PWI PWA 10pg 24

Diunggah oleh

Manzar KhanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

PWI PWA 10pg 24

Diunggah oleh

Manzar KhanHak Cipta:

Format Tersedia

PWA

ANSI / ASME B73.1

PROCESS PUMP

PWA ANSI/ASME B73.1 PROCESS PUMP

COMPETITIVE ADVANTAGES

5 Year Unconditional

Power Frame Warranty is

Standard at No Additional Cost.

Carbon Steel

vs. Ductile Iron

n High strength, impact resistant

Carbon Steel liquid ends for

improved durability and

pressure containment at

no additional cost.

n Replaces non-repairable,

ductile iron casing and

impellers, with repairable

carbon steel, for extended

component life.

Power Frame

Superiority

Flange Arrangement Options

n Standard ANSI class 150# flange

pressure rating, flat or raised face design, provided to meet

customer specified requirements at no additional cost.

n Optional ANSI class 300# flange (375 PSI MAWP),

flat or raised face design, provided at no additional cost over

150# flanges.

n Superior high strength carbon steel vs. inferior cast iron

power frame material.

n Addresses environmental and safety concerns.

n Exclusive finned bearing frame for maximum heat dissipation.

n Convenient dual oil level sight glasses provide flexible

viewing as standard.

Shaft and

Bearing Assembly

n Upgraded 316 SS vs. 4140 steel pump shaft is standard

at no additional cost.

n Proven flinger disk lubrication device to ensure effective

bearing lubrication. Provides 30% increased bearing L-10

life and minimum 15 lower bearing operating

temperatures compared to flood oil design.

Standard bore

Component seal

Tapered bore

Single cartridge seal

Big bore

Dual cartridge seal

Seal Chamber / Sealing Solutions

n Multiple seal chambers for maximum sealing flexibility

for all process applications.

n Accommodates all mechanical seal manufacturers

component and ANSI cartridge seal configurations.

n Supports the full array of CPI seal support system options.

n Ensures superior leak protection with maximum heat

dissipation, maximizing seal life and pump reliability.

Structural Steel Base

Fabricated Steel PLUS Base

Baseplate Systems

Fabricated Steel Base

n Baseplate mounting structures designed to meet the

full variety of installation applications.

n Designed for optimum unit reliability, while meeting

user preferences for economy, chemical resistance and

installation features.

Polymer composite, non-metallic

P r i c e

All materials are USA sourced to meet

all Country of Origin requirements.

D e l i v e r y

Q u a l i t y

G E T

A L L

PWA ANSI/ASME B73.1 PROCESS PUMP

DESIGN FEATURES AND BENEFITS

Casing Gasket

Fully confined to

maximize liquid sealing

Protects casing fits from

corrosion, therefore

increase maintenance

ease and proper

alignment during

reassembly

Seal Chamber / Sealing Options

Multiple seal chambers for maximum sealing flexibility for all process

applications.

Accommodates all mechanical seal manufacturers component and ANSI

cartridge seal configurations

Supports the full array of CPI seal support system options

Ensures superior leak protection with maximum heat dissipation, maximizing

seal life and pump reliability

Frame Adapter

Carbon Steel

standard for

increased

strength

and stability

Casing

Carbon Steel ASTM A216 material standard for

improved durability and pressure containment

Class 150# standard and 300# option

Self venting, centerline mounted discharge flange

Casing thickness exceeds ASME B73.1specification

for increased casing life

Back pull out design for easy maintenance

Full line of corrosive resistant materials

Quality

Manufactured and tested

in the USA

Impeller

Fully open for increased corrosion,

abrasion and solids wear resistance

Back pump out vanes for

reduced thrust loading and seal

chamber operating pressure

Delivery

Pump components strategically

inventoried for rapid shipment

in a variety of material options.

Casing Drain

Optional casing drain and

drain piping

Foot Mounted Casing

Maximum casing stability and

support for back pull out

maintenance feature

Reduced vibration

P r i c e

D e l i v e r y

Q u a l i t y

G E T

A L L

ePOD Pump Selector

Bearing Lubrication

Flinger disk lubrication

device to ensure effective

bearing lubrication and

lower bearing operating

temperatures

Access to end users and specifiers

to select your pump application online at

www.pumpworksindustrial.com

Labyrinth Oil Seal

Inpro VBXX-D bearing housing isolators providing

positive sealing environment preventing oil

contamination

Optional Sealed bearing frame with magnetic

seals and expansion chamber for severe

environments

Thrust Bearing

Heavy duty double row standard

Optional duplex angular contact thrust bearing

Externally Adjustable Shaft

and Impeller System

Easily adjust impeller to front casing clearance

without removal of pump from piping

Restoration to factory efficiencies

Bearing Housing

Large oil sump capacity for increased cooling

Standard flinger disk design, with optional regreasable,

purge oil mist and pure oil mist lubrication

Standard finned design for maximum heat dissipation

Contoured internal slope for positive collection of metal

contaminants by magnetic drain plug

Optional 316 SS Tube Finned Cooler for high process

temperatures above 350 F to 700 F

PWA ANSI/ASME B73.1 PROCESS PUMP

Filter Vent

Allows free

exchange of

clean, dry

filtered air

within the

bearing housing

protecting oil

and bearings

from moisture

and particle

contamination

Two Oil Level Sight Glasses

1" sight glass located on each side of bearing housing for flexible viewing

Oil Sump Drain Plug

Magnetic plug to maintain bearing housing cleanliness and increased protection

Shaft and Bearing System

Rigid, heavy duty design for minimal shaft deflection at seal area and increased reliability

