Electric Field and Potential Distributions Along Surface of Silicone Rubber Polymer Insulators Using Finite Element Method

Diunggah oleh

ostojic007Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Electric Field and Potential Distributions Along Surface of Silicone Rubber Polymer Insulators Using Finite Element Method

Diunggah oleh

ostojic007Hak Cipta:

Format Tersedia

International Journal of Electrical and Electronics Engineering 3:10 2009

Electric Field and Potential Distributions along

Surface of Silicone Rubber Polymer Insulators

Using Finite Element Method

B. Marungsri, W. Onchantuek, and A. Oonsivilai

along the specimen surface, Finite Element Method (FEM) is

adopted as mathematical tool for simulation electric field and

potential distributions.

AbstractThis paper presents the simulation the results of

electric field and potential distributions along surface of silicone

rubber polymer insulators. Near the same leakage distance subjected

to 15 kV in 50 cycle salt fog ageing test, alternate sheds silicone

rubber polymer insulator showed better contamination performance

than straight sheds silicone rubber polymer insulator. Severe surface

ageing was observed on the straight sheds insulator. The objective of

this work is to elucidate that electric field distribution along straight

sheds insulator higher than alternate shed insulator in salt fog ageing

test. Finite element method (FEM) is adopted for this work. The

simulation results confirmed the experimental data, as well.

II. ARTIFICIAL SALT FOG AGEING TEST RESULTS

Two insulator-type specimens, having straight and alternate

sheds, were prepared as shown in Fig. 1. All the specimens

were made of high-temperature vulcanized silicone rubber

(HTV SiR) with alumina trihydrate (ATH: Al2O33H2O) filler

contents of 50 parts per 100 by weight (pph). The insulatortype specimens were prepared by molding HTV SiR onto the

FRP rods. Molding lines or parting lines were found on these

insulator-type specimens. Two pieces of each specimen type

were used in this investigation. All specimen surfaces were

cleaned by ethyl alcohol 24 hours before starting the test.

KeywordsElectric field distribution, potential distribution,

silicone rubber polymer insulator, finite element method.

I. INTRODUCTION

OLYMER insulators, which are being used increasingly

for outdoor applications, have better characteristics than

porcelain and glass types: they have better contamination

performance due to their surface hydrophobicity, lighter,

possess higher impact strength, and so on. However, since

polymer insulators are made of organic materials,

deterioration through ageing is unavoidable. Hence, ageing

deterioration is a primary concern in the performance of

polymer insulators. Artificial salt fog ageing tests have been

most widely conducted on simple plates, rods, and small

actual insulators for evaluating the anti-tracking and/or antierosion performance of housing materials for polymer

insulators [17].

In previous work, salt fog ageing test have been conducted

on specimens having different configurations [8]. Although

tested specimens having the same leakage distance and made

of the same material, obviously degree of surface ageing on

tested specimens was obtained. Fully results and discussions

are found in [8]. However, briefly results are illustrated in

Section II.

In order to elucidate the effect of specimen configuration in

the view point of electric field and potential distributions

(a) Straight Shed

(b) Alternate Shed

Fig. 1 Test Specimens

All specimens were hung vertically in a plastic chamber as

shown in Fig. 2 and were tested together under the test

conditions shown in Table I. The cyclic salt fog ageing test

was conducted by injecting salt fog into the chamber for 8

hours and stopping it for 16 hours every day under AC 15kV.

The salt fog, with a salinity of 800 S/cm and an injection rate

of 0.5 l/hr/m3, was generated using an ultrasonic humidifier

and was injected from the top of the test chamber as shown in

Fig. 2. Leakage currents were continuously measured on

individual specimens.

B. Marungsri is with Suranaree University of Technology, Nakhon

Ratchasima, 30000, Thailand (phone: +66 4422 4366; fax: +66 4422 4601; email: bmshvee@ sut.ac.th).

W. Onchantuek and A. Oonsivilai are with Suranaree University of

Technology, Nakhon Ratchasima, 30000, Thailand.

