Swagelok High Pressure Fittings

Diunggah oleh

Syahirul AlimDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Swagelok High Pressure Fittings

Diunggah oleh

Syahirul AlimHak Cipta:

Format Tersedia

www.swagelok.

com

H i g h - P re s s u re F i t t i n g s

F e a t u re s

Pressures to 60 000 psi (4 134 bar)

Weep holes for instant leak detection

High-Pressure Fittings

Features

Fittings are machined from 316 stainless steel.

Back ferrule is manufactured from S17400 hardened

SNO-TRIK

stainless steel to ensure a secure grip on hardened or

annealed tubing.

Weep holes allow instant leak detection.

Unique ferrule action helps prevent excessive deformation

of the seal area of tube end and body.

Fitting does not reduce tube wall thickness.

Fittings can be made, disconnected, and remade easily to

provide a reliable leaktight seal.

Bleed slot on male thread connectors facilitates purging of

fluid before operation.

Pressure RatingsHigh-Pressure Fitting

The rating for high-pressure tube fittings and threaded

connectors is determined with Swagelok hardened tubing

at room temperature.

Materials of Construction

The rating for high-pressure tube fittings and threaded

Component

connectors with annealed tubing is 30 000 psig (2067 bar)

at room temperature.

Material

Back ferrule

S17400 SS

All other components

Pressure RatingsPipe Fitting

316 SS

Pipe thread pressure rating is based on laboratory testing

with both male and female threads manufactured by

Swagelok Company.

Ordering Information and Dimensions

High-Pressure Tube

Fitting to High-Pressure

Male Thread Connectors

Tube

OD

1/4

Bleed slot

Dimensions, in. (mm)

Uniform

Thread

Size

Ordering

Number

9/16-18

SS-440-1-44M

3/4-16

SS-440-1-64M

9/16-18

SS-640-1-44M

3/4-16

SS-640-1-64M

3/4-16

SS-940-1-64M

1 1/8-12

SS-940-1-94M

G

E

D

3/8

9/16

A

1.96

(49.8)

0.82

2.32

(20.8)

(58.9)

F

Flat

Pressure

Rating

psig (bar)

5/8

3/4

0.09

(2.3)

13/16

2.24

(56.9)

1.04

2.41

(26.4)

(61.2)

15/16

60 000

(4134)

0.12

(3.0)

3.01

(76.5)

1.45

3.19

(36.8)

(81.0)

0.19

1 1/4

1 3/8

(4.8)

Union Tees

Dimensions, in. (mm)

F

G

Tube

OD

Ordering

Number

1/4

SS-440-3

3/8

SS-640-3

E

D

D

9/16

A

Dimensions are for reference only and are subject to change.

SS-940-3

A

2.78

D

0.82

E

0.09

(70.6)

(20.8)

(2.3)

3.48

1.04

0.12

(88.4)

(26.4)

(3.0)

5.04

1.45

0.19

(128)

(36.8)

(4.8)

F

Flat

11/16

3/4

7/8

15/16

1 1/4

1 3/8

Pressure

Rating

psig (bar)

60 000

(4134)

High-Pressure Fittings

Unions

Dimensions, in. (mm)

F

Tube

OD

Ordering

Number

1/4

SS-440-6

3/8

SS-640-6

E

A

9/16

SS-940-6

A

2.25

D

0.82

E

0.09

(57.2)

(20.8)

(2.3)

2.70

1.04

0.12

(68.6)

(26.4)

(3.0)

3.69

1.45

0.19

(93.7)

(36.8)

(4.8)

F

Flat

5/8

3/4

13/16

15/16

1 1/4

1 3/8

Pressure

Rating

psig (bar)

60 000

(4134)

Reducing Unions

Tx Gx

G T

Dx

Dimensions, in. (mm)

T

Tube

OD

Tx

Tube

OD

Ordering

Number

3/8

1/4

SS-640-6-440

1/4

SS-940-6-440

D

1.04

Dx

0.82

E

0.09

(66.3)

(26.4)

(20.8)

(2.3)

3.22

9/16

3/8

A

2.61

SS-940-6-640

0.82

0.09

(81.8)

1.45

(20.8)

(2.3)

3.42

(36.8)

1.04

0.12

(26.4)

(3.0)

(86.9)

F

Flat

Gx

13/16

15/16

3/4

1 1/4

1 3/8

3/4

Pressure

Rating

psig (bar)

60 000

(4134)

15/16

Bulkhead Unions

G

E

Tube

OD

1/4

3/8

9/16

High-Pressure Tube

Fitting to High-Pressure

Female Thread

Connectors

F

Dimensions, in. (mm)

F

Flat

D

E

Ordering

Number

SS-440-61

3.30

0.82

0.09

(83.8)

(20.8)

(2.3)

3.72

1.04

0.12

(94.5)

(26.4)

(3.0)

5.07

1.45

0.19

(129)

(36.8)

(4.8)

SS-640-61

SS-940-61

Tube

OD

Uniform

Thread

Size

1 1/16

15/16

1 5/8

1 3/8

0.91

0.50

60 000

(23.1)