Exceeds ASME B73.1 bearing life specification requirements

316L Shaft material is standard with optional material upgrades available

P r i c e

D e l i v e r y

Q u a l i t y

G E T

A L L

PWA ANSI/ASME B73.1 PROCESS PUMP

LEVERAGING TECHNOLOGY

PumpWorks Industrial leverages technology by providing:

n Superior manufacturing capabilities.

n Company owned USA foundry.

n Extensive inventory selection.

n Professional, reliable service.

MANUFACTURING

n All of our pumps are manufactured and tested in the United

States of America, utilizing exclusive state-of-the-art

manufacturing equipment and US foundries for all castings.

This ensures consistent quality, product availability, and low cost

of ownership.

FOUNDRY PumpWorks Castings

n Precision investment cast

impellers yields exceptionally

smooth surface finish ensuring

repeatable, efficient hydraulic

performance.

n One ton piece part capacity.

Metallurgies from Carbon Steel

through Titanium.

n Complete in house casting inspection includes certified

spectrographic, hardness, physical properties and live casting

X-ray analysis.

INVENTORY

n Pump and component inventory in a variety of material

options are strategically located through the Northern

hemisphere ensuring consistent, rapid shipment tailored to

customer requirements.

SERVICE

n Fully staffed professional sales

and service teams providing

superior customer support is

available 24/7/365.

n ePOD Pump Selector access by end users and

specifiers available online at no additional cost at

www.pumpworksindustrial.com

P r i c e

D e l i v e r y

Q u a l i t y

G E T

A L L

PWA ANSI/ASME B73.1 PROCESS PUMP

HYDRAULIC

PERFORMANCE

COVERAGE

60 Hz

Performance

Coverage

Visit our web site at

www.pumpworksindustrial.com

and specify flow and

performance needs and obtain

pump selection, performance

curve, drawing, and data sheet.

Performances shown are nominal

and are to be used for preliminary

selection only.

50 Hz

Performance

Coverage

Visit our web site at

www.pumpworksindustrial.com

and specify flow and

performance needs and obtain

pump selection, performance

curve, drawing, and data sheet.

Performances shown are nominal

and are to be used for preliminary

selection only.

P r i c e

D e l i v e r y

Q u a l i t y

G E T

A L L

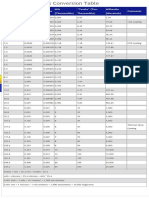

PWA ANSI/ASME B73.1 PROCESS PUMP

NEMA MOTOR

FRAME

WEIGHT

lb (kg)

182T

98 (45)

128 (58)

197 (89)

226 (103)

375 (170)

412 (187)

495 (225)

519 (235)

700 (318)

756 (343)

948 (430)

1009 (458)

1330 (603)

1820 (826)

1893 (859)

2343 (1073)

3020 (1370)

184T

213T

215T

254T

256T

284T

286T

324T

326T

364T

365T

Not to be used for

construction unless

certified by manufacturer.

405T

444T

445T

447T

449T

PUMP

PUMP DIMEDIMENSIONS

NSIONS and WEIGHTS AND WEIGHTS

FRAME

ANSI

DISCHARGE

DESIGNATION

SIZE

SIZE

1x1.5x6

1.5x3x6

GROUP 1

2x3x6

1x1.5x8

1.5x3x8

3x4x7

1 2x3x8

3x4x8

3x4x8G

1x2x10

1.5x3x10

2x3x10

GROUP 2 /

3x4x10

GROUP 3

3x4x10H

4x6x10G

4x6x10H

1.5x3x13

2x3x13

3x4x13

4x6x13

6x8x13

8x10x13

6x8x15

8x10x15

GROUP 4

8x10x15G

8x10x16H

4x6x17

6x8x17

8x10x17

AA

AB

SUCTION SIZE

1

1.5

2

1

1.5

3

2

3

3

1

1.5

2

3

3

4

4

1.5

2

3

4

6

8

6

8

8

8

4

6

8

AC

AA

AB

A70

A60

A70

A70

A05

A50

A60

A70

A40

A80

A80

A20

A30

A40

A80

A90

A100

A110

A120

A120

A120

A105

A110

A120

1.5

3

3

1.5

3

4

3

4

4

2

3

3

4

4

6

6

3

3

4

6

8

10

8

10

10

10

6

8

10

6.5 (165)