611

International Journal of Electrical and Electronics Engineering 3:10 2009

TABLE I

TEST CONDITIONS

Test Chamber

1590 mm1560 mm 1330H mm, (2m3)

Test Voltage

AC 15 kV, Continuously Applied

Salt Fog

Voltage Stress

Generation

Injection Rate

Conductivity

Test Sequence in

1 Cycle (24

hours)

60 V/mm for rod type, 51.3 V/mm for insulator types

Ultrasonic Humidifier (Model WM B NB 1000)

0.5 l / hr / m3

800 S / cm

Salt fog injected for 8 hours and stopped for 16

hours

(a) Straight Shed

(b) Alternate Shed

Fig. 4 Ageing of specimen surface after 50 Test Cycles

III. NUMERICAL EXPERIMENT

A. Equations for Electric Field and Potential Distributions

Calculation

Simply way for electric field distribution calculation is

calculate electric potential distribution. Then, electric field

distribution is calculated by minus gradient of electric

potential distribution. Due to electrostatic field distribution,

electric field distribution can be written as follows [9]:

E = V

Fig. 2 Test Arrangement

(1)

From Maxwells equation

During 50 test cycle of salt fog ageing test, stronger surface

discharges were observed on the specimen having straight

sheds comparing with the specimen having alternate sheds

although all specimens having the same leakage distance and

made of the same materials. The observation result is

illustrated in Fig. 3. After 50 test cycles, severe surface

ageing was observed on the trunk between sheds of specimens

having straight shed comparing with the specimen having

alternate sheds, as shown in Fig. 4. Considering the results,

the assumption is electric filed distribution along the specimen

having straight shed higher than the specimen having

alternated sheds.

E =

(2)

where is resistivity /m,

is dielectric constant of dielectric material

( = 0 r )

0 is air or space dielectric constant ( 8.854 1012

F/m)

r is relative dielectric constant of dielectric

material

Place equation (1) in equation (2) obtained Poissons

equation.

V =

(3)

Without space charge = 0 , Poissons equation becomes

Laplaces equation.

(4)

V = 0

B. Equations for FEM Analysis of the Electric Field

Distribution

The finite element method is one of the numerical analysis

methods based on the variation approach and has been widely

used in electric and magnetic field analyses since the late

1970s. Supposing that the domain under consideration does

not contain any space and surface charges, the twodimensional functional F(u) in the Cartesian system of

coordinates can be written as follows[10]:

(a) Straight Shed

(b) Alternate Shed

Fig. 3 Discharge on specimen surface during 50 Test Cycles

612

International Journal of Electrical and Electronics Engineering 3:10 2009

2

2

du

1 du

+

(5)

dxdy

x

y

2 D dx

dy

where x and y are the x- and y-components of the dielectric

constant in the Cartesian system of coordinates and u is the

electric potential. In the case of isotropic permittivity

distribution ( = x =y), Equation (5) can be rewritten as

du 2 du 2

1

F( u ) = + dxdy

(6)

2 D dx dy

If the effect of dielectric loss on the electric field

distribution is considered, the complex functional F(u) should

be taken as

2 2

du du

1

F( u ) = 0 ( j tg )

+

dxdy (7)

D

2

dx dy

Metal End Fitting

F( u ) =

Wheatear shed

FRP Core

(a) Straight Sheds

(b) Alternated Sheds

Fig. 5 Two dimension of the two type polymer insulators for FEM

analysis

The whole problem domain in Fig. 5 is fictitiously divided

into small triangular areas called domain. The potential, which

is unknown throughout the problem domain, is approximated

in each of these elements in terms of the potential in their

vertices called nodes. Details of Finite Element discretization

are found in [12]. The most common form of approximation

solution for the voltage within an element is a polynomial

approximation. PDE Tool in MATLAB is used for finite

element discretization. The obtaining results are 1,653 nodes

and 3,180 elements for straight sheds type insulator and 2,086

nodes and 4,030 elements for alternate sheds type insulator,

respectively. The obtaining results are shown in Fig. 6

where is angular frequency, 0 is the permittivity of free

space (8.85 10-12 F/m), tg is tangent of the dielectric loss

angle, and u* is the complex potential.

Inside each sub-domain De, a linear variation of the electric

potential is assumed, i.e.

ue ( x, y ) = e1 + e 2 x + e3 y ;( e = 1, 2 ,3,..ne )

(8)

where ue(x, y) is the electric potential of any arbitrary point

inside each sub-domain De, e1, e2 and e3 represent the

computational coefficients for a triangle element e, ne is the

total number of triangle elements.

