XX X XXXX XX XXXX 1rev XX Tank Farm Sleeper Design

Diunggah oleh

g4goharDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

XX X XXXX XX XXXX 1rev XX Tank Farm Sleeper Design

Diunggah oleh

g4goharHak Cipta:

Format Tersedia

Contractor name

Contractor Logo

CLIENT

PROJECT MANAGER

Project title

SLEEPER DESIGN

INSIDE TANK FARM

DOCUMENT

DESCRIPTION:

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

Prepared

Checked

Reviewed

Approved

Revised as marked

Issued for construction

B

A

Revised as marked.

Issued for Clients Approval.

Rev.

Date

Revision Description

DOCUMENT NUMBER

Type

Discp

Job

SJ

Seq

Format

A4

PAGES

OF

44

Client Logo

SLEEPER

DESIGN

INSIDE TANK

FARM

Job No:

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

Record of Revisions

Rev

Date

Revision Description

Issued for Clients Approval.

Revised by changing embedded beam to anchor lugs for sleepers.

Issued for Construction.

Clients comments incorporated and revised as marked.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 2 of 44

Client Logo

SLEEPER

DESIGN

INSIDE TANK

FARM

Job No:

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

TABLE OF CONTENTS

Sr.

Description

No.

Page No.

1.

Introduction

2.

Scope

3.

Design considerations

4.

Design of Steel beam and column.

5.

Design of foundation

32

6.

Annexure

Annexure 1- TANK FARM-6 SLEEPER LOADING DATA

40

Annexure 2- TANK FARM-7 SLEEPER LOADING DATA

41

Annexure 3- Beam flange bending check.

42

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 3 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

1. Introduction:

This document is produced to cover the design calculations of sleepers.

2. Scope:

This document presents design calculations of sleepers inside tank farm.

3. Design considerations:

a) Seismic load: Seismic load on the sleeper as per Design basis.

Seismic load combination and load factor.

While using UBC force for BS8110 combination shall be divided by 1.4 hence

Ve= 0.1/1.4 W = 0.0714 W.

BS code and Clients design criteria is silent on load combination of thermal (friction force on

Pipe rack and sleepers so reference is made to shell DEP refer next page.

Thermal effects shall be taken along with Seismic and wind loads.

Entire Pipe loading and thermal effects are considered as Imposed load (live load) and factor

of 1.6 is applied in operational condition. So load combination in operation condition is,

= (1.4) x Dead load + (1.6) x Pipe vertical load + (1.6) x Pipe lateral load.

= (1.4) x Dead load + (1.6) x Pipe vertical load + (0.15 x1.6) x vertical load*.

= (1.4) x Dead load + (1.6) x Pipe vertical load + (0.24) x vertical load*...a

Seismic load combination.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 4 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

= (1.2) x Dead load + (1.2) x Pipe vertical load + (1.2) x Pipe lateral load + (1.2) x Seismic load.

= (1.2) x Dead load + (1.2) x Pipe vertical load + (1.2 x 0.15) x Pipe vertical load* + (1.2 x 0.0714) x Pipe vertical

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 5 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

Load*.

= (1.2) x Dead load + (1.2) x Pipe vertical load + (0.18) x Pipe vertical load* + (0.0857) x Pipe vertical load*.

= (1.2) x Dead load + (1.2) x Pipe vertical load + (0.18 + 0.0857) x Pipe vertical load*.

= (1.2) x Dead load + (1.2) x Pipe vertical load + (0.266) x Pipe vertical load*..a

Comparing combination a and b, the operating load combination with load factor 1.6 found

more stringent so design of components are done with uniform factor of 1.6.

Although the thermal forces are not to be transferred to foundation, the foundation stability

and soil pressures are checked for forces with factor of 1.0. In this case, load component of

friction (0.15) is higher that the seismic (0.0714) so conservatively foundation are checked for

friction force of (0.15) vertical load to account for lower seismic force.

b) Wind load:

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 6 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

Refer BS 6399 Part -2,

Wind load on pipe sleeper having width more than 4m and pipes of 32 maximum,

Wind Load on 4 pipes = 1.2 x 4 x (32 x 0.0254) x 0.971 = 3.8 kN/m

Pipe operating weight is as follows,

Seismic load for pipes more than 4 Nos. is = 7.26 x 5 x 0.0714 = 2.6 < 3.8 kN/m is less severe than

seismic load so seismic load is governing load case over wind and wind load is neglected.