(12.7)

(4134)

(19.8)

1.34

(34.0)

1.87

0.82

(47.5)

(20.8)

9/16-18

SS-440-7-44F

3/8

3/4-16

SS-640-7-64F

1 1/8-12

3/4

Dimensions, in. (mm)

1/4

9/16

E

15/16

Pressure

Rating

psig (bar)

Ordering

Number

Max Panel

Thickness

Hole Drill

Size

0.78

SS-940-7-94F

2.26

1.04

(57.4)

(26.4)

3.13

1.45

(79.5)

(36.8)

F

Flat

0.09

(2.3)

7/8

3/4

0.12

(3.0)

0.19

(4.8)

1 1/8

15/16

1 3/8

1 3/8

Pressure

Rating

psig (bar)

60 000

(4134)

Dimensions are for reference only and are subject to change.

High-Pressure Fittings

Union Elbows

Dimensions, in. (mm)

Tube

OD

F

G

Ordering

Number

1/4

SS-440-9

1.39

0.82

(35.3)

(20.8)

(2.3)

3/8

SS-640-9

E

D

9/16

SS-940-9

F

Flat

0.09

11/16

3/4

7/8

15/16

1 1/4

1 3/8

1.74

1.04

0.12

(44.2)

(26.4)

(3.0)

2.52

1.45

0.19

(64.0)

(36.8)

(4.8)

Pressure

Rating

psig (bar)

60 000

(4134)

High-Pressure Male

Thread to Coned

Tube Stub Adapters

1/4

Bleed slot

Uniform

Thread

Size

Tube

OD

E

D

9/16-18

Dimensions, in. (mm)

Ordering

Number

F

Flat

SS-44M-A-441

2.01

1.00

0.06

(51.1)

(25.4)

(1.5)

5/8

2.47

1.25

0.12

(62.7)

(31.8)

(3.0)

3.34

1.76

0.19

(84.8)

(44.7)

(4.8)

3/8

3/4-16

SS-64M-A-641

9/16

1 1/8-12

SS-94M-A-941

High-Pressure

Male Thread Unions

F

Bleed slot

Uniform

Thread

Size

Bleed slot

9/16-18

13/16

1 1/4

Dimensions, in. (mm)

Pressure

Rating

psig (bar)

60 000

(4134)

45 000

(3100)

F

Flat

Pressure

Rating

psig (bar)

0.09

5/8

60 000

Ordering

Number

SS-44M-6

1.71

(43.4)

(2.3)

(4134)

E

A

Caps

Dimensions, in. (mm)

Tube

OD

D

A

Ordering

Number

1/4

SS-440-C

1.35

0.82

(34.3)

(20.8)

(2.3)

3/8

SS-640-C

9/16

SS-940-C

D

A

Dimensions are for reference only and are subject to change.

0.09

5/8

3/4

13/16

15/16

1 1/4

1 3/8

1.80

1.04

0.12

(45.7)

(26.4)

(3.0)

2.52

1.45

0.19

(64.0)

(36.8)

(4.8)

Port Connectors

E

F

Flat

Tube

OD

Ordering

Number

1/4

SS-441-PC

3/8

SS-641-PC

9/16

SS-941-PC

Dimensions, in. (mm)

E

0.06

Pressure

Rating

psig (bar)

60 000

(4134)

Pressure

Rating

psig (bar)

A

1.85

D

0.50

(47.0)

(12.7)

(1.5)

60 000

2.33

0.68

0.12

(4134)

(59.2)

(17.3)

(3.0)

3.41

1.06

0.19

45 000

(86.6)

(26.9)

(4.8)

(3100)

High-Pressure Fittings

High-Pressure Tube

Fitting to Coned Tube

Stub Reducers

E1

G T

Tx

E

A

T

Tube

OD

1/4

3/8

9/16

3/8

9/16

Tube

OD

Ordering

Number

1/4

SS-440-P

3/8

SS-640-P

9/16

SS-940-P

Tube

OD

Ordering

Number

1/4

SS-442-1

3/8

SS-642-1

9/16

SS-942-1

Nuts

High-Pressure Tube

Fitting to Male Pipe

Thread Connectors

F

E1

F

Flat

0.12

5/8

3/4

Pressure

Rating

psig (bar)

60 000

15/16

45 000

1 3/8

60 000

Ordering

Number

SS-440-R-641

2.53

0.82

0.09

(64.3)

(20.8)

(2.3)

(3.0)

3.28

1.04

0.12

0.19

(83.3)

(26.4)

(3.0)

(4.8)

3.31

1.45

0.19

0.12

(84.1)

(36.8)

(4.8)

(3.0)

SS-640-R-941

3/8

Plugs

Dimensions, in. (mm)

Tx

Tube

OD

SS-940-R-641

Dimensions, in. (mm)

A

0.95

1 1/4

Front

Ferrules

Pressure

Rating

psig (bar)

1.18

1/4

SS-443-1

3/8

SS-643-1

9/16

SS-943-1

Tube

OD

Ordering

Number

3/4

1/4

174PH-444-1

15/16

3/8

174PH-644-1

1 3/8

9/16

174PH-944-1

Pressure

Rating

psig (bar)

