Fabrication Workshop Project Report

Diunggah oleh

Burhaan TaskeenDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Fabrication Workshop Project Report

Diunggah oleh

Burhaan TaskeenHak Cipta:

Format Tersedia

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

TECHNOLOGIES

Technical

Know-how - A Gateway to Prosperity

A PROJECT REPORT

ON

FABRICATION WORKSHP FOR

SPECIALIZED JOB WORKS

AT VISAKHAPATNAM

Prepared By

S.A. AZAD

B.Sc. Tech ( Chem Tech ) , DFM, DNIIT

Ex. Sr. Manager HPCL ( Project Planning)

For

Mr Christopher J. Titus, Calicut

Phone : 0091 495 3272228, Cell - 09349881286

________________________________________________________________________

Research Centre: Hira Nagar, Akola Road, Khamgaon ( M.S.) 444303-India

Phone / Fax : 91-7263 259052

Email : sales@absoluteprojectreports.net

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

1

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

A PROJECT REPORT

ON

FABRICATION WORKSHP FOR

SPECIALIZED JOB WORKS

AT VISAKHAPATNAM

Disclaimer :

All efforts have been made for reasonable accuracy of information

presented in the following report. However, it is clarified that all the

information is based on the desk research and not the field research.

Therefore we disclaim any responsibility for and consequences, financial or

otherwise which may result of the owner action based on the information

contained in this report. If, the owner feels that he can pursue the project

further on the basis of this desk research, it is strongly recommended that,

the owner commission us for a Detailed Techno-Commercial Feasibility &

Detailed Engg. Report which will include a comprehensive field research,

market projections and the details of designing, engineering and cost

estimation to enable the owner to decide investment decision-making and

bigger financial commitments. The owner may please email, fax or write to

us for such a consultancy work and a Price _ Quotation to undertake such

an assignment.

Date : Sept. 14, 2009

Place : Absolute Technologies Research Center,

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

2

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

Khamgaon 444 303 ( M.S.) India

A PROJECT REPORT

ON

FABRICATION WORKSHP FOR

SPECIALIZED JOB WORKS

AT VISAKHAPATNAM

INDEX

CHAPTER

PAGE NO.

1.0 INTRODUCTION

2.0 TECHNICAL & SAFETY ASPECTS

3.0 WORKSHOP FACILITIES

31

4.0 COST ESTIMATE

33

5.0 FINANCIAL ANALYSIS

37

6.0 HOW TO SET UP AN ENTERPRISE

39

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

3

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

1.0 INTRODUCTION

1.1. BACKGROUND :

Visakhapatnam in Andhra Pradesh is a mega industrial city on the

Indian Eastern Coast. It boasts of a very huge industrial economy

sustained by continuous corporate growth in the public and private

sectors. The city has grown from a sleeping coastal town to a major

metropolitan city on the East Coast with appx. More than 20 Lakhs

population, largely supported by big public sector units like Visakh

Steel Plant,

Visakhapatnam Port Trust, HPCL, Hindustan Zinc Ltd.,

BHPV, Hindustan Shipyard and several private sector enterprises.

M/s ONGC, a Navratna Oil major corporation is also engaged in the

nearby Bay of Bengal ( Krishna Godavari Basin ) in Oil & Gas

Exploration and Processing venture. Also some of the exploration

blocks have been offered to the private sector big wigs like Reliance

Petroleum. As a result the area offers an extremely good business

potential for a full fledged fabrication workshop specializing in TIG &

MIG welding and 6G type of fabrication on job work basis which are

often outsourced by the Operation & maintenance departments of

these major corporations.

Also, the whole year round maintenance activities in these companies

engage thousands of small and medium contractors who in turn need

the job work infrastructure. Thus a continuous growth is observed in

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

4

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

this kind of business on a long and sustained basis in and around this

mega industrial township.

In view of this background, it is proposed to put up a reasonably good

fabrication workshop in the proximity of this city on a 2.5 acre of land.

The

land with N/A certification will be purchased outright for the

proposed project.

1.2

ACTIVITIES :

Fabrication and Welding involving most modern

equipment and tools, employing highly skilled manpower for the job

work of Stainless Steel Pipes, vessels, structural materials, spools and

other

process

equipments

normally

used

in

Oil

&

Gas

and

Petrochemical industries.

In the proposed fabrication workshop, most important activity will be

specialized welding of job works, mostly ordered from premier public

sector corporations like ONGC and others . As M/s ONGC is engaged in

various Oil & Gas Exploration and Processing activities particularly its

off shore exploration venture in Krishna Godavari basin, the proposed

fabrication workshop is expecting a reasonably good work load from

M/s ONGC at Viskhapatnam, specially for repair welding of pipes and

long length fabrication of pipe spools made of Stainless Steel and

Inconel Alloys.

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

5

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

2.0 TECHNICAL & SAFETY ASPECTS

In the proposed fabrication workshop, most important activity will be

specialized welding of job works,

mostly ordered from a premier

public sector corporation ONGC. As the company is engaged in various

Oil & Gas Exploration and Processing activities particularly its off shore

exploration venture in Krishna Godavari basin, the promoters of this

fabrication workshop are expecting a reasonably good work load from

M/s ONGC.

As such, welding of vessels, pipes and other structural

materials, being an important part of the workshop loading, the same

has been described in detail as follows :

2.1

WELDING PROCESS : Welding is a fabrication or sculptural

process that joins materials, usually metals or thermoplastics, by

causing coalescence. This is often done by melting the work pieces and

adding a filler material to form a pool of molten material (the weld

pool) that cools to become a strong joint, with pressure sometimes

used in conjunction with heat, or by itself, to produce the weld. This is

in contrast with soldering and brazing, which involve melting a lowermelting-point material between the work pieces to form a bond

between them, without melting the work pieces.

. Contd

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

6

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

Gas metal arc welding

Many different energy sources can be used for welding, including a gas

flame, an electric arc, a laser, an electron beam, friction, and

ultrasound. While often an industrial process, welding can be done in

many different environments, including open air, under water and in

outer

space.

Regardless

of

location,

however, welding

remains

dangerous, and precautions must be taken to avoid burns, electric

shock, eye damage, poisonous fumes, and overexposure to ultraviolet

light.

2.2 TYPES OF WELDING : Following types of welding are carried out

depending on the type of job and the metals involved.

