Gasket Principles I Course Introduction

Diunggah oleh

Blasko NikiforovDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Gasket Principles I Course Introduction

Diunggah oleh

Blasko NikiforovHak Cipta:

Format Tersedia

GASKET PRINCIPLES I

Course Introduction:

Gaskets, how are they applied? Gaskets are a crucial part of every day life in process

plants, but what do we really know about them? What are Gaskets made of? Where are

they used? What variables effect Gaskets and their ability to seal properly. This course

takes you through a thorough discussion of the Gasket and all of the variables that

surround its reliability.

Course Objective:

Upon completion of this course you will be able to identify Flanges types, describe the

purpose of a Gasket, identify various Bolted Flange Joints, explain Heat Exchanger

Operation, describe the Whole Joint: Flange, Gasket and Bolts, describe proper Gasket

Installation procedures and general troubleshooting remedies for typical faults and

causes.

Course Curriculum Length: 40 hours

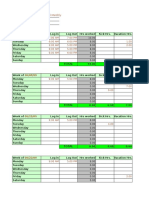

Course Modules & Syllabus

Introduction to Pipes & Flanges

o Pipe

Pipe Differentiation

Pipe

Piping Systems

Pipe Sizes and Schedules

Materials

Steel

Iron

Lined Pipes

FRP (Fiberglass Reinforced Pipe)

Non-ferrous Materials

Plastics

Jointing Methods

Welding

Threading

Brazing and Soldering

Adhesives

Mechanical joints

o Flanges

Flanges

Flange Standards

Flange Dimensions

Connecting the Pipe to the Flange

Integral Flanges

Welded Flanges

Socket Weld Flanges

Slip-on Flanges

Weld Neck Flanges

Lapped Flanges

Flange Facings

Plain Faced or Flat Faced Flange

Male and female / Tongue and Groove Faced

Flanges

Raised Faced Flanges

Ring Joints

Surface Finish

Surface Grooves

Surface Inspection

Surface Scale and Residual Gasket Material

Flange Parallelism

Bolting Assembly

Flange Rotation

Hydrostatic End Thrust

Gasketing

o Gaskets

Gasketing

Sheet Gaskets

o Compressed Fiber Sheets

Compressed Fiber Sheets

Non-asbestos Fibers

Elastomer Binders

Manufacturing Compressed Fiber Sheets

o PTFE Sheet Gaskets

PTFE Sheet Gaskets

o Flexible Graphite Sheet Gaskets

Flexible Graphite Sheet Gaskets

Oxidation of Graphite

o Metallic Gaskets

Spiral Wound Gaskets

Steel Trap Gaskets

o Gasket Test Standards

Gasket Test Standards

Compressibility and Recovery

Creep Relaxation

Sealability

Alternative Gasket Tests

o Selecting the Proper Gasket

Selecting the Proper Gasket

Chemical Compatibility

Temperature

Pressure

Thickness

Plant Specifications

Bolted Flange Joints

o Bolts and Threads

Bolts and Threads

Thread Design

How Bolts Work

Strength of Materials

o Tightening Methods

Tightening Methods

o Friction

Friction

o Nut Factor and Coefficient of Friction

Nut Factor and Coefficient of Friction

o Relaxation of Material

Relaxation of Material

Elastic Interactions

o Tolerances, Component Fit and Condition

Tolerances, Component Fit and Condition

Thread Engagement

o Thermal Expansion and Contraction

Thermal Expansion and Contraction

Other Factors

Heat Exchangers

o Heat Exchangers

Heat Exchangers

Live-loading Heat Exchangers

Thermal Cycling

Vibration

o Heat Exchanger Types

Heat Exchanger Types

Fixed Tubesheet Heat Exchanger

U-tube Heat Exchanger

Split Backing Ring, Floating Head Heat Exchanger

Pull-through Floating Head Heat Exchanger

o Heat Exchanger Classes

Heat Exchanger Classes

o Heat Exchanger Gaskets

Heat Exchanger Gaskets

The Whole Joint: Flange, Gasket & Bolts

o Overview

Overview

o ASME Boiler and Pressure Vessel Code

ASME Boiler and Pressure Code

o Gasket Installation Procedures

Installation Procedures

Disassembly

Assembly

o Gasket Troubleshooting Guide

Gasket Troubleshooting Guide

Anda mungkin juga menyukai

- Bodyweight and Dumbbell ExercisesDokumen79 halamanBodyweight and Dumbbell Exercisessureshr_42Belum ada peringkat