The calculation of the electric potential at every knot in the

total network composed of many triangle elements was carried

out by minimizing the function F(u), that is,

F( ui )

= 0 ;i = 1, 2 ,..np

(9)

ui

where np stands for the total number of knots in the

network.

Then we can get a metrical expression

(10)

S ji {ui } = T j i, j = 1, 2 ,..np

where [Sji] is the matrix of coefficients, {ui} is the matrix

vector of unknown values of the potential at the knots and

{Tj} is the metrical vector of free terms. The metrical equation

(10) can be solved using various methods, including the

(a) Straight Sheds insulator

(b) Alternate Sheds Insulators

Fig. 6 Finite element discretization results

{ }

IV. SIMULATION RESULTS AND DISCUSSIONS

Clean and contamination conditions are simulated in this

study. Potential Distribution results are shown in Fig. 7 and

electric field distribution are shown in Fig. 8. Although

nonlinear potential distribution along leakage distance of the

two type specimens, more nonlinear can be seen on the

straight sheds specimen comparing with the alternate shed

specimen, as shown in Fig. 9. In spite of clean condition,

electric field distribution on the straight sheds specimen is

higher than the alternate sheds specimen.

Contamination condition is simulated by place water

droplets on the two type insulator surfaces as shown in Fig. 10

and Fig. 12. The simulation results of electric field and

potential distributions are illustrated in Fig. 11 and Fig. 13,

respectively.

GaussSeidel iterative method.

C. Implementation for FEM Analysis

The basic design of a polymer insulator is as follows; A

fibre reinforced plastic (FRP) core having relative dielectric

constant 7.1, attached with two metal fittings, is used as the

load bearing structure. Weather sheds made of HTV silicone

rubber having relative dielectric constant 4.3 are installed

outside the FRP core. Surrounding of the insulator is air

having relative dielectric constant 1.0. AC 15 kV is energized

on the lower electrode while the upper electrode connected

with ground. Two dimensions of the two type polymer

insulators for FEM analysis are shown in Fig. 5.

613

International Journal of Electrical and Electronics Engineering 3:10 2009

Fig. 9 Comparison of Potential Distribution

(a) Straight Sheds Insulator

(b) Alternate Sheds Insulator

Fig. 10 Straight Sheds Insulator with Water Droplets on the Surface

Fig. 7 Potential Distribution under Clean Condition

(a) Potential Distribution

(a) Straight Sheds Insulator

(b) Electric Field Distribution

(b) Alternated Sheds Insulator

Fig. 11 Straight sheds Insulator with Water Droplets on the Surface

Fig. 8 Electric Field Distribution under Clean Condition

614

International Journal of Electrical and Electronics Engineering 3:10 2009

contamination condition, higher electric field distribution and

more nonlinear potential distribution obtained from the

straight sheds insulator comparing with the alternate sheds

insulators. The simulation results are agreed with the

experimental results. Higher magnitude of electric field

caused more electric discharge on the insulator surface. More

discharge activities caused severe surface damages.

V. CONCLUSION

Higher magnitude of electric field distribution and more

nonlinear potential distributions on the straight sheds insulator

comparing with the alternate shed insulators obtained from the

simulation results by using Finite Element Method. The

simulation results are agreed with the experimental results. In

spite of the same leakage distance and the same material,

different degree of surface aging obtained from polymer

insulator having different configurations.

Fig. 12 Alternate Sheds Insulator with Water Droplets on the Surface

REFERENCES

[1]

CIGRE TF33.04.07, Natural and Artificial Ageing and Pollution

Testing of Polymer Insulators, CIGRE Pub. 142, June 1999.

[2] G. G. Karady, H. M. Schneider and F. A. M. Rizk, Review of CIGRE

and IEEE Research into Pollution Performance of Non Ceramic

Insulators: Field Ageing Effects and Laboratory Test Techniques,

CIGRE 1994 Session Paper No. 33 103, August/September 1994.

[3] I. Gutman, R. Harting, R. Matsuoka and K. Kondo, Experience with

IEC 1109 1000h Salt Fog Ageing Test for Composite Insulators,

IEEE Electrical Insulation Magazine, Vol. 13, No. 3, May/June 1997,

pp. 36 39.