15/16

1.66

60 000

(4134)

1 3/8

(42.2)

Back

Ferrules

Dimensions, in. (mm)

A

0.81

(20.6)

0.97

(24.6)

1.44

(36.6)

(4134)

Ordering

Number

3/4

(30.0)

(3100)

Tube

OD

(24.1)

Tube

OD

13/16

(4134)

NPT

Male Pipe

Size

Dimensions, in. (mm)

F

Flat

D

E

Ordering

Number

1.84

0.82

0.09

(46.7)

(20.8)

(2.3)

2.09

1.04

0.12

(53.1)

(26.4)

(3.0)

2.80

1.45

0.19

(71.1)

(36.8)

(4.8)

1/4

1/4

SS-440-1-4

3/8

3/8

SS-640-1-6

9/16

1/2

SS-940-1-8

5/8

3/4

13/16

15/16

1 1/4

1 3/8

30 000

(2067)

High-Pressure

Tube Fitting to Male

Pipe Thread Elbows

A

Tube

OD

NPT

Male Pipe

Size

1.50

0.82

0.09

(38.1)

(20.8)

(2.3)

7/8

3/4

7/8

15/16

1 1/4

1 3/8

1/4

1/4

SS-440-2-4

3/8

3/8

SS-640-2-6

G

E

9/16

1/2

Dimensions, in. (mm)

Ordering

Number

SS-940-2-8

1.74

1.04

0.12

(44.2)

(26.4)

(3.0)

2.52

1.45

0.19

(64.0)

(36.8)

(4.8)

Pressure

Rating

psig (bar)

30 000

(2067)

Dimensions are for reference only and are subject to change.

High-Pressure Fittings

High-Pressure Tube

Fitting to Female Pipe

Thread Connectors

Tube

OD

NPT

Female

Pipe Size

2.07

0.82

0.09

(52.6)

(20.8)

(2.3)

7/8

3/4

15/16

1 1/4

1 3/8

1/4

1/4

SS-440-7-4

3/8

3/8

SS-640-7-6

9/16

1/2

SS-940-7-8

Dimensions, in. (mm)

Ordering

Number

2.36

1.04

0.12

(59.9)

(26.4)

(3.0)

2.99

1.45

0.19

(75.9)

(36.8)

(4.8)

Pressure

Rating

psig (bar)

20 000

(1378)

High-Pressure Tube

Fitting to Swagelok

Tube Fitting Unions

T

Tube

OD

1/4

F

Dx

Tx

Ordering

Number

Dx

SS-440-6-200

1.88

0.82

0.50

0.09

(47.8)

(20.8)

(12.7)

(2.3)

5/8

3/4

Pressure

Rating

psig (bar)

10 900

2.21

1.04

0.60

0.12

(56.1)

(26.4)

(15.2)

(3.0)

15/16

10 200

2.80

1.45

0.66

0.19

(71.1)

(36.8)

(16.8)

(4.8)

1 3/8

7 500

Tx

Tube

OD

1/8

3/8

1/4

Dimensions, in. (mm)

SS-640-6-400

G T

9/16

D

3/8

SS-940-6-600

13/16

1 1/4

(751)

(702)

(516)

E

A

Coned Tube Stub

to Male Pipe

Thread Adapters

NPT

Male Pipe

Size

Tube

OD

F

E

Dimensions, in. (mm)

Ordering

Number

1/4

1/4

SS-441-A-4

3/8

3/8

SS-641-A-6

9/16

1/2

SS-941-A-8

Coned Tube Stub

to Swagelok Tube

Fitting Adapters

T

Tube

OD

1/4

Tx G

D

3/8

9/16

High-Pressure Male

Thread to Male

Pipe Connectors

Thread

Size

3/8

1/2

D

A

Dimensions are for reference only and are subject to change.

(1.5)

9/16

2.12

0.12

(53.8)

(3.0)

2.85

0.19

(72.4)

(4.8)

11/16

30 000

(2067)

7/8

SS-441-A-400

1.97

0.60

0.06

(50.0)

(15.2)

(1.5)

1/2

9/16

2.31

0.66

0.12

(58.7)

(16.8)

(3.0)

11/16

7 500

2.96

0.90

0.19

(75.2)

(22.9)

(4.8)

7/8

6 700

SS-641-A-600

SS-941-A-810

NPT

Male Pipe

Size

1.55

1/4

SS-44M-1-4

3/4-16

3/8

SS-64M-1-6

1/2

SS-94M-1-8

5/8

13/16

Dimensions, in. (mm)

Ordering

Number

9/16-18

1 1/8-12

E

(46.7)

Dimensions, in. (mm)

Bleed slot

Pressure

Rating

psig (bar)

10 200

E

T

0.06

Ordering

Number

Tx

Tube

OD

1/4

1.84

Pressure

Rating

psig (bar)

0.09

5/8

(39.4)

0.56

(2.3)

1.78

(14.2)

0.12

(45.2)

(3.0)

2.30

0.75

0.19

(58.4)

(19.0)

(4.8)

