscrew seal assembly right hand.

Page 60 of 110 Rev. 01

SD-018239-01

Running and retrieval of 13.5/8" nom. BOP test tool

Equipment

One

13.5/8" nom. combination tool, BOP tester

and wear bushing running tool, NC50

threads top and bottom

Page 61 of 110 Rev. 01

Part no. 2125910-01

SD-018239-01

Page 62 of 110 Rev. 05

SD-018239-01

Running and retrieval of 13.5/8" nom. BOP test tool

Running the combination tool at this stage does not allow testing of the compact

housing upper annulus outlets. Should this be a requirement while testing the

BOP, then a cup tester is to be used.

1.0

Make up NC50 handling joint into combination tool with pins facing up (see

drawing).

Note: Do not tong on seal areas. Use minimum make up torque as the

handling joint will need to be backed out to test the blind rams. Make up

with chain tongs.

2.0

Check 'O' rings for damage and replace as necessary.

3.0

Lightly grease 'O' rings.

Note: Ensure the tiedown screws in the riser adaptor are fully retracted (4.25"

from O/D) and gland nuts are re-made tight before continuing with the

next stage.

4.0

Lower tool through BOP stack and riser and land on seal assembly.

Note: Compare stick up above rotary table with that calculated to ensure at

correct depth.

Note: Do NOT apply pressure below the Test Tool.

Note: The pressure test must be performed by applying pressure through Choke

/ Kill Lines. Ensure upper side pipe plug is correctly installed.

5.0

Fill stack full of water and close pipe rams around handling joint. Open the upper

outlet valves in the compact housing to monitor any fluid passing.

6.0

Apply test pressure to BOP through kill line for required hold period.

Note: Maximum test pressure is 5,000 psi or equal to the maximum working

pressure of the lowest rated item in the stack.

7.0

Release pressure and retract BOP rams.

Page 63 of 110 Rev. 05

SD-018239-01

Blind Ram Test

8.0

Back out handling joint from combination tool.

9.0

Fill stack full of water and close blind rams and open the upper outlet valves in

the compact housing.

10.0

Apply test pressure to BOP through kill line for required hold period. Monitor

open upper outlet valve for any leakage past the test plug.

Note: Maximum test pressure is 5,000 psi or equal to the maximum working

pressure of the lowest rated item in the stack.

11.0

Release pressure, ensure no check valve is in the kill line. Retract blind rams.

Close the upper valves in the compact housing. Retrieve the combination tool.

Page 64 of 110 Rev. 05

SD-018239-01

Running and retrieval of 13.5/8" nom. upper wear bushing

Equipment

One

13.5/8" nom. upper wear bushing,

8.845" min. bore

Part no. 2125916-01

One

13.5/8" nom. combination tool, BOP

Tester and wear bushing running tool,

NC50 threads top and bottom

Part no. 2125910-01

Page 65 of 110 Rev. 01

SD-018239-01

Page 66 of 110 Rev. 05

SD-018239-01

Running of wear bushing

1.0

Check that 'O' rings on wear bushing are in good condition. Replace as necessary.

Lightly grease 'O' rings.

2.0

Make up combination tool with pins down onto an NC50 handling joint, avoid

tonging on seal area.

3.0

Insert the combination tool into the wear bushing and rotate tool approx 90 right

hand to fully latch into the wear bushing.

Note: Ensure the tiedown screws in the riser adaptor are fully retracted (4.25"

from O/D) and gland nuts are re-made tight before continuing with the

next stage.

4.0

Lower wear bushing through B.O.P. stack and riser into the compact housing and

land off on the seal assembly.

Note: Compare stick up above rotary table with that calculated to ensure at

correct depth.

5.0

Lock wear bushing in place by engaging the two tiedown screws into the recess of

the wear bushing. To do this, the glands must be first loosened by turning left

hand with a 2-1/4" wrench approx. 2 turns. The tiedown screws can then be

rotated right hand with a 3/4" wrench until they come into contact with bushing

wall (approx 6 turns). Back off the tiedown screws 45 (1/8th turn) and re-tighten

the glands to 250 ft.lbf.

6.0

Rotate running tool left hand approx. 90 to disengage from 'Breech' connection

and retrieve tool.

Note: To ease rotation, some or all of the hang-off weight should be taken up

by the elevators.

Page 67 of 110 Rev. 01

SD-018239-01

Retrieval of wear bushing (continued)

7.0

Make up combination tool onto an NC50 handling joint.

8.0

Lower combination tool into compact housing and land on wear bushing. Slowly

rotate tool right hand to locate Breech connection until it drops 2.50".

Note: Compare stick up above rotary table with that calculated to ensure at

correct depth.