- The Art of Sculpture Welding: From Concept to CreationDari EverandThe Art of Sculpture Welding: From Concept to CreationBelum ada peringkat

- 1 How To Hide Links PDFDokumen6 halaman1 How To Hide Links PDFBlasko NikiforovBelum ada peringkat

- Mechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsDari EverandMechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsBelum ada peringkat

- ESAB - PipelinesDokumen65 halamanESAB - PipelinesLigia114100% (2)

- Pipelines Welding HandbookDokumen64 halamanPipelines Welding HandbookSixto GerardoBelum ada peringkat

- Diy - Popular Woodworking PlansDokumen108 halamanDiy - Popular Woodworking Plansrlfd14183% (6)

- Welding Pipeline HandbookDokumen64 halamanWelding Pipeline HandbookJose Luis Roca Cordova100% (1)

- THE MEDIUM SHAPES THE MESSAGEDokumen56 halamanTHE MEDIUM SHAPES THE MESSAGELudovica MatildeBelum ada peringkat

- Design of Steel-Concrete Composite Structures Using High-Strength MaterialsDari EverandDesign of Steel-Concrete Composite Structures Using High-Strength MaterialsBelum ada peringkat

- PIPING ELEMENTS: PIPES, FITTINGS, FLANGES, GASKETS & VALVESDokumen83 halamanPIPING ELEMENTS: PIPES, FITTINGS, FLANGES, GASKETS & VALVESRajeshSekarBelum ada peringkat

- Make $50 A Day Autopilot MethodDokumen4 halamanMake $50 A Day Autopilot MethodJadon BoytonBelum ada peringkat

- Plastic Pipe Systems: Failure Investigation and DiagnosisDari EverandPlastic Pipe Systems: Failure Investigation and DiagnosisBelum ada peringkat

- Tube To Tube SheetDokumen9 halamanTube To Tube Sheetcmpatel_00100% (2)

- Importance of Welding: QA/QC DepartmentDokumen55 halamanImportance of Welding: QA/QC Departmentimran jamil0% (1)

- Swagelok Flexible Metal Hoses MS-01-180Dokumen88 halamanSwagelok Flexible Metal Hoses MS-01-180paula09Belum ada peringkat

- DT & NDTDokumen46 halamanDT & NDTThulasi RamBelum ada peringkat

- Graphic Standards Field Guide to Residential ConstructionDari EverandGraphic Standards Field Guide to Residential ConstructionBelum ada peringkat

- DT & NDTDokumen46 halamanDT & NDTKumar SahebBelum ada peringkat

- Flange Gasket and Bolts - Piping StudyDokumen7 halamanFlange Gasket and Bolts - Piping Studyshantilal100% (1)

- Which Process?: A Guide to the Selection of Welding and Related ProcessesDari EverandWhich Process?: A Guide to the Selection of Welding and Related ProcessesBelum ada peringkat

- Concrete Pipe vs HDPE Drainage Pipe: A Performance ComparisonDokumen15 halamanConcrete Pipe vs HDPE Drainage Pipe: A Performance Comparisonyyanan1118Belum ada peringkat

- Audit Report of CompaniesDokumen7 halamanAudit Report of CompaniesPontuChowdhuryBelum ada peringkat

- L11 Mechanical FastenersDokumen91 halamanL11 Mechanical FastenersSHADES 4 ALLBelum ada peringkat

- Mechanical Seal Principles Chesterton)Dokumen6 halamanMechanical Seal Principles Chesterton)Joon EeoBelum ada peringkat

- Mechanical Seal Principles Chesterton)Dokumen6 halamanMechanical Seal Principles Chesterton)Joon EeoBelum ada peringkat

- Atomic and Ionic Arrangements Determine Material PropertiesDokumen35 halamanAtomic and Ionic Arrangements Determine Material PropertiesKai NganBelum ada peringkat