2.2.1. ARC WELDING : Arc welding uses a welding power supply to

create an electric arc between an electrode and the base

material to melt the metals at the welding point. They can use

either direct (DC) or alternating (AC) current, and consumable

or non-consumable electrodes. The welding region is sometimes

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

7

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

protected by some type of inert or semi-inert gas, known as a

shielding gas, and/or an evaporating filler material. The process

of arc welding is widely used because of its low capital and

running costs

Name

Characteristics

Applications

Atomic hydrogen

welding

Two metal electrodes in hydrogen

atmosphere

Historical

Bare metal arc

welding

Consummable electrode, no flux or

shielding gas

Historical

Carbon arc welding

Carbon electrode, historical

Copper, repair

(limited)

Electrogas welding

Continuous consumable electrode, vertical

positioning, steel only

Storage tanks,

shipbuilding

Electroslag welding

Continuous consumable electrode, vertical

positioning, steel only

Storage tanks,

shipbuilding

Flux cored arc

welding

Continuous consumable electrode filled

with flux

Industry,

construction

Gas metal arc

welding

Continuous consumable electrode and

shielding gas

Industry

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

8

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

Gas tungsten arc

welding

Non-consumable electrode, slow, high

quality welds

Aerospace

Plasma arc welding

Non-consumable electrode, constricted arc

Tubing,

instrumentation

Shielded metal arc

welding

Consumable electrode covered in flux, steel Construction,

only

outdoors

Stud arc welding

Welds studs to base material with heat and

pressure

Construction,

shipbuilding

Submerged arc

welding

Automatic, arc submerged in granular flux

Ship industry

1. Also known as metal inert gas (MIG) welding or metal active gas (MAG) welding

2. Also known as tungsten inert gas (TIG) welding

3. Also known as manual metal arc (MMA) welding or stick welding

2.2.2 Oxyfuel gas welding

Name

Characteristics

Applications

Air acetylene

welding

Chemical welding process, not popular

Limited

Oxyacetylene

welding

Combustion of acetylene with oxygen

produces high-temperature flame,

inexpensive equipment

Maintenance, repair

Oxyhydrogen

Combustion of hydrogen with oxygen

Limited

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

9

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

welding

produces flame

Pressure gas welding

Gas flames heat surfaces and pressure

produces the weld

Pipe, railroad rails

(limited)

2.2.3 Resistance welding

Name

Characteristics

Applications

Flash welding

Pressure-controlled

resistance welding

Projection welding

Resistance seam

welding

Two wheel-shaped electrodes roll along

work-pieces, applying pressure and current

Resistance spot

welding

Two pointed electrodes apply pressure and

current to two or more thin work-pieces

Upset welding

Butt joint surfaces heated and brought

together by force

Automobile industry

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

10

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

2.2.4 Other welding

Name

Characteristics

Solid State Friction

Welding

Thin heat affected zone, need sufficient

pressure

Electron beam

welding

Deep penetration, fast, high equipment cost

Electroslag welding

Welds thick workpieces quickly, vertical

position, steel only

Applications

Aerospace industry,

railway, land

transport

Heavy plate

fabrication,

construction

Flow welding

Induction welding

Laser beam welding

Deep penetration, fast, high equipment cost Automotive industry

Combines LBW with GMAW in the same

welding head, able to bridge gaps up to

Laser-hybrid welding

2mm (between plates), previously not

possible with LBW alone.

Automotive,

Shipbuilding,

Steelwork industries

Percussion welding

Thermite welding

Railway tracks.

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

11

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

2.2.5 References

Cary, Howard B. and Scott C. Helzer (2005). Modern Welding Technology. Upper

Saddle River, New Jersey: Pearson Education. ISBN 0-13-113029-3.

Lincoln Electric (1994). The Procedure Handbook of Arc Welding. Cleveland:

Lincoln Electric. ISBN 99949-25-82-2.

2.3 Gas tungsten arc welding

The Belgian artist Hubert Minnebo during the TIG welding of a

monumental bronze sculpture

Gas tungsten arc welding (GTAW), also known as tungsten inert

gas (TIG) welding, is an arc welding process that uses a nonconsumable tungsten electrode to produce the weld. The weld area is

protected from atmospheric contamination by a shielding gas (usually

an inert gas such as argon), and a filler metal is normally used, though

some welds, known as autogenous welds, do not require it. A

constant-current welding power supply produces energy which is

conducted across the arc through a column of highly ionized gas and

metal vapors known as a plasma.

GTAW is most commonly used to weld thin sections of stainless steel

and light metals such as aluminum, magnesium, and copper alloys.

The process grants the operator greater control over the weld than

competing procedures such as shielded metal arc welding and gas

metal arc welding, allowing for stronger, higher quality welds.

However, GTAW is comparatively more complex and difficult to master,

and furthermore, it is significantly slower than most other welding

techniques. A related process, plasma arc welding, uses a slightly

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

12

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

different welding torch to create a more focused welding arc and as a

result is often automated.[1]

This process was perfected in 1941, and became known as heliarc or

tungsten inert gas welding, because it utilized a tungsten electrode

and helium as a shielding gas. Initially, the electrode overheated

quickly, and in spite of tungsten's high melting temperature, particles

of tungsten were transferred to the weld. To address this problem, the

polarity of the electrode was changed from positive to negative, but

this made it unsuitable for welding many non-ferrous materials.

Finally, the development of alternating current units made it possible

to stabilize the arc and produce high quality aluminum and magnesium

welds.[3]

Linde Air Products developed water-cooled torches that helped to

prevent overheating when welding with high currents. [4] Additionally,

during the 1950s, as the process continued to gain popularity, some

users turned to carbon dioxide as an alternative to the more expensive

welding atmospheres consisting of argon and helium. However, this

proved unacceptable for welding aluminum and magnesium because it

reduced weld quality, and as a result, it is rarely used with GTAW

today.

In 1953, a new process based on GTAW was developed, called plasma

arc welding. It affords greater control and improves weld quality by

using a nozzle to focus the electric arc, but is largely limited to

automated systems, whereas GTAW remains primarily a manual, handheld method.[5] Development within the GTAW process has continued

as well, and today a number of variations exist. Among the most

popular are the pulsed-current, manual programmed, hot-wire, dabber,

and increased penetration GTAW methods.[6]

2.3.1.Operation

GTAW weld area

Manual gas tungsten arc welding is often considered the most difficult

of all the welding processes commonly used in industry. Because the

welder must maintain a short arc length, great care and skill are

required to prevent contact between the electrode and the work-piece.

Unlike most other welding processes, GTAW normally requires two

hands, since most applications require that the welder manually feed a

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

13

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

filler metal into the weld area with one hand while manipulating the

welding torch in the other. However, some welds combining thin

materials (known as autogenous or fusion welds) can be accomplished

without filler metal; most notably edge, corner, and butt joints.

To strike the welding arc, a high frequency generator provides a path

for the welding current through the shielding gas, allowing the arc to

be struck when the separation between the electrode and the workpiece is approximately 1.53 mm (0.060.12 in). Bringing the two into

contact in a "touch start" ("scratch start") also serves to strike an arc.

This technique can cause contamination of the weld and electrode.