13/16

1 1/4

(702)

(516)

(461)

Pressure

Rating

psig (bar)

30 000

(2067)

High-Pressure Fittings

High-Pressure Male

Thread to Female

Pipe Connectors

Thread

Size

NPT

Female

Pipe Size

Dimensions, in. (mm)

Ordering

Number

9/16-18

1/4

SS-44M-7-4

3/4-16

3/8

SS-64M-7-6

Bleed slot

1 1/8-12

1/2

SS-94M-7-8

1.66

0.09

(42.2)

(2.3)

7/8

1.94

0.12

(49.3)

(3.0)

2.48

0.19

(63.0)

(4.8)

Pressure

Rating

psig (bar)

20 000

(1378)

1 1/4

High-Pressure Male

Thread to Swagelok

Tube Fitting Adapters

Tube

OD

Thread

Size

1/8

F

Bleed Slot

SS-44M-A-200

1.61

0.50

(40.8)

9/16-18

1/4

SS-44M-A-400

3/8

E

A

1/2

High-Pressure Male

Thread to Tube

Socket Weld Adapters

F

Bleed slot

3/4-16

SS-64M-A-600

T

Tube

OD

1 1/8-12

Tx

OD

SS-94M-A-810

Thread

Size

(12.7)

0.09

1.70

0.60

(2.3)

5/8

(43.1)

(15.2)

1.97

0.66

0.12

(50.0)

(16.7)

(3.0)

2.41

0.90

0.19

(61.2)

(22.9)

(4.8)

7/16

10 900

9/16

10 200

11/16

7 500

13/16

7/8

6 700

Pressure

Rating

psig (bar)

1 1/4

Dimensions, in. (mm)

Ordering

Number

1.30

0.28

0.09

(33.0)

(7.1)

(2.3)

5/8

1.60

0.31

0.12

(40.6)

(7.9)

(3.0)

1.99

0.38

0.19

(50.5)

(9.7)

(4.8)

1/4

1/2

9/16-18

SS-44M-A-4TSW

3/8

5/8

3/4-16

SS-64M-A-6TSW

1/2

3/4

1 1/8-12

SS-94M-A-8TSW

T Tx

E

Pressure

Rating

psig (bar)

Dimensions, in. (mm)

Ordering

Number

13/16

1 1/4

(751)

(702)

(516)

(461)

20 000

(1378)

15 000

(1033)

Instructions for High-Pressure

Cone and Ferrule Tube Fittings

InstallationSwagelok Hardened Tubing

! The pre-setting tool (see page 8) must be used for

proper initial installation of high-pressure tube fittings

with hardened tubing.

1. Install the nut and ferrules onto the pre-setting tool.

2. Insert the coned tubing into the pre-setting tool.

3. Make sure that the tubing rests firmly on the tapered shoulder

of the pre-setting tool body.

4. Tighten the nut until the tubing cannot be turned by hand.

5. Scribe the nut at the 6 oclock position.

6. While holding the pre-setting tool steady, tighten the nut

1 1/4 turns to the 9 oclock position.

7. Loosen the nut and remove the tubing with pre-set ferrules

from the pre-setting tool.

8. Insert tubing with pre-set ferrules into the fitting body until

the front ferrule seats.

9. Make sure that the nut is finger-tight.

10. While holding fitting body steady with a back-up wrench,

tighten the nut 3/8 of a turn for 3/8 and 9/16 in. tubing and

1/4 of a turn for 1/4 in. tubing.

InstallationAnnealed Tubing

The pre-setting tool is suggested for proper installation of highpressure tube fittings with annealed tubing. When the pre-setting

tool is used, use the instructions for the hardened tubing. When

the pre-setting tool is not used, use the following instructions:

1. Insert coned tubing into the tube fitting.

2. Make sure that the tubing rests firmly on the tapered

shoulder of the tube fitting body.

3. Tighten the nut until the tubing cannot be turned by hand.

4. Scribe the nut at the 6 oclock position.

5. While holding fitting body steady with a back-up wrench,

tighten the nut 1 1/4 turns to the 9 oclock position.

InstallationHigh-Pressure Male and Female Threads

1. Make sure that the nut is finger-tight.

2. Tighten the nut 1/8 of a turn.

Reassembly Instructions

You may disassemble and reassemble a Swagelok high-pressure

tube fitting.

1. Insert tubing with pre-set ferrules into the fitting body until

the front ferrule seats.

2. Make sure that the nut is finger-tight.

3. While holding fitting body steady with a back-up wrench,

tighten the nut 3/8 of a turn for 3/8 and 9/16 in. tubing and

1/4 of a turn for 1/4 in. tubing.

Dimensions are for reference only and are subject to change.

Options and Accessories

Pre-Setting Tool

Visual Tube Inspection

The pre-setting tool is suggested for

initial makeup of Swagelok highpressure tube fittings when used with annealed tubing. The

pre-setting tool must be used for initial make-up of these tube

fittings when used with Swagelok hardened tubing.

A proper cone has ends that are faced and smooth.

Tube OD/

Tool Size, in.