13.5 (343)

4.0 (102)

5.25 (133)

SP

WEIGHT BARE

PUMP

lb (kg)

3.75 (95)

110 (50)

120 (55)

125 (57)

130 (59)

135 (61)

11 (280)

9.5 (242)

270 (122)

265 (120)

11 (280)

300 (137)

8.25 (210)

8.5 (216)

9.5 (242)

11 (280)

12.5 (318)

19.5 (496)

4 (102)

3.75 (95)

13.5 (343)

385 (175)

10 (254)

10.5 (267)

11.5 (292)

12.5 (318)

13.5 (343)

16 (406)

350 (159)

355 (161)

370 (168)

440 (200)

18 (457)

19 (483)

280 (127)

285 (129)

275 (125)

290 (132)

305 (138)

27.875 (708)

14.5 (368)

6 (152)

5.25 (133)

16 (406)

18 (457)

19 (483)

620 (281)

740 (336)

700 (318)

800 (363)

775 (352)

1030 (467)

720 (327)

815 (370)

885 (401)

Weights and dimensions are approximate and not to be used for construction.

BASEPLATE DIMENSIONS and WEIGHTS

BASEPLATE

AND WEIGHTS

BASEPLATE DIMENSIONS DIMENSIONS

and WEIGHTS

HD Max

MAX NEMA

FRAME

ANSI

BASEPLATE

NUMBER

HA

184T

256T

326TS

139

148

153

12 (381)

15 (457)

18 (533)

39 (991)

48 (1219)

53 (1346)

184T

215T

286T

365T

405TS

449TS

245

252

258

264

268

280

12 (381)

15 (457)

18 (533)

21 (533)

24 (660)

26 (660)

45 (1143)

52 (1321)

58 (1473)

64 (1626)

68 (1727)

80 (2032)

286T

405T

449T

368

380

398

24 (660)

26 (660)

26 (660)

68 (1727)

80 (2032)

98 (2489)

HB

D=5.25 (133)

D=8.25 (210)

D=10 (254)

9 (229)

10.5 (267)

12.88 (327)

12 (305)

12.38 (314)

13 (330)

13.88 (353)

14.88 (378)

15.88 (403)

HE

HF

HH

HP TYP

WEIGHT

lb (kg)

4.5 (114)

6 (152)

7.5 (191)

36.5 (927)

45.5 (1156)

50.5 (1283)

0.75 (19)

0.75 (19)

0.75 (19)

1.25 (32)

1.25 (32)

1.25 (32)

199 (90)

245 (111)

258 (117)

4.5 (114)

6 (152)

7.5 (191)

7.5 (191)

9.5 (241)

9.5 (241)

42.5 (1080)

49.5 (1257)

55.5 (1410)

61.5 (1562)

65.5 (1664)

77.5 (1969)

0.75 (19)

0.75 (19)

1 (25)

1 (25)

1 (25)

1 (25)

1.25 (32)

1.25 (32)

1.25 (32)

1.25 (32)

1.25 (32)

1.25 (32)

266 (212)

305 (138)

323 (147)

346 (157)

372 (169)

437 (198)

9.5 (241)

9.5 (241)

9.5 (241)

65.5 (1664)

77.5 (1969)

95.5 (2426)

1 (25)

1 (25)

1 (25)

1.25 (32)

1.25 (32)

1.25 (32)

493 (224)

580 (263)

710 (322)

D=14.5 (368)

13.75 (349)

14.13 (359)

14.75 (375)

14.75 (375)

14.88 (378)

15.88 (403)

19.25 (489)

19.25 (489)

19.25 (489)

Weights and dimensions are approximate and not to be used for construction.

