Heating, Ventilating, and Air Conditioning Load Calculations

Diunggah oleh

Abdalhady JoharjiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Heating, Ventilating, and Air Conditioning Load Calculations

Diunggah oleh

Abdalhady JoharjiHak Cipta:

Format Tersedia

0/36

Heating, Ventilating, and Air Conditioning

MET

Department of Mechanical Engineering Technology

Heating, Ventilating, and Air

Conditioning

N

PA

R T ME

LOGY

HNO

EC

Yanbu Industrial College

I NEER I NG

ENG

T

MECHANIC

AL

MET 412

Heating, Ventilating, and Air Conditioning

MET 412

Heating, Ventilating, and Air Conditioning

1/36

Chapter6

Cooling and Heating Load Calculations

4.1- Introduction

Before the cooling and heating load determination process starts, the customer

has to be contacted effectively in order to define all technical specification and

conditions under which the plant must run. This information then is used to design

the plant. The determination of the cooling load is an early step in the design.

The cooling load will be used in later calculations to determine the selection of the

mechanical refrigeration or AC plant.

Most customers carry out a cooling load calculation to see weather their own

estimate of the load matches with those in the various tenders. Thus it is

important to both customers and contractors to be able to evaluate cooling loads

accurately. If the estimate made is too conservative an excessively large and

expensive plant will result. If the load is underestimated the plant may not perform

to specification.

In this section the technical calculations for cooling load determination will be

described. Most of these follow the traditional approaches available in a number

of textbooks. There are also some update methods not found in textbooks, but

recommended by Professor Donald Cleland (Vice President of the International

Institute of Refrigeration) as being more accurate.

4.2- Cooling/Heating Load Definition

The rate at which heat must be removed from the refrigerated or AC space or

material in order to produce and maintain the desired temperature conditions is

called cooling load, the refrigeration load or the heat load.

4.3- Cooling /Heating Load main Sources

Cooling/heating Load is the summation of the heat, which usually evolves from

several different sources. Some of the more common sources of heat that supply

the load on refrigerating/AC equipment are:

1. Heat that leaks into the refrigerated or AC space from the outside by

conduction through the insulated walls (The Wall Gain Load).

2. Heat that is brought/ taken out into/from the space by warm/cold outside air

entering the space through open doors or through cracks around windows and

doors (Air Infiltration/Interchange/Ventilation Load).

3. Heat that enters the space by direct radiation through glass or other transparent

materials (Effect of Sun Radiation).

4. Heat given off by warm products (The Product Load,).

5. Heat given off by the people occupying the space and by equipment located

inside the space such as lights, electronic equipment (TV, VCR, computers,.),

fork lift, etc. (The Miscellaneous Load)

Heating, Ventilating, and Air Conditioning

MET 412

2/36

4.4- Equipment Running Time

In any refrigeration application using air, frost will accumulate if the evaporator

surface is below 0 oC. Periodic defrosting of the evaporator(s) is necessary to

maintain the heat transfer and air flow performance of the evaporator(s) and fans.

Therefore it is not practical to design the refrigerating system in such a way that

the equipment must operate continuously in order to handle the load in most

cases.

Experience has shown that when defrosting is required, the maximum allowable

running time is usually between 16-20 hrs out of each 24 hours period. Then the

total cooling load should be multiplied by (24hrs/maximum allowable running time

(RT)) in order to find the required system capacity (Qs.c.).

Qs.c .

24 hrs

Total CoolingLoad

RT

If maximum allowable running time=18 hrs, then the cooling load should be

multiplied by 24/18, which in fact increases the required system capacity of 33.3%

so that the selected equipment handle the 24 hrs cooling load in the required 16

hrs of operation time.

4.5- Cooling and Heating Load Calculations

To simplify cooling load calculations, the total cooling load is divided into a number

of individual loads according to the sources of heat supplying the load. The

summation of these individual loads is the total cooling load on the equipment.

4.5.1-The Wall Gain Load

The wall gain load, sometimes called the wall leakage load, is a measure of the

heating flow rate by conduction through the walls of the refrigerated space from

outside to the inside or from inside to outside of AC space in winter. The wall gain

load is common to all refrigeration and AC applications and is ordinarily a

considerable part of the total cooling load. Commercial storage coolers and

residential A/C applications are both example of application wherein the wall gain

load often accounts for the greater portion of the total load. Some exceptions to

this is liquid chilling applications, where the outside area of the chiller is small and

the walls to the chiller are well insulated.

Factors determining the wall gain

The quantity of heat transmitted through the walls of refrigerated space per unit of

time is the function of three factors whose relationship can be expressed in the

following equation.

Q w = A U T

Where

Q w :

the rate of heat transfer in Watts (W).

A:

the outside surface area of the wall (m2).

Heating, Ventilating, and Air Conditioning

MET 412

U:

the overall coefficient of heat transmission in W/m2.K.

T:

the temperature differential across the wall

3/36

The value of U factor depends on the thickness of the wall and on the materials

used in the wall construction.

Determining of U factors

The U factor for any type of wall construction can be calculated and provided for

each of the material used in the wall construction by knowing the thermal

conductivity (k) of the thermal conductance and the heat transfer coefficients of

outside and inside air, ho and hi. The thermal conductivity of most homogenous

materials used in wall construction and heat transfer coefficients can be tabulated

in Tables6.1 and6.2 of Appendix A. For any Cold store insulation material, the

thermal overall heat transfer coefficient is tabulated in Table6.3 of Appendix A.

The overall U factors can be expressed as,

U

1

1

n

Rth 1 x j 1

ho j 1 k j hi

where

ho outside air heat transfer coefficient, W/m2 K, see Table6.2. of Appendix A

hi inside air heat transfer coefficient, W/m2 K , see Table6. 2. of Appendix A

x insulation material thickness, m

Temperature Differential across Cold Storage Walls

The design temperature differential across cold store walls is usually taken as the

difference between the inside and outside design temperatures.

The inside design temperature is that which is to be maintained inside the

refrigerated space and usually depends upon the type of product to be stored and

the length of time the product is to be kept in the space. The recommended

storage temperature for various products is given in Tables6.5 6.8 of Appendix A.

The outside design temperature depends on the location of the cooler.

The differential across ceilings and floors

Ceiling

The design temperature of the ceiling depends on the cooler ceiling location.

When the cooler is located inside a building and there is an adequate clearance

between the top of the cooler and the ceiling of the building to allow free

circulation of air over the top of the cooler, the ceiling is treated the same as an

inside wall. Likewise when the top of the cooler is exposed to the outdoors, the

ceiling of the cooler is treated as an outdoor wall.

Floor

The design floor temperature depends on the floor design configuration. When

the floor of a cooler is laid directly on a slab on the ground, the ground

Heating, Ventilating, and Air Conditioning

MET 412

4/36

temperature under the slab varies only slightly all year round and is always

considerably less than the outdoor design dry bulb temperature for the region in

summer.

When the floor of a freezer is laid directly on a slab on the ground, some provision

should be made to prevent any damage to the floor slab and creation any frozen

water layer on the freezer floor which will be dangers to manpower and the

machine. Preventive measures usually include warm air ducts, electric heating

cables, and pipe coils for the circulation of brine or antifreeze solutions (Glycol).

4.5.2-The Air Infiltration/Interchange Load

Air infiltration/interchange is the term used to describe the replacement of cold air

in refrigerated space by the warm air from the outside. Whilst there usually is

leakage through door seals, some infiltration due to pressure equalized system

and sometimes deliberate infiltration when cool storage ventilation is required,

generally, the bulk of infiltration occurs during door openings.

The door entering the refrigerated space will lose both sensible heat in cooling,

and latent heat which is released on condensation or frosting of some of the water

vapour in the incoming air. Air infiltration is generally a greater problem in cold

and cool stores than in chillers and freezers.

The space heat load gain resulting from air changes in the refrigerated space is

difficult to determine with any real accuracy except in those few cases where a

known quantity of air is introduced into the space for ventilating purposes. When

the mass flow rate of the outside air entering the space is known, the space heat

gain resulting from air infiltration can be determined by applying the following

equation:

Q a ,i = m a (ho hi) x 103 = m a cpa T

Where

Q a ,i

air infiltration load (W)

ho:

enthalpy of outside air (kJ/kg)

hi:

enthalpy of inside air (kJ/kg)

m a :

mass flow rate of air (kg/s)

However, since air quantities are usually given in units of volume rather than in

units of mass, to facilitate calculations the heat gain per liter of outside air entering

the space is listed in Tables6.12A and6.12B of Appendix A for various inside and

outside air conditions. To determine the air infiltration rate in liters per second by

the appropriate enthalpy change factor from Tables6.6A or 6.6b of Appendix A.