[4] T. Zhao and R. A. Bernstorf, Ageing Tests of Polymeric Housing

Materials for Non ceramic Insulators, IEEE Electrical Insulation

Magazine, Vol. 14, No. 2, March/April 1998, pp. 26 33.

[5] R. S. Gorur, E. A. Cherney and R. Hackam, A Comparative Study of

Polymer Insulating Materials under Salt Fog Test, IEEE Trans. on

Electrical Insulation, Vol. EI 21, No. 2, April 1986, pp. 175 182.

[6] M. C. Arklove and J. C. G. Wheeler, Salt Fog Testing of Composite

Insulators, 7th Int. Conf. on Dielctric Material, Measurements and

Applications, Conf. Pub. No. 430, September 1996, pp. 296 302.

[7] S. H. Kim, R. Hackam, Influence of Multiple Insulator Rods on

Potential and Electric Field Distributions at Their Surface , Int. Conf.

on Electrical Insulation and Dielectric Phenomena 1994, October 1994,

pp. 663 668.

[8] B. Marungsri, H. Shinokubo, R. Matsuoka and S. Kumagai, Effect of

Specimen Configuration on Deterioration of Silicone Rubber for

Polymer Insulators in Salt Fog Ageing Test, IEEE Trans. on DEI, Vol.

13, No. 1 , February 2006, pp. 129 138.

[9] S. Sangkhasaad, High Voltage Engineering, 3nd edition, Printed in

Bangkok, Thailand, March 2006 (in Thai).

[10] C. N. Kim, J. B. Jang, X. Y. Huang, P. K. Jiang and H. Kim, Finite

element analysis of electric field distribution in water treed XLPE cable

insulation (1): The influence of geometrical configuration of water

electrode for accelerated water treeing test, J. of Polymer Testing, Vol.

26, 2007, pp. 482 488.

[11] P. Pao la or, A New Design of Low Vibration Induction Motor using

Finite Element Method, Doctoral Thesis, Suranaree University of

Technology, Nakhon Ratchasima, Thailand, 2006.

(a) Potential Distribution

(b) Electric Field Distribution

Fig. 13 Alternate Sheds Insulator with Water Droplets on the Surface

Fig. 14 Comparison of Potential Distribution under Contamination

Condition

Boonruang Marungsri, was born in Nakhon

Ratchasima Province, Thailand, in 1973. He received his

B. Eng. and M. Eng. from Chulalongkorn University,

Thailand in 1996 and 1999 and D. Eng. from Chubu

University, Kasugai, Aichi, Japan in 2006, all in

electrical engineering, respectively. Dr. Marungsri is

Comparison of potential distribution along leakage distance

under contamination condition is illustrated in Fig. 14. Under

615

International Journal of Electrical and Electronics Engineering 3:10 2009

currently a lecturer in School of Electrical Engineering, Suranaree University

of Technology, Thailand. His areas of interest are electrical power system and

high voltage insulation technologies.

Winai Onchantuek was born in Nakhon Ratchasima

Province, Thailand in 1983. He recived in B. Eng. in

Electrical Engineering from Suranaree University of

Technology, Nakhon Ratchasima, Thailand in 2005. He

has been teaching assistant in School of Electrical

Engineering, Suranaree University of Technology for one

year. Recently, he is graduate student in School of

Electrical Engineering in the same university. His research interesting area are

Finite Element Method and high voltage insulation technology.

Anant Oonsivilai, was born in Khon Kaen Province,

Thailand, in 1963. He received his B. Eng. fron Khon

Kaen University, and M. Eng. from King Mongkut

Institute of Technology North Bangkok, Thailand and

PhD. from Dalhousie University, Canada, all in

electrical Engineering, in 1986 , 1992 and 2000,

respectively. Dr. Oonsivilai is currently an Assistant

Professor in School of Electrical Engineering, Suranaree

University of Technology, Thailand. His areas of

interest are electrical power system, stability, control technology, advance

alternative, and sustainable energy.