- Auditing For Managers - The Ultimate Risk Management ToolDokumen369 halamanAuditing For Managers - The Ultimate Risk Management ToolJason SpringerBelum ada peringkat

- ASTM Reference RadiographsDokumen3 halamanASTM Reference RadiographsAkbar ShaikBelum ada peringkat

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsDari EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsPenilaian: 4 dari 5 bintang4/5 (6)

- NABARD Broiler Farming ProjectDokumen10 halamanNABARD Broiler Farming ProjectGrowel Agrovet Private Limited.Belum ada peringkat

- All-in-One Manual of Industrial Piping Practice and MaintenanceDari EverandAll-in-One Manual of Industrial Piping Practice and MaintenancePenilaian: 5 dari 5 bintang5/5 (1)

- 6 Acop v. OmbudsmanDokumen1 halaman6 Acop v. OmbudsmanChester Santos SoniegaBelum ada peringkat

- Casing and Liners for Drilling and Completion: Design and ApplicationDari EverandCasing and Liners for Drilling and Completion: Design and ApplicationPenilaian: 5 dari 5 bintang5/5 (3)

- ASME CODE Requirements - Heat ExchangerDokumen9 halamanASME CODE Requirements - Heat ExchangerJithin FrancizBelum ada peringkat

- Overview of ThermowellsDokumen14 halamanOverview of ThermowellsShibu ThomasBelum ada peringkat

- Porsche Scheduled Maintenance Plan BrochureDokumen2 halamanPorsche Scheduled Maintenance Plan BrochureDavid LusignanBelum ada peringkat

- GASKETDokumen8 halamanGASKETKun KunBelum ada peringkat

- Exp1 2Dokumen6 halamanExp1 2Alexis Joshua LaceBelum ada peringkat

- Gaskets Basic Training - 1Dokumen20 halamanGaskets Basic Training - 1castillote.robertBelum ada peringkat

- Gasket Documents PDFDokumen66 halamanGasket Documents PDFramnadh803181Belum ada peringkat

- ThesisDokumen48 halamanThesismuhammad amir100% (1)

- Gasket SelectionDokumen66 halamanGasket Selectionresume Fi-1401Belum ada peringkat

- Ensuring pipeline integrity through corrosion prevention and condition monitoringDokumen48 halamanEnsuring pipeline integrity through corrosion prevention and condition monitoringmaian sajaBelum ada peringkat

- Fastening: Manufacturing ProcessesDokumen51 halamanFastening: Manufacturing ProcessesCR MamRe GaringgingBelum ada peringkat

- Pipingsystempresentation 180824164941 PDFDokumen25 halamanPipingsystempresentation 180824164941 PDFAmit SharmaBelum ada peringkat

- MS 01 180Dokumen88 halamanMS 01 180DucVikingBelum ada peringkat

- Sealing GuideDokumen6 halamanSealing GuidemdjeckelBelum ada peringkat

- The Complete Guide to Hot Rolling of SteelDokumen13 halamanThe Complete Guide to Hot Rolling of SteelAndréBelum ada peringkat

- Methods of Salvaging Cast DefectsDokumen6 halamanMethods of Salvaging Cast DefectsDennis SumilaBelum ada peringkat

- Pipe (Material) : Pipe Is A Hollow Cylinder of Material. It Differs FromDokumen5 halamanPipe (Material) : Pipe Is A Hollow Cylinder of Material. It Differs FromSyed Aftab AhmedBelum ada peringkat

- 2 MarksDokumen7 halaman2 MarksloganathanBelum ada peringkat

- Ke Masterhose: Metallic and Rubber Flexible HosesDokumen40 halamanKe Masterhose: Metallic and Rubber Flexible HosesfcspekBelum ada peringkat

- FRP Piping Technical Aspects - Joints Etc.Dokumen15 halamanFRP Piping Technical Aspects - Joints Etc.A_ValsamisBelum ada peringkat

- Parker Push Fitting CatalogueDokumen12 halamanParker Push Fitting CatalogueAndrew McLeodBelum ada peringkat

- Ms 01 180Dokumen88 halamanMs 01 180FabricioBelum ada peringkat

- Manufacturing Technology SyllabusDokumen4 halamanManufacturing Technology Syllabushrana287Belum ada peringkat

