Failure Mode Effects Analysis (FMEA) - ASQ

Diunggah oleh

GYANA RANJAN SAHOOHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Failure Mode Effects Analysis (FMEA) - ASQ

Diunggah oleh

GYANA RANJAN SAHOOHak Cipta:

Format Tersedia

04/06/2016

Home

FailureModeEffectsAnalysis(FMEA)ASQ

Store

QualityProgress

ASQTV

ContactASQ

CreateAccount

ShoppingCart

ASQ is a global community of people passionate about quality,

who use the tools, their ideas and expertise to make our world

work better. ASQ: The Global Voice of Quality.

KnowledgeCenter

Membership

Certification

Training

Books&Standards

Conferences&Events

SelectCountry/Region

U.S./Canada

SearchASQ

Communities

AboutASQ

Failure Mode Effects Analysis (FMEA)

Articles

Books

Casestudies

Alsocalled:potentialfailuremodesandeffectsanalysisfailuremodes,effectsandcriticalityanalysis

(FMECA).

Training

Failuremodesandeffectsanalysis(FMEA)isastepbystepapproachforidentifyingallpossiblefailuresin

adesign,amanufacturingorassemblyprocess,oraproductorservice.

RelatedTopics

Failuremodesmeanstheways,ormodes,inwhichsomethingmightfail.Failuresareanyerrorsor

defects,especiallyonesthataffectthecustomer,andcanbepotentialoractual.

Processanalysis

toolsoverview

Benchmarking

Flowchart

Matrixdiagram

Mistakeproofing

Relationsdiagram

Spaghettidiagram

Effectsanalysisreferstostudyingtheconsequencesofthosefailures.

Sign In

UserName:

Password:

Failuresareprioritizedaccordingtohowserioustheirconsequencesare,howfrequentlytheyoccurand

howeasilytheycanbedetected.ThepurposeoftheFMEAistotakeactionstoeliminateorreducefailures,

startingwiththehighestpriorityones.

Failuremodesandeffectsanalysisalsodocumentscurrentknowledgeandactionsabouttherisksof

failures,foruseincontinuousimprovement.FMEAisusedduringdesigntopreventfailures.Lateritsused

forcontrol,beforeandduringongoingoperationoftheprocess.Ideally,FMEAbeginsduringtheearliest

conceptualstagesofdesignandcontinuesthroughoutthelifeoftheproductorservice.

Beguninthe1940sbytheU.S.military,FMEAwasfurtherdevelopedbytheaerospaceandautomotive

industries.SeveralindustriesmaintainformalFMEAstandards.

Whatfollowsisanoverviewandreference.BeforeundertakinganFMEAprocess,learnmoreabout

standardsandspecificmethodsinyourorganizationandindustrythroughotherreferencesandtraining.

SignIn

JoinASQ!(/membership/why

becomea

member/overview.html)

Featuredadvertisers

When to Use FMEA

Whenaprocess,productorserviceisbeingdesignedorredesigned,afterqualityfunction

deployment.

Whenanexistingprocess,productorserviceisbeingappliedinanewway.

Beforedevelopingcontrolplansforanewormodifiedprocess.

Whenimprovementgoalsareplannedforanexistingprocess,productorservice.

Whenanalyzingfailuresofanexistingprocess,productorservice.

Periodicallythroughoutthelifeoftheprocess,productorservice

FMEA Procedure

(Again,thisisageneralprocedure.Specificdetailsmayvarywithstandardsofyourorganizationor

industry.)

1.Assembleacrossfunctionalteamofpeoplewithdiverseknowledgeabouttheprocess,product

orserviceandcustomerneeds.Functionsoftenincludedare:design,manufacturing,quality,

testing,reliability,maintenance,purchasing(andsuppliers),sales,marketing(andcustomers)

andcustomerservice.