Example 6.1

The rate of air infiltration into a refrigerated space is 10 /s. If the inside of the

cooler is maintained at 5 oC and the outside dry bulb temperature and relative

humidity are 30 oC and 60% respectively. Determine the air change load in kW.

Heating, Ventilating, and Air Conditioning

MET 412

5/36

Solution

From Table 6.12A of Appendix A, the enthalpy change factor = 0.061 kJ/liter

Then, the Air infiltration Load =10*0.061 =0.61 kW

Average air Infiltration Rate

The quantity of outside air entering a refrigerated space through door openings in

a 24 hrs periods depends upon the size, and location of the door(s) and upon the

frequency and duration of the door openings. Since the combination effect of all

these factors vanes with the individual installation and is difficult to predict with

accuracy, it is general practice to estimate the air change quantity on the basis of

experience with similar application. Experience has shown that, as a general rule,

the frequency and duration of door openings and , hence the air change quantity,

depends on the inside volume of the cooler and the type of usage. Table 6.11 of

Appendix A lists the approximate infiltration rate s for various cooler sizes. The

values given are for average usage

Example 6.2

A storage cooler has outside dimensions of 6.5m X 6m X 3.45m. The outside

temperature is 30 oC and RH 60%. The inside of the cooler is maintained at 5 oC.

The walls of the cooler are approximately 150mm thick. Calculate the air

infiltration Load.

Solution

Since the walls thickness are 150 mm, the inside dimensions of the cooler are

0.3m less then the outside dimensions, so the inside volume is (4.2 X 5.7 X 3.15)

75.411 m3 say 75 m3. From Table 6.11 of Appendix A, the infiltration rate is 9

l/sec.

Air infiltration Load = Infiltration rate * Enthalpy Change

= 9 * 0.061 = 0.549 kW

Air Interchange load

The instantaneous cooling load due to air interchange

Q ic

n Vs

1

( ho hi ) 10 3 ( W )

24 60 60

vo

Where

n

Number of air changes per 24 hours (see Table 6. 13 of Appendix A)

Vs

Store volume (m3)

vo

Specific volume of fresh air m3/kg (from psychrometric chart at outside

conditions)

ho

Enthalpy at the outdoor conditions, see the psychometric chart

Heating, Ventilating, and Air Conditioning

MET 412

6/36

Enthalpy at the indoor conditions, see the psychometric chart

hi

Ventilation load

1

s

Q v n p

10 -3 ho hi 10 3

vo

Person

(W)

where

np

s

Number of people and

from Table 6. 14 of Appendix A.

Person

4.5.3-Effect of Sun Radiation

Whenever the walls of a refrigerator are so situated that they receive an excessive

amount of heat by radiation, either from the sun or from any hot body, the outside

surface temperature of the wall will usually be considerably above the temperature

of the ambient air. The amount by which the surface temperature exceeds the

surrounding air temperature depends upon the amount of radiant energy striking

the surface and upon the reflectivity of the surface. The energy waves are either

reflected by or absorbed by any opaque material that they strike. Light colored,

smooth surfaces will tend to reflect more and absorb less radiant energy than

dark, rough textured surfaces. Hence, the surface temperature of smooth, light

colored walls will be somewhat lower than that of dark, rough-textured walls under

the same conditions of solar radiation. Since any increase in the outside

temperature will increase the temperature differential across sunlight walls must

be corrected to compensate for the sun effect. Correction factors for sunlight walls

for cold store the temperature difference due to sunlight, Ts , can be calculated

directly from Table 6. 16 A of Appendix A, while for air conditioning can be

calculated as,

Ts

1.15 I

ho

Where is the surface absorption factor, see Table 6. 15 of Appendix A.

I is the sunlight intensity (W/m2), see Table 6. 16 B of Appendix A for air

conditioning.

ho is the heat transfer coefficient (W/ m2 K), see Table 6. 2 of Appendix A.

The Ts values should be added to the normal wall temperature differential.

4.5.4-Windows Load

Conduction load

The heat transfer across the windows glass can be expressed as,

Q g Ag U T

Where

Heating, Ventilating, and Air Conditioning

MET 412

is the window glass area m2.

Ag

is the window glass overall heat transfer coefficient, see Table 6.17

of Appendix A.

T:

7/36

the temperature differential across the window which normally is

equals to the temperature differential across the wall.

Direct sun load

The windows glass direct sun load is

, A Q SC

Q

s g

g

sun

Where

Q sun is the heat gain per unit area ( W/m2), see Table 6. 18 A of Appendix A

SC is the Shading Coefficient, see Table 6. 18 B of Appendix A.

4.5.5-Calculating the product Load

The heat that transfers from a product when it enter a storage space can be

computed by the following equation:

Qp = ( m ) (C ) T

Where Qp

the quantity of heat in kJ per kg.

mass of the product (kg)

the specific heat before freezing kJ/kg K(Can be obtained from

Tables 6.5-6.8 of Appendix A).

the change in the product temperature (K).

Example 6.3

Five ton of fresh beef enter a chilling cooler at 40 oC and chilled to 6 oC each day.

Calculate the product land in kJ.

Solution

From Table 6.7 of Appendix A the specific heat (C) of beef above (before) freezing

is 3.14 kJ/kg K.

Then

Qp

= 5000 X 3.14 X (40-6) = 533,800 kJ

As we can see from the above equation has no time element. Since time is

always considered in determining the cooling rate, then the above equation can be

written as follows:

Q p

m C T

desired cooling time in sec onds

Then if we assumed the beef described in above example is chilled in 20 hrs.

Heating, Ventilating, and Air Conditioning

MET 412

8/36

Q p = [5000 X 3.14 X (40-6)] /(20 X 3600) = 7.414 kW

Chilling Rate Factor

During the early part of the chilling period, the product load on the equipment is

considerably greater than the average hourly product load. Because of the high

temperature difference which exists between the product and the space air at the

start of the chilling period, the chilling rate is higher and the product load tends to

concentrate in the early part of the chilling period. Therefore, where the

equipment selection is based on the assumption that the product load is evenly

distributed over the entire chilling period, the equipment selected will usually have

insufficient capacity to carry the load during the initial stages of chilling when the

product load is at a peak. Consequently, a significant rise in the space

temperature can be expected during the early part of the chilling period.

When such a rise is undesirable, a chilling rate factor is sometimes introduced into

the chilling load calculation to compensate for the uneven distribution of the

chilling load.

The effect of the chilling rate factor is to increase the product load calculation by

an amount sufficient to make the average hourly cooling rate approximately equal

to the hourly load at the peak condition. This results in the selection of larger

equipment. Then the products cooling rate can be expressed as follows:

Chilling rate factors for various products are listed in Tables 6.5 through 6.8 of

Appendix A.

Q p

m C T

(desired cooling time in sec onds) (Chilling rate factor )

Example 6.4

Recalculated the product load described in the previous example employing the

appropriate chilling rate factor.

Solution

From Table 6. 7 of Appendix A, the chilling rate factor for beef is 0.67. The

Product load

Q p = [5000 X 3.14 X (40-6)] /(20 X 3600 X 0.67) = 11.065 kW

Product Freezing and Storage

When a product is to be frozen and stored at some temperature below its freezing

temperature, the heat involved is calculated in three parts:

1. The quantity of heat given off by the product in cooling from the entering

temperature to it freezing temperature.

2. The quantity of heat given off by the product in cooling from its freezing

temperature to its final storage temperature

9/36

Heating, Ventilating, and Air Conditioning

MET 412

3. The quantity of heat given off by the product in solidifying or freezing or

freezing.

The method of determining the quantity of heat resulting from temperature

reduction (parts 1 and 2) has already been established. The quantity of heat

resulting from freezing (part 3) can be calculated from the following equation:

Qf = ( m ) ( h )

Where

Qf

the quantity of heat given off by product solidification or freezing kJ /kg.

mass of the product (kg)

h the product latent heat in kJ/kg.

The latent heat for various products are listed in Tables 6.5 through 6.8 of

Appendix A.

Example 6.5

Five thousand kilograms of poultry enter a chiller at 5 oC and are frozen and

chilled to a final temperature of 15 oC for storage in 12 h. Determine the product

load.

