Product Blend

Diunggah oleh

Dianelis Guette TuiranDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Product Blend

Diunggah oleh

Dianelis Guette TuiranHak Cipta:

Format Tersedia

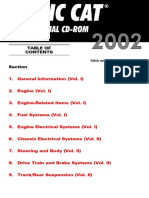

I/A

SERIES

APPLICATION

SOLUTION

Refinery Product

Blending Systems

REFORMATE

ALKYLATE

BLENDED

GASOLINE

ADJUSTMENTS

AND BLEND

ORDER

LSR

FCC GASO.

TYPICAL MEASUREMENTS

OCTANE

PIONA

RVP

VLI

NMR

Gasoline Blending

OXYGENATES

DISTILLATION

BENZENE

API GRAVITY

COKER

Benefits

To realize the greatest profitability in refinery blending

operations, a blend optimization

system is used to provide

management of the component

and product tanks, blend

header, online and laboratory

analytical systems, and planning/

scheduling activities. This

optimizer, Foxboros Blend

Optimization and Supervisory

System (BOSS), produces

blended products with a high

degree of precision to meet

specifications while minimizing

quality giveaway, maximizing

the use of the lowest-cost

components in the blend,

increasing the flexibility of the

tank farm operation, and

minimizing the frequency of

reblends. A flexible objective

function permits component

cost, inventory constraints, or

product specification to direct

the optimizer.

Providing BOSS with nearreal-time component stream

and blended product chemical

quality information is the NMR

analyzer. This information

enables multivariable analyzerdirected control including:

CDU

BLENDED

DIESEL OR

DISTILLATE

ADJUSTMENTS

AND BLEND

ORDER

Feedforward control for

component quality variations

Feedback control for

product quality variations

Quality integration of product

and component tanks

Projected product qualities

at the blend header

VDU

FCCU

TYPICAL MEASUREMENTS

Diesel or Distillate Blending

NMR

CETANE

FLASH PT.

CLOUD PT.

VISCOSITY

POUR PT.

DISTILLATION

API GRAVITY

ANILINE PT.

Advanced process control generally requires near-real-time stream

quality information. The exceptional availability of the NMR analyzer

enables this information to be supplied reliably for process control

while the technology ensures accuracy and repeatability. Because this

analyzer can be applied to numerous component quality measurements,

a single analyzer can often alleviate the need for multiple analyzers

to satisfy an APC application.

(continued on back)

A refinery gasoline blending

system upgrade project including

blend optimization can provide

benefits amounting to $0.15

to $0.30/bbl gasoline. Including

the cost of engineering studies,

new field equipment, and new

instrumentation in a tank farm

automation and blend optimization project, the payback

period is typically less than

18 months. This is true for

gasoline, diesel, and fuel oil

blending operations.

(continued from front)

To satisfy new gasoline reformulation requirements,

blend header complexity is increasing with the

rising number of blend components. Diesel and

other blended fuels are also subjected to more

severe blending requirements in order to comply

with environmental mandates. As a result, refiners

are compelled to evaluate the effectiveness of

their blending operations and are adding or

improving blend optimization to boost profitability.

Functions

Common blending operation targets are:

To reduce both reblends and product giveaway

To meet product specifications while

conforming to environmental requirements

To enhance effective inventory capability and

improve profitability

To lower risk of missed export schedules

To improve refinery planning/scheduling

accuracy

Actual process manipulations are made by existing

digital blend controllers or a Foxboro-supplied

Digital Blending System (DBS). DBS features

include uniform ramping, continuous pacing,

analyzer trim, temperature-compensated flow

measurement, and flexible loop configurations. It

may be configured to include an automated

procedure for manipulating the equipment

involved in blending, transfer, flushing, and

pigging operations.

Standard features

A refinery blending system upgrade project is

often more expansive than blend optimization. Blend

optimization demands accurate tank information,

and automating the tank farm is prerequisite in

order to gain most benefit. Then, to maximize

blend operation performance, Foxboro can

complement blend optimization with the Tank

Information System (TIS) and the Oil Movement

Information System (OMIS) software applications.

TIS provides tank inventory information, tank

monitoring functions, and tank status and

information reports that satisfy internal and regulatory

information reporting requirements. This system

compiles data provided by tank gauging systems,

and is usually an integral part of a blend

The Foxboro Company

Foxboro, MA 02035-2099

+1-508-543-8750

1-888-FOXBORO

Fax: 1-508-549-4492

www.foxboro.com

optimization control scheme.

The tank information system database contains

static and dynamic configuration data as well as

calculated and measured data. Static data

includes information such as tank ID, tank

contents ID, API table ID, reference temperature,

and tank strapping table values. Dynamic data

includes level and temperature alarm limits, and

calculated data includes volume correction factor,

tank volume, thermal expansion coefficient, dry

volume, available volume, ullage, net weight,

and more. Accurate tank information allows

operation with lower inventories, and the material

balancing capability can be used to detect tank

leakage. Particularly useful for blend scheduling,

it can alert the planner of a potential conflict.

OMIS supplies the engine for automating the

tank farm. This system provides resource

management of equipment, sequencing and

logic functions to control equipment, and flow

path selection. System functions include movement

planning, automatic movement control, equipment

monitoring and management, and product

movement and storage reporting and archiving.

The equipment database covers tanks, pumps,

valves, pipelines, and mixers.

An expert system-based guidance system

directs the operator to minimize the potential for

human error in setting up movements, protecting

equipment from damage, and avoiding stream

cross-contamination. The systems "illegal" tank

level change information provides a leak detection

capability, using both level and flow measurement

data. Another system feature is the option to

select a swing tank or another pump without the

need of a shutdown.