Once the arc is struck, the welder moves the torch in a small circle to

create a welding pool, the size of which depends on the size of the

electrode and the amount of current. While maintaining a constant

separation between the electrode and the work-piece, the operator

then moves the torch back slightly and tilts it backward about 1015

degrees from vertical. Filler metal is added manually to the front end

of the weld pool as it is needed.[7]

Welders often develop a technique of rapidly alternating between

moving the torch forward (to advance the weld pool) and adding filler

metal. The filler rod is withdrawn from the weld pool each time the

electrode advances, but it is never removed from the gas shield to

prevent oxidation of its surface and contamination of the weld. Filler

rods composed of metals with low melting temperature, such as

aluminum, require that the operator maintain some distance from the

arc while staying inside the gas shield. If held too close to the arc, the

filler rod can melt before it makes contact with the weld puddle. As the

weld nears completion, the arc current is often gradually reduced to

allow the weld crater to solidify and prevent the formation of crater

cracks at the end of the weld.[8][9]

2.3.2 Operation Modes

GTAW can use a positive direct current, negative direct current or an

alternating current, depending on the power supply set up. A negative

direct current from the electrode causes a stream of electrons to

collide with the surface, generating large amounts of heat at the weld

region. This creates a deep, narrow weld. In the opposite process

where the electrode is connected to the positive power supply

terminal, positively charged ions flow from the tip of the electrode

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

14

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

instead, so the heating action of the electrons is mostly on the

electrode. This mode also helps to remove oxide layers from the

surface of the region to be welded, which is good for metals such as

Aluminium or Magnesium. A shallow, wide weld is produced from this

mode, with minimum heat input. Alternating current gives a

combination of negative and positive modes, giving a cleaning effect

and imparts a lot of heat as well.

2.3.3 Safety

Like other arc welding processes, GTAW can be dangerous if proper

precautions are not taken. The process produces intense ultraviolet

radiation, which can cause a form of sunburn and, in a few cases,

trigger the development of skin cancer. Flying sparks and droplets of

molten metal can cause severe burns and start a fire if flammable

material is nearby, though GTAW generally produces very few sparks

or metal droplets when performed properly.

It is essential that the welder wear suitable protective clothing,

including leather gloves, a closed shirt collar to protect the neck

(especially the throat), a protective long sleeve jacket and a suitable

welding helmet to prevent retinal damage or ultraviolet burns to the

cornea, often called arc eye. The shade of welding lens will depend

upon the amperage of the welding current. Due to the absence of

smoke in GTAW, the arc appears brighter than shielded metal arc

welding and more ultraviolet radiation is produced. Exposure of bare

skin near a GTAW arc for even a few seconds may cause a painful

sunburn. Additionally, the tungsten electrode is heated to a white hot

state like the filament of a lightbulb, adding greatly to the total

radiated light and heat energy. Transparent welding curtains, made of

a polyvinyl chloride plastic film, dyed in order to block UV radiation,

are often used to shield nearby personnel from exposure.

Welders are also often exposed to dangerous gases and particulate

matter. Shielding gases can displace oxygen and lead to asphyxiation,

and while smoke is not produced, the arc in GTAW produces very short

wavelength ultraviolet light, which causes surrounding air to break

down and form ozone. Metals will volatilize and heavy metals can be

taken into the lungs. Similarly, the heat can cause poisonous fumes to

form from cleaning and degreasing materials. For example chlorinated

products will break down producing poisonous phosgene. Cleaning

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

15

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

operations using these agents should not be performed near the site of

welding, and proper ventilation is necessary to protect the welder.[10]

2.3.4 Applications

While the aerospace industry is one of the primary users of gas

tungsten arc welding, the process is used in a number of other areas.

Many industries use GTAW for welding thin workpieces, especially

nonferrous metals. It is used extensively in the manufacture of space

vehicles, and is also frequently employed to weld small-diameter, thinwall tubing such as those used in the bicycle industry. In addition,

GTAW is often used to make root or first pass welds for piping of

various sizes. In maintenance and repair work, the process is

commonly used to repair tools and dies, especially components made

of aluminum and magnesium. [11] Because the weld metal is not

transferred directly across the electric arc like most open arc welding

processes, a vast assortment of welding filler metal is available to the

welding engineer. In fact, no other welding process permits the

welding of so many alloys in so many product configurations. Filler

metal alloys, such as elemental aluminum and chromium, can be lost

through the electric arc from volatilization. This loss does not occur

with the GTAW process. Because the resulting welds have the same

chemical integrity as the original base metal or match the base metals

more closely, GTAW welds are highly resistant to corrosion and

cracking over long time periods, GTAW is the welding procedure of

choice for critical welding operations like sealing spent nuclear fuel

canisters before burial.[12]

2.3.5 Quality

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

16

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

GTAW fillet weld

Engineers prefer GTAW welds because of its low-hydrogen properties

and the match of mechanical and chemical properties with the base

material. Maximum weld quality is assured by maintaining the

cleanliness of the operationall equipment and materials used must

be free from oil, moisture, dirt and other impurities, as these cause

weld porosity and consequently a decrease in weld strength and

quality. To remove oil and grease, alcohol or similar commercial

solvents may be used, while a stainless steel wire brush or chemical

process can remove oxides from the surfaces of metals like aluminum.

Rust on steels can be removed by first grit blasting the surface and

then using a wire brush to remove any embedded grit. These steps are

especially important when negative polarity direct current is used,

because such a power supply provides no cleaning during the welding

process, unlike positive polarity direct current or alternating current.[13]

To maintain a clean weld pool during welding, the shielding gas flow

should be sufficient and consistent so that the gas covers the weld and

blocks impurities in the atmosphere. GTA welding in windy or drafty

environments increases the amount of shielding gas necessary to

protect the weld, increasing the cost and making the process

unpopular outdoors.

Because of GTAW's relative difficulty and the importance of proper

technique, skilled operators are employed for important applications.

Welders in the U.S. should be qualified following the requirements of

the American Welding Society or American Society of Mechanical

Engineers. Low heat input, caused by low welding current or high

welding speed, can limit penetration and cause the weld bead to lift

away from the surface being welded. If there is too much heat input,

however, the weld bead grows in width while the likelihood of

excessive penetration and spatter increase. Additionally, if the welder

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

17

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

holds the welding torch too far from the workpiece, shielding gas is

wasted and the appearance of the weld worsens.

If the amount of current used exceeds the capability of the electrode,

tungsten inclusions in the weld may result. Known as tungsten

spitting, it can be identified with radiography and prevented by

changing the type of electrode or increasing the electrode diameter. In

addition, if the electrode is not well protected by the gas shield or the

operator accidentally allows it to contact the molten metal, it can

become dirty or contaminated. This often causes the welding arc to

become unstable, requiring that electrode be ground with a diamond

abrasive to remove the impurity.[14]

2.4.5 Equipment

GTAW torch with various electrodes, cups, collets and gas diffusers

GTAW torch, disassembled

The equipment required for the gas tungsten arc welding operation

includes a welding torch utilizing a nonconsumable tungsten electrode,

a constant-current welding power supply, and a shielding gas source.

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

18

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

1. Welding torch

GTAW welding torches are designed for either automatic or manual

operation and are equipped with cooling systems using air or water.