Solution

From Table 6. 7 of Appendix A

Specific heat above (before) freezing = 3.18 kJ/kg.K

Specific heat below (after) freezing = 1.55 kJ/kg.K

Latent heat = 246 kJ/kg

Freezing temperature = -2.75 oC

Chilling rate factor =1

1.

To cool poultry from entering temperature to freezing

temperature, applying

Qp,1 = ( m ) (C ) T

= (5000)(3.18)[5-(-2.75)] = 123225 kJ

2.

To freeze, applying

Qf = ( m ) (hl)

= (5000)(246) = 1230000 kJ

3.

To cool from

temperature, applying

freezing

temperature

Qp,2 = ( m ) (C ) T

= (5000)(3.18)[-2.75-(-15)] = 194775 kJ

to

final

storage

Heating, Ventilating, and Air Conditioning

MET 412

10/36

The total heat given up by product is equal to the summation of 1,2, and 3)

Qp,t= Qp,1 + Qf + Qp,2 = 123225+1230000+194775 = 1548000 kJ

The equivalent product load

QP ,t

(desired cooling time in seconds) (Chilling rate factor)

1548000

35.833 kW

12 * 3600

Respiration Heat

Fruit and vegetables are still alive after harvesting and continue to undergo

changes while in storage. The heat released is called respiration heat must be

considered as part of the product load where considerable quantities of fruit and

/or vegetables are held in storage.

Respiration heat for various fruits and vegetables is listed in Tables 6.9 and 6.10

of Appendix A.

Note

Since respiration rate is given in Watt per kg, the product load accruing from

respiration heat is found by the following equation:

Qp,r= Mass of product (kg) x Respiration rate(W/kg)

Packing Heat Load

Many product are chilled or frozen in packages. The packaging can often be 10%

or more of the direct product weight. As well as removing heat from the product

the refrigeration system must also remove the heat from the packaging. Most

packaging materials (cardboard, plastics, metals, wood) have very low moisture

so change of phase is unlikely to occur and the same calculations can be used to

estimate the packaging heat load for both chilling and freezing:

Q pk

m pk c pk T

desired cooling time in seconds

Where Q pk : Packing load (W)

mpk: Mass of packaging (kg)

cpk: Specific heat capacity of packaging kJ/kg.k

Typical heat capacities for typical packaging materials see Table 6.19 of Appendix

A.

8.5.6- Miscellaneous Heat Loads

The miscellaneous load consists primarily of heat given by light, people, and

equipment

a-Light

Q = Nl w x used time/24

Heating, Ventilating, and Air Conditioning

MET 412

11/36

Where Q : Heat load due to light (W)

Nl:

Number of light

w: Wattage of each light (W)

b- People

Q pe = t Npe x Percent of present time (i.e 8/24)

Where t is the total human heat (sensible + Latent), see Tables 6.20 and 6.21

of Appendix A

Q pe : Heat load due to people (W)

Npe: Number of people

c- Mechanical devices

Q md = Z Nm m x used time/24

Where Nm: Number of motors of equal rating

m Nominal motor rating (W)

Z

Motor rating correction factors which is often about 0.9.

The total miscellaneous load is equal to the summation Q pe + Q pe + Q md

4.5.7- Defrost heat Load

There are two load-related effects of defrost-extra heat added to the refrigerated

space that is not removed with the melt water, and the loss of refrigeration effect

while a coil is being defrosted.

The amount of heat required to melt the frost can be directly related to the latent

heat load component if a typical melt temperature of about 5 oC is assumed. The

average heat load to defrost can be calculated using:

1 d

Q d 0.13 Qlat (

)

Where Q d

Average heat load due to defrost (W)

Q lat Total average latent heat component (W)

d Defrost efficiency. It is suggested that defrosting efficiencies of 20%

for hot gas and 30% for water

4.5.8-Fan heat load

Fan energy is a major source of energy input for refrigerated facilities using air as

the cooling medium. For facilities using liquids or refrigerants as the cooling

medium pumps are the equivalent sources.

The best estimate of fan energy use is given by

Heating, Ventilating, and Air Conditioning

MET 412

12/36

V P

Q fan

Nf

where

Q fan fan heat load (W)

V

Volumetric flow rate (m3/s)

P Pressure drop in facility or pressure boost by fan (Pa)

f

Combined fan and fan motor efficiency

Number of fans of equal ratings

4.6-Short Method Load Calculations

The cooling load can be determined by using the procedures se forth in the

preceding sections. However, when coolers are used for general-purpose

storage, the product load is frequently unknown and/ or varies somewhat from day

to day so that it is not possible to compute the product load with any real accuracy.

In such cases, a short method load calculation can be employed which involves

the use of load factors (Table 6. 22 of Appendix A) which have been determined

by experience. When the short method of calculation is employed, the entire

cooling load is divided into two parts.(1) the wall gain load and (2) the usage or

service load.

The wall gain load is calculated as outlined in previous section. The usage load is

computed by the following equation.

Usage Load (W) = Interior Volume (m3) x usage factor x T

4.7- Safety Factor

The total cooling load is the summation of the heat gains as calculated in the

foregoing sections. It is a common practice to add (5%-15%) to this value as a

safety factor. As a general rule 10% is used.

Home Work

1- Each day a chiller cools 16 tonne batch of cheese blocks (C=3.25 kJ/kg K)

from 25 C to 7 C. Calculate the chilling load.

MET 412

Heating, Ventilating, and Air Conditioning

13/36

2-Each day 24 tonne of peas at 12oC are loaded into a cold store 18oC. The

frozen specific capacity is 2.1 kJ/kg. K . What is the product cooling load.

3- A cold store operating at 20 C has 8 fans with an overall efficiency of 60%.

Each fan produces 10,000 cfm against a combined room and evaporator coil

pressure drop of 2 inches water gauge. What is the annual cost of operating

the fans with a unit cost of SAR0.08/kW h and a peak charge of SAR 120

/kVA/quarter? Take power factor to be 0.93.

Heating, Ventilating, and Air Conditioning

MET 412

14/36

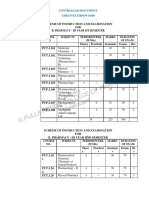

Assignment # 1.

A cold store , 15m, 10m and 5.5m (L,W and H), maintained at 85% RH and 18oC

and designed to cool 200 units of mass 40 kg of Beeffresh, Average from 23 oC

to 18. The allotted and freezing hours are 8 hrs and 12 hrs respectively. There

are 20 lights with 150 W each and 4 forklifts used by 5 occupants for 8 hours. The

average heat gain of forklifts is 500 W and there are 6 evaporator fans inside the

cold store.. Outside air conditions are 30 oC , and 65% RH. The store walls and

roof are fabricated from 20cm thick expanded polystyrene (smooth).

Calculate the required system capacity if the equipment running time is 22hrs,

12% S.F. and 5 oC solar radiation allowance.

Results

Roof

Floor

Walls

Glass

Solar

Lights

People

Appliances

Product: Above freezing

Product: Below freezing

Packing Load

Freezing Load

Air Infiltration

Air Interchange

Ventilation

Heat Load (W)

Safety Factor (W)

Total heat Gain (W)

Required Equipment Capacity (W)

Tons of Refrigeration

MET 412

Heating, Ventilating, and Air Conditioning

15/36

Solved Examples

Example 6.6

A holding cooler 6m x 10m x 5m high is used for the short-term storage of fresh

beef -Average. Thirty thousand kilograms of beef enter the cooler at 10 oC and

are cooled to the storage temperature of 2.5 oC each day. All the walls are

partitions adjacent to unconditioned spaces (35 oC and 60 %) except the east wall

(6m x 5m) which is adjacent to a chilling room maintained at the same inside

design temperature. Wall construction is 100mm cinder block insulated with 100

mm corkboard equivalent. The floor, located over an unconditioned space, is a

125 mm concrete slab insulated with 100mm corkboard equivalent and finished

with 75 mm of concrete. The ceiling, situated under an unconditioned space, is a

100mm concrete slab with wood sleepers and insulated with equivalent of 100mm

of corkboard. Three people work in the space during the loading periods (5 hrs),

usage is average , the lighting load is 500 W and lights are in use 5h/day.

Determine the required equipment capacity based on a 22 hours operating time

and 10 % safety factor.