616

Anda mungkin juga menyukai

- Calculation of The Electric Field On An Insulator String Using The Finite Elements MethodDokumen4 halamanCalculation of The Electric Field On An Insulator String Using The Finite Elements Methodostojic007Belum ada peringkat

- Shielding of Electromagnetic Waves: Theory and PracticeDari EverandShielding of Electromagnetic Waves: Theory and PracticeBelum ada peringkat

- 1A DefectDokumen8 halaman1A Defectdaniel_sa2011Belum ada peringkat

- Electric Field DistributionDokumen15 halamanElectric Field DistributionGonzalo GómezBelum ada peringkat

- BaniaDokumen9 halamanBaniaAlways. BangtanBelum ada peringkat

- SHMvol 2 N 2 June 2003Dokumen15 halamanSHMvol 2 N 2 June 2003MohamedBelum ada peringkat

- Aguado Measurement 1Dokumen6 halamanAguado Measurement 1HADHI HASSAN KHANBelum ada peringkat

- The Cavity Perturbation Method For The Measurement of The Dielectric Properties of (Polystyrene/carbon Black) CompositeDokumen7 halamanThe Cavity Perturbation Method For The Measurement of The Dielectric Properties of (Polystyrene/carbon Black) CompositeTouseef HayatBelum ada peringkat

- Analysis of EMG Waves From A Pulse Source: RL Il JK ×R TL Il JK ×RDokumen5 halamanAnalysis of EMG Waves From A Pulse Source: RL Il JK ×R TL Il JK ×RArun KumarBelum ada peringkat

- SPE 59532 Electrical Dissipation Factor: A Novel Way To Detect Changes in Shale Water ContentDokumen7 halamanSPE 59532 Electrical Dissipation Factor: A Novel Way To Detect Changes in Shale Water ContentcmkohBelum ada peringkat

- ananda,+NAT 77 V1i1 p13 25Dokumen13 halamanananda,+NAT 77 V1i1 p13 25Bereket YohanisBelum ada peringkat

- Progress in Electromagnetics Research, Vol. 115, 441-460, 2011Dokumen20 halamanProgress in Electromagnetics Research, Vol. 115, 441-460, 2011Noam ShakedBelum ada peringkat

- Carbon Black in EPOXI ResinDokumen6 halamanCarbon Black in EPOXI ResingonzalomonsalveBelum ada peringkat

- Simple Metamaterial Structure Enabling Triple-Band Perfect AbsorberDokumen7 halamanSimple Metamaterial Structure Enabling Triple-Band Perfect AbsorberanhtrinhndBelum ada peringkat

- MEMS Electrostatic Acoustic Pixel: Corresponding Author: 4700 KAUST, Kingdom of Saudi Arabia, Arpys - Arevalo@kaust - Edu.saDokumen7 halamanMEMS Electrostatic Acoustic Pixel: Corresponding Author: 4700 KAUST, Kingdom of Saudi Arabia, Arpys - Arevalo@kaust - Edu.sadiegoBelum ada peringkat

- Secondary Flows and Turbulence For Staggered and Non-Staggered Electrode EmittersDokumen16 halamanSecondary Flows and Turbulence For Staggered and Non-Staggered Electrode EmittersjayakrishnaBelum ada peringkat

- New Technologies For Air-Coupled Ultrasonic Transducers: Creative Commons CC-BY-NC LicenceDokumen9 halamanNew Technologies For Air-Coupled Ultrasonic Transducers: Creative Commons CC-BY-NC LicencegorkembaytenBelum ada peringkat

- Accurate Equivalent Circuits For Unloaded Piezoelectric ResonatorsDokumen4 halamanAccurate Equivalent Circuits For Unloaded Piezoelectric ResonatorsHafid Papeda SaguBelum ada peringkat

- Article 15Dokumen18 halamanArticle 15Maroc EcoloadBelum ada peringkat

- 21.characterization and Optimization - FullDokumen12 halaman21.characterization and Optimization - FullTJPRC PublicationsBelum ada peringkat

- Fowler Nordheim Tunneling in Thin SiO2 FilmsDokumen7 halamanFowler Nordheim Tunneling in Thin SiO2 FilmskobelkBelum ada peringkat

- Electrical Equivalent Circuit of Ceramic Insulators With RTV Silicone Rubber Coating and Computer Simulation of Leakage CurrentsDokumen10 halamanElectrical Equivalent Circuit of Ceramic Insulators With RTV Silicone Rubber Coating and Computer Simulation of Leakage CurrentsFari PratomosiwiBelum ada peringkat