The automatic and manual torches are similar in construction, but the

manual torch has a handle while the automatic torch normally comes

with a mounting rack. The angle between the centerline of the handle

and the centerline of the tungsten electrode, known as the head angle,

can be varied on some manual torches according to the preference of

the operator. Air cooling systems are most often used for low-current

operations (up to about 200 A), while water cooling is required for

high-current welding (up to about 600 A). The torches are connected

with cables to the power supply and with hoses to the shielding gas

source and where used, the water supply.

The internal metal parts of a torch are made of hard alloys of copper

or brass in order to transmit current and heat effectively. The tungsten

electrode must be held firmly in the center of the torch with an

appropriately sized collet, and ports around the electrode provide a

constant flow of shielding gas. Collets are sized according to the

diameter of the tungsten electrode they hold. The body of the torch is

made of heat-resistant, insulating plastics covering the metal

components, providing insulation from heat and electricity to protect

the welder.

The size of the welding torch nozzle depends on the amount of

shielded area desired. The size of the gas nozzle will depend upon the

diameter of the electrode, the joint configuration, and the availability

of access to the joint by the welder. The inside diameter of the nozzle

is preferably at least three times the diameter of the electrode, but

there are no hard rules. The welder will judge the effectiveness of the

shielding and increase the nozzle size to increase the area protected

by the external gas shield as needed. The nozzle must be heat

resistant and thus is normally made of alumina or a ceramic material,

but fused quartz, a glass-like substance, offers greater visibility.

Devices can be inserted into the nozzle for special applications, such as

gas lenses or valves to improve the control shielding gas flow to

reduce turbulence and introduction of contaminated atmosphere into

the shielded area. Hand switches to control welding current can be

added to the manual GTAW torches.[15]

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

19

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

2. Power supply

Gas tungsten arc welding uses a constant current power source,

meaning that the current (and thus the heat) remains relatively

constant, even if the arc distance and voltage change. This is

important because most applications of GTAW are manual or

semiautomatic, requiring that an operator hold the torch. Maintaining a

suitably steady arc distance is difficult if a constant voltage power

source is used instead, since it can cause dramatic heat variations and

make welding more difficult.[16]

GTAW power supply

The preferred polarity of the GTAW system depends largely on the type

of metal being welded. Direct current with a negatively charged

electrode (DCEN) is often employed when welding steels, nickel,

titanium, and other metals. It can also be used in automatic GTA

welding of aluminum or magnesium when helium is used as a shielding

gas. The negatively charged electrode generates heat by emitting

electrons which travel across the arc, causing thermal ionization of the

shielding gas and increasing the temperature of the base material. The

ionized shielding gas flows toward the electrode, not the base material.

Direct current with a positively charged electrode (DCEP) is less

common, and is used primarily for shallow welds since less heat is

generated in the base material. Instead of flowing from the electrode

to the base material, as in DCEN, electrons go the other direction,

causing the electrode to reach very high temperatures. To help it

maintain its shape and prevent softening, a larger electrode is often

used. As the electrons flow toward the electrode, ionized shielding gas

flows back toward the base material, cleaning the weld by removing

oxides and other impurities and thereby improving its quality and

appearance.

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

20

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

Alternating current, commonly used when welding aluminum and

magnesium manually or semi-automatically, combines the two direct

currents by making the electrode and base material alternate between

positive and negative charge. This causes the electron flow to switch

directions constantly, preventing the tungsten electrode from

overheating while maintaining the heat in the base material. Surface

oxides are still removed during the electrode-positive portion of the

cycle and the base metal is heated more deeply during the electrodenegative portion of the cycle. Some power supplies enable operators to

use an unbalanced alternating current wave by modifying the exact

percentage of time that the current spends in each state of polarity,

giving them more control over the amount of heat and cleaning action

supplied by the power source. In addition, operators must be wary of

rectification, in which the arc fails to reignite as it passes from straight

polarity (negative electrode) to reverse polarity (positive electrode). To

remedy the problem, a square wave power supply can be used, as can

high-frequency voltage to encourage ignition.[17]

3. Electrode

ISO ISO

Class Color

AWS

Class

AWS

Color

Alloy

WP

EWP

Green

None

WC20 Gray

EWCe-2

Orange ~2% CeO2

WL10 Black

EWLa-1

Black

WL15 Gold

EWLa-1.5 Gold

Green

[18]

~1% La2O3

~1.5% La2O3

WL20 Sky-blue EWLa-2

Blue

~2% La2O3

WT10 Yellow

EWTh-1

Yellow ~1% ThO2

WT20 Red

EWTh-2

Red

~2% ThO2

WT30 Violet

~3% ThO2

WT40 Orange

~4% ThO2

WY20 Blue

~2% Y2O3

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

21

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

WZ3 Brown

WZ8 White

EWZr-1

Brown ~0.3% ZrO2

~0.8% ZrO2

The electrode used in GTAW is made of tungsten or a tungsten alloy,

because tungsten has the highest melting temperature among pure

metals, at 3,422 C (6,192 F). As a result, the electrode is not

consumed during welding, though some erosion (called burn-off) can

occur. Electrodes can have either a clean finish or a ground finish

clean finish electrodes have been chemically cleaned, while ground

finish electrodes have been ground to a uniform size and have a

polished surface, making them optimal for heat conduction. The

diameter of the electrode can vary between 0.5 millimeter and

6.4 millimeters (0.020.25 in), and their length can range from 75 to

610 millimeters (324 in).

A number of tungsten alloys have been standardized by the

International Organization for Standardization and the American

Welding Society in ISO 6848 and AWS A5.12, respectively, for use in

GTAW electrodes, and are summarized in the adjacent table. Pure

tungsten electrodes (classified as WP or EWP) are general purpose and

low cost electrodes. Cerium oxide (or ceria) as an alloying element

improves arc stability and ease of starting while decreasing burn-off.

Using an alloy of lanthanum oxide (or lanthana) has a similar effect.

Thorium oxide (or thoria) alloy electrodes were designed for DC

applications and can withstand somewhat higher temperatures while

providing many of the benefits of other alloys. However, it is somewhat

radioactive. Inhalation of the thorium grinding dust during preparation

of the electrode is hazardous to one's health. As a replacement to

thoriated electrodes, electrodes with larger concentrations of

lanthanum oxide can be used. Electrodes containing zirconium oxide

(or zirconia) increase the current capacity while improving arc stability

and starting and increasing electrode life. In addition, electrode

manufacturers may create alternative tungsten alloys with specified

metal additions, and these are designated with the classification EWG

under the AWS system.

Filler metals are also used in nearly all applications of GTAW, the major

exception being the welding of thin materials. Filler metals are

available with different diameters and are made of a variety of

materials. In most cases, the filler metal in the form of a rod is added

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

22

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

to the weld pool manually, but some applications call for an

automatically fed filler metal, which often is stored on spools or coils.

[19]

4. Shielding gas

GTAW system setup

As with other welding processes such as gas metal arc welding,

shielding gases are necessary in GTAW to protect the welding area

from atmospheric gases such as nitrogen and oxygen, which can cause

fusion defects, porosity, and weld metal embrittlement if they come in

contact with the electrode, the arc, or the welding metal. The gas also

transfers heat from the tungsten electrode to the metal, and it helps

start and maintain a stable arc.

