Integrarea Tehnologiei Informatiei În Activitatea de Management

Diunggah oleh

Gavrus Andreea0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

21 tayangan5 halamanIntegrarea Tehnologiei Informatiei În Activitatea de Management

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniIntegrarea Tehnologiei Informatiei În Activitatea de Management

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

21 tayangan5 halamanIntegrarea Tehnologiei Informatiei În Activitatea de Management

Diunggah oleh

Gavrus AndreeaIntegrarea Tehnologiei Informatiei În Activitatea de Management

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 5

Contents

Foreword

Preface

Chapter 1

Main Issues of Supply Chain Management

Sebastian Kot

1.1. Conception of Supply Chain Management

1.2. Strategy and Activity of Enterprises in Supply Chain Management

1.3. Theoretical Development of Supply Chain Management

Chapter 2

Network Solutions and Bullwhip Effect in Supply Chains

Marta Starostka-Patyk

2.1. Basic Information On Network Solutions

2.2. Bullwhip Effect

2.3. Possibilities of Bullwip Effect Reduction

2.4. Partners Integration as the Key in Networks Relations

2.5. Systems Supporting the Networks Creation and Developmen

2.6. Networks Creation and Development

Chapter 3

Collaborative Business Process Management

Virgil Popa

3. 1. Collaborative Business Management

3.1.1. Collaborative Excellence - Improved Productivity and Growth

3.1.2. Collaborative Management Based on Data from POS (Point of

Sale)

3.1.3. JAG (Jointly Agreed Growth) model of collaborative growth

3. 2. Supply Chain Excellence through Practicing Collaborative Business

Process Standards

3.2.1. Collaborative Management

3.2.2. SCM 4 ECR. Supply Chain Management for Efficient

Consumer Response

3.2.3. Through Business process Improvement to Business Process

Management

3.2.4. The Redesign Process Project

3.3. The Management of SCM Processes Using the SCOR Model

3.3.1. Description

3.3.2. SCOR Model Structure

3.3.3. Performance Attributes and Level Indicators

3.4. The Redisign of Logistic Chain Processes

3.4.1. Proactive Action with Selected Clients

3.4.2. The Advanced Partnership can be Made Using Some

Techniques:

3.4.3. Experiencing a Complete Supply Chain

3.4.4. The APQC Process Classification Framework

3.5. Continuous Replenishment (CRP) and logistic chain management

3.5.1. Changing Relationship between Trading Partners

3.5.2. ECR Proceses

3.5.3. Continuous Replenishment

Chapter 4

Information Systems Supporting Cooperation in Supply Chains

Sebastian Kot, Marta Starostka-Patyk and Beata lusarcyk

4.1. Relations and Cooperation in Supply Chains

4.2. Informatics Technologies in Supply Chains

4.3. Strategic Support for IT Systems in Supply Chains

Chapter 5

The Sustainable Development Conception in Supply Chain

Management

Paula Badjor

5.1. The Essence of Sustainable Development Conception

5.2. Sustainable Development Elements in Supply Chain Management

5.3. Transport and Supply as the Integral Parts of Supply Chain

Management

5.4. Identification of Sustainable Development Elements in the Processes

of Transport and Supply

Chapter 6

Strategic Alignment in Suplly Chain

Virgil Popa

6.1. Strategic Alignment of Service Providers (3PL Third Part Logistics)

6.1.1. Transport and Logistics in Europe

6.1.2. ECR Europe Projects

6.1.3. Sustainable Transport Challenges to Overcome

6.1.4. Transport Optimization Guidelines

6.1.5. The ECR Model for Sustainable Transport Road Map

6.1.6. ECR Europe Project on Sustainable Transport Working

Together to Deliver to Consumers Whilst Minimizing Environmental

Impact

6.2. Techniques and Tools in Logistics Services

6.2.1. Techniques and Enablers

6.2.2. Efficient Unit Loads

6.2.3. Unit Load Identification and Tracking (ULIT)

6.3. Collaborative Project for New Product Development. Case Study

6.3.1. Introduction

6.3.2. New Concept Development Model

6.3.3. Developed, collect and screen ideas

6.3.4. New Product Introduction (NPI) in food industry

6.3.5. Managing The NPI Forecasting & Planning Process: Current

Practices

6.3.6. Internal and external NPI collaboration

6.3.7. Involvement of supply chain management

6.3.8. Money being lost on new product introductions

6.3.9. The long-term value argument

6.3.10. Global Commerce Initiative

6.3.11. NPI Process Management Project The Engineer-to-Order

Process (SCOR Model)