- Guan Jun ZhangDokumen5 halamanGuan Jun ZhangReda BelBelum ada peringkat

- Comparison On Space Charge and Voltage Distribution of High Voltage Insulator Subjected To Different Contamination LevelsDokumen8 halamanComparison On Space Charge and Voltage Distribution of High Voltage Insulator Subjected To Different Contamination LevelsFiras AryanBelum ada peringkat

- Electric Field and Voltage Distribution Along InsuDokumen6 halamanElectric Field and Voltage Distribution Along Insuالبيوع البيوعBelum ada peringkat

- Investigation of Diverse Characteristics of Strained III-V Nitride Quantum WellDokumen4 halamanInvestigation of Diverse Characteristics of Strained III-V Nitride Quantum WellUlhasBelum ada peringkat

- Ijetr022484 PDFDokumen4 halamanIjetr022484 PDFsonawaneulhas292Belum ada peringkat

- 1111 2524 PDFDokumen15 halaman1111 2524 PDFEsthi KusumaBelum ada peringkat

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Dari EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Belum ada peringkat

- HV Sheets (2015) A FDokumen7 halamanHV Sheets (2015) A FMANS عسيريBelum ada peringkat

- Experimental and Numerical Analysis of A Transducer For The Generation of Guided WavesDokumen9 halamanExperimental and Numerical Analysis of A Transducer For The Generation of Guided Wavesdavood abbasiBelum ada peringkat

- Organic Ambipolar Light Emitting Field Effect TransistorDokumen3 halamanOrganic Ambipolar Light Emitting Field Effect Transistorajayiitm05Belum ada peringkat

- Study On The Dielectric Characteristics of Gaseous, Liquid, and Solid Insulation Materials For A High Voltage Superconducting ApparatusDokumen4 halamanStudy On The Dielectric Characteristics of Gaseous, Liquid, and Solid Insulation Materials For A High Voltage Superconducting ApparatusYousaf KhanBelum ada peringkat

- Physics Electric Current and Direct Current Circuit NotesDokumen118 halamanPhysics Electric Current and Direct Current Circuit NoteskumuthaBelum ada peringkat

- NPSC RVI InsulatorsDokumen4 halamanNPSC RVI InsulatorsJordan RileyBelum ada peringkat

- Comp 12Dokumen36 halamanComp 12Tanu RdBelum ada peringkat

- Wei - Paper For PetrophysicDokumen13 halamanWei - Paper For Petrophysicyangwei00414312Belum ada peringkat

- Ecc DerivationDokumen3 halamanEcc DerivationJawed AquilBelum ada peringkat

- Propagation of Electromagnetic Signal PDFDokumen170 halamanPropagation of Electromagnetic Signal PDFed varBelum ada peringkat

- Effect of Surface Shallow Traps On FlashoverDokumen7 halamanEffect of Surface Shallow Traps On FlashoverVU Thi Thu NgaBelum ada peringkat

- Engg Approach To Design of Tapered Dielectric Rod Horn AntDokumen9 halamanEngg Approach To Design of Tapered Dielectric Rod Horn Antవేలుసామి లింగాసామిBelum ada peringkat

- Differential Forms on Electromagnetic NetworksDari EverandDifferential Forms on Electromagnetic NetworksPenilaian: 4 dari 5 bintang4/5 (1)

- Electromagnetic Field Analysis and Its Applications To Product DevelopmentDokumen9 halamanElectromagnetic Field Analysis and Its Applications To Product Developmentkaushikray06Belum ada peringkat

- HW 2Dokumen1 halamanHW 2siddharth mohantyBelum ada peringkat

- Progress in Electromagnetics Research, Vol. 114, 51-66, 2011Dokumen16 halamanProgress in Electromagnetics Research, Vol. 114, 51-66, 2011Mohammed Sabry YasseenBelum ada peringkat

- Nonlinear Electrical Conductivity in A 1D Granular MediumDokumen9 halamanNonlinear Electrical Conductivity in A 1D Granular MediumNoita EnolaBelum ada peringkat