Setting up an oil movement involves selecting

the appropriate tanks, pumps, pipelines, etc.

from an oil movement planning display. Once the

selection is made and the selected path and

equipment are validated by the system, the flow

path is established. Operation of the flow path

equipment can be performed in either an automatic

or semiautomatic mode, depending on a need for

operator intervention.

FOXBORO and I/A Series are registered trademarks of

The Foxboro Company. All other trademarks are marks of their

respective companies.

The Foxboro Company 1999

Foxboro, MA 02035-2099

All rights reserved.

Printed in U.S.A.

Bulletin B67-40 12/99

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- What Is Air Fuel (Fuel Air) Ratio - Rich, Lean, Stoichiometric Mixture Used For Ic EngineDokumen1 halamanWhat Is Air Fuel (Fuel Air) Ratio - Rich, Lean, Stoichiometric Mixture Used For Ic EngineNopparat SvtBelum ada peringkat

- Aprilia Ditech Quick Workshop Manual PDFDokumen33 halamanAprilia Ditech Quick Workshop Manual PDFModesto Olmedo RamirezBelum ada peringkat

- Clack-WS1 1.25 Drawings and Service ManualDokumen48 halamanClack-WS1 1.25 Drawings and Service ManualGreg ReynekeBelum ada peringkat

- System GC PDFDokumen12 halamanSystem GC PDFkholisenangBelum ada peringkat

- Inside Techron: What's Special About Caltex With Techron®?Dokumen2 halamanInside Techron: What's Special About Caltex With Techron®?Ardrei Carl Ac GuevarraBelum ada peringkat

- Mini Striker Data SheetDokumen4 halamanMini Striker Data SheetCarlos Jahir Chavez CarreñoBelum ada peringkat

- Briggs and Stratton 13.5 HP ManualDokumen112 halamanBriggs and Stratton 13.5 HP ManualChris NoblesBelum ada peringkat

- Isw2001nbf - Aeb (Versione 6.1.3) - Cad - EngDokumen35 halamanIsw2001nbf - Aeb (Versione 6.1.3) - Cad - EngDerioBelum ada peringkat

- Energetic Utilization of HydrogenDokumen13 halamanEnergetic Utilization of HydrogenKristopher HerrellBelum ada peringkat

- Formula SAE Turbocharger Engine DevelopmentDokumen134 halamanFormula SAE Turbocharger Engine DevelopmentravigobiBelum ada peringkat

- Catalagram 91 - 2002Dokumen44 halamanCatalagram 91 - 2002saleh4060Belum ada peringkat

- Tech Manual EngDokumen42 halamanTech Manual EngGerman SalasBelum ada peringkat

- Briggs and StrattonDokumen28 halamanBriggs and StrattonJay SanghrajkaBelum ada peringkat

- Thermochemistry & Fuels.8 Dec 19Dokumen60 halamanThermochemistry & Fuels.8 Dec 19Jawad AhmedBelum ada peringkat

- Energy generation on a budgetDokumen104 halamanEnergy generation on a budgetNguyen Vu Hoang ThachBelum ada peringkat

- PRODUCTION OF BIOETHANOL FROM POMELO (Citrus Maxima) PEEL (MANDIA) 2019Dokumen60 halamanPRODUCTION OF BIOETHANOL FROM POMELO (Citrus Maxima) PEEL (MANDIA) 2019Carlo Quinsayas SablanBelum ada peringkat

- Shri I.M. Nanavati Memorial Moot Draft AnalysisDokumen46 halamanShri I.M. Nanavati Memorial Moot Draft AnalysisDarshan AwareBelum ada peringkat

- 2002 Snowmobile Service ManualDokumen654 halaman2002 Snowmobile Service ManualRobert FenskeBelum ada peringkat

- Astm d471 Pdqv6897Dokumen13 halamanAstm d471 Pdqv6897Nayth Andres Galaz100% (1)

- Victory Hammer Chapter01Dokumen32 halamanVictory Hammer Chapter01arndude2100% (1)

- Abstract and Litreature ReviewDokumen6 halamanAbstract and Litreature ReviewUttarwar RuturajBelum ada peringkat

- Platts 30 Janv 2013Dokumen9 halamanPlatts 30 Janv 2013Wallace YankotyBelum ada peringkat

- BB-BI - Sugarcane - Inititating CoverageDokumen23 halamanBB-BI - Sugarcane - Inititating CoverageBruno ChiaramontiBelum ada peringkat

- Case Puma 165 180 195 210 225 CVX Repair ManualDokumen2.144 halamanCase Puma 165 180 195 210 225 CVX Repair ManualRemigijus Bubliauskas91% (35)

- Ethanol Combustion Review - Cold StartDokumen4 halamanEthanol Combustion Review - Cold StartAlessandro Silva Vila NovaBelum ada peringkat

- NLC Mechanical PDFDokumen18 halamanNLC Mechanical PDFramasamy bBelum ada peringkat

- Alcohol Classification and FormationDokumen50 halamanAlcohol Classification and FormationNurhikmah NurhikmahBelum ada peringkat

- Stihl FS FC HL BG SH Service ManualDokumen50 halamanStihl FS FC HL BG SH Service ManualBrianCook75% (4)

- SSP 560 The Caddy 2016Dokumen56 halamanSSP 560 The Caddy 2016Javier GarciaBelum ada peringkat

- The First Electric Vehicle Was A Three-Wheeler, Invented by Scooter's India PVT LTD in 1996, and It Was Named VIKRAM SAFADokumen2 halamanThe First Electric Vehicle Was A Three-Wheeler, Invented by Scooter's India PVT LTD in 1996, and It Was Named VIKRAM SAFANayan B BijuBelum ada peringkat