P r i c e

D e l i v e r y

Q u a l i t y

G E T

A L L

PWA ANSI/ASME B73.1 PROCESS PUMP

PWA INTERCHANGEABILITY CHART

Group

Shaft and Frame

Assembly

Adapter

Cover

Impeller

Case

1X1.5X6 AA

1.5X3X6 AB

2X3X6 AC

1X1.5X8 AA

1.5X3X8 AB

Group 1

1-3/8 Shaft

Dia. Max BHP40HP

3X4X7 A70

2X3X8 A60

3X4X8 A70

3X4X8G A70

1X2X10 A05

1.5X3X10 A50

2X3X10 A60

3X4X10 A70

3X4X10H A40

4X6X10G A80

4X6X10H A80

1.5X3X13 A20

2X3X13 A30

3X4X13 A40

4X6X13 A80

Group 2

1-3/4 Shaft

Dia. Max BHP122HP

1X2X10 A05

1.5X3X10 A50

2X3X10 A60

3X4X10 A70

3X4X10H A40

4X6X10G A80

4X6X10H A80

1.5X3X13 A20

2X3X13 A30

3X4X13 A40

4X6X13 A80

Group 3

2-1/8 Shaft

Dia. Max BHP200HP

6X8X13 A90

8X10X13 A100

6X8X15 A110

8X10X15 A120

8X10X15G A120

8X10X16H A120

4X6X17 A105

6X8X17 A110

8X10X17 A120

Group 4

2-1/2 Shaft

Dia. Max BPH250HP

17 IN PWA has

2-3/4 Shaft

Dia. Max BHP350HP

Size

P r i c e

D e l i v e r y

Q u a l i t y

G E T

A L L

PWA ANSI/ASME B73.1 PROCESS PUMP

PARTS LIST AND MATERIALS OF CONSTRUCTION

Item Ref

Number

Carbon Steel

Carbon Steel

w/ 316 SS

Impeller

316SS

CA6NM (12 % Chrome)

Duplex SS

Super Duplex SS

Alloy 20

Monel

Nickel

Hastelloy B & C

Titanium

100

Casing

Carbon Steel

Carbon steel

316SS

CA6NM (12%Chrome)

Duplex SS CD4 Gr1B

Super Duplex SS CD4 Gr5A

Alloy 20

Monel

Nickel

Hastelloy B & C

Titanium

101

Impeller

Carbon Steel

316SS

316SS

CA6NM (12%Chrome)

Duplex SS CD4 Gr1B

Super Duplex SS CD4 Gr5A

Alloy 20

Monel

Nickel

Hastelloy B & C

Titanium

105

Lantern Ring

106

Packing, Stuffing Box

108

Adapter, Frame

112A

Thrust Bearing

122

Shaft - Less Sleeve

Alloy 20

Monel

Nickel

Hastelloy B & C

Titanium

122

Shaft with Sleeve

Alloy 20

Monel

Nickel

Hastelloy B & C

Titanium

Part Name

Glass Filled Teflon

Teflon - Impregnated Fibers

Carbon Steel

Double Row Angular Contact - note (1)

316L (Optional-Alloy 20 & A2205)

316L (Optional-Alloy 20 & A2205)

316SS (Optional-Alloy 20 & A2205)

126

Shaft Sleeve

136

Bearing Lock Nut and Lock Washer

168A

Radial Bearing

Duplex SS CD4 Gr1B

Super Duplex SS CD4 Gr5A

Steel

Single Row Deep Groove

184

Cover, Stuffing Box (Packed Box)

Carbon Steel

Carbon Steel

316SS

CA6NM (12%Chrome)

Duplex SS CD4 Gr1B

Super Duplex SS CD4 Gr5A

Alloy 20

Monel

Nickel

Hastelloy B & C

Titanium

184

Seal Chamber (Mechanical Seal)

Carbon Steel

Carbon Steel

316SS

CA6NM (12%Chrome)

Duplex SS CD4 Gr1B

Super Duplex SS CD4 Gr5A

Alloy 20

Monel

Nickel

Hastelloy B & C

Titanium

228

Frame, Bearing

248A

Flinger with Set Screw

250

Gland - Seal/Packing

Alloy 20

Monel

Nickel

Hastelloy B & C

Titanium

370H

Stud/Nut, Cover to Adapter

Alloy 20

Monel

Nickel

Hastelloy B & C

Titanium

Carbon Steel

Bronze with Steel Set Screw

CA6NM (12%Chrome)

316SS

Duplex SS CD4 Gr1B

Super Duplex SS CD4 Gr5A

304SS

319

Sight Glass - Oil

332A

INPRO-Oil Seal (Outboard)

333A

INPRO-Oil Seal (Inboard)

351

Gasket, Casing

358

Plug, Casing Drain (Optional)

360F

Gasket, Frame to Adapter

Buna Rubber

360C

Gasket, Bearing End Cover

Cellulose Fiber with Binder

370

Cap Screw, Adapter to Casing

412A

O-ring, Impeller

Glass/Steel

Bronze

Stainless Steel/Bronze

Aramid Fiber with Binder

Carbon Steel

Carbon Steel

316SS

CA6NM (12%Chrome)

Duplex SS CD4 Gr1B

Super Duplex SS CD4 Gr5A

Steel

Glass Filled Teflon

418

Jacking Bolt

469B

Dowel Pin, Frame to Adapter

496

O-ring, Bearing Housing

Buna Rubber

637

Filter Vent

Carbon Steel

304SS

Steel

(1) Duplex angular contact bearing Standard on Group 3, Bearing Frame and optional on Group 1, 2, and 4.