- Takaaki Musha - Explanation of Dynamical Biefeld-Brown Effect From The Standpoint of ZPF FieldDokumen6 halamanTakaaki Musha - Explanation of Dynamical Biefeld-Brown Effect From The Standpoint of ZPF FieldRtpomBelum ada peringkat

- A Memadmittance Systems Model For Thin Film Memory MaterialsDokumen4 halamanA Memadmittance Systems Model For Thin Film Memory MaterialsBlaise_Mouttet100% (1)

- Solution Manual-2nd EdDokumen55 halamanSolution Manual-2nd EdSami Rajput50% (2)

- Full-Wave Analysis of Nanoscale Optical TrappingDokumen4 halamanFull-Wave Analysis of Nanoscale Optical TrappingmarkrichardmuradBelum ada peringkat

- Journal of Kones 2014 No. 1 Vol. 21 Issn 1231-4005 BarskiDokumen8 halamanJournal of Kones 2014 No. 1 Vol. 21 Issn 1231-4005 BarskiKaleeswaran EinsteinBelum ada peringkat

- Accepted Manuscript: Materials LettersDokumen8 halamanAccepted Manuscript: Materials Lettersالعلم نور والجهل ظلامBelum ada peringkat

- Study Equivalent: On The Electrical Circuit Models of Polluted Outdoor InsulatorsDokumen4 halamanStudy Equivalent: On The Electrical Circuit Models of Polluted Outdoor InsulatorsKamello AssisBelum ada peringkat

- Vibration Energy Harvesting Using Single and Comb-Shaped Piezoelectric Beam Structures: Modeling and SimulationDokumen7 halamanVibration Energy Harvesting Using Single and Comb-Shaped Piezoelectric Beam Structures: Modeling and SimulationAmir JoonBelum ada peringkat

- Acoustical Determinations On A Composite Materials (Extruded Polystyrene Type/ Cork)Dokumen6 halamanAcoustical Determinations On A Composite Materials (Extruded Polystyrene Type/ Cork)pinoyarkiBelum ada peringkat

- Wo3 NanorodsDokumen6 halamanWo3 NanorodsinfinitopBelum ada peringkat

- R7 210205 Electromagnetic FieldsDokumen2 halamanR7 210205 Electromagnetic FieldssivabharathamurthyBelum ada peringkat

- 18625-Article Text-65207-1-10-20180821Dokumen7 halaman18625-Article Text-65207-1-10-20180821PALACIO, LANDER M.Belum ada peringkat

- What Influences Length of CCT?: Zaneta - Eleschova@stuba - SKDokumen6 halamanWhat Influences Length of CCT?: Zaneta - Eleschova@stuba - SKostojic007Belum ada peringkat

- Electric Field Analysis of High Voltage InsulatorsDokumen5 halamanElectric Field Analysis of High Voltage Insulatorsostojic007Belum ada peringkat

- Evaluation of Power System Transient Stability and Definition of The Basic Criterion PDFDokumen8 halamanEvaluation of Power System Transient Stability and Definition of The Basic Criterion PDFostojic007Belum ada peringkat

- Finite Element Modeling For Electric Field and Voltage Distribution Along The Polluted Polymeric InsulatorDokumen11 halamanFinite Element Modeling For Electric Field and Voltage Distribution Along The Polluted Polymeric Insulatorostojic007Belum ada peringkat

- Finite Element Analysis On Post Type Silicon Rubber Insulator Using MATLABDokumen6 halamanFinite Element Analysis On Post Type Silicon Rubber Insulator Using MATLABostojic007Belum ada peringkat

- Reliability of Electrical Insulating Systems - Statistical Approach To Empirical Endurance ModelsDokumen5 halamanReliability of Electrical Insulating Systems - Statistical Approach To Empirical Endurance Modelsostojic007Belum ada peringkat

- CIGRE 2008: 21, Rue D'artois, F-75008 PARISDokumen8 halamanCIGRE 2008: 21, Rue D'artois, F-75008 PARISostojic007Belum ada peringkat

- Loss-Of-Excitation Protection and Underexcitation Controls Correlation For Synchronous Generators in A Real-Time Digital SimulatorDokumen12 halamanLoss-Of-Excitation Protection and Underexcitation Controls Correlation For Synchronous Generators in A Real-Time Digital Simulatorostojic007100% (1)