9.0

Continue rotating tool right hand approx 90 until it is fully engaged.

Note: Ensure the tiedown screws in the riser adaptor are fully retracted (4.25"

from O/D) and the gland nuts are re-made before continuing with the

next stage.

10.0

Retrieve wear bushing and running tool. Pick up slowly to ensure bushing is free.

Note: Overpull should not be required. Check tiedown screws if the wear

bushing does not come free.

Page 68 of 110 Rev. 01

SD-018239-01

Washout of compact housing upper seal areas

Equipment

One

Wash out tool, NC50 box thread

Page 69 of 110 Rev. 01

Part no. 2125914-01

SD-018239-01

Page 70 of 110 Rev. 05

SD-018239-01

Washout of compact housing upper seal areas

1.0

Make-up wash tool onto handling joint and connect to a clean water supply.

2.0

Open upper outlets in the compact housing.

3.0

Lower tool through rotary and begin washing at the top of BOP stack, using a

flowrate of approximately 900 litres/min. Washout tool should be slowly rotated

to achieve full circumferential effect.

Note: Ensure the tiedown screws in the riser adaptor are fully retracted (4.25"

from O/D) and gland nuts are re-made tight before continuing with the

next stage.

4.0

Lower wash out tool slowly, continuing to wash housing bore until wash out tool

lands on top face of seal assembly.

Note: As tool approaches fully landed position on seal assembly, the volume of

water passing through the tool may have to be reduced to reduce back

pressure build up.

5.0

Continue to jet water until water flowing out of the outlets is clean.

6.0

Stop water jet and retrieve tool.

Note: DO NOT jet water and clean on retrieval of tool back up the stack, as

this may wash any remaining debris that could have lodged in the ram

cavities/annular back down hole.

Page 71 of 110 Rev. 01

SD-018239-01

This Page

Intentionally Left Blank

Page 72 of 110 Rev. 01

SD-018239-01

Installation and testing of tubing hanger

Equipment

One

13.5/8" nom. tubing hanger, 7" Vam Top

Part no. 2205088-05

One

Tubing hanger running tool, 7.5/8" Vam Top

Part no. 2180000-04-07

One

Installation tool for split lockdown ring

Part no. 2230761-02

(Service tool)

Page 73 of 110 Rev. 04

SD-018239-01

Page 74 of 110 Rev. 01

SD-018239-01

Installation and testing of tubing hanger

1.0

Inspect the running threads on both the hanger and the running tool and lubricate.

Inspect tubing hanger seals for damage, replace as necessary. Apply a light coat of

valve grease to seals.

2.0

Check 'O' ring on the running tool is in good condition. Replace as necessary.

Note: The tubing hanger is supplied with a protector sleeve for the 'SRL' seal

preparation. This should remain in place until installation of the tree

assembly

3.0

Attach the snap ring lock to the snap ring but do not collapse it until the hanger is

ready to be run at the rig floor.

Note: In order to confirm the correct landing position for the tubing hanger,

paint a band on the 45 chamfer (see drawing). On installation, the

painted band can be reviewed through the upper outlet valve or flange.

Once the hanger is landed off, the painted band should be central in the

upper annulus outlet.

4.0

Make up the running tool onto the handling joint (if not already made up). Tong

only on the running tool neck.

5.0

Run the tubing string complete with control line per completion program. Make

up hanger onto the last joint of tubing.

6.0

Cut and bevel the control line at a height of approx. 8 ft above the hanger, strip

back encapsulation and check for any scarring of stripped lines. Slide the 1/4"

NPT fitting over the control line (thread towards the top). Insert continuous

control line through the port in the tubing hanger.

7.0

Make up the compression fittings on top and bottom of the tubing hanger.

8.0

Pressure test the gallery around the control line through the test port on the O/D of

the tubing hanger to a maximum of 5,000 psi.

9.0

Collapse the snap ring using the snap ring lock mechanism.

10.0

Lift the running tool above the tubing hanger and insert the control line through

the hole provided in the running tool.

Page 75 of 110 Rev. 01

SD-018239-01

Page 76 of 110 Rev. 05

SD-018239-01

Installation and testing of tubing hanger (continued)

Note: The pins in the running tool sleeve will ensure the control lines through

the hanger are aligned with the through hole in the sleeve.

11.0

Re-attach the spooled control line to the control line exiting the tool with a

coupling, ensuring that the coupling will fit through the hole in the running tool.

12.0

Pick up the running tool and carefully lower it onto the tubing hanger assembly.

13.0

Make up the running tool to the tubing hanger by rotating the tool right hand with

respect to the tubing hanger. Be sure to keep the outer sleeve of the running tool

from rotating by sliding the pins in the outer barrel into their respective slots in

the hanger. Also be sure to properly capture the snap ring with the running tool.