Also 1.4 DL + 1.6 LL + 1.6 LL (lateral); for superstructure design,

Is severe than 1.2 DL + 1.2 LL + 1.2 LL (lateral) + 1.2 Seismic; for superstructure design, as 1.2 x

0.0714 =0.086 W < (1.6 -1.2). For local anchors, seismic lateral force the load factor of LL (lateral)

(1.6-1.2=0.4) over 0.0714 x 1.2 seismic is governing. So stringent combination of 1.6 factor for

component design is followed for simplicity in calculations.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 7 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

4. Design of Steel beam and column.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 8 of 44

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

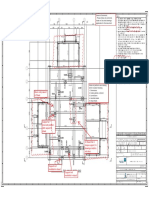

Notes: (refer table on next page)

1. Stool height varies from 100mm to 250mm as the pipes are provided at slope of 1:1000.

2. For each sleeper located 6m apart the level difference is 6mm, towards manifold.

3. Stools are shown indicative and height is worked out based on piping information i.e. drawing

number ---------and ---------------. The stools will be provided by piping group.

4. The total height for working out moment at foundation base level is = depth of foundation

below ground + height of steel beam top above FGL + stool height + half of pipe diameter.

5. Maximum size of pipe is considered for working out the moment in each sleeper in the above

expression.

6. Orientation of sleeper in table is 1 when the sleeper is along North-South and 0 when it is

Along East-West.

7. Two groups are identified in sleeper for further design, up-to lateral load of 31kN and 32kN to

63 kN.

8. Sleeper SL-053 is located on middle of culvert so only superstructure design is applicable.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 9 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 10 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 11 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

SL-053 RESTING ON PIPE CULVERT- FOUNDATION IS DESIGNED WITH PIPE CULVERT

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 12 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

Beam stress check: (detailed calculation done for SL-117A and all other sleeper tabulated in table).

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 13 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 14 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 15 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 16 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

SLEEPER

DESIGN

INSIDE TANK

FARM

Job No:

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

Factored forces on beam for anchor bolt design:

SL-117A Anchor design:

Resultant shear force = 1002+11.8

- 78.68 x (where co-eff of friction between steel

and concrete (ACI 318 Design guide).

=53.48 kN (to be used for anchor bar design)

Vertical force P= 78.68kN and moment M =18.8 kN-m (for base plate and anchor pullout

design), (minimum vertical load and max. moment is more stringent combination so adopted)

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 17 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 18 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 19 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

SLEEPER

DESIGN

INSIDE TANK

FARM

Job No:

Doc.

Contractor Logo

Contractor Name

Revision :

1

Tensile force on Anchor P= 74.9 kN = 16.83 kips.

Shear force on Anchor S= 53.48 kN = 12.02 kips.

Supplimentry reinforcement for tension:

Ast = Pu/0.9 x Fy = 74.9 x 1000 / (0.9 x 460 ) = 180mm2 .

Top 4-Nos T12 bars having area of 452mm2

Supplimentry reinforcement for shear:

Ast = Su/0.9 x Fy = 53.48 x 1000 / (0.9 x 460 ) = 129 mm2 .

Top 4-Nos T8 bars having area of 200mm2

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 20 of 44

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 21 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

SLEEPER

DESIGN

INSIDE TANK

FARM

Job No:

Contractor Logo

Contractor Name

Revision :

1

Doc.

Date:

All other sleeper anchor design. (SL-0116)

Maximum moment and corresponding axial load is considered.

Shear force is considered maximum of both tank farms.

Resultant shear force = 54.462+27.72 - 92.35 x

(where co-eff of friction between steel

and concrete. =5.69 kN (to be used for anchor bar design).

Vertical force P= 72.62kN and moment M =10.23 kN-m (for base plate and anchor pullout

design), (minimum vertical load and max. moment is more stringent combination so adopted).

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 22 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 23 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 24 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

SLEEPER

DESIGN

INSIDE TANK

FARM

Job No:

Doc.

Supplimentry reinforcement for tension:

Ast = Pu/0.9 x Fy = 32.44 x 1000 / (0.9 x 460 ) = 78.4mm2 .