1/4

Ordering

Number

MS-440-PT

Minimum OD

Required, in.

0.250

3/8

MS-640-PT

0.375

9/16

MS-940-PT

0.562

The cone should be free of any scratches and

leave-off marks.

T

Tube Preparation

T

in.

1/4

N

in.

1/8

3/8

7/32

9/16

9/32

56-59

N

NOTE: For tubing tolerance requirements, contact your

Swagelok independent sales and service representative.

Pre-Coned Tubing

Coning Tool

Pre-coned tube lengths of hardened or annealed tubing are

available from 2 to 120 inches (5 to 304 cm) in length. Tube

lengths are precisely coned with a high-quality finish. Annealed

tubing is rated to 30 000 psig (2 067 bar). Hardened tubing

is rated to 60 000 psi (4 134 bar).

High-pressure tubing used with

Swagelok high-pressure tube

fittings should be prepared with

a Swagelok coning tool. The

Swagelok coning tool cuts a

smooth, concentric cone on the

tube end to help ensure reliable

sealing in the fitting body. It is

designed to prepare 1/4, 3/8, and

9/16 in. OD heavy wall tubing.

OD

in.

Each coning tool comes in a

carrying case with CL60 cutting

lubricant; 1/4, 3/8, and 9/16 in.

collets and tool bits; and ID

deburring tool.

For operating instructions,

see the Coning Tool

Users Manual.

Replacement

Parts

To order additional

items separately,

select an ordering

number.

1/4

Description

Coning tool

Description

Cutting lubricant

Ordering

Number

MS-469-CT

Ordering

Number

MS-CL60

1/4 in. collet

MS-469CT-2-4

1/4 in. tool bit

MS-469CT-7-4

3/8 in. collet

MS-469CT-2-6

3/8 in. tool bit

MS-469CT-7-6

9/16 in. collet

MS-469CT-2-9

9/16 in. tool bit

MS-469CT-7-9

Deburring tool

MS-44CT-27

Safe Product Selection

When selecting a product, the total system design must

be considered to ensure safe, trouble-free performance.

Function, material compatibility, adequate ratings,

proper installation, operation, and maintenance are the

responsibilities of the system designer and user.

3/8

9/16

Length

in. (cm)

2 (5.0)

Hardened

Ordering

Number

SS-483-T-2

Annealed

Ordering

Number

SS-483-A-2

Wall

Thickness

in. (mm)

4 (10.1)

SS-483-T-4

SS-483-A-4

0.083

8 (20.3)

SS-483-T-8

SS-483-A-8

(2.1)

12 (30.4)

SS-483-T-12

SS-483-A-12

4 (10.1)

SS-495-T-4

SS-495-A-4

8 (20.3)

SS-495-T-8

SS-495-A-8

12 (30.4)

SS-495-T-12

SS-495-A-12

0.095

(2.4)

3 (7.6)

SS-612-T-3

SS-612-A-3

4 (10.1)

SS-612-T-4

SS-612-A-4

0.125

8 (20.3)

SS-612-T-8

SS-612-A-8

(3.2)

12 (30.4)

SS-612-T-12

SS-612-A-12

4 (10.1)

SS-918-T-4

SS-918-A-4

8 (20.3)

SS-918-T-8

SS-918-A-8

12 (30.4)

SS-918-T-12

SS-918-A-12

0.187

(4.7)

Dimensions are for reference only and are subject to change.

Caution: Do not mix or interchange parts with those of

other manufacturers.

SwagelokTM Swagelok Company

2002 Swagelok Company

Printed in U.S.A., GLL

March 2002, R2

MS-01-34

Anda mungkin juga menyukai

- Making A BurnerDokumen13 halamanMaking A BurnerangelBelum ada peringkat

- E01000 - Cat - en - A4 - Eur - Pressure Regulators - e - xNFeTNDokumen84 halamanE01000 - Cat - en - A4 - Eur - Pressure Regulators - e - xNFeTNGUDANG KARAOKE KITABelum ada peringkat

- Pocket Guide to Flanges, Fittings, and Piping DataDari EverandPocket Guide to Flanges, Fittings, and Piping DataPenilaian: 3.5 dari 5 bintang3.5/5 (22)

- MC Handbook Section A OverviewDokumen355 halamanMC Handbook Section A OverviewSyahirul Alim100% (5)

- MC Handbook Section A OverviewDokumen355 halamanMC Handbook Section A OverviewSyahirul Alim100% (5)

- Cat-CMP Cable GlandDokumen64 halamanCat-CMP Cable GlandSyahirul Alim100% (1)

- Cat-CMP Cable GlandDokumen64 halamanCat-CMP Cable GlandSyahirul Alim100% (1)

- Armatury CZ Trunnion Mounted Ball ValvesDokumen28 halamanArmatury CZ Trunnion Mounted Ball ValvesLuka BornaBelum ada peringkat

- Piping Joints HandbookDokumen161 halamanPiping Joints HandbookYip Ying MunBelum ada peringkat

- Astm A733 Niples PDFDokumen4 halamanAstm A733 Niples PDFyesBelum ada peringkat

- Pipe & FittingDokumen28 halamanPipe & Fittinghelman novrandoBelum ada peringkat