Approximately 10-1/2 turns are required, note turns.

14.0

Remove the snap ring lock and ensure that the snap ring is below flush with the

body of the tubing hanger. If it is not then the running tool must be further

engaged onto the hanger by additional right hand rotation.

15.0

Pressure test control lines as required.

16.0

Just prior to landing, drain BOP stack and ensure tubing is central in rotary table.

17.0

Lower hanger and running tool through BOP stack and riser into the compact

housing and land on top of seal assembly.

Note: Compare stick up above rotary table with that calculated to ensure

correct depth. Look through upper outlet valve in the compact housing

and confirm painted band is in the correct position. Close valve.

18.0

Slowly rotate the running tool left hand to disengage the snap ring from the

running tool and engage it into the compact housing. After 4 turns the snap ring

should be checked for engagement into the housing by an overpull of 20,000 lbf

above string weight.

Note 1:

If visual confirmation of the correct snap ring engagement is

required, prior to overpull, remove the blanking plug and view

through the viewing port provided.

Note 2:

Visual confirmation of the correct overpull test can be achieved by

viewing through the upper 'A' annulus. The hanger should lift a

maximum of 0.15" and then stop when the snap ring 'float' has been

taken up.

Page 77 of 110 Rev. 01

SD-018239-01

19.0

Test between the tubing hanger seals through test port 2 (see drawing) in the

compact housing to 5000 psi for required hold period.

20.0

After successful test, release pressure and re-install fittings (see section 3.7).

21.0

Proceed with wireline work as necessary.

22.0

Refer to running procedure RP-002398 for installation of two way check valve

(see section 3.9) into tubing hanger through the landing string. Torque to 400

ft.lbf and test to 5000 psi per completion procedure.

23.0

Disengage running tool from tubing hanger by left hand rotation, after

approximately 10-1/2 turns, see 13.0 and 18.0. Begin to slowly lift the running

tool out of the housing ensuring the tool has fully disengaged. After approx. 8 ft

the control line must be monitored to ensure couplings do not hang in the running

tool.

24.0

Release pressure in control lines and cut either just below or above the running

tool at rig floor level. Remove running tool from landing string.

Page 78 of 110 Rev. 04

SD-018239-01

Page 79 of 110 Rev. 01

SD-018239-01

Termination of control lines

Note: Terminate control line as follows:

1.0

Nipple down the BOP stack from the 13-5/8" compact housing.

2.0

Lift the riser adaptor and stack clear and remove the CF-13 gasket.

3.0

Remove the control line blind flange where applicable.

4.0

Wrap control line around the hanger neck and feed through the control line exit

port in the compact housing.

5.0

Clean and lightly oil gasket preps in the needle valve and control line exit flange

on compact housing.

6.0

Install fitting nut, ferrule and No. 14 gasket over each tubing. Cut control line to

length, use a tube cutter not a hacksaw. Ensure sufficient line is available to work

with and that excess can be pushed back into the compact housing.

7.0

Make-up compression fitting (ferrule and nut) into control line needle valve.

8.0

Install control line needle valve, secure with cap screws pushing excess tubing

back into compact housing. Connect control line for SSSV to port in control line

as required.

Note: To ease installation of the needle valve block, use two 1/2" UNC

threaded stud bolts approx. 8" long as guides, before installing the

needle valve onto the wellhead.

Page 80 of 110 Rev. 05

SD-018239-01

Installation and testing of xmas tree

Equipment

One

Xmas tree, 6.3/8" 5000 'FLS' valves

Part no. 2115330-04

One

7" 'SRL' seal

Part no. 2120000-34-03

One

'CF-13' gasket

Part no. 2162890-01-01

One

7" 'SRL' seal installation tool

Part no. 2119760-34-01

Page 81 of 110 Rev. 01

SD-018239-01

Page 82 of 110 Rev. 01

SD-018239-01

Installation and testing of xmas tree

1.0

Remove the BOP stack from the compact housing by backing out drive screws in

the fastlock drilling adaptor left hand until they bottom out.

2.0

Lift the BOP and riser clear and remove the 'CF-13' gasket.

3.0

Install studs into the compact housing 50 to 100 ft.lbf. After installation of studs,

confirm 7.13" maximum height (see drawing).

Note: Do not over torque.

4.0

Thoroughly clean seal preps in top of the compact housing and in the bottom of

the xmas tree.

5.0

Fit new 'CF-13' gasket into the compact housing.

6.0

Prise out protector sleeve from seal prep in the hanger neck.

7.0

Ensure prep for 'SRL' seal in hanger neck is clean and free from defects. Apply a

light coat of oil only and install seal. Prior to installing seal, drift through the seal

with spare BPV.

