Minerals System 800xa MInerals Library Flyer 3BHS 206 683 ZAB RevA

Diunggah oleh

anon_253637875Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Minerals System 800xa MInerals Library Flyer 3BHS 206 683 ZAB RevA

Diunggah oleh

anon_253637875Hak Cipta:

Format Tersedia

InformIT System 800xA Minerals Library

Suite of Control Objects for Minerals Processing

What is inside the System 800xA Minerals Library

There are numerous control object categories comprising the

Minerals Library:

Basic objects (AI, DI, AO, DO)

Group objects (sequential group control, cyclic group

control, pre-selections, start warning)

Consumer objects (uni- and bi-directional motor

control, variable speed drive control, damper/

actuator control, valve control)

Intelligent drive control (incl. serial interfaces)

Loop objects (PID control)

Power monitoring objects (intelligent relays)

Dosing objects (weigh feeder control)

Report objects (counters)

Communication objects (for controller to controller

communication)

What is System 800xA Minerals Library

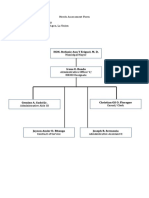

Actual Project

System 800xA Minerals Library is a suite of re-usable control

objects for control applications that have been designed using

ABBs vast experience of three decades in the minerals processing

industry and is fully integrated into the IndustrialIT System 800xA.

Embracing the principles of open, real-time networking, System

800xA with the Minerals Library provides a modern scalable

solution that spans and integrates your loop, unit, area, operation,

and multi operation controls. At the core of the System 800xA is

its industry unique integrated object oriented system environment

for operations, control and engineering.

System 800xA with Minerals Library contains pre-engineered

objects containing control logic, human-machine-interface and

communication for application creation in drag-and-drop manner.

It provides a complete set of operator functions, including realistic

process displays with graphic elements and faceplates, superior

trending capabilities, intelligent alarm and event handling with

remote messaging, reporting, as well as drawings such as wiring

diagrams.

Solution Object Data

Library

Benefits from System 800xA Minerals Library

Economic gain

Enables effective and smooth plant operation and real-time

analysis of events through proven solutions

Maximizes performance of your assets through reduced time

to repair through optimized work processes and reduction of

unnecessary maintenance and down-time

Lowers engineering, commissioning and administration costs

Compliance

Compliant with the IEC 61131-3 standard

Provides a platform to enable the enterprise to reach their

environmental, production and quality goals and standards

Delivers reliable, consistent and complete information geared

for the minerals processing industry through industry specific

graphic displays

Top quality at peak rates

Efficient real-time operation and control providing the foun dation for continuous improvement through easy navigation

and alarm/event management

Consistently delivering information to trained personnel to

allow informed decision making for maximizing the production rate

Gear-up with experience

Take advantage of ABB vast minerals processing experience

in providing enhanced industry specific solutions for over 30

years

Predefined, rich in process knowledge solutions provide

predictable results, due to adoption of proven industry best

practices

Higher employee productivity

Contextual navigation based on the users job function and

the task at hand allow real-time decision making and action

Fast and informed decision support through enhanced aspect

integration and object orientation

Fast, reliable and efficient operation due to predefined and

pretested functions, optimized system resources and excellent

library software performance

ABB Switzerland Ltd

Phone: +41 (58) 586 84 44, Fax: +41 (58) 586 73 33

E-mail: process.industries@ch.abb.com

www.abb.com/minerals

3BHS 206 683 ZAB REV A (10.06 500 Pomcanys)

Engineering and Commissioning Efficiency

Fully integrated engineering environment for development,

re-use of intellectual assets and streamlined engineering

workflow throughout the lifecycle

Shorter commissioning times across numerous operations

through reduced testing and validation with scalable, reusable

solutions and best practices

Eliminates the need for manual data input and validation by

automated incorporation of customer and I/O data

Provides modularization and system wide, single point

change management with revision control

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Starbucks Delivering Customer Service Case Solution PDFDokumen2 halamanStarbucks Delivering Customer Service Case Solution PDFRavia SharmaBelum ada peringkat

- Cover LetterDokumen2 halamanCover LetterSasi Gangadhar BBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- How To Post Bail For Your Temporary Liberty?Dokumen5 halamanHow To Post Bail For Your Temporary Liberty?Ruel Benjamin Bernaldez100% (1)

- Why CPVC Pipes FailDokumen12 halamanWhy CPVC Pipes FailNikita Kadam100% (1)