2.IdentifythescopeoftheFMEA.Isitforconcept,system,design,processorservice?Whatare

theboundaries?Howdetailedshouldwebe?Useflowchartstoidentifythescopeandtomake

sureeveryteammemberunderstandsitindetail.(Fromhereon,wellusethewordscopeto

meanthesystem,design,processorservicethatisthesubjectofyourFMEA.)

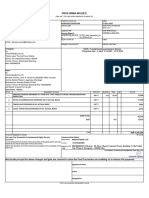

3.FillintheidentifyinginformationatthetopofyourFMEAform.Figure1showsatypicalformat.

Theremainingstepsaskforinformationthatwillgointothecolumnsoftheform.

http://asq.org/learnaboutquality/processanalysistools/overview/fmea.html

1/3

04/06/2016

FailureModeEffectsAnalysis(FMEA)ASQ

Figure1FMEAExample(clickimagetoenlarge)

4.Identifythefunctionsofyourscope.Ask,Whatisthepurposeofthissystem,design,processor

service?Whatdoourcustomersexpectittodo?Nameitwithaverbfollowedbyanoun.

Usuallyyouwillbreakthescopeintoseparatesubsystems,items,parts,assembliesorprocess

stepsandidentifythefunctionofeach.

5.Foreachfunction,identifyallthewaysfailurecouldhappen.Thesearepotentialfailuremodes.

Ifnecessary,gobackandrewritethefunctionwithmoredetailtobesurethefailuremodesshow

alossofthatfunction.

6.Foreachfailuremode,identifyalltheconsequencesonthesystem,relatedsystems,process,

relatedprocesses,product,service,customerorregulations.Thesearepotentialeffectsof

failure.Ask,Whatdoesthecustomerexperiencebecauseofthisfailure?Whathappenswhen

thisfailureoccurs?

7.Determinehowseriouseacheffectis.Thisistheseverityrating,orS.Severityisusuallyratedon

ascalefrom1to10,where1isinsignificantand10iscatastrophic.Ifafailuremodehasmore

thanoneeffect,writeontheFMEAtableonlythehighestseverityratingforthatfailuremode.

8.Foreachfailuremode,determineallthepotentialrootcauses.Usetoolsclassifiedascause

analysistool,aswellasthebestknowledgeandexperienceoftheteam.Listallpossiblecauses

foreachfailuremodeontheFMEAform.

9.Foreachcause,determinetheoccurrencerating,orO.Thisratingestimatestheprobabilityof

failureoccurringforthatreasonduringthelifetimeofyourscope.Occurrenceisusuallyratedon

ascalefrom1to10,where1isextremelyunlikelyand10isinevitable.OntheFMEAtable,list

theoccurrenceratingforeachcause.

10.Foreachcause,identifycurrentprocesscontrols.Thesearetests,proceduresormechanisms

thatyounowhaveinplacetokeepfailuresfromreachingthecustomer.Thesecontrolsmight

preventthecausefromhappening,reducethelikelihoodthatitwillhappenordetectfailureafter

thecausehasalreadyhappenedbutbeforethecustomerisaffected.

11.Foreachcontrol,determinethedetectionrating,orD.Thisratingestimateshowwellthecontrols

candetecteitherthecauseoritsfailuremodeaftertheyhavehappenedbutbeforethecustomer

isaffected.Detectionisusuallyratedonascalefrom1to10,where1meansthecontrolis

absolutelycertaintodetecttheproblemand10meansthecontroliscertainnottodetectthe

problem(ornocontrolexists).OntheFMEAtable,listthedetectionratingforeachcause.

12.(Optionalformostindustries)Isthisfailuremodeassociatedwithacriticalcharacteristic?

(Criticalcharacteristicsaremeasurementsorindicatorsthatreflectsafetyorcompliancewith

governmentregulationsandneedspecialcontrols.)Ifso,acolumnlabeledClassification

receivesaYorNtoshowwhetherspecialcontrolsareneeded.Usually,criticalcharacteristics

haveaseverityof9or10andoccurrenceanddetectionratingsabove3.