Note: The 'SRL' seal is an interference fit in the bore of the tubing hanger

(and xmas tree) and requires a certain load to fully install it. The seal

can be carefully installed in the tubing hanger using the 'SRL' seal

installation tool. Alternatively, use a block of wood and a sharp rap with

a hammer. The seal will be fully installed during installation of xmas

tree.

8.0

Ensure prep for 'SRL' seal in xmas tree is clean and free from defects. Check 'NS'

seal is in good condition. Replace as necessary.

10.0

Remove autoclave fittings from test port and vent port (see drawing) in the xmas

tree. Ensure all gates and swab cap vent port in the vertical bore of the xmas tree

are open to prevent trapped pressure when landing tree.

11.0

Lift tree and orientate to suit site requirements. Ensure tree is as near vertical as

possible. It is recommended at this stage to fill the compact housing annulus with

test fluid. This will aid the connection pressure test.

Note: Ensure correct lifting eyes are used to lower tree onto the compact

housing.

Page 83 of 110 Rev. 01

SD-018239-01

Page 84 of 110 Rev. 01

SD-018239-01

Note: It is recommended at this stage to fill the annulus in the top of the

housing with light oil (pressure test fluid). This will assist the connection

pressure test later.

Installation and testing of xmas tree

12.0

Slowly lower tree onto housing taking extra care as the tree slides over the

projecting hanger neck.

13.0

Install the 24 nuts onto studs to make up Flangelock connection. Tighten in stages

in an opposite and alternate pattern to evenly make up connection. Final torque to

be within range of 750 ft.lbf min. to 970 ft.lbf max.

Connection pressure test

14.0

Apply pressure through test port 3 (see drawing) to 5,000 psi and lock in for

required hold period.

Note: Ensure the vent port is open to monitor any leakage past the 'NS' seal.

15.0

After successful test, release pressure and install fittings (see section 3.7).

'SRL' hanger neck seal test

16.0

The 'SRL' hanger neck seal is a uni-directional metal to metal seal. It cannot be

tested via an external test port.

Note: Under no circumstances apply a pressure test through the vent port.

17.0

The test is performed by pressurising the flow bore of the tree against the two way

check valve set in the tubing hanger. Pressure to 5,000 psi and lock in for required

hold period. Monitor for leakage through the vent port (see drawing).

18.0

After successful test, release pressure and install fittings (see section 3.7).

19.0

Test each valve on xmas tree.

20.0

Install and pressure test lubricator and retrieve the two way check valve (see

section 3.9).

Page 85 of 110 Rev. 04

SD-018239-01

Removal of xmas tree and retrieval of tubing hanger

1.0

Install two way check valve and pressure test.

2.0

Disconnect flowline from tree and remove flangelock nuts. Lift tree as vertical as

possible.

3.0

Clean the top of the tubing hanger in readiness for the tubing hanger running tool.

4.0

Disconnect control line exit and remove control line needle valve from compact

wellhead outlet. Plug the control line in the wellhead outlet. Cut off the control

line 1/2" above the tubing hanger fitting. Clean the top of the tubing hanger in

readiness for the tubing hanger running tool.

5.0

Install and pressure test the BOP against the blind ram only. Function test BOP.

Note: The BOP should have been pressure tested on the test stump so only a

pressure test of the connection to the wellhead is necessary.

6.0

Recover two way check valve.

Note: Recover other plugs, pump fluid etc. as required by the workover

programme.

7.0

Remove 4 off pins from the tubing hanger running tool outer sleeve. Lower the

tool on the landing string down onto the tubing hanger. When landed, turn the

landing string right hand to make up the tubing hanger running tool to the tubing

hanger. Approx. 8.1/2 to 9 turns are required to fully collapse the hanger snap

ring.

8.0

Slowly retrieve the tubing hanger with a straight vertical lift.

Page 86 of 110 Rev. 01

SD-018239-01

Installation of 20" nom. emergency lowermost housing

Equipment

One

20.3/4" emergency lower casing head housing

Part no. 2289213-01

One

20" nom. lower housing running tool,

21.25"-2 TPI LH stub acme x 20" buttress

Part no. 2125904-01

One

Crossover, 20" buttress x 18.5/8" buttress

Part no. 2205444-01

Page 87 of 110 Rev. 07

SD-018239-01

Page 88 of 110 Rev. 07

SD-018239-01

Installation of 20" nom. emergency lowermost housing

1.0

In the event that the 18.5/8" casing becomes stuck during running and it is

required to cement, centralise the casing and cement per completion programme.

2.0

Cut and dress the 18.5/8" casing 7.50" +/- 0.25" (190.56.4mm) above the

conductor (see drawing).