- EFCO Valve Repair ProductsDokumen20 halamanEFCO Valve Repair Productsjay_rajeshirkeBelum ada peringkat

- Tube SupportsDokumen8 halamanTube SupportsSyahirul AlimBelum ada peringkat

- F10ca004-Gb 0597Dokumen8 halamanF10ca004-Gb 0597gabyorBelum ada peringkat

- Bleed Ring - ANSI Class 150-2500 (In)Dokumen2 halamanBleed Ring - ANSI Class 150-2500 (In)ulfatBelum ada peringkat

- Specification:: Hammer UnionsDokumen5 halamanSpecification:: Hammer Unionscmpuck100% (1)

- UK Material CodesDokumen34 halamanUK Material CodesAan Sarkasi Amd100% (1)

- Grayloc ToolsDokumen33 halamanGrayloc Toolsjemakl1568100% (1)

- Garlock Metal - Gaskets TorqueDokumen48 halamanGarlock Metal - Gaskets TorqueakenathorBelum ada peringkat

- Spiraltec Non-Metallic FillersDokumen1 halamanSpiraltec Non-Metallic FillersJakir HossainBelum ada peringkat

- Maurice Nicoll The Mark PDFDokumen4 halamanMaurice Nicoll The Mark PDFErwin KroonBelum ada peringkat

- Gas-Liquid Separator CatalogDokumen17 halamanGas-Liquid Separator CatalogkommuBelum ada peringkat

- Introduction To Valves - Only The Basics - Valves Are Mechanical Devices That Controls The Flow and Pressure Within A System or ProcessDokumen6 halamanIntroduction To Valves - Only The Basics - Valves Are Mechanical Devices That Controls The Flow and Pressure Within A System or Processamit100% (1)

- Ring Joint GasketsDokumen5 halamanRing Joint GasketsBahman Matouri100% (1)

- LP-PTG-701002 Inst Spec Rev DDokumen79 halamanLP-PTG-701002 Inst Spec Rev DSyahirul AlimBelum ada peringkat

- Mag General Business: Mill Test CertificateDokumen1 halamanMag General Business: Mill Test CertificateRaul Sebastiam100% (1)

- Catalogue of ProductsDokumen96 halamanCatalogue of Productssf wBelum ada peringkat

- HTTP WWW - Wermac.org Fittings Buttweld Fittings Part5Dokumen4 halamanHTTP WWW - Wermac.org Fittings Buttweld Fittings Part5prabu prasad100% (1)

- Swagelok Ball ValveDokumen8 halamanSwagelok Ball ValveSyahirul AlimBelum ada peringkat

- Mersen Process Technologies ProviderDokumen6 halamanMersen Process Technologies ProviderIbhar Santos MumentheyBelum ada peringkat

- Valvulas PDFDokumen32 halamanValvulas PDFMilena Lemus FonsecaBelum ada peringkat

- NORSOK STANDARD Electrical, Instrumentation and Telecommunication InstallationDokumen39 halamanNORSOK STANDARD Electrical, Instrumentation and Telecommunication Installationlj_treelsBelum ada peringkat

- Spirajet Spray NozzleDokumen2 halamanSpirajet Spray NozzleykozeBelum ada peringkat

- All-in-One Manual of Industrial Piping Practice and MaintenanceDari EverandAll-in-One Manual of Industrial Piping Practice and MaintenancePenilaian: 5 dari 5 bintang5/5 (1)

- Swagelok ValveDokumen24 halamanSwagelok ValveSyahirul AlimBelum ada peringkat

- Kirloskar Valves Technical Specification CatalogueDokumen24 halamanKirloskar Valves Technical Specification CatalogueAbhinay SuratkarBelum ada peringkat

- Garlock Catalogo GasketDokumen46 halamanGarlock Catalogo GasketServilab LudicasBelum ada peringkat

- ISO 5211 Drilling Patterns Imperial SizesDokumen1 halamanISO 5211 Drilling Patterns Imperial Sizesjkhgvdj mnhsnjkhgBelum ada peringkat

- Spiral Wound GasketsDokumen7 halamanSpiral Wound GasketsYap HSBelum ada peringkat

- B-Flex EngDokumen6 halamanB-Flex EngbikarexpansionjointsBelum ada peringkat

- Swagelok Tube Metric PDFDokumen2 halamanSwagelok Tube Metric PDFSyahirul AlimBelum ada peringkat

- Electrical Symbols and Line DiagramDokumen37 halamanElectrical Symbols and Line DiagramMatthew GarciaBelum ada peringkat

- FD 410 Asl en 2930154202Dokumen38 halamanFD 410 Asl en 2930154202gabrielBelum ada peringkat

- Swagelok Weld FittingsDokumen16 halamanSwagelok Weld FittingstotcsabBelum ada peringkat

- Flexitallic BrochureDokumen8 halamanFlexitallic BrochurealdaadrinaBelum ada peringkat

- Swagelok Flange AdaptersDokumen6 halamanSwagelok Flange AdapterstotcsabBelum ada peringkat