The selection of a shielding gas depends on several factors, including

the type of material being welded, joint design, and desired final weld

appearance. Argon is the most commonly used shielding gas for GTAW,

since it helps prevent defects due to a varying arc length. When used

with alternating current, the use of argon results in high weld quality

and good appearance. Another common shielding gas, helium, is most

often used to increase the weld penetration in a joint, to increase the

welding speed, and to weld metals with high heat conductivity, such as

copper and aluminum. A significant disadvantage is the difficulty of

striking an arc with helium gas, and the decreased weld quality

associated with a varying arc length.

Argon-helium mixtures are also frequently utilized in GTAW, since they

can increase control of the heat input while maintaining the benefits of

using argon. Normally, the mixtures are made with primarily helium

(often about 75% or higher) and a balance of argon. These mixtures

increase the speed and quality of the AC welding of aluminum, and

also make it easier to strike an arc. Another shielding gas mixture,

argon-hydrogen, is used in the mechanized welding of light gauge

stainless steel, but because hydrogen can cause porosity, its uses are

limited.[20] Similarly, nitrogen can sometimes be added to argon to help

stabilize the austenite in austentitic stainless steels and increase

penetration when welding copper. Due to porosity problems in ferritic

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

23

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

steels and limited benefits, however, it is not a popular shielding gas

additive.[21]

2.3.6 Materials

Gas tungsten arc welding is most commonly used to weld stainless

steel and nonferrous materials, such as aluminum and magnesium, but

it can be applied to nearly all metals, with notable exceptions being

lead and zinc. Its applications involving carbon steels are limited not

because of process restrictions, but because of the existence of more

economical steel welding techniques, such as gas metal arc welding

and shielded metal arc welding. Furthermore, GTAW can be performed

in a variety of other-than-flat positions, depending on the skill of the

welder and the materials being welded.[22]

1. Aluminum and magnesium

A TIG weld showing an accentuated AC etched zone

Close up view of an aluminum TIG weld AC etch zone

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

24

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

Aluminum and magnesium are most often welded using alternating

current, but the use of direct current is also possible, depending on the

properties desired. Before welding, the work area should be cleaned

and may be preheated to 175 to 200 C (350 to 400 F) for aluminum

or to a maximum of 150 C (300 F) for thick magnesium workpieces

to improve penetration and increase travel speed. AC current can

provide a self-cleaning effect, removing the thin, refractory aluminium

oxide (sapphire) layer that forms on aluminium metal within minutes

of exposure to air. This oxide layer must be removed for welding to

occur. When alternating current is used, pure tungsten electrodes or

zirconiated tungsten electrodes are preferred over thoriated

electrodes, as the latter are more likely to "spit" electrode particles

across the welding arc into the weld. Blunt electrode tips are preferred,

and pure argon shielding gas should be employed for thin workpieces.

Introducing helium allows for greater penetration in thicker

workpieces, but can make arc starting difficult.

Direct current of either polarity, positive or negative, can be used to

weld aluminum and magnesium as well. Direct current with a

negatively charged electrode (DCEN) allows for high penetration.

Argon is commonly used as a shielding gas for DCEN welding of

aluminum. Shielding gases with high helium contents are often used

for higher penetration in thicker materials. Thoriated electrodes are

suitable for use in DCEN welding of aluminum. Direct current with a

positively charged electrode (DCEP) is used primarily for shallow

welds, especially those with a joint thickness of less than

1.6 millimeters (0.06 in). A thoriated tungsten electrode is commonly

used, along with a pure argon shielding gas.[23]

2. Steels

For GTA welding of carbon and stainless steels, the selection of a filler

material is important to prevent excessive porosity. Oxides on the filler

material and workpieces must be removed before welding to prevent

contamination, and immediately prior to welding, alcohol or acetone

should be used to clean the surface. Preheating is generally not

necessary for mild steels less than one inch thick, but low alloy steels

may require preheating to slow the cooling process and prevent the

formation of martensite in the heat-affected zone. Tool steels should

also be preheated to prevent cracking in the heat-affected zone.

Austenitic stainless steels do not require preheating, but martensitic

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

25

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

and ferritic chromium stainless steels do. A DCEN power source is

normally used, and thoriated electrodes, tapered to a sharp point, are

recommended. Pure argon is used for thin workpieces, but helium can

be introduced as thickness increases.[24]

3. Copper alloys

TIG welding of copper and some of its alloys is possible, but in order to

get a seam free of oxidation and porosities, shielding gas needs to be

provided on the root side of the weld. Alternatively, a special "backing

tape", consisting of a fiberglass weave on heat-resistant aluminum

tape can be used, to prevent air reaching the molten metal.

4. Dissimilar metals

Welding dissimilar metals often introduces new difficulties to GTAW

welding, because most materials do not easily fuse to form a strong

bond. However, welds of dissimilar materials have numerous

applications in manufacturing, repair work, and the prevention of

corrosion and oxidation. In some joints, a compatible filler metal is

chosen to help form the bond, and this filler metal can be the same as

one of the base materials (for example, using a stainless steel filler

metal with stainless steel and carbon steel as base materials), or a

different metal (such as the use of a nickel filler metal for joining steel

and cast iron). Very different materials may be coated or "buttered"

with a material compatible with a particular filler metal, and then

welded. In addition, GTAW can be used in cladding or overlaying

dissimilar materials.

When welding dissimilar metals, the joint must have an accurate fit,

with proper gap dimensions and bevel angles. Care should be taken to

avoid melting excessive base material. Pulsed current is particularly

useful for these applications, as it helps limit the heat input. The filler

metal should be added quickly, and a large weld pool should be

avoided to prevent dilution of the base materials.[25]

2.3.7 Process variations

1. Pulsed-current

In the pulsed-current mode, the welding current rapidly alternates

between two levels. The higher current state is known as the pulse

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

26

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

current, while the lower current level is called the background current.

During the period of pulse current, the weld area is heated and fusion

occurs. Upon dropping to the background current, the weld area is

allowed to cool and solidify. Pulsed-current GTAW has a number of

advantages, including lower heat input and consequently a reduction in

distortion and warpage in thin workpieces. In addition, it allows for

greater control of the weld pool, and can increase weld penetration,

welding speed, and quality. A similar method, manual programmed

GTAW, allows the operator to program a specific rate and magnitude of

current variations, making it useful for specialized applications. [26]

2. Dabber

The dabber variation is used to precisely place weld metal on thin

edges. The automatic process replicates the motions of manual

welding by feeding a cold filler wire into the weld area and dabbing (or

oscillating) it into the welding arc. It can be used in conjunction with

pulsed current, and is used to weld a variety of alloys, including

titanium, nickel, and tool steels. Common applications include

rebuilding seals in jet engines and building up saw blades, milling

cutters, drill bits, and mower blades.[27]

3. Hot Wire

Welding filler metal can be resistance heated to a temperature near its

melting point before being introduced into the weld pool. This

increases the deposition rate of machine and automatic GTAW welding

processes. More pounds per hour of filler metal is introduced into the

weld joint than when filler metal is added cold and the heat of the

electric arc introduces all of the heat. This process is used extensively

in base material build up before machining, clad metal overlays, and

hardfacing operations.