3.0

Make up the emergency lowermost housing running tool to landing string.

4.0

Prepare 20" nom. emergency lowermost housing for running by backing off 8

sliplock activating screws. Ensure that the slips are in their uppermost position

and lock in by tightening the slip retaining screws hand tight only.

5.0

Make up running tool to housing by left hand rotation 200 ft.lbf max,

approximately 4.1/2 turns (note turns).

6.0

Lower housing over the casing stub. Prior to landing on conductor pipe / plate,

loosen the slip retaining screws. Confirm that outlet orientation conforms to site

requirements.

7.0

Energise 'P' seals, see Section 3.5.

8.0

Test between the two 'P' seals through test port in the emergency lowermost

housing (see drawing) to 80% of casing collapse pressure.

9.0

After successful test, release pressure and re-install fittings (see section 3.6).

10.0

Run in the eight slip activating screws and torque up evenly in sequence to 100 to

200 ft.lbf. to engage the slip segments onto the casing.

Note: It is important to successfully test the 'P' seals prior to setting the slips.

In the event that the seals fail a pressure test and require replacing, it

may be necessary to remove the housing. It will be impossible to pull the

housing after setting the slips.

11.0

To ensure that the slip segments have gripped the casing, perform an overpull test

to approx. 30,000 lbf.

12.0

Remove running tool by right hand rotation approximately 4.1/2 turns (see 5.0).

13.0

Thoroughly flush out and clean housing bore and install outlet equipment.

14.0

Continue with operations, see page 9.

Page 89 of 110 Rev. 07

SD-018239-01

This Page

Intentionally Left Blank

Page 90 of 110 Rev. 01

SD-018239-01

Installation of 13.3/8" emergency sliplock connector

Equipment

One

13.5/8" nom. 'SSMC' 2 stage compact,

complete with annulus equipment

Part no. 2115330-16

One

Compact housing running tool

Part no. 2125909-01

One

Emergency sliplock connector, 13.3/8"

68 # BTC pin x 13.3/8" slips

Part no. 2055120-05

Four

1.1/2" nom. outlet blanking plug

Part no. 268689-01

(Service tools)

Three

Control line outlet flush plug

Part no. 2125647-01

(Service tools)

Four

Installation studs (1/2" UNC x 3" long

screwed bar) for hold down ring

(Service tool)

Page 91 of 110 Rev. 07

SD-018239-01

Page 92 of 110 Rev. 07

SD-018239-01

Installation of 13.3/8" emergency sliplock connector

1.0

In the event that the 13.3/8" casing becomes stuck during running and it is

required to cement, ensure that there are no casing collars or centralisers within

the lowermost housing. Centralise the casing and cement per completion

programme.

2.0

Using a rig internal casing cutter, cut and bevel the 13.3/8" casing. To determine

the position, measure from the top of the compact hub to the bottom face of the

sliplock connector. Take 21.25" from this dimension to give the correct cut-off

height (see drawing). There is a +/- 2.00" (50.8 mm) tolerance on this dimension.

3.0

Nipple down 20.3/4" BOP stack by backing out drilling adaptor drive screws.

4.0

Dress and chamfer top of 13.3/8" casing.

5.0

Measure diameter of the 13.3/8" casing stub and select the appropriate 'T' seals.

Casing diameter

13.308 / 13.375

13.375 / 13.442

13.442 / 13.509

[338.02 / 339.72mm]

[339.72 / 341.43mm]

[341.43 / 343.13mm]

'T' seal part no.

2017924-03-01

2017924-02-01

2017924-01-01

Assemble the selected seals and retainer wires into the sliplock connector.

6.0

Check 'O'-ring on compact housing running tool is in good condition. Replace as

necessary.

7.0

Ensure the compact housing annulus equipment is removed and four off plugs

part no. 268689-01 are fitted.

8.0

Make up compact housing running tool to landing joint.

9.0

Make up running tool into compact housing left hand to 200 ft.lbf maximum.

Approx. 4 turns are required (note turns).

10.0

Make up 13.3/8" sliplock connector / crossover into the bottom of the compact

housing.

11.0

Check 'O'-rings on the compact housing are in good condition. Replace as

necessary.

Page 93 of 110 Rev. 07

SD-018239-01

Page 94 of 110 Rev. 07

SD-018239-01

Installation of 13.3/8" emergency sliplock connector (continued)

12.0

Loosen but do not remove the 4 off transportation socket head screws locking the

slips in place. Ensure that the screws are below the O/D of the connector. Confirm

that the slips are held in the uppermost position.

13.0

Run compact housing and sliplock connector over casing stub and into lowermost

housing. Ensure outlets conform to site requirement.