Solution

MET 412

Heating, Ventilating, and Air Conditioning

16/36

Example 6.7

Four thousand and five hundred lug boxes of apples are stored at 2.5 oC in a

storage cooler 15 m x 12 m x 6 m high. The apples enter the cooler at a

temperature of 30 oC and at the rate of 250 lugs per days each day for the 18 day

harvesting period. The walls including floor and ceiling are constructed of 25 mm

boards on both sides of 50 mm x 100mm studs and are insulated with 100mm of

mineral wool. All of the walls are shaded and the ambient conditions are 35 oC

and RH 50%.The average weight of apples per lug box is 25 kg. The lug boxes

have an average weight of 2 kg and a specific heat value of 2.3 kJ/kg.K. The

lighting load is 500 W for 6 hrs per day. Two people and one battery operated

forklift (4.17 kW) are in the space for 4 hrs per day. Determine the average load in

kilowatts on the equipment based on a 16 hrs per day equipment operating time.

(Assume the insulation k factor (0.045 W/m K and S.F. 10%).

Solution

MET 412

Heating, Ventilating, and Air Conditioning

17/36

Example 6.8

Twenty three thousand liters of partially frozen ice cream at 4oC are entering a

hardening room 9 m x 6 m x 5 m high each day. Hardening is completed and the

temperature of the ice cream is lowered to -28 oC in 10 hrs. The walls, including

floor and ceiling, are insulated with 150mm of polyurethane and the overall

thickness of the walls is 250mm. The ambient temperature is 35 oC and the RH is

50%. The lighting load is 500 W for 6 hrs per day. Two people and one battery

operated forklift (4.5 kW) are in the space for 6 hrs per day Assume the average

density of the ice cream is 0.6 kg/L, the average specific heat below freezing is 2.1

kJ/kg K, and the average latent heat per kg is 233 kJ. Determine the average

hourly load based on 18 hrs.

Solution

Heating, Ventilating, and Air Conditioning

MET 412

18/36

Assignment # 2.

Three thousand kilograms of dressed poultry are blast- frozen on hand trucks

each day (24 h) in a freezing tunnel 4 m x 3m x 3.5 m high. The poultry is

precooled to 7 oC before entering the freezer where it is frozen and its temperature

lowered to -20 oC and 90% RH for storage. The lighting load is 200 watts and the

lights are on 16 hrs per day. The north and east partitions adjacent to the

equipment room and vestibule are constructed of 150 mm clay tile insulated with

150mm polyurethane. The south and west partitions adjacent to storage cooler

are 100 mm clay tile with 50mm polyurethane insulation. The roof is a 150 mm

concrete slab insulated with 150 mm polyurethane and covered with tar, felt, and

gravel. The floor is a 150mm concrete slab insulated with 150mm polyurethane

and insulated with 100 mm of concrete. The floor is over a ventilated crawl space.

Roof is exposed to the sun. The equipment room is well ventilated so that the

temperature inside is approximately the outdoor design temperature for the region

(33oC and 60% RH). The inside design temperature for both the storage room

and the freezer is 20 oC. The vestibule temperature and relative humidity are 10

o

C and 70 %, respectively. Determine the average hourly refrigeration load based

on 20 hrs per day operating time for the equipment and S.F. 10%.

Results

Roof

Floor

Walls

Glass

Solar

Lights

People

Appliances

Product: Above freezing

Product: Below freezing

Packing Load

Freezing Load

Air Infiltration

Air Interchange

Ventilation

Heat Load (W)

Safety Factor (W)

Total heat Gain (W)

Required Equipment Capacity (W)

Tons of Refrigeration

MET 412

Heating, Ventilating, and Air Conditioning

Appendix A

Cooling and Heating Load Calculations Tables

19/36

MET 412

Heating, Ventilating, and Air Conditioning

Table (6.1) Thermal conductivity of materials (W/m K)

Material

Aluminum

Asphalt

Asbestos

Corkboards

Polyurethane

Polystyrene

Soil

Gypsum

Concrete

Soft wood

Hard wood

Sand

Arch. Glass

Heat resisting glass

Steel

Glass wool

Paint

Common brick

Face brick

Cotton

Cement Plaster

Air

k

220.00

1.15

0.16

0.043

0.025

0.043

1.10

0.46

1.28

0.012

0.16

0.30

0.78

1.10

46.50

0.04

0.72

0.72

1.32

0.07

0.72

0.03

20/36

21/36

Heating, Ventilating, and Air Conditioning

MET 412

Table (6.2) Heat transfer coefficient (W/m2 K)

Surface type

A-Still air

Horizantal

Horizantal

Vertical

Heat direction

Up

Down

Horizantal

9.37

6

8

Any direction

Any direction

34.1

22.7

B-Moving Air

6.7 m/s (24 km/h)

3.35 m/s (12 km/h)

Table (6.3) Coefficients of heat transfer (U factor) of typical cold storage walls,

roofs and factors (W/m2 K)

Insulation thermal conductivity, k, (W/ m K)

Insulation

thickness

0.025

0.030

0.035

0.040

0.045

0.050

0.055

0.060

25

0.732

0.834

0.931

1.013

1.091

1.163

1.229

1.289

50

0.420

0.489

0.556

0.617

0.675

0.731

0.784

0.834

75

0.295

0.346

0.397

0.443

0.489

0.533

0.576

0.617

100

0.227

0.267

0.308

0.346

0.383

0.420

0.455

0.489

125

0.182

0.218

0.252

0.283

0.315

0.346

0.376

0.405

150

0.153

0.184

0.213

0.240

0.267

0.294

0.320

0.346

175

0.136

0.159

0.185

0.208

0.232

0.256

0.279

0.302

200

0.119

0.140

0.163

0.184

0.206

0.227

0.247

0.267

(mm)

Table (6.4) Design temperatures of major cities in KSA

o

City

Dry bulb temp C

Wet bulb temp C.

Jeddah

Riyadh

Dhahran

41

43.5

44.0

29.5

25.5

29.5

22/36

Heating, Ventilating, and Air Conditioning

MET 412

Table (6.5) Storage requirements of perishable products

Product

Storage temp

oC

RH

Specific Heat

kJ/kg K

Above

Below

freezing

freezing

Latent

heat

kJ/kg

Approx.

Freezing

temp.

oC

Approx.

Storage

life

Water

Content

%

Chilling

rate

factor

Fruits and Melons

Apples

Apricots

Avocados - Green

Bananas

Blackberries

Blueberries

Cantetoupe(Rock

Melon)