13.Calculatetheriskprioritynumber,orRPN,whichequalsSOD.AlsocalculateCriticalityby

multiplyingseveritybyoccurrence,SO.Thesenumbersprovideguidanceforrankingpotential

failuresintheordertheyshouldbeaddressed.

14.Identifyrecommendedactions.Theseactionsmaybedesignorprocesschangestolower

severityoroccurrence.Theymaybeadditionalcontrolstoimprovedetection.Alsonotewhois

responsiblefortheactionsandtargetcompletiondates.

15.Asactionsarecompleted,noteresultsandthedateontheFMEAform.Also,notenewS,OorD

ratingsandnewRPNs.

FMEA Example

AbankperformedaprocessFMEAontheirATMsystem.Figure1showspartofitthefunctiondispense

cashandafewofthefailuremodesforthatfunction.TheoptionalClassificationcolumnwasnotused.

Onlytheheadingsareshownfortherightmost(action)columns.

NoticethatRPNandcriticalityprioritizecausesdifferently.AccordingtotheRPN,machinejamsand

heavycomputernetworktrafficarethefirstandsecondhighestrisks.

Onehighvalueforseverityoroccurrencetimesadetectionratingof10generatesahighRPN.Criticality

doesnotincludethedetectionrating,soitrateshighesttheonlycausewithmediumtohighvaluesforboth

severityandoccurrence:outofcash.Theteamshouldusetheirexperienceandjudgmenttodetermine

http://asq.org/learnaboutquality/processanalysistools/overview/fmea.html

2/3

04/06/2016

FailureModeEffectsAnalysis(FMEA)ASQ

appropriateprioritiesforaction.

ExcerptedfromNancyR.TaguesTheQualityToolbox,SecondEdition,ASQQualityPress,2004,pages

236240.

MEDIAROOM

CAREERCENTER ADVERTISING&SPONSORSHIP CUSTOMERSERVICE SITEMAP TERMSOFUSE PRIVACYPOLICY

AMERICANSOCIETYFORQUALITY.ALLRIGHTSRESERVED.

http://asq.org/learnaboutquality/processanalysistools/overview/fmea.html

3/3

Anda mungkin juga menyukai

- QMS Audit Check SheetDokumen7 halamanQMS Audit Check Sheetaboo2uBelum ada peringkat

- Primer On Market ProfileDokumen4 halamanPrimer On Market Profilechalasanica100% (2)

- 3P Memo 11.36.58 AMDokumen2 halaman3P Memo 11.36.58 AM王葳蕤Belum ada peringkat

- Mvrla 5s Ppt-SustenanceDokumen185 halamanMvrla 5s Ppt-SustenanceChethan Nagaraju KumbarBelum ada peringkat

- ISO 14001 Audit Checklists SamplesDokumen33 halamanISO 14001 Audit Checklists SamplesMuhammad Sofwan ZulkepliBelum ada peringkat

- Presentation On Lean Manufacturing: Course Title: Ergonomics and Productivity Engineering Sessional Course Code: IPE 3202Dokumen26 halamanPresentation On Lean Manufacturing: Course Title: Ergonomics and Productivity Engineering Sessional Course Code: IPE 3202Ayman Sajjad AkashBelum ada peringkat

- 2020 Annual Report Melexis enDokumen156 halaman2020 Annual Report Melexis enAnthonyWittendorpBelum ada peringkat

- 8D Problem Solving Excel WorksheetDokumen6 halaman8D Problem Solving Excel WorksheetecdtcenterBelum ada peringkat

- Jakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeDokumen24 halamanJakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeLeonardoViannaBelum ada peringkat

- Chapter 4-: Statistical Process Control (SPC)Dokumen80 halamanChapter 4-: Statistical Process Control (SPC)Dv DickosBelum ada peringkat

- Error Proofing BasicsDokumen16 halamanError Proofing BasicsJohn OoBelum ada peringkat