2.3.8 References

American Welding Society (2004). Welding Handbook, Welding Processes Part 1.

Miami Florida: American Welding Society. ISBN 0-87171-729-8.

ASM International (2003). Trends in Welding Research. Materials Park, Ohio:

ASM International. ISBN 0-87170-780-2

Cary, Howard B. and Scott C. Helzer (2005). Modern Welding Technology. Upper

Saddle River, New Jersey: Pearson Education. ISBN 0-13-113029-3.

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

27

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

Jeffus, Larry (2002). Welding: Principles and Applications. Thomson Delmar.

ISBN 1-4018-1046-2.

Lincoln Electric (1994). The Procedure Handbook of Arc Welding. Cleveland:

Lincoln Electric. ISBN 99949-25-82-2.

Messler, Robert W. (1999). Principles of Welding. Troy, New York: John Wiley &

Sons, Inc. ISBN 0-471-25376-6

Minnick, William H. (1996). Gas Tungsten Arc Welding handbook. Tinley Park,

Illinois: Goodheart-Willcox Company. ISBN 1-56637-206-2.

Weman, Klas (2003). Welding processes handbook. New York: CRC Press LLC.

ISBN 0-8493-1773-8.

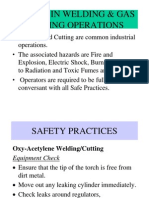

2.4 Safety issues :

Correct and safe arc welding station

Welding can be a dangerous and unhealthy practice without the proper

precautions; however, with the use of new technology and proper

protection the risks of injury or death associated with welding can be

greatly reduced.

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

28

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

2.4.1 Heat and sparks

Because many common welding procedures involve an open electric

arc or flame, the risk of burns is significant. To prevent them, welders

wear protective clothing in the form of heavy leather gloves and

protective long sleeve jackets to avoid exposure to extreme heat,

flames, and sparks.

2.4.2 Eye damage

The brightness of the weld area leads to a condition called arc eye in

which ultraviolet light causes inflammation of the cornea and can burn

the retinas of the eyes. Goggles and helmets with dark face plates are

worn to prevent this exposure and, in recent years, new helmet

models have been produced featuring a face plate that self-darkens

upon exposure to high amounts of UV light. To protect bystanders,

transparent welding curtains often surround the welding area. These

curtains, made of a polyvinyl chloride plastic film, shield nearby

workers from exposure to the UV light from the electric arc, but should

not be used to replace the filter glass used in helmets.[26]

Those dark face plates must be much darker than those in sunglasses

or blowtorching goggles. Sunglasses and blowtorching goggles are not

adequate for arc welding protection.

In 1970, a Swedish doctor, ke Sandn, developed a new type of

welding goggles that used a multilayer interference filter to block most

of the light from the arc. He had observed that most welders could not

see well enough, with the mask on, to strike the arc, so they would flip

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

29

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

the mask up, then flip it down again once the arc was going: this

exposed their naked eyes to the intense light for a while. By

coincidence, the spectrum of an electric arc has a notch in it, which

coincides with the yellow sodium line. Thus, a welding shop could be lit

by sodium vapor lamps or daylight, and the welder could see well to

strike the arc. The Swedish government required these masks to be

used for arc welding, but they were not used in the United States.

They may have disappeared.[27]

2.4.3 Inhaled matter

Welders are also often exposed to dangerous gases and particulate

matter. Processes like flux-cored arc welding and shielded metal arc

welding produce smoke containing particles of various types of oxides.

The size of the particles in question tends to influence the toxicity of

the fumes, with smaller particles presenting a greater danger.

Additionally, many processes produce various gases (most commonly

carbon dioxide and ozone, but others as well) that can prove

dangerous if ventilation is inadequate. Furthermore, the use of

compressed gases and flames in many welding processes pose an

explosion and fire risk; some common precautions include limiting the

amount of oxygen in the air and keeping combustible materials away

from the workplace.[28]

2.4.4 Interference with pacemakers

Certain welding machines which use a high frequency AC current

component have been found to affect pacemaker operation when

within 2 meters of the power unit and 1 meter of the weld site [29].

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

30

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

3.0 WORKSHOP FACILITIES

The proposed workshop is planned in a sprawling 2.5 acre of N / A

land in the vicinity of Visakhapatnam. The following facilities are

planned to make this as a full fledged fabrication workshop.

3.1 Workshop Shed

Appx. 35,000 sq. feet ( appx. 1 acre of

land ) of industrial shed will be built in the area which would be closest

to the road / highway to facilitate heavy vehicle movement for

transporting heavy equipments, long and big diameter pipes, spool

pieces and other job work items. Also this will enable easy dumping

of raw materials ( metal sheets ) and consumables

like electrodes,

gas cylinders, power supply gadgets and other required welding

equipments.

3.2 Captive DG Set and Generator Room : A DG set of suitable

capacity is proposed to be provided to take care of APSEB power

outages and fluctuations so that all priority jobs can continue

uninterruptedly and delivery commitments are met satisfactorily.

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

31

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

3.3

Tool Room cum Store House : A separate hall is proposed to

be constructed on an appx. 500 sq. feet area which will house all

important tools and valuable stores materials like consumables

and safety gadgets.

3.4

Safety

Showers

and

Fire

Fighting

Facilities

comprehensive network of fire fighting pipeline, fire hydrants,

hose pipes in glass door housings, safety showers, and a fire

water pond of suitable capacity will be provided as the repair job

works relate to Oil, Gas & Petrochemical Industries which deal

with highly inflammable petroleum / petrochemical products.

3.5

Administration Building :

A separate plot of appx. 2000 sq.

feet area in the heart of the layout shall be used to construct a

modern Administrative Block comprising Directors / Partners

offices,

Accounts

section,

Inventory

Control

section,

Shift

Supervisors room and Workers change room etc.

3.6

Workshop & Welding Equipments : Following machineries

including welding equipment will be purchased and installed in

the workshop.

Rs. 000

1. Arc based TIG Welding machine 300 A - 2 No.

250

2. Auto TIG pipe welding machine - 2 No.

100

3. Micro TIG welding machine - 1 No.

50

4. Inverter based MMA welding machine 2 No.

5. Welding Torches Assorted 20 No.

6. Power Supply Kits / Rectifiers 2 No.

80

20

100

7. Inert Gas cylinders Argon & Nitrogen 20 No.

20

8. Plasma Arc Welding & Cutting machines

100

9. Lathe machines 1 big and 1 small size 1 No.

10.

350

Pipe Bending machines, upto 12 mm and one higher size :

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

32

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

11.

Shearing machine , 1 big and 1 small

30

12.

Gas cutting sets. 2 No.