Casaba Melons

Cherries

Coconuts

Cranberries

Currents

Dates- Cured

Dew Berries

Figs- Dried

- Fresh

Frozen Fruits

Gooseberries

Grapefruit

Grapes

Honeydew Melons

Lemons

Limes

Mangoes

Mectarines

Olives - Fresh

Oranges

0range Juice

Papaw

Peaches

Pears

Persian Melons

Persimmons

Pineapples

Plums

Pomegranates

Prunes - Fresh

- Dried

Quinces

Raspberries

Strawberries

Tangerines

Watermelons

-1 to 4

0

7 to 10

0

0

90 to 95

90 to 95

85 to 90

85 to 95

90 to 100

90 to 100

3.65

3.68

3.01

3.35

3.68

3.58

1.89

1.90

1.65

1.78

1.90

1.86

280

284

217

250

284

274

-1.1

-1.1

-0.3

-0.8

-0.8

-1.6

3 to 8 m

1 to 2 w

2 to 4 w

2 to 3 d

2w

84

88

65

78

88

82

0.67

0.67

0.67

0.1

2 to 4

90

3.92

1.99

307

-1.2

5 to 15 d

92

0.9

7 to 10

-1 to 0

0 to 2

2 to 4

-0.5 to 0

-18 or 0

0

0 to 4

-1 to 0

-23 to -18

0

14 to 16

-1 to 0

7 to 10

15 to 18

9 to 10

13

0

7 to 10

5

-1 to 2

13

0

-1.6 to 0

7 to 10

-1

20

-0.5 to 0

0

-1 to 0

0 to 4

-1 to 0

0

0

0

5 to 10

85 to 95

95

80 to 85

90 to 95

90 to 95

75 or less

90 to 95

50 to 60

85 to 90

90 to 95

90 to 95

85 to 90

95 to 100

90

85 to 90

85 to 90

85 to 90

90

85 to 90

85 to 90

3.95

2.41

3.51

3.75

3.68

1.5

3.68

1.61

3.45

3.82

3.82

3.58

3.95

3.82

3.72

3.55

3.58

3.35

3.75

3.82

3.88

3.82

3.61

3.95

3.45

3.68

3.72

3.58

3.72

1.77

3.68

3.55

3.85

3.75

3.95

2

1.84

1.43

1.93

1.90

1.09

1.90

1.12

1.81

1.95

1.95

1.86

2

1.95

1.92

1.85

1.86

1.78

1.93

1.95

1.98

1.95

1.88

2

1.81

1.9

1.92

1.86

1.92

1.19

1.9

1.85

1.97

1.93

2

310

267

157

290

284

67

284

77

260

297

297

274

310

297

287

270

274

250

290

297

304

297

277

310

260

284

287

274

287

284

270

300

290

310

-1.1

-1.8

-0.9

-0.9

-1

-16

-1.3

4 to 6 w

2 to 3 w

1 to 2 m

2 to 4 m

10 to 14 d

6-12 m

3d

9 to 12 m

7 to 10 d

6 to 12 m

1 to 2 w

4 to 6 w

3 to 6 m

3 to 4 w

1-6 m

6 to 8 w

2w

1 to 2 w

4 to 6 w

3 to 12 w

3 to 6 w

1 to 3 w

2 to 3 w

2 to 6 w

2w

3 to 4 m

1 to 4 w

1 to 4 w

2 to 4 m

2 to 4 m

5 to 8 m

2 to 3 m

2 to 3 d

5 to 7 d

2 to 4 w

2 to 3 w

93

80

47

87

85

20

88

23

78

89

89

82

93

89

86

81

82

75

87

89

91

89

83

93

78

85

86

82

86

28

88

81

90

87

93

0.9

90

90 to 95

90 to 95

90 to 95

90

85 to 90

90 to 95

90

90 to 95

55 to 60

90

90 to 100

90 to 100

90 to 95

85 to 90

-2.4

-1.1

-1.1

-2

-0.9

-1.4

-1.6

-0.9

-0.9

-1.4

-0.8

-0.8

-0.9

-1.6

-0.8

-2.2

-1

-0.8

-3

0.8

-2

-1.1

-0.8

-1.1

-0.4

0.67

0.8

1.0

0.9

0.7

0.80

0.80

0.9

0.67

0.67

23/36

Heating, Ventilating, and Air Conditioning

MET 412

Table (6.6) Storage requirements of perishable products

Product

Storage

temp oC

RH

Specific Heat

kJ/kg K

Above

Below

freezing

freezing

Latent

heat

kJ/kg

Approx.

Freezing

temp.

oC

Approx.

Storage

life

Water

Content

%

2w

5m

2 to 3 w

7 to 10 d

1 to 2 w

3 to 5 m

10 to 14 m

3 to 5 w

1 to 4 m

4 to 6 m

4 to 5 m

2-4 w

1-2 m

4-8 d

10 to 14 d

7d

2 to 3 w

6 to 12 m

6 to 7 m

10 to 12 m

3 to 4 w

2 to 4 w

1-3 m

2 to 3 w

3 to 4 d

1 to 8 m

1 to 2 m

2 to 6 m

1 to 2 w

6 to 8 m

2 to 3 w

6m

88

80

93

89

Chilling

rate

factor

Vegetables

Artichokes -Globe

-Jerusalem

Asparagus

Beans - Green

Beetroot-Bunch

-Topped

Broccoli

Brussels Sprouts

Cabbage

Carrots-Topped, Immature

- Topped, Mature

Cauliflower

Celery

Corn - Sweet

Cucumbers

Eggplant

Endive (Escarole)

Frozen Vegetables

Garlic-Dry

Horseradish

Kale

Kohlrabi

Leeks - Green

Lettuce - Head

Mushrooms

Onions-Dry

Parsley

Parsnips

Peas - Green

- Dried

Peppers - Sweet

- Dry, Chili

Potatoes - Culinary

- Sweet

Pumpkins

Radishes -Topped

Rhubarb

Rutabaga

Silver beet (Spinach)

Squash - Button

- Hard Shell

Tomatoes - Firm, Ripe

- Mature, Green

Turnips

Yams

0

0

0 to 2

7 to 10

0

0

0

0

0

0

0

0

0

0

10

7 to 10

0

-23 t0 -18

0

0

0

0

0

0

0

0

0

0

0

10

7 to 13

0 to 10

7

13 to 16

13

0

0

0

0

7

13

5 to 7

13

0

16

95 to 100

90 to95

95 to 100

95 to 100

95 to 100

95 to 100

95 to 100

95 to 100

98 to 100

98 to 100

98 to 100

95 to 100

95 to 100

95 to 98

95 to 100

90 to 95

90 to 100

3.65

3.47

3.95

3.82

1.89

84

2

1.95

280

267

310

297

3.78

3.85

3.68

3.92

3.78

3.78

3.92

3.98

3.31

4.05

3.95

3.95

1.94

1.97

1.90

1.99

1.94

1.94

1.99

2.02

1.76

2.04

2.0

2

294

300

284

307

294

294

307

314

247

320

310

310

-1.2

-2.5

-0.6

-0.7

-0.4

-0.9

-0.6

-0.8

-0.9

-1.4

-1.4

-0.8

-0.5

-0.6

-0.5

-0.8

-0.1

65 to 70

95 to 100

95

90 to 100

95

95 to 100

95

65 to 70

95 to 100

98 to 100

95 to 98

70

90 to 95

60 to 70

90 to 95

85 to 90

85 to 90

90 to 95

95

90 to 95

95 to 98

95 to 100

85 to 90

90 to 95

90 to 95

95

85 to 90

2.88

3.35

3.75

3.85

3.68

4.02

3.88

3.78

3.68

3.48

3.31

1.24

3.92

1.24

3.45

3.15

3.88

4.02

4.02

3.82

3.95

3.98

3.68

3.98

3.95

3.92

3.31

1.6

1.78

1.93

1.97

1.90

2.03

1.98

1.94

1.90

1.83

1.76

0.99

1.99

0.99

1.81

1.7

1.98

2.03

2.03

1.95

2

2.02

1.9

2.02

2

1.99

1.76

203

250

290

300

284

317

304

294

284

264

247

-0.8

-1.8

-0.5

-1

-0.7

-0.2

-0.9

-0.8

-1.1

-0.9

-0.6

307

-0.7

260

230

304

317

317

297

310

314

284

313

310

307

247

-0.7

-1.3

-0.8

-0.7

-0.9

-1.1

-0.3

-0.5

-0.8

-0.5

-0.6

-1.1

4 to 6 m

2 to 3 m

3 to 4 w

2 to 4 w

2 to 4 m

1 to 2 w

1 to 3 w

1 to 3 m

4-7 d

1 to 2 w

4 to 5 m

3 to 6 m

88

90

85

92

88

88

92

94

74

96

93

93

61

75

87

90

85

95

91

88

85

79

74

12

92

12

78

69

91

95

95

89

93

94

85

94

93

92

74

0.9

0.80

0.80

0.80

1

0.70

0.7

0.30

0.67

0.67

0.70

0.80

0.67

24/36

Heating, Ventilating, and Air Conditioning

MET 412

Table (6.7) Storage requirements of perishable products

Product

Storage

temp oC

RH

Specific Heat

kJ/kg K

Above

Below

freezing

freezing

Latent

heat

kJ/kg

Approx.

Freezing

temp.

oC

Approx.

Storage

life

Water

Content

%

Chilling

rate

factor

1 to 6 w

62 to 77

0.67

5d

1 to 7 d

6 to 12 m

70

66

0.56

0.56

5 to 12 d

60 to 70

0.75

Meat-Fish -Shellfish

206 to

257

233

220

-2.2 to 2.7

-1.7

1.6 to 1.7

200 to

233

-2.2 to 1.7

3.31

1.76

247

-2.8

3.11

2.91 to

1.85

1.69

1.61 to

1.85

227

207 to

270

Beef - Fresh, average

0 to 1

88 to 92

2.9 to 3.4

1.6 to 1.8

-Liver

- Veal

- Frozen

0

0 to 1

-23 to -18

90

90

90 to 95

3.18

3.05

1.71

1.66

Lamb- Fresh , average

0 to 1

85 to 90

2.8 to 3.2

-Frozen

Poultry- Fresh, average

- Frozen

Rabbits -Fresh

-23 to -18

-2 to 0

-23 to -18

0 to 1

90 to 95

85 to 90

90 to 95

90 to 95

Fish Fresh, average

-1 to 1

95 to 100

- Frozen

Scallops-Meat

Shrimp

Oysters, Clams-Meat and

Liquid

Oysters In shell

Shellfish - Frozen

-29 to -18

0 to 1

-1 to 1

90 to 95

95 to 100

95 to 100

3.51

3.38

1.84

1.79

0 to 2

100

3.75

5 to 10

-29 to -18

95 to 100

90 to 95

3.51

8 to 12 m

1w

8 to 12 m

1 to 5 d

74

68

-2.2

5 to 14 d

62 to 81

267

254

-2.2

-2.2

6 to 12 m

12 d

12 to 14 d

80

76

1.93

290

-2.2

5 to 8 d

87

1.84

267

-2.8

5d

3 to 8 m

80

25/36

Heating, Ventilating, and Air Conditioning

MET 412

Table (6.8) Storage requirements of perishable products

Product

Storage

temp oC

RH

Specific Heat

kJ/kg K

Above

Below

freezing

freezing

Approx.