- AristocratDokumen38 halamanAristocratTiến ThànhBelum ada peringkat

- Cost of QualityDokumen10 halamanCost of QualityPatricia MandiBelum ada peringkat

- VDA 4530 Disposable Small Load CarrierDokumen32 halamanVDA 4530 Disposable Small Load CarrierEd RiBelum ada peringkat

- Statistical Process ControlDokumen57 halamanStatistical Process ControlSandeep PasumarthiBelum ada peringkat

- Top 10 Forex Trading RulesDokumen3 halamanTop 10 Forex Trading Rulescool_cyrusBelum ada peringkat

- Total Quality Management (TQM) - Philosophy & ImplementationDokumen181 halamanTotal Quality Management (TQM) - Philosophy & Implementationmayank patelBelum ada peringkat

- COPQ Training - EPC (Repaired)Dokumen15 halamanCOPQ Training - EPC (Repaired)syedfahadraza627Belum ada peringkat

- DFMA DFM DFA Design For Manufacturing and AssemblyDokumen15 halamanDFMA DFM DFA Design For Manufacturing and AssemblyNuria VarelaBelum ada peringkat

- Value Streams: Fundamentals of Manufacturing Excellence ProgramDokumen30 halamanValue Streams: Fundamentals of Manufacturing Excellence ProgramTuan AnhBelum ada peringkat

- Navistar Supplier Quality RequirementsDokumen50 halamanNavistar Supplier Quality RequirementsJaskaran SinghBelum ada peringkat

- Customer Complaints Management Drive Loyality and Mitigate Risk Across Your OrganizationDokumen10 halamanCustomer Complaints Management Drive Loyality and Mitigate Risk Across Your Organizationtolga aktasBelum ada peringkat

- Rocess Ontrol Tatistical: C C I P P S E EDokumen71 halamanRocess Ontrol Tatistical: C C I P P S E EalwaleedrBelum ada peringkat

- Manufacturing CostDokumen30 halamanManufacturing CostPradika WibowoBelum ada peringkat

- Thesis Process Maps (10 Mins)Dokumen67 halamanThesis Process Maps (10 Mins)Ray SefianeBelum ada peringkat

- Lean Six Sigma Mid-Term Ass Final 1.0Dokumen21 halamanLean Six Sigma Mid-Term Ass Final 1.0era nominBelum ada peringkat

- Schneider Production System: The Global Specialist in Energy ManagementDokumen16 halamanSchneider Production System: The Global Specialist in Energy ManagementAmrBelum ada peringkat

- NOTES Software Quality ManagementDokumen382 halamanNOTES Software Quality Managementgirish_kodagantiBelum ada peringkat

- SAP SD Functional Analyst ResumeDokumen10 halamanSAP SD Functional Analyst ResumedavinkuBelum ada peringkat

- Chap15 Statistical Quality ControlDokumen111 halamanChap15 Statistical Quality Controljohn brownBelum ada peringkat

- Cascade Aerospace Presentation To SMICG - 11 Dec 2015: Kevin Lemke - VP OperationsDokumen21 halamanCascade Aerospace Presentation To SMICG - 11 Dec 2015: Kevin Lemke - VP OperationsDanielBelum ada peringkat

- Quality Function DeploymentDokumen8 halamanQuality Function DeploymentNivedh VijayakrishnanBelum ada peringkat

- Abm 115 TRMDokumen329 halamanAbm 115 TRMgurubabBelum ada peringkat

- Fmea Methodology For Quality Improvement in Sheet Metal Industry IJERTV5IS010123Dokumen5 halamanFmea Methodology For Quality Improvement in Sheet Metal Industry IJERTV5IS010123DanistergladwinBelum ada peringkat

- A Proposed Bpo Hub in Arca SouthDokumen22 halamanA Proposed Bpo Hub in Arca SouthKent Francisco0% (1)

- Homologation and Self-CertificationDokumen10 halamanHomologation and Self-CertificationAli Raza Virk100% (1)