20

13.

Chain Pulley Blocks / Overhead Crane

50

14.

Safety equipment like gloves, glasses etc.

30

-----------1200

Rs. 12 Lakhs

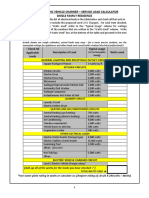

4.0 COST ESTIMATE

A total of 400 job work are expected to be executed in one calendar

year. It is estimated that each work order will be of quantity 300 to

500 Kgs. Weight. As per SS fabrication rates, it is assessed that @ Rs.

120 / Kg of labor cost, the order value for an avg. 400 Kg job would

work out to Rs. 48,000 each. On an avg. daily output would be 400 /

300 working days or 1.33 job work per day. Financially, the value of

daily out put is expected to be Rs. 63,840 per day. For handling such

assignments, a broad assessment of fixed capital expenditure as

covered in the chapter 3, as well as the operating cost has been made

in the following paras.

4.1 CAPITAL EXPENDITURE :

Estimated capital cost for the facilities as mentioned in the chapter 3 is

given as hereunder :

S.No

1

2

3

Item

Est. Cost

Land 2.5 acre N/A Plot

Workshop Shed 35,000 sq. feet

Captive DG set, 400 KVA

( Rs. Lakhs )

50

70

10

Remarks

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

33

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

4

5

6

7

8

Tool Room & S / House 750 sqf

Administrative building, 1500 sqf

Fire Fighting Facilities

Workshop machineries

Power feeder & installation

TOTAL

7.5

15

10

12

4

178.5

See chap. 3

See chap. 3

4.2 WORKING CAPITAL REQUIREMENT :

The

overall

operating

cost

is

distributed

over

labor,

power,

consumables and overheads / contingencies. The consumables include

electrodes, inert gases, flux or filler materials. From the experience

and the statistical data, it is estimated that cost factor wise unit cost

of 125 / Kg can be distributed as follows :

1. Manpower / labor

40

2. Power / Electricity

10

3. Consumables

20

4. Contingencies

5. Overheads

10

6. Margins

35

----------------120

-----------------

4.2.1 Manpower Requirement : ( Basis 2 shift operation )

Amount in Rs.

Manpower

No. Monthly wages

Total

1.

General Manager

30,000

30,000

2.

Shift Supervisor

10,000

20,000

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

34

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

3.

Skilled welders

10

4.

Skilled machine operators

5.

semi / unskilled workers

15,000

1,50,000

15,000

30,000

10

9,000

90,000

6. Leave coverage staff

12,000

60,000

7. Accountant / Clerks

10,000

50,000

8. Security staff watchmen

4

7,500

30,000

------------------------------------

Monthly wage bill

39

4,60,000

------------------------------------4.2.2 Power Requirement : ( Basis 2 shift operation )

As such the power consumption depends on the quantum of

fabrication, repair and welding work required for each job. The

installation would be provided a guaranteed 100 HP feeder lines, to

cater to a maximum load. However, as per the cost index, we estimate

that a total of Rs. 1,33,000 per month would be spent on electricity

bills alone.

4.2.3 consumables :

Similarly, the consumables are welding electrodes, safety gadgets like

glasses, hand gloves, metal filler materials, potable and non potable

water. These are all linked with the quantum of work load or jobs on

hand. Therefore as per the cost index, it is estimated that a monthly

expenses of Rs. 2,66,000 would be incurred on the consumables.

4.2.4 Overheads & Contingencies :

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

35

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

As per the job related index, it is estimated that a total of Rs. 2 Lakhs

will have to be appropriated to take of this accounting head on each

month basis.

4.2.5. TOTAL WORKING CAPITAL 60 DAYS BASIS :

If we sum up all above operating expenses, and consider 2 months

minimum working capital provisions, it works out to be Rs.

21,20,000.

4.3 TOTAL CAPITAL ( FIXED + WORKING ) REQUIREMENT :

To sum up fixed capital and working capital ( 60 days ), the total

project cost works out to be Rs. 1,99,70,000.

4.3 IMPLEMENTATION SCHEDULE :

As the machineries required to set up this workshop are quite

standardized and readily available in the market, the only time factor

from the commencement till completion is civil and mechanical work

required to complete the Workshop shed and other civil construction

like Administrative Building, Tool Room cum Store House and the

related

interior works. It is assessed that the entire project can be

completed in about 3 to 4 months time once the funds are

appropriated and the construction plans are approved from the

Municipal / relevant Govt. Authorities.

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

36

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

5.0 FINANCIAL ANALYSIS

5.1 PROFITABILITY :

INCOME :

-

No. of Jobs to be done / year :

Revenues from each job = Rs. 400 Kg x 120 / Kg

= Rs. 48,000

Expected Revenues / year = 400 x Rs. 48,000

400

= 1,92,00,000 . A

EXPENSES :

-

Salary & Wages

=

=

12 x 4,60,000

Rs. 55,20,000 .. B

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

37

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

Electricity Expenses

12 x 1,33,000

= Rs. 15,96,000 C

-

Consumables

12 x 2,66,000

31,92,000 .. D

Overheads & Contingencies =

=

12 x 2,00,000

Rs. 24,00,000 .. E

Total Expenditure = B + C + D + E

=

Therefore Yearly Profitability

Rs. 1,27,08,000 F

=

AF

Rs. 64,92,000

5.2 Net Profit after Tax :

Yearly Revenues

64.92 Lakhs

Service Tax Provision @ 10.4 = 6.75 Lakhs

Income Tax on Gross Profit

@ 30 % appx.

Therefore Net Profit after Tax

5.3 Rate of Return

= Rs. 17.45 Lakhs

Rs. 40.72 Lakhs

Net profit / Total Capital Exp.

40.72 / 199.7 x 100

20.4 %

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

38

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

5.4 Ratio of Sales / Capital Cost

192 / 199.7

96.1 %

6.0 HOW TO SET UP AN ENTERPRISE:

6.1. DECISION TO BE AN ENTREPRENEUR:

The following two important considerations have to be immediately

addressed before starting an enterprise.

6.2 CHOOSING YOUR FORM OF BUSINESS ORGANISATION :

The business could be

proprietary, partnership or a private limited

company. If the number of share holders are more and exceed

beyond a number specified by the Company law, the company

becomes a public limited company and no more remains private

limited. Consult a chartered accountant for more information on

company formation.

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

39

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

6.3 MAKING A PRODUCT CHOICE

Make a careful analysis of the product or service you are choosing,

sometimes in short run, there is a shortage of a particular commodity in

the market, you may even come to know you will get almost two weeks in

advance to supply fresh stock. Does that mean you can jump into that

business. First thing in such a condition is to analyze the situation. Keep

in mind that shortages may occur due to a number of reasons and a

good entrepreneur always examine the pros and cons before setting up a

business. It may tempt you to think that perhaps you have found a good

businesses idea. But do not be easily influenced by these temporary

shortages. Carefully analyze the future demand-supply position of the

product, say for the next 3 to 5 years. Only when you are certain that the

shortage will remain there for considerable period of time and you would

be able to generate enough profits in the very first or second year of

operation and that you can produce quality item within an acceptable

pricing, then only you should venture into such a business.