Freezing

temp.

oC

Approx.

Storage

life

Water

Content

%

106 to

123

-2.2

3 to 6 m

32 to 37

-20 to

0.6

3 to 13 w

16

-13

-13

12 m

12 m

6m

6 to 12 m

37

37

1

2 to 4 m

10 to 15

5 to 6 m

2 to 3 w

1y+

Several

years

1y+

Several

months

66

66

74

8 to 12 m

3 to 6

1y+

4 to 6 w

16

10

Latent

heat

kJ/kg

Chilling

rate

factor

Miscellaneous

Bread - Frozen

- 18

1.99

Butter

0 to 4

75 to 85

Butter - Frozen

Cheese -Cheddar

-Cheddar

Chocolate Milk

-23

0 to 1

4.4

-18 to 1

70 to 85

65

65

40

Coffee -Green

2 to 3

80 to 85

Eggs - Whole

- Whole

-Frozen, Whole

-2 to 0

10 to 13

-18 or less

80 to 85

70 to 75

Furs and Fabrics

1 to 4

45 to 55

Honey

Below 10

Hops

-2 to 0

1.27

1.37

1.04

53

2.07

2.07

0.87

1.17 to

1.34

3.05

3.05

3.31

1.3

1.3

0.85

0.96 to

1.03

1.66

1.66

1.76

123

123

3.3

33 to

50

220

220

247

1.4

1.05

57

3.75

0.94 to

1.04

1.37

1.17

1.93

0.88 to

0.91

1.04

0.96

290

10 to

20

53

33

-2.2

-2.2

50 to 60

Milk-Whole, Pasteurized

0 to 1

Nuts

0 to 10

65 to 75

Oleomargarine

Popcorn- Unpopped

2

0 to 4

60 to 70

85

-0.6

0.85

14

87

0.85

26/36

Heating, Ventilating, and Air Conditioning

MET 412

Table (6.9) Heat of Respiration: Watt/Tonne

Product

Apples

Apricots

AvocadosGreen

Blackberries

Blueberries

Cantaloupe

(Rock Melon)

Cherries Sweet

Cranberries

Figs Fresh

Gooseberries

Grapefruit

Grapes

Honeydew

Melons

Lemons

Limes

Mangoes

Olives- Fresh

Oranges

Papaw

Peaches

Pears

Persimmons

Pineapples

Plums

Raspberries

Strawberries

Watermelons

Storage temperature oC

5

10

15

Fruits and Melons

20

31-20

35-27

11-56

18-80

61-102

88-58

88-388

81-80

388-281

360-415

358-915

88-136

98-36

86

905-432

303-183

388-582

154-259

26-30

300-114

132-192

32-16

98-42

88-133

83-195

68-68

20-26

39-14

11-39

16-40

8-6

8-16

98

6-10

36 -17

88-68

8-31

8-17

5-13

12-19

8-15

6-9

52-74

36-52

30-19

33-16

35-27

38-39

38

4-6

39-27

59-114

85-98

91-59

98-34

89-165

386-281

99

386-188

68-56

18

96-31

33-54

169-282

52

18-88

59-71

88

38-13

311

68-116

18-60

80-60

58-396

86-388

18-42

18-50

18-37

103-301

933-274

67

20-55

223-449

114-145

60-90

176-304

101-231

59-71

65-105

53-77

340-727

303-581

51-74

27/36

Heating, Ventilating, and Air Conditioning

MET 412

Table (6.10) Heat of Respiration: Watt/ Tonne

Product

Artichokes-Globe

Asparagus

Beans - Green

Beetroot - Topped

Broccoli

Brussels Sprouts

Cabbage - White

Carrots - Topped

Cauliflower

Celery

Corn - Sweet

Cucumbers

Garlic - Dry

Horseradish

Kohlrabi

Leeks - Green

Lettuce - Head

Mushrooms

Onions-Dry

Parsley

Parsnips

Peas - Green

Peppers - Sweet

Potatoes- Immature

- Mature

Radishes- Topped

Rhubarb-Topped

Rutabaga

Silver beet (Spinach)

Tomatoes - Colored and

Ripe

- Mature, Green

Turnips- Roots

0

68-133

83-238

Storage temperature oC

5

10

15

Vegetables

36-21

88 -68

86-71

38-40

86

81

90

396

58-178

369-404

303-104

98-28

309- 888

56-144

99- 64

88

63

10

910

5 -19

98

10

98-85

98-50

81-130

5

58-137

18-46

50-139

38-29

19

85

88-86

80 -59

930

30

356-252

96-52

361 -227

36-18

24-39

6-8

96

18

38-20

91-24

11-54

38-15

316

369-292

138-904

369-173

18-40

388-251

16-98

51

300

119

68-86

98-29

88

51

385-202

83-119

93

185-487

63-78

81

89-62

90-30

88

198

995-430

889-971

989-276

80-69

838-1008

981-317

88-170

338

318

300

881

83-98

11-81

58

386

988-347

338-121

11

898-662

56-127

810-600

68

89-92

90-35

89-97

59-135

19-47

813

20

404-692

809-1484

351-386

825-1011

267-564

209

238

170

855

92-143

30-54

132

178

782-939

50

582-757

728-1072

130

54-134

20-47

142-146

119-169

682

36

68-75

65-115

31-22

98-30

81-75

68-71

75-110

71-74

MET 412

Heating, Ventilating, and Air Conditioning

Table (6.11) Average Air Infiltration Rates in / s due to door openings

Room Volume

3

(m )

/ s Infiltration *

Rooms

Rooms

o

o

above 0 C

below 0 C

8

3.1

2.3

8.5

3.4

2.6

10

3.7

2.8

15

4.4

3.3

20

5.0

3.8

25

5.5

4.2

30

5.9

4.6

40

6.8

5.4

50

7.5

5.8

75

9.0

6.9

100

10.2

7.9

150

12.2

9.4

200

13.9

10.9

250

15.3

11.9

300

16.7

12.9

400

19.0

14.9

500

21.4

16.8

600

23.6

18.1

700

24.3

18.6

800

25.9

20.4

900

27.1

21.9

1000

28.9

23.1

* For heavy usage, add 50% to table values

28/36

29/36

Heating, Ventilating, and Air Conditioning

MET 412

Tables (6.12 a) Kilojoules per liter removed in cooling air to storage conditions above C

o

Storage

room temp.

o

C

15

10

5

0

Inlet Air Temperature C

10

15

Inlet air relative humidity %

25

80

0.0128

0.0266

0.0388

0.0493

60

0.0186

0.0323

0.0445

0.0550

80

0.0246

0.0382

0.0502

0.0606

80

0.0281

0.0319

0.0536

0.0639

60

0.0357

0.0491

0.0610

0.0713

80

0.0441

0.0574

0.0693

0.0794

80

0.0500

0.0591

0.0708

0.0808

40

60

0.0563

0.0694

0.0810

0.0910

80

0.0663

0.0792

0.0906

0.1003

60

0.0795

0.0992

0.1036

0.1141

Tables (6.12 b) Kilojoules per liter removed in cooling air to storage conditions below C

o

Storage

Room

o

temp C

0

-5

-10

-15

-20

-25

-30

-35

-40

5

80

0.0092

0.0193

0.0271

0.0350

0.0427

0.0501

0.0571

0.0640

0.0708

10

80

0.0111

0.0210

0.0288

0.0367

0.0444

0.0523

0.0588

0.0657

0.0725

80

0.0142

0.0235

0.0309

0.0383

0.0456

0.0525

0.0591

0.0656

0.0720

Inlet Air Temperature C

25

Inlet air relative humidity %

80

0.0154

0.0247

0.0321

0.0395

0.0468

0.0537

0.0604

0.0668

0.0732

80

0.0505

0.0592

0.0662

0.0732

0.0801

0.0866

0.0929

0.0989

0.1050

60

0.0562

0.0649

0.0719

0.0788

0.0857

0.0922

0.0985

0.1045

0.1106

80

0.0650

0.0736

0.0805

0.0873

0.0941

0.0998

0.1067

0.1126

0.1185

30

35

60

0.0724

0.0809

0.0877

0.0945

0.1013

0.1077

0.1138

0.1197

0.1256

80

0.0820

0.0903

0.0970

0.1037

0.1102

0.1165

0.1225

0.1283

0.1341

60

0.0921

0.1004

0.1071

0.1137

0.1203

0.1265

0.1325

0.1382

0.1440

Table (6.13) Typical data for the number of refrigerated room volumes of air

interchange in a 24 hour period as a function of room volume (m 3)