- 1 - APQP Process FlowDokumen13 halaman1 - APQP Process FlowGONZALEZNIETOBelum ada peringkat

- Week 2 Handout 2 - Swakarya Dry and CleanDokumen11 halamanWeek 2 Handout 2 - Swakarya Dry and CleantazkiaBelum ada peringkat

- SWOT AnalysisDokumen38 halamanSWOT AnalysisNur SyuhadahBelum ada peringkat

- Kano Model PDFDokumen5 halamanKano Model PDFdanielmugaboBelum ada peringkat

- Revised JD Tool Room Manager - Press ShopDokumen4 halamanRevised JD Tool Room Manager - Press ShopAmiya Kumar0% (1)

- MPH Mission Vision Goals ObjectivesDokumen78 halamanMPH Mission Vision Goals ObjectivesBenjie Moronia Jr.Belum ada peringkat

- Free Quality Function Deployment QFD House of Quality Template Excel DownloadDokumen6 halamanFree Quality Function Deployment QFD House of Quality Template Excel DownloadKaren AriasBelum ada peringkat

- Lean Production FinalDokumen9 halamanLean Production Finalmomen jamalBelum ada peringkat

- Difference Between Rework & Repair As Per IATF 16949?: by - Arun Kumar SharmaDokumen19 halamanDifference Between Rework & Repair As Per IATF 16949?: by - Arun Kumar SharmaDanang Widoyoko100% (1)

- Design FMEA 2-Day Workshop by TetrahedronDokumen2 halamanDesign FMEA 2-Day Workshop by TetrahedrontetrahedronBelum ada peringkat

- Total Quality Management (TQM) ToolsDokumen84 halamanTotal Quality Management (TQM) ToolsSameer_Khan_60Belum ada peringkat

- Design Failure Mode and Effect Analysis - Case StuDokumen13 halamanDesign Failure Mode and Effect Analysis - Case Stusanjay chamoliBelum ada peringkat

- TQMDokumen866 halamanTQMSrishti KhandagaleBelum ada peringkat

- 8 Wastes of ProductionDokumen17 halaman8 Wastes of ProductionBrașovean LaurențiuBelum ada peringkat

- Cause-And-Effect Diagram: Why Implement Cost of Quality (COQ) ?Dokumen3 halamanCause-And-Effect Diagram: Why Implement Cost of Quality (COQ) ?Doren Joy BatucanBelum ada peringkat

- 06control Chart 1Dokumen37 halaman06control Chart 1abishank09100% (1)

- Sec 04 Quality Control ProcessDokumen37 halamanSec 04 Quality Control Processapi-3699912Belum ada peringkat

- DFSS Short PresentationDokumen4 halamanDFSS Short PresentationSSI - Six Sigma & InnovationBelum ada peringkat

- Planning and Decision MakingDokumen132 halamanPlanning and Decision MakingGleiza Two BaguioBelum ada peringkat

- Creating Product and Process Control SystemsDokumen35 halamanCreating Product and Process Control SystemsNeydi DávilaBelum ada peringkat

- OPM101Chapter5 000Dokumen40 halamanOPM101Chapter5 000Gagan Karwar100% (1)

- Current State of Quality in The Automotive Industry: Scott Gray Director, Quality Products and Services, AIAGDokumen26 halamanCurrent State of Quality in The Automotive Industry: Scott Gray Director, Quality Products and Services, AIAGSelvaraj SBelum ada peringkat

- SWOT - v1Dokumen79 halamanSWOT - v1Alpha Excellence consultingBelum ada peringkat

- Cost of Poor Quality 2Dokumen6 halamanCost of Poor Quality 2Shavin AvinBelum ada peringkat

- Factors, Measures, and Problems of Quality Costs Program Implementation in The Manufacturing EnvironmentDokumen6 halamanFactors, Measures, and Problems of Quality Costs Program Implementation in The Manufacturing EnvironmentFahad IzharBelum ada peringkat