Top 4-Nos T12 bars having area of 452mm2

Supplimentry reinforcement for shear:

Ast = Su/0.9 x Fy = 5.7 x 1000 / (0.9 x 460 ) = 13.8 mm2 .

Top 4-Nos T8 bars having area of 200mm2

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 25 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 26 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 27 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 28 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

SLEEPER

DESIGN

INSIDE TANK

FARM

Job No:

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

Beam Flange and web check for local bending/Bucking load:

Maximum load from page No of 37 of this document is 139kN/m and stiffners are provided at

750mm c/c. Weight of 8m long pipe filled with product of density is worked out on next page

and beam is checked for the same.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 29 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

With load factor of 1.6, shear force is

132.8 kN.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 30 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 31 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

5. Design of foundation

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 32 of 44

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 33 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 34 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

Moment due to eccentricity = Fy x e = 37.5 x 0.5 = 18.75 kNm (for SL019B)

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 35 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

Note

-1

Note

-2

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 36 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Note

-2

Contractor Logo

Contractor Name

Revision :

1

Date:

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 37 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

Note

-1

Notes:1) Note-1: sleeper shifted on pipe culvert, Note 2: Sleeper deleted.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 38 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 39 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

Annexure 1- TANK FARM-6 SLEEPER LOADING DATA

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 40 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

Annexure 2- TANK FARM-7 SLEEPER LOADING DATA

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 41 of 44

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

Annexure 3- Beam flange bending check.

C/c distances of biggest pipes (32) are 1000mm for TF6 and TF7 respectively as shown.

Shoe support as per PDMS snapshot.

Beam size 203 x 133 x 25.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 42 of 44

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 43 of 44

Contractor Logo

Contractor Name

Revision :

1

Date:

Client Logo

Job No:

SLEEPER

DESIGN

INSIDE TANK

FARM

Doc.

Contractor Logo

Contractor Name

Revision :

1

Date:

Notes:

1. As the pipe is very stiff it is not possible that it will bend with respect to beam flange and bear on the

corner of flange. Due to any other reason it bears then it will get self adjusted by a small deflection.

2. Beam is considered as rigidly held between support point (anchor bolts) but which is not a real case It

will follow a small rotation (twisting) along with stool bottom surface to bring in one level.

XX-X-XXXX-XX-XXXX-1Rev xx-Tank-farm Sleeper design.doc

Page 44 of 44

Anda mungkin juga menyukai

- Review Vessel Drawings Foundation Loads DesignDokumen5 halamanReview Vessel Drawings Foundation Loads DesignarnoldistunoBelum ada peringkat

- Offsite Pipe Rack FinalDokumen10 halamanOffsite Pipe Rack Finalhalder.kalyanBelum ada peringkat

- Foundation Design and Oil Containment for EquipmentDokumen21 halamanFoundation Design and Oil Containment for Equipmentjakeer7100% (1)

- Foundation Design Philosophy For Bullet VesselsDokumen5 halamanFoundation Design Philosophy For Bullet Vesselsdicktracy11Belum ada peringkat

- WeldDokumen43 halamanWeldAuggie AranzadoBelum ada peringkat

- DS For FW TankDokumen9 halamanDS For FW TankAbhay Kumar0% (1)

- Hfy-3800-0000-Civ-db-0001 - 1 Civil, Structural and Architectural Design Basis Code ADokumen69 halamanHfy-3800-0000-Civ-db-0001 - 1 Civil, Structural and Architectural Design Basis Code ANashaat DhyaaBelum ada peringkat

- GLACIER LAr Tank Design (Deliverable 2.2)Dokumen76 halamanGLACIER LAr Tank Design (Deliverable 2.2)atiqulaBelum ada peringkat

- Sample Design Calculations For Block Found. For Vib. Equip.Dokumen17 halamanSample Design Calculations For Block Found. For Vib. Equip.Adam Michael GreenBelum ada peringkat

- Qap-15-23 - rg1700 01 Rev-5 Design Criteria For Concrete Foundations and StructuresDokumen23 halamanQap-15-23 - rg1700 01 Rev-5 Design Criteria For Concrete Foundations and StructuresAnonymous uLAATWpfBelum ada peringkat

- Calculation Note For Control Building - Rev A1Dokumen83 halamanCalculation Note For Control Building - Rev A1maniaxpdfBelum ada peringkat

- Raft FoundationDokumen2 halamanRaft Foundation_jesseca100% (1)