Store volume

m3

Air change per

24 hours

30

90

80

60

80

300

380

900

100

800

600

800

3000

3800

9000

1000

>8000

11

99

38

12

10

9

7

5.8

4.8

4.2

3.4

2.9

2.5

1.9

1.7

1.4

1.2

Heating, Ventilating, and Air Conditioning

MET 412

Ls

Table (6.14) Outdoor air requirements for Ventilation rate

Person

Application

Smoking

Flat

Bank

Hair dresser

Sometimes

Sometimes

Sometimes

Heavy

NO

NO

NO

Heavy

Heavy

Sometimes

Sometimes

Sometimes

Commercial Shops

Factories

Hospital

Hotels

Meeting rooms

Offices

Restaurants

Cafeteria

Ventilation rate

Minimum

Recommended

7

9.5

5

7.5

5

7

12

15

2.5

3.5

3.5

5

12

14

12

14

14

24

7

12

7.5

10

3.5

6

Table (6.15) Surface absorption factor ()

Material

Absorption factor

Asphalt

0.89

Concrete

0.65

Red bricks

0.77

White bricks

0.26

Cements

0.57

Gypsum

0.4

Thermal insulation

0.91

30/36

31/36

Heating, Ventilating, and Air Conditioning

MET 412

Table (6.16 A ) Effect of Sun Radiation (Cold stores)

Surface type

Wall

East

West

North

South

Roof

No of hours

Average sunlight

intensity (W/m2)

Ts

869

39

869

39

83

8

39

338

111

1

5

32/36

Heating, Ventilating, and Air Conditioning

MET 412

Table (6.17) Window glass overall heat transfer coefficient (W/m2 K)

Single glass

Insulating double glass with

5mm air gap

6mm air gap

13 mm air gap

Summer

4.7

Winter

8

3.2

3.1

2.8

8

2.7

3.4

Table (6.18 A) Maximum heat gain per unit area,

20o North Latitude

Direction

Month

West

South

East

Jan

618

688

618

Feb

831

885

831

March

888

161

888

April

835

381

835

May

688

311

688

June

661

311

661

July

665

316

665

August

658

380

658

Sep

830

160

830

Oct

688

816

688

Nov.

699

66

699

Dec

850

831

850

Maximum

748

713

748

, ( W/m2)

Q

sun

North

53

58

308

390

388

386

383

396

338

303

53

88

186

Horizontal

819

810

856

508

851

880

888

881

868

838

896

688

905

Table (6.18 B) Shading Coefficient (SC)

Glass type

Thickn

ess

(mm)

Without

shading

(Venetian Blinds)

(Roller Shade)

Light

Medium

Light

Dark

1

6-39

6

1

0.95

0.70

0.55

0.55

0.53

0.64

0.64

0.57

0.25

0.25

0.30

0.59

0.59

0.40

1

6

6

0.9

0.83

0.2-0.4

0.51

0.51

-

0.57

0.57

0.2-0.3

0.25

0.25

-

0.6

0.6

-

Single

Regular

sheet

Colored

Heat

Absorbing

Double

Regular

sheet

Colored

Reflective

coated

33/36

Heating, Ventilating, and Air Conditioning

MET 412

Table (6.16 B) Solar intensity (W/m2) ( AC space)

Month

21

June

23 July

24

August

22

Sep

Direction

N

E

S

W

Hor

N

E

S

W

Hor

N

E

S

W

Hor

N

E

S

W

Hor

6

380

958

310

45

365

110

45

245

50

-

7

155

600

345

120

595

320

10

868

388

880

60

380

8

90

635

560

55

640

540

688

80

880

608

388

188

9

15

555

745

565

25

735

880

380

680

880

988

888

10

410

45

900

420

90

980

810

938

818

898

180

818

11

220

90

1000

225

140

990

910

968

580

610

868

818

Hour

12

105

1025

155

1020

988

588

888

880

13

90

220

1000

380

998

550

968

910

580

898

910

818

14

45

410

900

98

868

818

380

880

680

988

880

888

15

15

555

745

98

868

818

380

880

680

988

880

888

16

90

635

560

88

680

880

80

688

880

388

608

188

17

155

600

188

338

168

330

88

988

80

-

18

150

395

130

390

858

190

10

868

988

60

880

380

33/36

Heating, Ventilating, and Air Conditioning

MET 412

Table (6.19) Packaging material specific heat

Packaging Material

Fiberite packaging

Wood

Steel

Plastics

Aluminium

Specific Heat (kJ/kg

K)

1.4

2.3

0.5

1.6

0.85

Table (6.20) Heat equivalent to Occupancy (AC)

Human

Activities

Seated at rest

Seated, very

light work

Medium work

Standing and

light work

Walking

slowly

Seated,

eating

Moderate

work

Moving

regularly

Medium work

Heavy work

Sport

exercises

Typical

application

Theater

Office, flat,

hotel

Office, flat,

hotel

Commercial

shops

Sensible

heat

66

Latent heat

Total

31

97

72

45

117

73

59

132

73

59

132

Bank

73

73

146

Restaurant

81

81

162

Factory

81

139

229

Factory

110

183

293

Factory

factory

88

170

204

255

292

425

Gymnasium

170

255

425

Table (6.21) Heat equivalent to Occupancy (Refrigeration)

Storage tem. oC

-30

-25

-20

-10

-5

0

5

10

Q t

450

410

390

300

275

250

225

200

34/36

Heating, Ventilating, and Air Conditioning

MET 412

Table (6.22) Usage heat gain, W/m3 K

Room Volume

(m3)

0.6

0.85

1.5

2.0

3.0

6.0

8.5

11.0

14.0

17.0

23.0

28.0

34.0

43.0

57.0

85.0

140.0

200.0

280.0

560.0

1400.0

2100.0

2800.0

Service

Average

3.63

2.56

1.77

1.44

1.25

1.07

1.01

0.96

0.94

0.91

0.86

0.85

0.77

0.71

0.65

0.58

-

Heavy

3.97

3.57

2.76

2.24

1.96

1.72

1.61

1.52

1.45

1.44

1.37

1.30

1.23

1.16

-

Long-term

storage

0.6

0.45

0.31

0.24

0.19

0.16

0.14

0.14

0.13

Anda mungkin juga menyukai

- Refrigeration Midterm Exam ###Dokumen3 halamanRefrigeration Midterm Exam ###Patience LastyBelum ada peringkat

- Residential Cooling Load CalculationDokumen24 halamanResidential Cooling Load CalculationAngeloTomalonBelum ada peringkat

- Cooling Load Calculation: (Aircon Lab)Dokumen24 halamanCooling Load Calculation: (Aircon Lab)matthew ocampoBelum ada peringkat

- Load CalculationDokumen4 halamanLoad CalculationVirani BharatBelum ada peringkat

- Macabeo Me150p E01 Hw1 Chapter14&15Dokumen24 halamanMacabeo Me150p E01 Hw1 Chapter14&15Patricia MacabeoBelum ada peringkat

- NEET Test SeriesDokumen4 halamanNEET Test SeriesAbir Dn100% (1)

- Industrial Plant Engineering Design ConceptsDokumen39 halamanIndustrial Plant Engineering Design ConceptsCj SiguenzaBelum ada peringkat

- COOLING Load Estimation ReportDokumen72 halamanCOOLING Load Estimation ReportDikshit Tomer100% (2)

- Refrigeration COP and Capacity CalculationDokumen12 halamanRefrigeration COP and Capacity CalculationxofigoBelum ada peringkat

- Carrier Cold Room Calculaton PDFDokumen28 halamanCarrier Cold Room Calculaton PDFMohammad Amer93% (60)