- Histogram Box Plot Statistics AdaptiveBMSDokumen13 halamanHistogram Box Plot Statistics AdaptiveBMSashutoshrvBelum ada peringkat

- IATF16949+Chapter+33 +Internal+AuditsDokumen19 halamanIATF16949+Chapter+33 +Internal+AuditsSathish Kumar RockkzzBelum ada peringkat

- 5S & Visual Workplace Management Workshop/TrainingDokumen2 halaman5S & Visual Workplace Management Workshop/TrainingLeanAdvisors100% (4)

- 5S Audits Check Sheet and Comments Sheet - Issue2Dokumen2 halaman5S Audits Check Sheet and Comments Sheet - Issue2PrakashBelum ada peringkat

- Automotive Quality Management Systems A Complete Guide - 2020 EditionDari EverandAutomotive Quality Management Systems A Complete Guide - 2020 EditionBelum ada peringkat

- MGT 422 AssignmentDokumen2 halamanMGT 422 AssignmentNavila ZamanBelum ada peringkat

- Application For Employment: Evadel Home Care LLCDokumen6 halamanApplication For Employment: Evadel Home Care LLCAdel Carmen WaiderBelum ada peringkat

- Listing Reg. EX-50% NED - 1/3 Ned But Related - 50%Dokumen3 halamanListing Reg. EX-50% NED - 1/3 Ned But Related - 50%Avinash BahadurBelum ada peringkat

- Kasus 7.1 Mercator Corp.Dokumen3 halamanKasus 7.1 Mercator Corp.Septiana DA0% (3)

- Test Code: ME I/ME II, 2009Dokumen15 halamanTest Code: ME I/ME II, 2009paras hasijaBelum ada peringkat

- Tax - Cases 1-15 - Full TextDokumen120 halamanTax - Cases 1-15 - Full TextNoel RemolacioBelum ada peringkat

- Advanced Cost and Management Accounting ConceptsDokumen17 halamanAdvanced Cost and Management Accounting ConceptsharlloveBelum ada peringkat

- CB Consumer MovementDokumen11 halamanCB Consumer Movementbhavani33% (3)

- Isa 600Dokumen27 halamanIsa 600Anser Raza100% (1)

- RTHD L3gxiktDokumen2 halamanRTHD L3gxiktRobin RahmanBelum ada peringkat

- PDFDokumen17 halamanPDFRAJAT DUBEYBelum ada peringkat

- MohanrajResume BangDokumen3 halamanMohanrajResume BangMohan RajBelum ada peringkat

- totallyMAd - 18 January 2008Dokumen2 halamantotallyMAd - 18 January 2008NewsclipBelum ada peringkat

- MEC 1st Year 2018-19 English-Final PDFDokumen9 halamanMEC 1st Year 2018-19 English-Final PDFUmesh Kumar MahatoBelum ada peringkat

- Service Proforma Invoice - ACCEPTANCE Tata Projects-020Dokumen1 halamanService Proforma Invoice - ACCEPTANCE Tata Projects-020maneesh bhardwajBelum ada peringkat

- IRS Depreciation Guide With Optional Rate TablesDokumen118 halamanIRS Depreciation Guide With Optional Rate TablesManthan ShahBelum ada peringkat

- S3 Migrate Your Current or Legacy Rockwell PLCsDokumen56 halamanS3 Migrate Your Current or Legacy Rockwell PLCsReynaldo MercadoBelum ada peringkat

- Revaluation ModelDokumen7 halamanRevaluation ModelkyramaeBelum ada peringkat

- PDFDokumen5 halamanPDFRiana RusdiantoBelum ada peringkat

- IMRADDokumen21 halamanIMRADRosalie RosalesBelum ada peringkat

- 1.supply Chain MistakesDokumen6 halaman1.supply Chain MistakesSantosh DevaBelum ada peringkat

- Rodrigo Rene Robles ResumeDokumen1 halamanRodrigo Rene Robles Resumeapi-530692408Belum ada peringkat