Chapter 7

Global Standards and Managerial Instruments in SCM in Consumer

Goods and Retail Industry

Virgil Popa

7.1. Radio Frequency Identification (RFID) and Electronic Product Code

(EPC) in Supply Chain Management

7.1.1. Introduction

7.1.2. The Technology of RFID

7.1.3. The RFID Technology

7.1.4. Examples Of RFID Applications

7.1.5. The Supply Chains of Today

7.1.6. Electronic Product Code (EPC)

7.1.7. The Benefits of EPC for the Modern Supply Chain

7.1.8. The Potential Benefits of EPC for the Modern Supply Chain

7.1.9. Considerations for EPC Adoption

7.1.10. RFID-based EPC will Fail in Supply Chains Built on

Inaccurate Data

7.1.11. A free Flow of Goods

7.1.12. The EPC Network

7.2. Information Alignment in SCM Through Standards Global Data

Synchronization (GDS)and EPC Global

7.2.1. Introduction

7.2.2. Overview of Global Data Synchronization (GDS)

7.2.3. Master Data Synchronization

7.2.4. Global Upstream Supply Initiative (GUSI)

7.2.5. Business Rationale

7.2.6. Integrated Suppliers

7.2.7. Case for Using Existing GS1 Item and Location Coding

Standards

7.2.8. The Upstream Integration Model (UIM)

7.2.9. An Integrated View of the Global Data Synchronization

Network with Electronic Product Code Network

7.2.10. Creating the Business Case for Global Data Synchronization

in the Company

7.2.11. Global Trade Item Number (GTIN) Definition

7.2.12. An Introduction to the Serial Shipping Container Code

7.2.13. CPG Company Best Practices (Nestl)

7.3. Collaborative Planning, Forecasting and Replenishment (CPFR)

7.3.1. Defining CPFR

7.3.2. Key Requirements for Collaboration

7.3.3. Analysis of Existing Processes

7.3.4. Main Gaps that Persist through Current Practice of Forecasting

and Planning

7.3.5. Opportunities That Arise Through CPFR

7.3.6. Other benefits of CPFR

7.3.7. The CPFR Process

Chapter 8

General aspects of reverse logistics

Marta Starostka-Patyk

8.1. Theoretical Framework for Reverse Logistics Concept

8.2. Reverse Logistics Main Processes

8.3. Closed and Open Loops in Reverse Logistics

8.4. Place of Reverse Logistics in Sustainable Development

8.5. Reverse Logistics in Companies Practice for Environmental

Management and Protection

8.6. Barriers to Reverse Logistics Implementation in Companies Practice

Chapter 9

Performance Management of Collaboration in Supply Chain

Virgil Popa

9.1. Supply Chain Performance and Strategic Collaborative Management

through Balanced Scorecard. Case Study

9.1.1. Introduction

9.1.2. ECR Europe Studies Regarding Alliance Performances

9.1.3. The Collaborative Management of ECR Alliance

9.2. Performance Dashboard - a Piloting Tool of a SC Processes. Case

Study

9.2.1. Managing and Measuring the Performance of Supply Chain

Processes

9.2.2. The Five Major Processes of a High Performance Supply

Chain

9.2.3. Performance Dashboard - a Piloting Tool of a SC Processes.

Case Study

9.2.4. The Logistic Chain of SC. ILDTA SA

9.2.5. Piloting the Supply Chain of S.C. ILDA SA using the

Balanced Scorecard

9.3. Measuring the Alliance Performance Between Two Organizations to

Promote a Fast Moving Consumer Goods (FMCG). Case Study

9.3.1. Manufacturer/Distributor-Retailer Alliance Performance

Measurement

9.3.2. Development of the Process for Measuring Sales Promotion

Performance

9.3.3. Defining Key Performance Indicators (KPI) of the Impact of

Promotion

9.3.4. The Common Workflow for Entry-Level Scorecard and KPI

9.3.5. Promotion Optimization

9.3.6. Case Study

9.4. Performance Management of Supply Chain Using Balanced Scorecard

in Nonprofit Organizations

9.4.1. Supply Chain in NGOs

9.4.2. Supply Chain Measures for a Nonprofit Organization

9.4.3. The Balanced Scorecard (BSC)

9.4.4. Example. A nonprofit Organization that Adopted Balanced

Scorecard

9.4.5. Implementing a Performance Management System

Capter10

New Direction in SCM in The New Economy

Virgil Popa and Madalina Barna

10.1. Collaborative Business for Value Chain Management

10.1.1. A New Model for Enhanced Collaboration

10.1.2. The Consumer Centric

10.1.3. Best practices for New Generation SCM Model

10.2. Corporate Social Responsibility (CSR) in Collaborative Supply

Chain of Consumer Goods Industry and Retail

10.2.1. Introduction

10.2.2. Social Responsibility in Supply Chain Management

10.2.3. CSR in Supply Chain

10.2.4. Global Projects in SCM

10.2.5. CSR in the Supermarkets

10.3. The Financial Supply Chain Management (FSCM): a Response to

the New Economy