- Calculation Report For New Substation Building C0148.64-2.41-680-B-EDokumen361 halamanCalculation Report For New Substation Building C0148.64-2.41-680-B-EkarthiBelum ada peringkat

- CLB FC 0X Se Rep 0096 - C1Dokumen193 halamanCLB FC 0X Se Rep 0096 - C1jeddijBelum ada peringkat

- Cenpes: Index of Revisions REV Description And/Or Revised Sheets 0 Original A General RevisionDokumen27 halamanCenpes: Index of Revisions REV Description And/Or Revised Sheets 0 Original A General RevisionArildo Chaves de AndradeBelum ada peringkat

- Vertical Equation Foundation-Spread Sheet PDFDokumen6 halamanVertical Equation Foundation-Spread Sheet PDFmassive85Belum ada peringkat

- Civil Works MtoDokumen28 halamanCivil Works MtoNassim SabriBelum ada peringkat

- Calculation For Operating Platform-043-Plf-31004: Tangguh Expansion - Project ExecuteDokumen112 halamanCalculation For Operating Platform-043-Plf-31004: Tangguh Expansion - Project ExecuteRiesang Wirawan Probogumilang100% (2)

- 3 Major Design Philosophies - Working Stress, Ultimate Load and Limit State - CivilDigitalDokumen6 halaman3 Major Design Philosophies - Working Stress, Ultimate Load and Limit State - CivilDigitalStacy JohnsonBelum ada peringkat

- BPCL PuneDokumen9 halamanBPCL PuneDeependra SinghBelum ada peringkat

- Lngj-Bywg-Civ-Cal-015 Me - LNG Storage - BywgDokumen56 halamanLngj-Bywg-Civ-Cal-015 Me - LNG Storage - BywgHamidAffandy100% (1)

- Brackets & ConnectionsDokumen3 halamanBrackets & ConnectionsKory EstesBelum ada peringkat

- Design of Three Story Warehouse StructureDokumen25 halamanDesign of Three Story Warehouse StructureKajal SutharBelum ada peringkat

- 6.5 Design of Precast Protection Slab 6.5.1 Materials: Job: Made by Sheet No. Total Sh. Set No. Date Rev. No. Job NoDokumen47 halaman6.5 Design of Precast Protection Slab 6.5.1 Materials: Job: Made by Sheet No. Total Sh. Set No. Date Rev. No. Job NobalaramBelum ada peringkat

- BLA-FTP-C-CC-00-012-Rev.0B Calculation of Miscellaneous Pipe Support at AR Cluster PDFDokumen232 halamanBLA-FTP-C-CC-00-012-Rev.0B Calculation of Miscellaneous Pipe Support at AR Cluster PDFAndreas SchlagerBelum ada peringkat

- COP-WFP-CHK-03-2013-v1 Civil Foundations and Pile CapsDokumen4 halamanCOP-WFP-CHK-03-2013-v1 Civil Foundations and Pile CapsMario OvejeroBelum ada peringkat

- Calculation Sheet Pipe SupportDokumen33 halamanCalculation Sheet Pipe SupportKhamal Rachmanda AdamBelum ada peringkat

- 3814-AI-SG-000001-Is04 General Specification For Steel WorksDokumen19 halaman3814-AI-SG-000001-Is04 General Specification For Steel Worksgchaves504100% (1)

- Pump Shelter Steel Structure Design Calculation FEM MethodDokumen79 halamanPump Shelter Steel Structure Design Calculation FEM Methodcharleshutabara951Belum ada peringkat

- Steel Structure Design Report for Loading Station ShelterDokumen35 halamanSteel Structure Design Report for Loading Station ShelterAkram FerchichiBelum ada peringkat

- Stacks and Tanks WInd LoadDokumen2 halamanStacks and Tanks WInd LoaddantevariasBelum ada peringkat

- Erc - Valve Pit CalculationDokumen30 halamanErc - Valve Pit Calculationisaacjoe77Belum ada peringkat

- Technical Specifications For Earthworks, Geosynthetics Rev.CDokumen121 halamanTechnical Specifications For Earthworks, Geosynthetics Rev.Cvisnupada100% (1)

- 00 UEG C 51 301 001 (Rev.X0)Dokumen28 halaman00 UEG C 51 301 001 (Rev.X0)Amr AbdeinBelum ada peringkat