GROUP 1

Sectional View PWA

248A

637

GROUP 2 / GROUP 3

370

100

228 168A 333A

136

332A

122

112A

GROUP 4

248A

228

P r i c e

358

351 184

637 333A 360F 126 184 108

370

Sectional View PWA

370

136

100

101

122

412A

332A

496

319

Sectional View PWA

112A

332A

122

136

360C

112A

412A

250 418

168A

228

101

496

319

248A 637 168A 333A 469B 108

184

351

360F 250 418

358

100

101

412A

496

250

D e l i v e r y

418

184

358

351

Q u a l i t y

G E T

A L L

PWA ANSI/ASME B73.1 PROCESS PUMP

TECHNICAL DATA

GP1

GP2

GP3

GP4

0.75 (19)

1 (25)

1.25 (32)

1.5 (38)

(Less sleeve)

1.375 (35)

1.75 (45)

2.125 (54)

2.5 (64)

(With sleeve)

1.125 (29)

1.5 (38)

1.875 (48)

2 (51) note 1

3.125 (79)

All dimensions in inches and (mm)

Shaft Diameter at Impeller

Diameter in Stuffing Box/Seal Chamber

Diameter Between Bearings

Shaft

1.5 (38)

2.125 (54)

2.5 (64)

Diameter at Coupling

0.875 (22)

1.125 (29)

1.875 (48)

2.375 (60)

Overhang

6.125 (156)

8.375 (213)

8.375 (213)

9.969 (253)

Maximum Shaft Deflection

0.002 (0.05)

Shaft Deflection Index (L3/ D 4)

(Less sleeve)

64

63

48

25

(With sleeve)

143

116

29

62

Outside Diameter thru Stuffing Box/Seal Chamber

1.375 (35)

1.75 (45)

2.125 (54)

2.5 (64) note 1

Radial

Thrust

Bearing Span

6207

3306

4.125 (105)

6309

3309

6.75 (171)

6311

7310

6.875 (164)

6313

3313

9.25 (235)

Large Bore Seal Chamber

Bore

2.875 (73)

3.5 (89)

3.875 (98)

4.75 (120) note 1

Stuffing Box

Bore

2 (51)

2.5 (64)

2.875 (73)

3.375 (86) note 1

1.1 (0.82)

3.4 (2.6)

5.6 (4.2)

14 (10.5) note 2

Sleeve

Bearings

Maximum Power Limits

HP (kW) per 100 RPM

up to 280 PSI (1931 kPa) at 100 o F with 150 # flanges

Maximum Allowable Working Pressure

note 3

Maximum Temperature

note 5

Casing

MAWP PSI (kPa) *

up to 375 PSI (2586 kPa) at 100 o F with 300 # flanges note 4

*

Consult Pressure Temperature chart for various temperatures

Oil or Grease Lubricated Bearing Frame without Optional Cooling

350 o F (177o C)

Oil Lubricated Power Frame with Option Cooling

700 o F (370 C)

Corrosion Allowance

0.125 minimum

NOTES:

1. 17 inch pump sizes - Shaft diameter at Stuffing Box / Seal Chamber is 2.25 inches (57) with sleeve. Shaft Sleeve Outside Diameter is 2.75 inches (70) for packing and

2.5 inches (64) for mechanical seals.

Seal chamber bore is 4.75 inches (121). Stuffing box bore is 3.625 inches (92).

2. 17 inch pump sizes power limitation per 100 RPM is 20HP (15kW).

3. Hydro-static test pressure equal to 1.5 times Maximum Allowable Working Pressure.

4. Pressure ratings to 740 PSI (5137 kPa) consult factory.

5. Tube Finned Cooler, Jacketed Seal Chamber, Graphite Impeller O-ring and Casing Gasket for temperatures between 450 F (232 C) to 700 F (370 C).

Test Facilities

n Test flows up to 7,500 GPM.

n Discharge test pressures up to 740 PSI.

n Supply tank rated from full vacuum to

65 psi.

n 460 volt through 500 HP, 3600 RPM.

n Variable Frequency Drive for precise

speed control through 500 HP @ 460

volt.

See our Test Facilities Brochure for more

information.

Typical Industries

n

n

n

n

n

n

n

n

n

Chemical/Petrochemical

Pulp and Paper

Food and Beverage

Oil and Gas

Primary Metals Manufacturing

Mining

Power Generation

Waste Treatment

General Industrial

PumpWorks Industrial www.pumpworksindustrial.com

PWA Brochure-1015

Anda mungkin juga menyukai

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Asimov Quick MathsDokumen190 halamanAsimov Quick MathsDani Ibrahim100% (2)

- Closure Weld RequirementsDokumen1 halamanClosure Weld RequirementsManzar Khan0% (1)

- API 610 PumpsDokumen8 halamanAPI 610 PumpsSaurabh Singh67% (3)

- Section Viii Div 1 Div 2 Div ComparisonDokumen2 halamanSection Viii Div 1 Div 2 Div Comparisonapparaokr100% (5)

- Gas Turbines A Manual PDFDokumen74 halamanGas Turbines A Manual PDFHenry Pannell100% (1)

- Gas Turbines A Manual PDFDokumen74 halamanGas Turbines A Manual PDFHenry Pannell100% (1)