14.0

Test between the compact seals through test port in the lowermost housing (see

drawing) to 3,000 psi for required hold period.

15.0

After successful test, release pressure and re-install fittings (see Section 3.6).

16.0

Retrieve running tool by rotating right hand approximately 4 turns (see 9.0) and

pulling vertically. Lift slowly to ensure the tool has fully dis-engaged.

17.0

Ensure threads on the 20" nom. lowermost housing are free of debris and greased.

18.0

Pass the hold down ring over the compact housing and thread into the 20" nom.

lower housing by turning left hand using the 1/2" installation studs (approx. 3

turns).

19.0

Install inner and outer 'O'-rings seals onto the hold down ring for debris

protection.

20.0

Remove blanking plugs, clean out and re-install outlet equipment as required. For

the final A and B annuli outlet configuration and connection pressure testing see

page 106 to 109.

21.0

Install 13.5/8" nom. drilling adaptor with BOP and riser, see page 31.

22.0

Run 13.3/8" casing spear below casing cut-off.

23.0

Pull required tension in the casing, slowly release to set slips.

24.0

Pressure test sliplock connector seals by applying pressure against 13.3/8" cup

tester.

Page 95 of 110 Rev. 07

SD-018239-01

This Page

Intentionally Left Blank

Page 96 of 110 Rev. 01

SD-018239-01

Installation of 9.5/8" or 10.3/4" emergency slip bowl assembly

Equipment

One

13.5/8" nom. x 9.5/8" emergency slip bowl

assembly (includes 4 off handling rods)

Part no. 2119357-01-01

OR

One

13.5/8" nom. x 10.3/4" emergency slip bowl

assembly (includes 4 off handling rods)

Page 97 of 110 Rev. 01

Part no. 2179369-01

SD-018239-01

Page 98 of 110 Rev. 07

SD-018239-01

Installation of 9.5/8" or 10.3/4" emergency slip bowl assembly

1.0

In the event that either the 9.5/8" or 10.3/4" casing becomes stuck during running

and it is required to cement the casing as is, the mandrel casing hanger cannot be

used. Ensure there are no casing collars or centralisers within the compact

housing. Centralise the casing and cement per completion programme.

2.0

When the well is in a safe condition, nipple down 13.5/8" BOP stack by backing

out drilling adaptor drive screws. Lift BOP stack at least 24" clear to gain access

to casing.

3.0

Select the appropriate slip bowl assembly. Assemble four 1/2" handling rods, as

supplied, into slip bowl assembly. Unbolt two halves of emergency slip assembly

and wrap around casing. Bolt two halves back together.

4.0

Loosen slip retaining screws ensuring that the screws remain below the O/D of the

slip bowl.

5.0

Lower slip bowl assembly into housing and land out on 45 shoulder. Remove

handling rods.

6.0

Pick up casing and pull required tension, 15,000 lbf. Confirm casing is central and

adjust as required to allow slips to set down evenly.

7.0

Release tension to set slips.

8.0

Make a rough cut on the casing, leaving the casing stub above the face of the

compact housing.

9.0

Retrieve cut casing back to rig floor and discard.

10.0

Position BOP stack away from the wellhead to gain further access to the casing

stub and secure.

11.0

Accurately cut the casing inside the compact housing 19.75" +/-.25" [501.76.35]

from top face of the compact using the internal casing cutter. Refer to Furmanite

operation instructions.

12.0

Dress casing stub with a 3/16" x 30 chamfer and remove all cuttings etc. from

around the casing stub.

13.0

Thoroughly clean 'CF-13' gasket prep on the bottom of 13.5/8" drilling adaptor

and top of the compact housing.

Page 99 of 110 Rev. 07

SD-018239-01

14.0

Ensure segments of fastlock connector are fully retracted prior to make-up to the

compact housing.

15.0

Install 'CF-13' gasket into compact housing hub and lower BOP stack with drilling

riser adaptor onto connection.

16.0

Make-up the fastlock connector by tightening each drive screw in sequence and to

the correct torque specification. The correct sequence is to tighten opposite screws

in pairs and work around the connector in a right hand or left hand direction. A

second application of torque at the correct torque specification should be applied

in the same sequence to ensure make-up. The torque for each drive screw is 600

ft.lbf.

17.0

Washout seal areas in housing per procedure see page 47.

18.0

See page 101 for installation of 9.5/8" or 10.3/4" emergency seal assembly as

applicable.