- FTG F1 Concrete Calculations Spreadsheet Data AnalysisDokumen7 halamanFTG F1 Concrete Calculations Spreadsheet Data AnalysisRené Mella CidBelum ada peringkat

- Client Comment Response - DG FoundationDokumen7 halamanClient Comment Response - DG FoundationAnnelzBelum ada peringkat

- SP 1275 Rev 02 Spec and Criteria For Design of Civil Building Works Update 03 96Dokumen200 halamanSP 1275 Rev 02 Spec and Criteria For Design of Civil Building Works Update 03 96santhosh kumar BudiBelum ada peringkat

- Design Specification for Civil and Structural WorksDokumen49 halamanDesign Specification for Civil and Structural WorksAdhitiya Rizki Pratama100% (1)

- (WWW - Indowebster.com) - Microsoft Word - TUGAS AKHIR LIFTINGDokumen36 halaman(WWW - Indowebster.com) - Microsoft Word - TUGAS AKHIR LIFTINGsholehamikBelum ada peringkat

- Inquiry For Package 2. EPC Building WorksDokumen46 halamanInquiry For Package 2. EPC Building WorksDonny B TampubolonBelum ada peringkat

- Sacs Training - Jacket LegDokumen2 halamanSacs Training - Jacket LegThis ManBelum ada peringkat

- Design Plan 1 - CSDokumen5 halamanDesign Plan 1 - CScashloverBelum ada peringkat

- Sand Cushion: 1. IntroductionDokumen2 halamanSand Cushion: 1. Introductionlokesh nandinaBelum ada peringkat

- Technodyne International Limited: Refrigerated Project ListDokumen3 halamanTechnodyne International Limited: Refrigerated Project ListSir AlaaBelum ada peringkat

- Col Eff Lenth & Slenderness EffectDokumen3 halamanCol Eff Lenth & Slenderness EffectAnonymous Of0C4dBelum ada peringkat

- Mathcad C 8220Dokumen29 halamanMathcad C 8220Landon MitchellBelum ada peringkat

- STEEL CONNECTION DESIGN BASISDokumen5 halamanSTEEL CONNECTION DESIGN BASISvijaystructuralBelum ada peringkat

- Tank Foundation Load CombinationsDokumen43 halamanTank Foundation Load CombinationsVivek Manohar PatilBelum ada peringkat

- Storage Tank Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignDokumen39 halamanStorage Tank Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignAlexander100% (1)

- Circular Footing Design Based On ACI 318-14: Input Data & Design SummaryDokumen3 halamanCircular Footing Design Based On ACI 318-14: Input Data & Design SummaryinnovativekarthiBelum ada peringkat

- SP 10 16Dokumen7 halamanSP 10 16Ak OraBelum ada peringkat

- Guide Document For Itemized Spring Hangers and Tie-Rod Data SheetsDokumen19 halamanGuide Document For Itemized Spring Hangers and Tie-Rod Data SheetsAHMED AMIRABelum ada peringkat

- Pump FoundationDokumen4 halamanPump FoundationbabuBelum ada peringkat

- Sleeper DesignDokumen4 halamanSleeper DesignriccecriBelum ada peringkat

- Calculation 240 (Rev02)Dokumen15 halamanCalculation 240 (Rev02)KM YapBelum ada peringkat

- Combined Foundation Design PDFDokumen8 halamanCombined Foundation Design PDFkvamshi_1971Belum ada peringkat

- Petrofac Spreadsheet ValidationDokumen33 halamanPetrofac Spreadsheet ValidationALBERTBelum ada peringkat

- 1.1 Design of Pipe Racks Writeup PDFDokumen5 halaman1.1 Design of Pipe Racks Writeup PDFCarlosAlbertoGrimaldoBarajasBelum ada peringkat

- Manifold XX RCC Pit DesignDokumen135 halamanManifold XX RCC Pit Designg4goharBelum ada peringkat

- XX X XXXX XX XXXX REV XX Civil Structural Design BasisDokumen75 halamanXX X XXXX XX XXXX REV XX Civil Structural Design Basisg4goharBelum ada peringkat

- Annuli Riser 17dec2018Dokumen3 halamanAnnuli Riser 17dec2018g4gohar50% (2)

- This Spool Is Removed and Flnage Directly Welded With WeldoletDokumen7 halamanThis Spool Is Removed and Flnage Directly Welded With Weldoletg4goharBelum ada peringkat