- Pump Products: Hydraulic EngineeringDokumen16 halamanPump Products: Hydraulic EngineeringLászló Szabó100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Cortec Choke CatalogDokumen8 halamanCortec Choke Catalogamjath584100% (1)

- An Analysis of Transformer Failures, Part 1Dokumen4 halamanAn Analysis of Transformer Failures, Part 1Miguel CanoBelum ada peringkat

- GE Reciprocating Compressor BrochureDokumen13 halamanGE Reciprocating Compressor Brochurepratik banerjeeBelum ada peringkat

- Purine Table Provides Foods Highest and Moderately High in PurinesDokumen10 halamanPurine Table Provides Foods Highest and Moderately High in PurinesYohan Parulian SinagaBelum ada peringkat

- 01 Chemical ProcessDokumen333 halaman01 Chemical ProcessDavid ValladaresBelum ada peringkat

- BB5Dokumen16 halamanBB5Roozbeh PBelum ada peringkat

- CVO Paper PDFDokumen10 halamanCVO Paper PDFvigneshwaran100% (1)

- Stair Construction and LayoutDokumen13 halamanStair Construction and LayoutManzar Khan100% (1)

- Code PresentationDokumen60 halamanCode PresentationwenigmaBelum ada peringkat

- Bombas CentrifugasDokumen12 halamanBombas CentrifugasIsaac Deusdedit Salazar EhuanBelum ada peringkat

- Nozzle Check ValvesDokumen12 halamanNozzle Check Valvesjshadwan100% (1)

- Valves & ControlsDokumen16 halamanValves & ControlseborresonBelum ada peringkat

- Weir Split Case BrochureDokumen4 halamanWeir Split Case Brochure'Muhammad Saiful Rahman HmmwBelum ada peringkat

- Mark 3 ASME Pumps PDFDokumen94 halamanMark 3 ASME Pumps PDFInf IngBelum ada peringkat

- ValvesDokumen8 halamanValvespravin_2011Belum ada peringkat

- Serial Port Pinout of GE PLCDokumen15 halamanSerial Port Pinout of GE PLCAbde EsselamBelum ada peringkat

- DVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L IDokumen6 halamanDVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L Imiguel hernandezBelum ada peringkat

- The Performance Meets The Promise: Vectra Series Models GL & XLDokumen12 halamanThe Performance Meets The Promise: Vectra Series Models GL & XLNicolás Villarin100% (1)

- Chock Flow LineDokumen24 halamanChock Flow LineTarisahBelum ada peringkat

- BBS E00584Dokumen8 halamanBBS E00584gloohuis463Belum ada peringkat

- Delta Et Vacuum SystemDokumen16 halamanDelta Et Vacuum SystemsanjeevnnBelum ada peringkat

- Brochure BEGEMANN PA Pumps-Low ResolutionDokumen6 halamanBrochure BEGEMANN PA Pumps-Low ResolutionIsaac RubioBelum ada peringkat

- NEEDLE KF Valve BrochureDokumen11 halamanNEEDLE KF Valve Brochureheldermanuel100Belum ada peringkat

- 3G Node B (RBS) ViewDokumen49 halaman3G Node B (RBS) ViewKayode Philip Ogundare100% (2)

- Coir Geotex in Rural RoadsDokumen43 halamanCoir Geotex in Rural RoadsKrishna PrasadBelum ada peringkat

- Bombas Centrífugas BlackmerDokumen180 halamanBombas Centrífugas BlackmerGustavo Restrepo100% (1)

- Vroom-Yetton-Jago: Deciding How To DecideDokumen11 halamanVroom-Yetton-Jago: Deciding How To DecideJean Paula MercadoBelum ada peringkat

- Aurora Pump 6-491-12aDokumen28 halamanAurora Pump 6-491-12ajuan yenqueBelum ada peringkat

- Personal Satellite Communication SystemDokumen4 halamanPersonal Satellite Communication SystemvydeoBelum ada peringkat

- Boletin Tecnico No. 3 Turbinas de Vapor ElliottDokumen12 halamanBoletin Tecnico No. 3 Turbinas de Vapor Elliottcristobal_tl227750% (2)

- Change Gout - The Gout Diet PDFDokumen2 halamanChange Gout - The Gout Diet PDFManzar Khan100% (1)

- BB3 Catalogue 2015Dokumen8 halamanBB3 Catalogue 2015nima hasanzadehBelum ada peringkat

- CHTR PDFDokumen8 halamanCHTR PDFhenryBelum ada peringkat

- Aurora 340 DsDokumen4 halamanAurora 340 DsdesuyaBelum ada peringkat

- Aurora PumpsDokumen12 halamanAurora PumpsM Alim Ur RahmanBelum ada peringkat

- System OneDokumen4 halamanSystem OnerasottoBelum ada peringkat

- 4030 / 4280 Series: End Suction PumpsDokumen8 halaman4030 / 4280 Series: End Suction PumpsShrikant WalseBelum ada peringkat