- Ultimate Tapping ScrewDokumen2 halamanUltimate Tapping Screwfhscomtech3Belum ada peringkat

- 2023 01 Gasket-HandbookDokumen216 halaman2023 01 Gasket-Handbookrbnotosagoro100% (1)

- 346 Tubing and Hose System Maintenance Course DescriptionDokumen1 halaman346 Tubing and Hose System Maintenance Course DescriptionAnonymous q9eCZHMuSBelum ada peringkat

- FRP Piping SystemDokumen15 halamanFRP Piping Systemindia100% (1)

- Lecture 2Dokumen36 halamanLecture 2Florian Ananias ByarugabaBelum ada peringkat

- Strength of Material - Torsion of Round BarsDokumen7 halamanStrength of Material - Torsion of Round Barsfangyingtee25Belum ada peringkat

- Beyond Standard Our Answer For Your Requirements: Metal Hat Grounding RingDokumen1 halamanBeyond Standard Our Answer For Your Requirements: Metal Hat Grounding RingRakesh Karan SinghBelum ada peringkat

- General TrainingDokumen46 halamanGeneral TrainingChris MedeirosBelum ada peringkat

- PIPE and TubesDokumen11 halamanPIPE and TubesnamBelum ada peringkat

- Small-Scale Poultry Production GuideDokumen120 halamanSmall-Scale Poultry Production GuidebolaaajiiiBelum ada peringkat

- Fast Food Restaurant Business Plan19Dokumen52 halamanFast Food Restaurant Business Plan19Blasko NikiforovBelum ada peringkat

- The Fragmented Warehouse: Location Assignment For Multi-Item PickingDokumen7 halamanThe Fragmented Warehouse: Location Assignment For Multi-Item PickingBlasko NikiforovBelum ada peringkat

- Potential Muscular StrengthDokumen6 halamanPotential Muscular StrengthBlasko NikiforovBelum ada peringkat

- TO DO List ExcelDokumen5 halamanTO DO List ExcelGary PearsBelum ada peringkat

- 03.1BasicMonthly Sick VacationDokumen6 halaman03.1BasicMonthly Sick VacationBlasko NikiforovBelum ada peringkat

- Neuro FactorsDokumen3 halamanNeuro FactorsBlasko NikiforovBelum ada peringkat

- BBS - Translation ITDokumen37 halamanBBS - Translation ITBlasko NikiforovBelum ada peringkat

- The 242 Method by Anthony Mychal PDFDokumen80 halamanThe 242 Method by Anthony Mychal PDFYuldash100% (6)

- Weekly workout schedule with yoga and ab exercisesDokumen2 halamanWeekly workout schedule with yoga and ab exercisesBlasko NikiforovBelum ada peringkat

- MThomas KinesiologyDokumen80 halamanMThomas KinesiologyBlasko NikiforovBelum ada peringkat

- Hazmat Shipping GuideDokumen150 halamanHazmat Shipping GuideZied Hemaier100% (1)

- Learn Anytime with Online Training CoursesDokumen1 halamanLearn Anytime with Online Training CoursesBlasko NikiforovBelum ada peringkat

- 25 Ways To Lower Supply Chain Inventory CostsDokumen8 halaman25 Ways To Lower Supply Chain Inventory CostsAli AhmedBelum ada peringkat

- High Frequency Training Workout Mass1Dokumen28 halamanHigh Frequency Training Workout Mass1Blasko NikiforovBelum ada peringkat

- Advanced Lip Seal For Bearing and Gearbox ProtectionDokumen2 halamanAdvanced Lip Seal For Bearing and Gearbox ProtectionBlasko NikiforovBelum ada peringkat

- Flange Bolt Disc Springs: ChestertonDokumen2 halamanFlange Bolt Disc Springs: ChestertonBlasko NikiforovBelum ada peringkat

- Broiler Inners IMPDokumen14 halamanBroiler Inners IMPAhmadBelum ada peringkat

- Problem Solution - 5 Why's Analysis: ... Here Is Our "Wheel" Life ExampleDokumen10 halamanProblem Solution - 5 Why's Analysis: ... Here Is Our "Wheel" Life ExampleBlasko NikiforovBelum ada peringkat