- Informal Upright Style Bonsai: Notes I. ObjectivesDokumen5 halamanInformal Upright Style Bonsai: Notes I. Objectivesg4goharBelum ada peringkat

- Project Description of LPG PlantDokumen8 halamanProject Description of LPG PlantEnoch TwumasiBelum ada peringkat

- 1Dokumen21 halaman1g4goharBelum ada peringkat

- Calculation For The Weight of Steel in KG/FT When The Length of Bar Is 1ftDokumen4 halamanCalculation For The Weight of Steel in KG/FT When The Length of Bar Is 1ftg4goharBelum ada peringkat

- Formal Upright Bonsai StyleDokumen7 halamanFormal Upright Bonsai Styleg4goharBelum ada peringkat

- TS20 ShortCutsDokumen1 halamanTS20 ShortCutsBalaji SubramanianBelum ada peringkat

- Bill of Material Mark No QTY Size WT - KG Length (M) MaterialDokumen3 halamanBill of Material Mark No QTY Size WT - KG Length (M) Materialg4goharBelum ada peringkat

- 10 CHDokumen14 halaman10 CHg4goharBelum ada peringkat

- Beam-To-Beam Joints With Bolted End-Plate Connections Concerning Steel Platforms Angra 2 NPPDokumen10 halamanBeam-To-Beam Joints With Bolted End-Plate Connections Concerning Steel Platforms Angra 2 NPPihpeterBelum ada peringkat

- Formal Upright Bonsai StyleDokumen7 halamanFormal Upright Bonsai Styleg4goharBelum ada peringkat

- Design of Transformer Foundation Transformer Detail: Ref DRG NoDokumen16 halamanDesign of Transformer Foundation Transformer Detail: Ref DRG Nottbharat67% (3)

- Design of Transformer Foundation Transformer Detail: Ref DRG NoDokumen16 halamanDesign of Transformer Foundation Transformer Detail: Ref DRG Nottbharat67% (3)

- Modification of Inertia For SectionsDokumen1 halamanModification of Inertia For Sectionsg4goharBelum ada peringkat

- Pad Foundation DesignDokumen4 halamanPad Foundation Designg4goharBelum ada peringkat

- InertiaDokumen3 halamanInertiag4goharBelum ada peringkat

- 1mht. 800-T-029 TANK R3Dokumen6 halaman1mht. 800-T-029 TANK R3g4goharBelum ada peringkat

- Mass Calculation for Beam Cross SectionDokumen3 halamanMass Calculation for Beam Cross Sectiong4goharBelum ada peringkat

- Design HakeemDokumen3 halamanDesign Hakeemg4goharBelum ada peringkat

- Footings and FoundationsDokumen13 halamanFootings and Foundationsg4goharBelum ada peringkat

- 2 Years Diploma in Ophthalmic TechnicianDokumen2 halaman2 Years Diploma in Ophthalmic Techniciang4gohar100% (1)

- Notes 2 For ENGI3731Dokumen52 halamanNotes 2 For ENGI3731selflearning24Belum ada peringkat

- Tax Collector Correspondence3520141927613 PDFDokumen2 halamanTax Collector Correspondence3520141927613 PDFg4goharBelum ada peringkat

- 2.4 Design Parameters: Technical Reference ManualDokumen3 halaman2.4 Design Parameters: Technical Reference ManualArifinBelum ada peringkat

- Typrical Piping TCCIDokumen18 halamanTyprical Piping TCCIsaminasritnBelum ada peringkat

- East Hampton High School Design Phases GuideDokumen12 halamanEast Hampton High School Design Phases Guideg4goharBelum ada peringkat

- C13 Organic ChemistryDokumen37 halamanC13 Organic ChemistryAnonymous veG2gNOdRMBelum ada peringkat

- TycoDokumen69 halamanTycog4goharBelum ada peringkat

- 2.4first Angle Projection PDFDokumen6 halaman2.4first Angle Projection PDFg4goharBelum ada peringkat

- PV Elite (Construccion de Recipiente) MDMTDokumen8 halamanPV Elite (Construccion de Recipiente) MDMTAlejandro CanoBelum ada peringkat