- Ball Valve BrochureDokumen32 halamanBall Valve BrochureHakan KuruoğluBelum ada peringkat

- GouldsDokumen11 halamanGouldsKaren Isabel Ambiado Rivas100% (1)

- Bezrms PumpDokumen2 halamanBezrms PumpAndres BojorquezBelum ada peringkat

- CVT Vertically Suspended Sump PumpDokumen6 halamanCVT Vertically Suspended Sump PumpJose CarlosBelum ada peringkat

- CP Range: Redefining Flow ControlDokumen8 halamanCP Range: Redefining Flow ControlSmootherBelum ada peringkat

- Vertical Turbine Pumps for Demanding ApplicationsDokumen16 halamanVertical Turbine Pumps for Demanding ApplicationsAlex Arma del CarpioBelum ada peringkat

- Compact End Suction PumpsDokumen8 halamanCompact End Suction PumpsRohith RavindranathBelum ada peringkat

- HoodedProp CatalogDokumen52 halamanHoodedProp CatalogTed K NagaraBelum ada peringkat

- Single Stage ANSI Chemical Process Pump: ANSI Std. B 73.1: OH1Dokumen47 halamanSingle Stage ANSI Chemical Process Pump: ANSI Std. B 73.1: OH1Karoline EnríquezBelum ada peringkat

- Viking Heavy Duty Pumps: SERIES 4193 AND 493 Steel ExternalsDokumen12 halamanViking Heavy Duty Pumps: SERIES 4193 AND 493 Steel ExternalsBenicio Joaquín Ferrero BrebesBelum ada peringkat

- Brochure BEGEMANN BS Pumps-Low ResolutionDokumen6 halamanBrochure BEGEMANN BS Pumps-Low ResolutionunknownsaylorBelum ada peringkat

- Smithco Product Brochure 2011Dokumen8 halamanSmithco Product Brochure 2011Carlos Luis Esquerdo MarcanoBelum ada peringkat

- Durco Mark 3 Brochure PDFDokumen36 halamanDurco Mark 3 Brochure PDFVic Van PeborghBelum ada peringkat

- Horizontal Split CasingDokumen6 halamanHorizontal Split CasingsahildhingraBelum ada peringkat

- Zero Quality PDFDokumen6 halamanZero Quality PDFDia Putranto HarmayBelum ada peringkat

- Aurora Regenerative Turbine 150 Series BrochureDokumen8 halamanAurora Regenerative Turbine 150 Series Brochurethehammer2Belum ada peringkat

- Innomag BrochureDokumen8 halamanInnomag BrochureHENDRIK2011Belum ada peringkat

- B-313 Series E-1510 Technical BrochureDokumen8 halamanB-313 Series E-1510 Technical BrochureAnonymous 7xHNgoKE6eBelum ada peringkat

- Catalogo Cameron 1Dokumen32 halamanCatalogo Cameron 1RoyBelum ada peringkat

- SpecificationDokumen4 halamanSpecificationviksursBelum ada peringkat

- Series21&41 CatalogDokumen16 halamanSeries21&41 CatalogWillin08Belum ada peringkat

- 6 Konitzer2Dokumen32 halaman6 Konitzer2mchramziBelum ada peringkat

- Ebara EVN CurvesDokumen16 halamanEbara EVN CurvesMarcelo De Miranda ReisBelum ada peringkat

- Conexao de Dupla Anilha RotarexDokumen68 halamanConexao de Dupla Anilha RotarexElias Barros de FigueiredoBelum ada peringkat

- KG Brochure Butterfly BTDokumen12 halamanKG Brochure Butterfly BTmmmlormamBelum ada peringkat

- CPC Pumps Corporate BrochureDokumen8 halamanCPC Pumps Corporate BrochureArdiBarkahBelum ada peringkat

- Pneumatic Butterfly Valves Technical SpecificationDokumen12 halamanPneumatic Butterfly Valves Technical SpecificationFactory FactoryBelum ada peringkat

- PuttyDokumen2 halamanPuttyJignesh PatelBelum ada peringkat

- Carbon Pipe Dimensions WeightsDokumen3 halamanCarbon Pipe Dimensions WeightsManzar KhanBelum ada peringkat

- Material Specification ChartDokumen1 halamanMaterial Specification ChartIdu Baz AzharBelum ada peringkat

- Coating Converter PDFDokumen1 halamanCoating Converter PDFManzar KhanBelum ada peringkat

- Code Comparison of ASME Boiler and Pressure Vessel Codes, Pressure Piping and API Standard Practices: ©Dokumen5 halamanCode Comparison of ASME Boiler and Pressure Vessel Codes, Pressure Piping and API Standard Practices: ©Manzar Khan100% (1)

- Coating ConverterDokumen1 halamanCoating ConverterManzar KhanBelum ada peringkat