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDari EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryBelum ada peringkat

- Commenly Used Materials: Rolta Training Center, Mumbai - IndiaDokumen1 halamanCommenly Used Materials: Rolta Training Center, Mumbai - IndiaTAMIZHKARTHIKBelum ada peringkat

- LOCK O RING Flanges and PlugsDokumen6 halamanLOCK O RING Flanges and PlugsochableBelum ada peringkat

- BAF-ball Valves Rev 1 PDFDokumen40 halamanBAF-ball Valves Rev 1 PDFJack ChavanBelum ada peringkat

- Hot TappingDokumen2 halamanHot TappingRochdi SahliBelum ada peringkat

- 316 Stainless Steel Tube Fitting SpecificationDokumen3 halaman316 Stainless Steel Tube Fitting SpecificationSam Chong Ks100% (1)

- KL UHP Catalog 2011-02 PDFDokumen30 halamanKL UHP Catalog 2011-02 PDFaconibet9040Belum ada peringkat

- Prochem Ball ValvesDokumen5 halamanProchem Ball Valvesmd_taheriBelum ada peringkat

- EagleBurgmann H75VN enDokumen2 halamanEagleBurgmann H75VN enbryandownBelum ada peringkat

- MSS SP 6Dokumen6 halamanMSS SP 6d1a9v8i3d100% (1)

- RTJ Catalogue Rev1Dokumen9 halamanRTJ Catalogue Rev1steventrigochasin3537Belum ada peringkat

- A338 Steel StandardDokumen2 halamanA338 Steel StandardguilhermehsssBelum ada peringkat

- Hydraulics CurriculumDokumen8 halamanHydraulics CurriculumChris ChrisBelum ada peringkat

- Is 4310 Spec Weldeable Steel Pipe Fittings For Marine PurposesDokumen12 halamanIs 4310 Spec Weldeable Steel Pipe Fittings For Marine Purposesnarasimhareddy415Belum ada peringkat

- WFA Hose FittingsDokumen0 halamanWFA Hose Fittingsedhy_03Belum ada peringkat

- Virgo Trunnion Ball ValveDokumen16 halamanVirgo Trunnion Ball ValveKamalBelum ada peringkat

- SP-P-001 - Specification For StrainerDokumen30 halamanSP-P-001 - Specification For Strainervishal bhamreBelum ada peringkat

- Spir Star Valves & Fittings PDFDokumen26 halamanSpir Star Valves & Fittings PDFMidfiild CosminBelum ada peringkat

- Hot Tapping MachineDokumen4 halamanHot Tapping Machinedanigna77Belum ada peringkat

- Forged Valves - Operation & Maintenance ManualDokumen16 halamanForged Valves - Operation & Maintenance ManualKoolkrayzeh KLBelum ada peringkat

- Spiral Wound GasketsDokumen3 halamanSpiral Wound GasketsHarish GundaBelum ada peringkat

- PiggingDokumen5 halamanPiggingDendi AriyonoBelum ada peringkat

- Types of Flanges-Definition of FlangesDokumen4 halamanTypes of Flanges-Definition of FlangesindikumaBelum ada peringkat

- Orbit Parts List and Ordering InstructionsDokumen24 halamanOrbit Parts List and Ordering Instructionskeertiraj09Belum ada peringkat

- SWI Products MetalDokumen21 halamanSWI Products MetalPrasanth PrasadBelum ada peringkat

- Pig Sig IVDokumen7 halamanPig Sig IVsebas_vBelum ada peringkat

- Compression Packing Selection Guide: Sealing Products For IndustryDokumen13 halamanCompression Packing Selection Guide: Sealing Products For IndustryAdverBelum ada peringkat

- Piping Spec C ClassDokumen1 halamanPiping Spec C Classnestor ferrel floresBelum ada peringkat

- Thread o Ring FittingsDokumen4 halamanThread o Ring FittingsLê Đức ThiệnBelum ada peringkat

- Flexitallic FlexproDokumen7 halamanFlexitallic FlexproHeryanto SyamBelum ada peringkat

- Valve Material ApplicationDokumen16 halamanValve Material Applicationswapneel_kulkarniBelum ada peringkat

- Globe Valve PresentationDokumen11 halamanGlobe Valve Presentationmayur22785Belum ada peringkat

- API 682 SealDokumen14 halamanAPI 682 Sealpawan kumar gangwarBelum ada peringkat

- Autodesk Educational Product DocumentDokumen3 halamanAutodesk Educational Product DocumentSyahirul AlimBelum ada peringkat

- Swagelok SAF 2507 Write-Up PDFDokumen14 halamanSwagelok SAF 2507 Write-Up PDFSyahirul AlimBelum ada peringkat

- Swagelok Duplex Ss FittingDokumen8 halamanSwagelok Duplex Ss FittingSyahirul AlimBelum ada peringkat

- Swagelok High Pressure FittingsDokumen8 halamanSwagelok High Pressure FittingsSyahirul AlimBelum ada peringkat

- Swagelok Trunnion Ball ValveDokumen10 halamanSwagelok Trunnion Ball ValveSyahirul AlimBelum ada peringkat