- Hitachi Sumitomo Scx1500 2 Hydraulic Crawler Crane SpecificationsDokumen2 halamanHitachi Sumitomo Scx1500 2 Hydraulic Crawler Crane Specificationsmargeret100% (50)

- Real Time Automatic Helmet Detection of Bike Riders PDFDokumen3 halamanReal Time Automatic Helmet Detection of Bike Riders PDFShubhBelum ada peringkat

- Engineering Mechanics Tutorial Question BankDokumen13 halamanEngineering Mechanics Tutorial Question Bankrajeev_kumar365Belum ada peringkat

- GBU Profile 12 PDFDokumen5 halamanGBU Profile 12 PDFsurabhidivyaBelum ada peringkat

- FANUC Robot R-2000iB SeriesDokumen4 halamanFANUC Robot R-2000iB SeriesChandan KanuBelum ada peringkat

- GSM Channels LogicalDokumen8 halamanGSM Channels LogicalbeetelnutsBelum ada peringkat

- Phoenix Contact 3247055 enDokumen6 halamanPhoenix Contact 3247055 enDGBelum ada peringkat

- PTH Crusher GBDokumen16 halamanPTH Crusher GBElvis Eberth Huanca MachacaBelum ada peringkat

- Manual Akaso V50 XDokumen44 halamanManual Akaso V50 XLucas T. CavalcantiBelum ada peringkat

- DP TV Aver 15022 DriversDokumen94 halamanDP TV Aver 15022 DriversMohammed Tahver Farooqi QuadriBelum ada peringkat

- HSP Power Point PresentationDokumen10 halamanHSP Power Point PresentationocintezaBelum ada peringkat

- Environmental Tech.Dokumen31 halamanEnvironmental Tech.csyena28225Belum ada peringkat

- ASTMDokumen4 halamanASTMSupriyo PBelum ada peringkat

- Kali Linux For BeginnersDokumen13 halamanKali Linux For Beginnersnihal0% (1)

- Francis Turbines PDFDokumen12 halamanFrancis Turbines PDFabbas bilal100% (1)

- Sunscreen FabricDokumen36 halamanSunscreen Fabricfakhrurr44Belum ada peringkat

- CV Software Engineer Sarika DhingraDokumen2 halamanCV Software Engineer Sarika DhingravirenderbishnoiBelum ada peringkat

- Amerlock 400CDokumen5 halamanAmerlock 400CbalangceBelum ada peringkat

- Reading 03 - Iron Lady The Eiffel TowerDokumen2 halamanReading 03 - Iron Lady The Eiffel TowerFernando Elías Valderrama GómezBelum ada peringkat

- Thomson VTH 7090 VCR ManualDokumen33 halamanThomson VTH 7090 VCR ManualTrickyDicky2Belum ada peringkat

- Load Case CombinationsDokumen5 halamanLoad Case CombinationsFrancisco UgarteBelum ada peringkat

- Wacker Silres Ren - 60 - Silicone Resin Solution For Medium Solids or High Solids Heat ResistancDokumen3 halamanWacker Silres Ren - 60 - Silicone Resin Solution For Medium Solids or High Solids Heat ResistancJameel AhsanBelum ada peringkat

- Well Control - Fundamental - W2 - Well Control PrincipleDokumen17 halamanWell Control - Fundamental - W2 - Well Control PrincipleGilbert SunaryoBelum ada peringkat

- J320 Maintenance Spare Parts ListDokumen1 halamanJ320 Maintenance Spare Parts ListKeith ChengBelum ada peringkat

- Ganz Hydro-Power: Over 150 Years of ExperienceDokumen1 halamanGanz Hydro-Power: Over 150 Years of ExperiencepalanaruvaBelum ada peringkat

- Cisco Expressway IP Port Usage For Firewall Traversal Deployment Guide X12 5Dokumen60 halamanCisco Expressway IP Port Usage For Firewall Traversal Deployment Guide X12 5JodieBelum ada peringkat

- Haffmans DPT: Dew Point TesterDokumen2 halamanHaffmans DPT: Dew Point TesterLaura Elianne QuirogaBelum ada peringkat

- Improved M16A2 - A3 - A4 Zero TargetDokumen6 halamanImproved M16A2 - A3 - A4 Zero Targetbeetho1990Belum ada peringkat

- Wall Climbing Surveillance Robot ReportDokumen79 halamanWall Climbing Surveillance Robot Reportneha gupta100% (3)