- Live Load CurriculumDokumen5 halamanLive Load CurriculumBlasko NikiforovBelum ada peringkat

- Hydraulics CurriculumDokumen8 halamanHydraulics CurriculumChris ChrisBelum ada peringkat

- Pub 2897 Broiler PRDokumen8 halamanPub 2897 Broiler PRahmrakBelum ada peringkat

- Reguli Pentru SapunDokumen7 halamanReguli Pentru SapunAnca OrhaBelum ada peringkat

- Uwp PDFDokumen23 halamanUwp PDFBlasko Nikiforov100% (1)

- FINC 301 MQsDokumen40 halamanFINC 301 MQsMichael KutiBelum ada peringkat

- Gustilo Vs Gustilo IIIDokumen1 halamanGustilo Vs Gustilo IIIMoon BeamsBelum ada peringkat

- Brochure of H1 Series Compact InverterDokumen10 halamanBrochure of H1 Series Compact InverterEnzo LizziBelum ada peringkat

- SMG Wireless Gateway ManualV2.2.0Dokumen95 halamanSMG Wireless Gateway ManualV2.2.0shahedctgBelum ada peringkat

- Operations Management For Competitive Advantage 11Th Edition Solutions Manual PDFDokumen2 halamanOperations Management For Competitive Advantage 11Th Edition Solutions Manual PDFLouis DodsonBelum ada peringkat

- Family health assessment nursing problemsDokumen8 halamanFamily health assessment nursing problemsMari MazBelum ada peringkat

- Computer Science Practical File WorkDokumen34 halamanComputer Science Practical File WorkArshdeep SinghBelum ada peringkat

- GeM Bidding 2568310Dokumen9 halamanGeM Bidding 2568310SICURO INDIABelum ada peringkat

- TN1Ue Reference Manual Issue 9.0Dokumen144 halamanTN1Ue Reference Manual Issue 9.0Reinaldo Sciliano juniorBelum ada peringkat

- Nº SSR-1 NS-R-3 Draf R1 Site Evaluation For Nuclear Installations FRDokumen33 halamanNº SSR-1 NS-R-3 Draf R1 Site Evaluation For Nuclear Installations FRdaniel addeBelum ada peringkat

- Unit 4 Probability AssignmentsDokumen8 halamanUnit 4 Probability AssignmentsSumycheen BhusalBelum ada peringkat

- Superelement Modeling-Based Dynamic Analysis of Vehicle Body StructuresDokumen7 halamanSuperelement Modeling-Based Dynamic Analysis of Vehicle Body StructuresDavid C HouserBelum ada peringkat

- Manual Centrifugadora - Jouan B4i - 2Dokumen6 halamanManual Centrifugadora - Jouan B4i - 2Rita RosadoBelum ada peringkat

- Best Practices For SAP-PM History DocumentationDokumen8 halamanBest Practices For SAP-PM History DocumentationLaammeem Noon100% (1)

- Lessee Information StatementDokumen1 halamanLessee Information Statementmja.carilloBelum ada peringkat

- Applied Econometrics ModuleDokumen142 halamanApplied Econometrics ModuleNeway Alem100% (1)

- Eileen MarcelDokumen3 halamanEileen Marcelapi-3825833Belum ada peringkat

- Daftar Pustaka Marketing ResearchDokumen2 halamanDaftar Pustaka Marketing ResearchRiyan SaputraBelum ada peringkat

- Memo in Motion For ContemptDokumen118 halamanMemo in Motion For ContemptMark SternBelum ada peringkat

- GFRDDokumen9 halamanGFRDLalit NagarBelum ada peringkat

- Naoh Storage Tank Design Description:: Calculations For Tank VolumeDokumen6 halamanNaoh Storage Tank Design Description:: Calculations For Tank VolumeMaria Eloisa Angelie ArellanoBelum ada peringkat

- COA (Odoo Egypt)Dokumen8 halamanCOA (Odoo Egypt)menams2010Belum ada peringkat

- Cold Fear manual_englishDokumen10 halamanCold Fear manual_englishHelmi IsmunandarBelum ada peringkat