- Refrigeration Technology Chapter 1 SummaryDokumen94 halamanRefrigeration Technology Chapter 1 SummaryAbdalhady JoharjiBelum ada peringkat

- Refrigeration Technology Chapter 1 SummaryDokumen94 halamanRefrigeration Technology Chapter 1 SummaryAbdalhady JoharjiBelum ada peringkat

- Topic 5 Energetics-Thermochemistry MCQsDokumen32 halamanTopic 5 Energetics-Thermochemistry MCQsADEEL AHMADBelum ada peringkat

- Lecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDokumen14 halamanLecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDeniell Joyce MarquezBelum ada peringkat

- Chapter 15 ProblemsDokumen3 halamanChapter 15 ProblemsJoshua Phillip Austero FederisBelum ada peringkat

- Ventilation Lesson Guide Natural Forced CoolingDokumen13 halamanVentilation Lesson Guide Natural Forced CoolingMohammed SiddiqueBelum ada peringkat

- Cooling and heating load principlesDokumen18 halamanCooling and heating load principlesSaif AliBelum ada peringkat

- Hvac Rpoblems NewDokumen20 halamanHvac Rpoblems NewGrace Joy CariBelum ada peringkat

- Brochure Air Cooled CondenserDokumen8 halamanBrochure Air Cooled CondenserFathur Rahman Handoko100% (1)

- Design of Hydraulic Road BlockerDokumen52 halamanDesign of Hydraulic Road BlockerAbdalhady Joharji100% (1)

- Design of A Cold Storage Unit For BananaDokumen24 halamanDesign of A Cold Storage Unit For BananaRona Jane Abadilla100% (2)

- CHAPTER 10 Cooling Load January 2012Dokumen50 halamanCHAPTER 10 Cooling Load January 2012Franky FlamBelum ada peringkat

- AIR CONDITIONING AND VENTILATION SYSTEM Prelim ExamDokumen1 halamanAIR CONDITIONING AND VENTILATION SYSTEM Prelim ExamJames Patrick TorresBelum ada peringkat

- R22 Refrig Plant Cylinder Dimensions COP PowerDokumen2 halamanR22 Refrig Plant Cylinder Dimensions COP PowerAndrew PantaleonBelum ada peringkat

- Retrofitting of Refrigeration TrainerDokumen21 halamanRetrofitting of Refrigeration TrainerRome John FranciscoBelum ada peringkat

- Assignment 7 - MEENG322 - 3BDokumen3 halamanAssignment 7 - MEENG322 - 3BKing Cyruz PabloBelum ada peringkat

- Case Study in Industrial Plant EngineeringDokumen11 halamanCase Study in Industrial Plant EngineeringRenz Gabrielle Montalbo SomatizaBelum ada peringkat

- Questions and solutions for engineering problemsDokumen82 halamanQuestions and solutions for engineering problemsRyan Llona FernandezBelum ada peringkat

- Domestic LPG RefrigeratorDokumen13 halamanDomestic LPG RefrigeratorKrishna Rama67% (3)

- Ref Systems Lecture Notes 1Dokumen9 halamanRef Systems Lecture Notes 1Retro GamerBelum ada peringkat

- Industrial Plant Engineering Elements Review PDF FreeDokumen4 halamanIndustrial Plant Engineering Elements Review PDF FreeRoss AlteaBelum ada peringkat

- Rac Problems Set 1Dokumen6 halamanRac Problems Set 1Mohammad Umair100% (1)

- Part 1Dokumen3 halamanPart 1Jester NavarquezBelum ada peringkat

- Diesel Power Plant GuideDokumen10 halamanDiesel Power Plant GuideyanyanBelum ada peringkat

- Lecture On Specific Speed 2019Dokumen22 halamanLecture On Specific Speed 2019Ariel GamboaBelum ada peringkat

- ThermoDokumen6 halamanThermoE.G Boy GudaBelum ada peringkat

- Part I Refrigeration Chapter 1Dokumen43 halamanPart I Refrigeration Chapter 1eskewt0% (1)

- FLR - Performance of A Tubular CondenserDokumen12 halamanFLR - Performance of A Tubular CondenserNazario Emil LintagBelum ada peringkat

- Heat Transfer - A Practical Approach-Solution Manual (EXP-6588) Exp-6588-2/)Dokumen4 halamanHeat Transfer - A Practical Approach-Solution Manual (EXP-6588) Exp-6588-2/)lorena silveiraBelum ada peringkat

- Ideal Gas Refrigeration Cycle & R-134a Vapor Compression Refrigerator PerformanceDokumen3 halamanIdeal Gas Refrigeration Cycle & R-134a Vapor Compression Refrigerator Performanceanask15Belum ada peringkat

- Neil Chester C. HernaezDokumen5 halamanNeil Chester C. HernaezSka dooshBelum ada peringkat

- Mechanical Engineering Laboratory 1 PlanimeterDokumen8 halamanMechanical Engineering Laboratory 1 PlanimeterChristopher Lennon Dela CruzBelum ada peringkat

- Performance Analysis of Ice Plant Using Ecofriendly RefrigerantsDokumen9 halamanPerformance Analysis of Ice Plant Using Ecofriendly RefrigerantsAungThawNyeinChanBelum ada peringkat

- Neil Chester C. HernaezDokumen6 halamanNeil Chester C. HernaezSka dooshBelum ada peringkat

- Me Lab 3Dokumen27 halamanMe Lab 3Jerome Vega AndesBelum ada peringkat

- Heat Transfer Chapter 1 ProblemsDokumen8 halamanHeat Transfer Chapter 1 ProblemsVon A. Damirez0% (1)

- Experiment No. 1Dokumen4 halamanExperiment No. 1subhamgupta7495100% (1)

- PPE TerminologiesDokumen3 halamanPPE TerminologiesJamiel CatapangBelum ada peringkat

- MAPÚA UNIVERSITY WRITTEN REPORT ON PNEUMATICSDokumen14 halamanMAPÚA UNIVERSITY WRITTEN REPORT ON PNEUMATICSAndreBelum ada peringkat

- Solved Problems A Solved Refrigeration ProblemsDokumen29 halamanSolved Problems A Solved Refrigeration Problemsbasil.delacruzBelum ada peringkat

- PADILLAMD Module 7 Exercises Problem No. 4Dokumen2 halamanPADILLAMD Module 7 Exercises Problem No. 4Leyzer MalumayBelum ada peringkat

- TUP Mechanical Engineering Steam Powerplant Design Lab ReportDokumen10 halamanTUP Mechanical Engineering Steam Powerplant Design Lab ReportRouen Jay CorpuzBelum ada peringkat

- Refrigeration-Systems Part 1Dokumen11 halamanRefrigeration-Systems Part 1Sean GuanzonBelum ada peringkat

- Teodoro Chapter 19Dokumen21 halamanTeodoro Chapter 19Reinzo GallegoBelum ada peringkat

- Air conditioning system design problemsDokumen6 halamanAir conditioning system design problemsSka dooshBelum ada peringkat

- Front Page and Expirement Number 1Dokumen3 halamanFront Page and Expirement Number 1Ron Kristian OpolintoBelum ada peringkat

- Me6301 QBDokumen46 halamanMe6301 QBNaveen Dhanuraj100% (1)

- 3 Gas Vapor Mixtures ExerciseDokumen9 halaman3 Gas Vapor Mixtures ExercisefikriBelum ada peringkat

- Bell Coleman cycle expression temperature ideal cycleDokumen2 halamanBell Coleman cycle expression temperature ideal cycleShridhar Walavalkar50% (2)

- NR-410305 - Refrigeration and Air ConditioningDokumen8 halamanNR-410305 - Refrigeration and Air ConditioningSrinivasa Rao GBelum ada peringkat

- Methods of Handling Air SupplyDokumen10 halamanMethods of Handling Air SupplySka dooshBelum ada peringkat

- REFSYS - 3ME-8 (2ND SEM/ A.Y. 2020-2021) Midterm ExaminationDokumen3 halamanREFSYS - 3ME-8 (2ND SEM/ A.Y. 2020-2021) Midterm ExaminationRobert GarlandBelum ada peringkat

- Ee 4101Dokumen183 halamanEe 4101Franz TabioloBelum ada peringkat

- Diesel Power Plant With Tons of IceDokumen124 halamanDiesel Power Plant With Tons of IceMycky VillanuevaBelum ada peringkat

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemDari EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemBelum ada peringkat

- MET 412, HVAC Course.Dokumen7 halamanMET 412, HVAC Course.Abdalhady JoharjiBelum ada peringkat