- Top Notch 1, 3° Edicion Workbook Answer KeyDokumen14 halamanTop Notch 1, 3° Edicion Workbook Answer KeyLuis Lopez90% (61)

- Color Management Handbook Vol2Dokumen28 halamanColor Management Handbook Vol2ianjpr100% (2)

- Strategic PlanningDokumen24 halamanStrategic PlanningSara Sharma0% (1)

- Account Statement From 27 Dec 2017 To 27 Jun 2018Dokumen4 halamanAccount Statement From 27 Dec 2017 To 27 Jun 2018mrcopy xeroxBelum ada peringkat

- Unit 13 Developing, Using, and Organizing Resources in A Specialist AreaDokumen21 halamanUnit 13 Developing, Using, and Organizing Resources in A Specialist AreaKan SonBelum ada peringkat

- Digit Sep 09Dokumen107 halamanDigit Sep 09dukerexBelum ada peringkat

- 3-Module 3-23-Feb-2021Material I 23-Feb-2021 Error Detection and CorrectionDokumen39 halaman3-Module 3-23-Feb-2021Material I 23-Feb-2021 Error Detection and CorrectionPIYUSH RAJ GUPTA 19BCE2087Belum ada peringkat

- Needs Assessment Form Company Name: HRMO Address: Sta. Barbara Agoo, La UnionDokumen2 halamanNeeds Assessment Form Company Name: HRMO Address: Sta. Barbara Agoo, La UnionAlvin LaroyaBelum ada peringkat

- A Case Study On Mahindra's Blue Sense Application Project by RohitDokumen43 halamanA Case Study On Mahindra's Blue Sense Application Project by RohitrohitBelum ada peringkat

- Appendix 24 - QUARTERLY REPORT OF REVENUE AND OTHER RECEIPTSDokumen1 halamanAppendix 24 - QUARTERLY REPORT OF REVENUE AND OTHER RECEIPTSPau PerezBelum ada peringkat

- Đo Nhiệt Độ LI-24ALW-SelectDokumen4 halamanĐo Nhiệt Độ LI-24ALW-SelectThang NguyenBelum ada peringkat

- Ticket - Abibus PDFDokumen1 halamanTicket - Abibus PDFJosephBelum ada peringkat

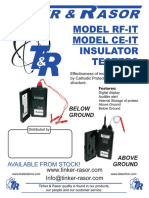

- R R O S A: Model Rf-It Model Ce-It Insulator TestersDokumen2 halamanR R O S A: Model Rf-It Model Ce-It Insulator Testersvictor raul sandoval martinezBelum ada peringkat

- Sharp AR-C172M ServiceM EN PDFDokumen308 halamanSharp AR-C172M ServiceM EN PDFpiaggio_nrgBelum ada peringkat

- Incorporation of Industrial Wastes As Raw Materials in Brick's Formulation (Wiemes-Brasil-2016)Dokumen9 halamanIncorporation of Industrial Wastes As Raw Materials in Brick's Formulation (Wiemes-Brasil-2016)juan diazBelum ada peringkat

- One For All Urc-8350 Instruction Manual PDF DownloadDokumen5 halamanOne For All Urc-8350 Instruction Manual PDF DownloademinaBelum ada peringkat

- Official Journal 14092012 Part IDokumen366 halamanOfficial Journal 14092012 Part Ivenkatesh_1829Belum ada peringkat

- Project Execution and Control: Lunar International College July, 2021Dokumen35 halamanProject Execution and Control: Lunar International College July, 2021getahun tesfayeBelum ada peringkat

- Difference Between Distinct and Group byDokumen1 halamanDifference Between Distinct and Group byPavelStrelkovBelum ada peringkat

- Final - Far Capital - Infopack Diana V3 PDFDokumen79 halamanFinal - Far Capital - Infopack Diana V3 PDFjoekaledaBelum ada peringkat

- Calculation of Work IndexDokumen5 halamanCalculation of Work IndexEnryan Oreski RiyadiBelum ada peringkat

- Device Protocol - v2.2.4Dokumen81 halamanDevice Protocol - v2.2.4Aston MartinBelum ada peringkat

- Oil & Grease CatalogDokumen4 halamanOil & Grease Catalogmanoj983@gmail.comBelum ada peringkat

- Pas 16 - Property Plant and EquipmentDokumen4 halamanPas 16 - Property Plant and EquipmentJessie ForpublicuseBelum ada peringkat

- IT 118 - SIA - Module 1Dokumen9 halamanIT 118 - SIA - Module 1Kim Zyrene DominoBelum ada peringkat