Page 100 of 110 Rev. 07

SD-018239-01

Installation and testing of 9.5/8" or 10.3/4" emergency seal assembly

Equipment

One

13.5/8" nom. emergency seal assembly

to suit 9.5/8" casing

Part no. 2119379-01-01

OR

One

13.5/8" nom. emergency seal assembly

to suit 10.3/4" casing

Part no. 2179370-01

One

Seal assembly running tool, NC50 threads

top and bottom

Part no. 2095627-01

One

Installation tool for split lockdown ring

Part no. 2230761-02

(Service tool)

Page 101 of 110 Rev. 04

SD-018239-01

Page 102 of 110 Rev. 07

SD-018239-01

Installation and testing of 9.5/8" or 10.3/4" emergency seal assembly

1.0

Prepare seal assembly. Inspect for damage, paying particular attention to the 'LS'

and 'T' seals. Replace as necessary. Ensure spring loaded anti-rotational pins

depress and retract.

2.0

Make up the running tool onto NC50 handling joint.

Note: A minimum weight of 10,000 lbf is required to install the seal assembly.

This may require the use of heavy weight drill collars hung from the

NC50 box thread below the running tool to supplement total hangoff

weight.

3.0

Partially screw seal assembly left hand onto running tool until tool contacts

tapered portion of split lockdown ring. Approximately 4 turns are required to

contact split lockdown ring. Note number of turns.

4.0

Adjust bolt on the installation tool to compress the split lockdown ring.

5.0

As ring is compressed, screw the seal assembly further onto the running tool.

6.0

Repeat 4.0 and 5.0 until O/D of split lockdown ring is flush with or just below the

O.D. of the seal assembly body. Approximately 4 further turns are required to

fully compress the split lockdown ring. Note number of turns.

7.0

With the running tool fully engaged on split lockdown ring, adjust bolt on the

installation tool and remove tool.

Note: After removal of the installation tool, split lockdown ring must be flush

with or just below the O/D of the seal assembly. If required, replace

installation tool and repeat from 4.0.

8.0

Clean seal assembly and lubricate all seals with valve grease.

9.0

Open lower outlets in the compact housing.

10.0

Slowly lower seal assembly through BOP stack and riser into housing.

Note: An increase in resistance will be felt as the I/D seals engage onto the

casing.

11.0

Compare stick up above rotary table with that calculated to ensure at correct

depth. This can be verified by viewing through lower outlets.

Page 103 of 110 Rev. 01

SD-018239-01

Installation and testing of 9.5/8" or 10.3/4"emergency seal assembly

(continued)

12.0

13.0

Mark angular datum on handling joint and back out running tool 4 turns right

hand to allow split lockdown ring to expand into its groove in the housing.

Note 1:

Initial rotation right hand of the 9.5/8" seal assembly will locate the

two anti-rotation spring loaded pins of the seal assembly into the slip

bowl. This will be achieved within 180. A revised angular datum

should then be marked at this point.

Note 2:

Initial rotation right hand of the 10.3/4" seal assembly will locate the

three anti-rotation spring loaded pins of the seal assembly into the slip

bowl. This will be achieved within 120. A revised angular datum

should then be marked at this point.

Note 3:

If confirmation of ring expansion is required, an overpull of 20,000

lbf can be applied to the running tool at this stage.

Ensure lower outlets are open on housing, do not retrieve running tool at this

stage.

Pressure testing of seal assembly

Note: The split lockdown ring must be expanded into the lockdown groove

before pressure testing commences. Failure to do this can result in

damage to the seal assembly.

14.0

Remove autoclave plug and gland from test port 1 (see page 100) in housing.

15.0

Connect pressure test pump into the test port and apply pressure while bleeding

air from the opposite port. Test pressure is to be 80% of collapse of casing. Lock

in for required hold period.

16.0

After successful test, release pressure, and re-install plug and gland (see Section

3.6).

17.0

Fully back out running tool by right hand rotation, approximately 4 further turns

(see 3.0) and retrieve. Lift slowly to ensure that the tool has fully disengaged.

Page 104 of 110 Rev. 06

SD-018239-01

Installation and testing of 9.5/8" or 10.3/4" emergency seal assembly

(continued)

Retrieval of seal assembly

Note: In the unlikely event that a successful pressure test is not obtained on

the seal assembly, it may be necessary to retrieve the seal assembly and

investigate the problem.

1.0

If the running tool is still engaged on the seal assembly down hole, proceed to 5.0.

2.0

Make up running tool onto NC50 handling joint. Lubricate threads and inner lip

of tool.

3.0

Slowly lower running tool through BOP and riser into the compact housing

landing out on top of the seal assembly.

4.0

Rotate left hand to engage tool onto seal assembly thread.