- Security Door & Grille Catalogue 2007Dokumen24 halamanSecurity Door & Grille Catalogue 2007Manzar KhanBelum ada peringkat

- Cb51ab 709854 4046 B190 209c5ad0e PDFDokumen61 halamanCb51ab 709854 4046 B190 209c5ad0e PDFManzar KhanBelum ada peringkat

- P # NumberDokumen4 halamanP # NumberManzar KhanBelum ada peringkat

- Technical Specifications For Tig WeldingDokumen12 halamanTechnical Specifications For Tig WeldingManzar KhanBelum ada peringkat

- Lifebook Uh552 Lifebook Uh572: System Operating ManualDokumen61 halamanLifebook Uh552 Lifebook Uh572: System Operating ManualManzar KhanBelum ada peringkat

- Tig Welding BookletDokumen26 halamanTig Welding BookletstiryakiiBelum ada peringkat

- Rolled Pipe FormulaDokumen1 halamanRolled Pipe FormulaManzar KhanBelum ada peringkat

- Pipe Schedules PDFDokumen2 halamanPipe Schedules PDFManzar KhanBelum ada peringkat

- Vedic MathsDokumen220 halamanVedic Mathstargettutorials5740100% (7)

- Esaal e SawabDokumen33 halamanEsaal e SawabPeyam_e_HaqBelum ada peringkat

- Chapter 10Dokumen32 halamanChapter 10Shahadatuliskandar RosliBelum ada peringkat

- Kiya Bad Mazhab Syed HainDokumen22 halamanKiya Bad Mazhab Syed HainManzar KhanBelum ada peringkat

- FPD 1314 eDokumen4 halamanFPD 1314 eManzar KhanBelum ada peringkat

- Shell Corena Oil AP Advanced Synthetic LubricantDokumen2 halamanShell Corena Oil AP Advanced Synthetic LubricantGanesh AnandBelum ada peringkat

- Stainless Steel Grade 316 (UNS S31600)Dokumen4 halamanStainless Steel Grade 316 (UNS S31600)achari_swapnilBelum ada peringkat

- Thailand British Council Ielts Scholarship Application Thailand ApprovedDokumen4 halamanThailand British Council Ielts Scholarship Application Thailand ApprovedPear NopchanokBelum ada peringkat

- 1400 Kva MitsubishiDokumen4 halaman1400 Kva MitsubishiAbid LakhaniBelum ada peringkat

- EN - User Manual Collimator R302 With Filterselection - RevM - 2007-05Dokumen77 halamanEN - User Manual Collimator R302 With Filterselection - RevM - 2007-05pietroko100% (1)

- Field Service Calibration ReportDokumen8 halamanField Service Calibration ReportemiljuchiacBelum ada peringkat

- Wimax 802.16E Indoor Iad: Key FeaturesDokumen2 halamanWimax 802.16E Indoor Iad: Key Featuresmehedi2636Belum ada peringkat

- CT TheoryDokumen37 halamanCT TheoryShahid Ullah100% (1)

- F2608 PDFDokumen8 halamanF2608 PDFAhmad Zubair RasulyBelum ada peringkat

- Code of Conduct - Hellofresh: Core Values and Corporate CultureDokumen6 halamanCode of Conduct - Hellofresh: Core Values and Corporate CultureMadi100% (1)

- Submission Sites ListDokumen6 halamanSubmission Sites Listkumari yogeshreeBelum ada peringkat

- Arduino IspDokumen10 halamanArduino IspAnonymous H3E7i3YzydBelum ada peringkat

- Elective III E CommerceDokumen6 halamanElective III E CommercepocketoxyBelum ada peringkat

- aADAPTIvE LightDokumen28 halamanaADAPTIvE LightDensonLauTengHuiBelum ada peringkat

- Definition of Quality of Service Parameters and Their ComputationDokumen39 halamanDefinition of Quality of Service Parameters and Their ComputationbinusidBelum ada peringkat

- KPBR Regularization OrderDokumen46 halamanKPBR Regularization Ordersooji456Belum ada peringkat

- 21-2-PGW-Admin GuideDokumen12 halaman21-2-PGW-Admin GuideFebriBelum ada peringkat

- Maverickautokrafters 2Dokumen59 halamanMaverickautokrafters 2Adriano CesarBelum ada peringkat

- Network Design ToolsDokumen13 halamanNetwork Design ToolsUmang SomeshwarBelum ada peringkat

- QTD Instruction ManualDokumen56 halamanQTD Instruction Manualfredd100% (1)

- Fund Mech Eng SiemensDokumen150 halamanFund Mech Eng SiemensRafael Pacheco100% (2)

- Semantic Search Demo BookletDokumen20 halamanSemantic Search Demo BookletStéphane CroisierBelum ada peringkat

- Lecture 5 - Typicyl Website File & Folder StructureDokumen17 halamanLecture 5 - Typicyl Website File & Folder StructureCedric CedricBelum ada peringkat