10.3.1. Financial Supply Chain Management (FSCM)

10.3.2. Supply Chain Finance

10.3.3. Working Capital Management

10.3.4. A New Financial Solution: Factoring and Reverse Factoring

vs. Commercial Credit

10.3.5. Good Practices in Romania and Community Acquis

Appendices

Index

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Case Study - Exel and JITDokumen3 halamanCase Study - Exel and JITThompsonBW100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Presentation - CIBAP Exam PreparationDokumen249 halamanPresentation - CIBAP Exam PreparationAhmad Farouk0% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- EQPS MAF451 - July2020Dokumen10 halamanEQPS MAF451 - July2020Nur AthirahBelum ada peringkat

- Praveen Balaji.RDokumen3 halamanPraveen Balaji.RPraveen Balaji RamachandranBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Plastics Guide Chem ResDokumen364 halamanPlastics Guide Chem ResRebe RealyBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- TQM at MindaDokumen14 halamanTQM at MindaVivek RanjanBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Pso SCMDokumen18 halamanPso SCMArfa PunjaniBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Value Stream MappingDokumen3 halamanValue Stream Mappinghendryaristyo100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Supplier Quality Agreement TemplateDokumen5 halamanSupplier Quality Agreement Templatejuda823100% (3)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- 12 Task Performance 1Dokumen3 halaman12 Task Performance 1Razel AntiniolosBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Microeconomics - Tutorial Practice Attempt 8&9Dokumen5 halamanMicroeconomics - Tutorial Practice Attempt 8&9Kelyn KokBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- 20 Ways To Improve Productivity in Garment Production and Planning CapacityDokumen8 halaman20 Ways To Improve Productivity in Garment Production and Planning CapacityCucak RowoBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- OM Project AssignmentDokumen3 halamanOM Project Assignmentsoham agarwalBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Chapter 20 Process Cost SystemsDokumen89 halamanChapter 20 Process Cost SystemsThanakrit LerdmatayakulBelum ada peringkat

- Value-Adding: 5% Muda: 95%: Inventory Motion Waiting Knowledge DisconnectionDokumen5 halamanValue-Adding: 5% Muda: 95%: Inventory Motion Waiting Knowledge DisconnectionDavid Osiris Fernandez AvalosBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Characteristics of Jit SystemDokumen5 halamanCharacteristics of Jit SystemnehaBelum ada peringkat

- Gantt: Having Fun WithDokumen51 halamanGantt: Having Fun WithDelmar José Ribeiro SábioBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Purchasing Documents TypesDokumen8 halamanPurchasing Documents TypesMohamed Awad100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- About Hemant Urdhwareshe: Fellow of ASQDokumen3 halamanAbout Hemant Urdhwareshe: Fellow of ASQKumar AbhishekBelum ada peringkat

- Schedule Machine Installation FP 3Dokumen14 halamanSchedule Machine Installation FP 3hardidwiBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Chapter 8 Supplier Quality ManagementDokumen28 halamanChapter 8 Supplier Quality Managementsantiny sanBelum ada peringkat

- All CertificateDokumen25 halamanAll CertificateFerdie OSBelum ada peringkat

- Session 12 Inventory ManagementDokumen35 halamanSession 12 Inventory ManagementTulus Dika PamungkasBelum ada peringkat

- SCDL - PGDBA - Finance - Sem 2 - Production & Operations ManagmentDokumen32 halamanSCDL - PGDBA - Finance - Sem 2 - Production & Operations Managmentapi-376241991% (11)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

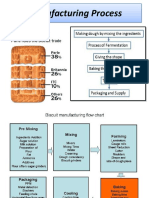

- Manufacturing ProcessDokumen12 halamanManufacturing ProcessmehrezBelum ada peringkat

- EileenDokumen82 halamanEileenBhawna KhoslaBelum ada peringkat

- Synergy BIM and Lean ConstructionDokumen33 halamanSynergy BIM and Lean ConstructionNicolae VedovelliBelum ada peringkat

- Port Aka Bin Case Study Lean ProductionDokumen7 halamanPort Aka Bin Case Study Lean ProductionEmma JonesBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Chapter 2 Schoeder - Operations and Supply Chain StrategyDokumen19 halamanChapter 2 Schoeder - Operations and Supply Chain StrategyMuhamad FuadBelum ada peringkat

- Module 1 - The Nature of ProjectsDokumen30 halamanModule 1 - The Nature of Projectsmysterix01Belum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)