There are many organizations, which are in possession of information

on business opportunities; you can contact these organizations to get

an idea about products

1. Absolute Technologies Research Center

2. District Industries Centers

3. Centers for Entrepreneurship Development

4. Small Industry Service Institutes

5. Industrial Extensions Bureaus (These exist in several states) they are known

by such names as index, Udyog Mitra, Udyog Sahayk and so on).

6. National Industrial Development Corporation, New Delhi

7. Khadi and Village Industries Commission, New Delhi

8. Commissioner of Cottage Industries

9. Entrepreneurship Development Institute of India, Ahmedabad

10. National Institute of Entrepreneurship and Small Business Development,

New Delhi

11. National Institute of Small Industry Extension and Training, Hyderabad

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

40

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

This information could be in the form of:

Project profiles

Feasibility studies

Industry studies

Area development studies.

6.4

OTHER IMPORTANT DECISIONS TO BE MADE:

LOCATION OF INDUSTRY

PREPARATION OF BUSINESS PLAN

SOURCING PROCESS, RAW MATERIALS, MACHINERIES

INFRASTRUCTURE - LAND & BUILDING, WATER AND POWER

6.5

LEGAL ASPECTS TO COMPLY

* PROVISIONAL

REGISTRATION

OF

THE

UNIT

IN

THE

CONCERNED STATE / UNION TERRITORY

* DOCUMENTS

REQUIRED

FOR

REGISTRATION

ON

PROVISIONAL BASIS

* PERMISSIONS/CLEARENCES REQUIRED

7.0 CENTRAL GOVT. POLCIY INITITATIVES TO INCREASE EXPORTS :

Since agricultural exports offer greatest potential for increasing the

farm income, tackling unemployment, earning foreign exchange, the

Govt. has been providing a thrust to agricultural exports by building

upon conducive policy environment. A number of policy changes have

been introduced to make agricultural exports more viable. Some of

the measures include:

Import of capital goods on concessional custom duty

Zero duty in case of CIF value of capital goods of Rs. 5 crores or more

for agriculture, aquaculture, horticulture, floriculture etc. with export

obligation of 6 times CIF value of CG on FOB prices or 5 times CIF

value of CG on NFE basis with 6 years period for fulfillment of export

obligation.

Permitting 50% of the production in value terms to be sold in the

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

41

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

Domestic Tariff area subject to positive net foreign exchange earnings.

.

Entitlement of Special Import Licnece ;

- 1 % additional SIL for export of products like fruits, vegetables,

floriculture and horticulture products provided export of these

items is more than 10% of exports during that period.

7.1 INCENTIVES & BENEFITS AVAILABLE FROM THE GOVERNMENT:

The existing procedure of issuing eligibility certificate by the District

Industries Centre and admission of claim by Maharashtra State Electricity Board will

continue.

7.2 Special Tax Concessions

The Government offers a wide range of concessions to investors in India to

promote industrial growth and exports. The important concessions include :

Deduction of preliminary and preoperative expenses in setting up a project.

Complete tax exemption for profits from exports.

Five year tax holidays within the first eight years of commercial operations for

100% EOUs and units in EPZ.

Deduction of 30% of gross total income for 10 years for new industrial

undertakings established by companies.

Deduction of capital research and development expenditure.

7.3 Relief for Foreign Nationals :

A "Short Stay" exemption applies where all the following conditions are met :

The individual is a foreign national employed by a foreign company not doing

business in India

His stay in India does not exceed 90 days in a tax year (extended to 183 days in

certain tax treaties); and

His remuneration is not deductible in arriving at his employer's Indian taxable

income.

- Foreign technicians in certain prescribed areas are eligible for a special exemption

from tax on their salary income. The tax on their salaries could be paid by their

employees without such tax being held as part of salary for tax purposes. This

special concession is available for four years and is also fully deductible for

corporate tax purpose.

Foreign nationals are exempt from tax for home leave travel benefits for

themselves and their families, provided by the employer.

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

42

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

7.4 SSI Regulations:

7.4.1

-

FOREIGN DIRECT INVESTMENT APPROVAL POLICY HIGHLIGHTS

An industrial undertaking, i.e., a company with interests in

industry can invest upto 24% equity in a SSI unit.

- If the equity goes beyond 24%, the industrial unit loses its SSI

status.

- There is no restriction on the extent of equity that can be held

by a Non-resident Indian (NRI) as an individual/partner in a SSI

unit.

- Automatic approval is granted by Reserve Bank for foreign

investment upto 51% in 35 high priority industries.

- Investors need to file an application with the Reserve Bank of

India (RBI) in the prescribed format and approval is ordinarily

granted within 15 days.

- For foreign investment outside the automatic route, clearance

has to be obtained from Foreign Investment Promotion Board

(FIPB).

- Applications for setting up a 100% Export Oriented Unit are

also required to be filed with the SIA.

- For setting up an unit in an Export Processing Zone (EPZ),

application has to be filed with the Development Commissioner

of the concerned EPZ.

- Under automatic procedures, foreign technology agreements

are being permitted in respect of industries that are designated

as high priority industries.

- The use of foreign brand names and / or trade mark of goods

is

also

now

being

permitted

freely.

- To provide access to international markets, majority foreign

equity holding upto 51% equity is being permitted for

international trading companies that are primarily engaged in

export activities.

7.4.2

OPERATING

ENVIRONMENT

AND

TAXATION

POLICIES

FDI can be in the form of cash or capital goods and there is no

minimum cash requirement, Branch organisations are

permitted only in a few specified service industries such as

banking, shipping, airlines etc., or export-oriented ventures.

Mktg Off : Residency Road, Sadar, Nagpur 440 001, ( M.S.)

Ph : 0712 2565152 , Email :smbprojcts@yahoo.co.in

43

ABSOLUTE TECHNLOGIES

Cell : 09860240852

Visit Our Website : www.absoluteprojectreports.net

Certain industries, as mentioned in the industrial policy, require

license by their nature, while others require such a license only

if

located

in

the

proximity

of

a

large

city.

This licensing applies uniformly to domestic and foreign

investment.

Also certain products are reserved for the small scale sector

and large undertakings are ordinarily permitted equity

participation up to 24 percent of total shareholding in these.

There is no restrictions regarding access to domestic markets

or

user

of

foreign

brand

names.

A work-permit as such is not required for expatriate employees,

but permission to stay is required from the Government where

the period of stay is more than three months.

RBI permission is also required to employ expatriates where

remittance of salary in foreign exchange is envisaged.

7.4.3

FDI

APPROVAL

METHODOLOGY

The highlight of the policy is the promoted prducts category

(Priority Sector in FDI)where approval for up to 51% equity

investment proposals is automatic and where only an

application to the Reserve Bank of India is required. This

procedure is also applicable to investment proposals involving