- Swagelok Tubing DataDokumen8 halamanSwagelok Tubing DataSyahirul Alim100% (1)

- Swagelok Duplex Ss FittingDokumen8 halamanSwagelok Duplex Ss FittingSyahirul AlimBelum ada peringkat

- GeneralDokumen50 halamanGeneralSyahirul AlimBelum ada peringkat

- Swagelok Duplex Ss FittingDokumen8 halamanSwagelok Duplex Ss FittingSyahirul AlimBelum ada peringkat

- Swagelok Duplex Ss FittingDokumen8 halamanSwagelok Duplex Ss FittingSyahirul AlimBelum ada peringkat

- Swagelok Manifold PDFDokumen18 halamanSwagelok Manifold PDFSyahirul AlimBelum ada peringkat

- List Training Oil and Gas Di BatamDokumen1 halamanList Training Oil and Gas Di BatamSyahirul AlimBelum ada peringkat

- Kvs PTC Dev CRCMDokumen1 halamanKvs PTC Dev CRCMSyahirul AlimBelum ada peringkat

- Conexoes Aco INOXDokumen56 halamanConexoes Aco INOXCristiano MartinsBelum ada peringkat

- Electrical TrainingDokumen29 halamanElectrical TrainingSyahirul AlimBelum ada peringkat

- Thermolator TW Ugh014 0100Dokumen78 halamanThermolator TW Ugh014 0100daniel menaBelum ada peringkat

- Donaldson AccessoriesDokumen74 halamanDonaldson AccessoriesCentral HydraulicsBelum ada peringkat

- ThreadsDokumen122 halamanThreadsferBelum ada peringkat

- Conectores SwagelotDokumen20 halamanConectores SwagelotecjhonnBelum ada peringkat

- ISV Product Summary SB-300.13 Rev00 - WebDokumen8 halamanISV Product Summary SB-300.13 Rev00 - WebLuis Gustavo HernandezBelum ada peringkat

- Ancla Tubing in Ficha Tecnica-WeatherfordDokumen3 halamanAncla Tubing in Ficha Tecnica-WeatherfordDaniel Eduardo Ramos RicardezBelum ada peringkat

- Self-Opening Die Head Instruction Sheet: WarningDokumen4 halamanSelf-Opening Die Head Instruction Sheet: WarningCesar Carito ValenciaBelum ada peringkat

- Jastram Model H Helm Pumps: Engineered For Life at SeaDokumen2 halamanJastram Model H Helm Pumps: Engineered For Life at SeaingdanilocfBelum ada peringkat

- Cat HY14 3000 Republic, Manatrol - 07 06Dokumen166 halamanCat HY14 3000 Republic, Manatrol - 07 06James PhamBelum ada peringkat

- Product Data Sheet Product Data Sheet B6F Type Ball Valve B6F Type Ball ValveDokumen1 halamanProduct Data Sheet Product Data Sheet B6F Type Ball Valve B6F Type Ball ValveArunBelum ada peringkat

- Water Softner ManualDokumen64 halamanWater Softner ManualreaditpleaseBelum ada peringkat

- Installation: S19314 SeriesDokumen59 halamanInstallation: S19314 SeriesAndrés Juárez SánchezBelum ada peringkat

- How To Specify & Order Class 150 Stainless Steel Threaded Pipe FittingsDokumen15 halamanHow To Specify & Order Class 150 Stainless Steel Threaded Pipe FittingsJoesmoBelum ada peringkat

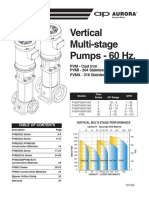

- Vertical Multi-Stage Pumps GuideDokumen12 halamanVertical Multi-Stage Pumps GuideCarol ParedesBelum ada peringkat

- Dac Manntek PDFDokumen32 halamanDac Manntek PDFomernoumanBelum ada peringkat

- BKH Ball Valve For Gas Steel: Available Sizes ConnectionsDokumen3 halamanBKH Ball Valve For Gas Steel: Available Sizes ConnectionstadilakshmikiranBelum ada peringkat

- 2016 Water Works Catalog InteractiveDokumen50 halaman2016 Water Works Catalog InteractiveRizqi PriatnaBelum ada peringkat

- PXLHDokumen10 halamanPXLHEsteban Escobar ValenciaBelum ada peringkat

- Capri ADE 1F2 - Technical Specification and Ordering GuideDokumen6 halamanCapri ADE 1F2 - Technical Specification and Ordering GuideneymarronBelum ada peringkat

- Final MNGL HarshalDokumen96 halamanFinal MNGL Harshalakhil mohanBelum ada peringkat

- Haltec 2018 PDFDokumen59 halamanHaltec 2018 PDFRodney Marin GrlicaBelum ada peringkat

- NPT Pipe - Threads - PDF As Per B1.20.1Dokumen1 halamanNPT Pipe - Threads - PDF As Per B1.20.1sudhirggBelum ada peringkat

- Ansi Y14.6m 1978Dokumen31 halamanAnsi Y14.6m 1978tuanBelum ada peringkat