5.0

Continue rotation approximately 8 turns (see 3.0 and 6.0 on page 99) until tool is

fully engaged on thread and a firm stop is encountered. The torque will increase

as the tool approaches the 8th turn, DO NOT exceed 4,500 ft.lbf of make-up

torque as the seal assembly latch pins may be sheared. Back off from this point a

maximum of 45 (1/8th of a turn) right hand.

6.0

Retrieve seal assembly by overpull.

Note: An overpull of 15,000 lbf should be satisfactory to retrieve the assembly,

DO NOT exceed 25,000 lbf.

7.0

To remove seal assembly from running tool, replace the installation tool and

adjust bolt to fully compress the lockdown ring. Unscrew seal assembly right

hand.

Page 105 of 110 Rev. 06

SD-018239-01

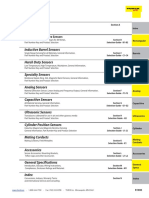

Final A and B-annuli wellhead configuration and connection pressure

testing

Equipment

5 ea.

2-1/165000 psi manual gate valve

Part no. 141521-31-34-01

24 ea.

Stud .875-9UNC x 6.00 LG

Part no. 702533-08-10-60

48 ea.

Nut HVY HEX .875-9UNC

Part no. 2709000-09-10

4 ea.

RX-24 gasket

Part no. 702002-02-42

4 ea.

2-1/16 5000 psi companion flange

Part no. 142362-01-03-02

4 ea.

2.00 LP bull plug

Part no. 2221884-13-01

1 ea.

Valve removal plug 1-1/2"

Part no. 2222164-02-01

6 ea.

1/2" NPT needle valve

Part no. 007482-40

2 ea.

1/2" NPT HEX nipple

Part no. 062224-04-06

2 ea.

1/2 NPT screw end Tee

Part no. 062229-04-06

2 ea.

Pressure gauge 5000 psi

Part no. 007484-40

4 ea.

1/2" NPT HEX HD pipe plug

Part no. 005930-03-10

Install wellhead outlet valves as per JV Gas wellhead configuration drawing

following the next steps:

Note: Prior to commencing the wellhead configuration, check the wellhead

annuli for (trapped) pressure. All annuli should be depressurized.

A-annulus active side:

1.0

Leave the 2 ea. annulus valves on the wellhead, these valves were previously

installed by drilling.

2.0

Remove the 2.00-5K Weco flange and replace by 2-1/16-5K companion flange.

3.0

Make up the companion flange connection with new ring gasket, fit the bull plug,

and wellhead monitoring manifold with pressure gauge.

A-annulus non active side:

4.0

Remove the 2.00-5K Weco flange and remove the outer annulus valve previously

installed by drilling. Leave the inner annulus valve in place.

Page 106 of 110 Rev. 07

SD-018239-01

5.0

Make up the companion flange connection with new ring gasket, fit the bull plug,

and needle valve.

6.0

Open the valve and leave in the open position

B-annulus non active side:

7.0

Remove both the 2 ea. annual valves previously installed by drilling and leave the

wellhead outlet open.

B-annulus active side:

8.0

Leave 2 ea. annulus valves on the wellhead, these valves were previously installed

by drilling.

9.0

Remove the 2.00-5K Weco flange and replace by 2-1/16-5K companion flange.

10.0

Make up the companion flange connection with new ring gasket, fit the bull plug,

and wellhead monitoring manifold with pressure gauge.

Pressure testing the B-annulus end connections active side

11.0

Connect hand pump test hose and fitting to the bleed needle valve of the wellhead

monitoring manifold. Ensure the needle valves of the wellhead monitoring

manifold are in the open position.

12.0

Close the outer annulus valve (back off hand wheel 1/4 turn) and start pumping.

13.0

Pump to the required test pressure as specified by the Customer and bleed

off the pressure.

14.0

Repeat this step a couple of times to bleed trapped air from the valve bore.

15.0

Apply the final pressure as per Customers requirement and holding period.

16.0

After successful pressure testing bleed off the test pressure to zero and open the

outer annulus valve. Leave the outer annulus valve open.

17.0

Disconnect the test pump.

Pressure testing the A-annulus end connections active side

18.0

Connect hand pump test hose and fitting to the bleed needle valve of the wellhead

monitoring manifold. Ensure the needle valves of the wellhead monitoring

manifold are in the open position.

19.0

Close the outer annulus valve (back off hand wheel 1/4 turn) and start pumping.

Page 107 of 110 Rev. 07

SD-018239-01

20.0

Pump to the required test pressure as specified by the Customer and bleed

off the pressure.

21.0

Repeat this step a couple of times to bleed trapped air from the valve bore.

22.0

Apply the final pressure as per Customers requirement and holding period.

23.0

After successful pressure testing bleed off the test pressure to zero and open the

outer annulus valve. Leave the outer annulus valve open.

24.0