- Electric Field and Voltage Distribution Along Non-Ceramic Insulators PDFDokumen16 halamanElectric Field and Voltage Distribution Along Non-Ceramic Insulators PDFostojic007Belum ada peringkat

- Lechler Brochure Billetcooler Flex enDokumen12 halamanLechler Brochure Billetcooler Flex enhungleteBelum ada peringkat

- 1 Input Data: Profis Anchor 2.9.4Dokumen4 halaman1 Input Data: Profis Anchor 2.9.4MohMohkBelum ada peringkat

- The Influence of Recycled Expanded Polystyrene (EPS) On Concrete Properties: Influence On Flexural Strength, Water Absorption and ShrinkageDokumen6 halamanThe Influence of Recycled Expanded Polystyrene (EPS) On Concrete Properties: Influence On Flexural Strength, Water Absorption and ShrinkageDg IRfanBelum ada peringkat

- JGS 1811 To 1816 EnglishDokumen34 halamanJGS 1811 To 1816 EnglishNeetu Bhargava100% (1)

- 1SDA104331R1 E2 2s E9 2500 Ekip Touch Lsi 3p FHRDokumen4 halaman1SDA104331R1 E2 2s E9 2500 Ekip Touch Lsi 3p FHRAhmedBDBelum ada peringkat

- Ch6 LateralEarthPressureDokumen39 halamanCh6 LateralEarthPressure彭宇鑫Belum ada peringkat

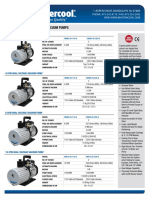

- 2 Stage Dual Voltage Vacuum PumpsDokumen1 halaman2 Stage Dual Voltage Vacuum PumpsPrimero Valencia LuisBelum ada peringkat

- Chapter 3 - Force and MotionDokumen4 halamanChapter 3 - Force and MotionJerico LlovidoBelum ada peringkat

- Moisture in The Atmosphere and Weather ChangesDokumen40 halamanMoisture in The Atmosphere and Weather ChangesPatricia Sofia DizonBelum ada peringkat

- 3 Mathematical Mathods Used in Equilibrium Calculations PDFDokumen15 halaman3 Mathematical Mathods Used in Equilibrium Calculations PDFHevertonJonnysBelum ada peringkat

- Hev - Chim.acta.200588523 545. DikonversiDokumen24 halamanHev - Chim.acta.200588523 545. Dikonversiasmaul mashadBelum ada peringkat

- Molecular Orbital TheoryDokumen6 halamanMolecular Orbital TheoryinfistudeeeeBelum ada peringkat

- Aakash Home Assignment 8Dokumen19 halamanAakash Home Assignment 8Pranav KapadiaBelum ada peringkat

- PZT Thermal Properties - 065437Dokumen38 halamanPZT Thermal Properties - 065437FlatironsviewBelum ada peringkat

- Fire On The Velvet Horizon PLAIN TEXT PDFDokumen224 halamanFire On The Velvet Horizon PLAIN TEXT PDFGordon G0% (1)

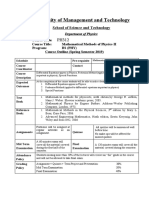

- MMP-II, Course Outline Spring 2019Dokumen3 halamanMMP-II, Course Outline Spring 2019Ehsan AdeebBelum ada peringkat

- Operating Manual: Flame Monitor AAL 75 For Continuous Operation or Intermittent OperationDokumen13 halamanOperating Manual: Flame Monitor AAL 75 For Continuous Operation or Intermittent OperationPiyushkumar SBelum ada peringkat

- Week 7 and 8 Performance of Single Phase Short Transmission LinesDokumen21 halamanWeek 7 and 8 Performance of Single Phase Short Transmission LinessensamedicBelum ada peringkat

- Aci318-08 Moment Shear Torsion DesignDokumen7 halamanAci318-08 Moment Shear Torsion DesignMohammed HanafiBelum ada peringkat

- TCS 01Dokumen6 halamanTCS 01Vishnu PrajapatiBelum ada peringkat

- Sintering Performance of Magnetite-Hematite-GoethiDokumen19 halamanSintering Performance of Magnetite-Hematite-GoethiDeidaBelum ada peringkat

- Year 11 MathsDokumen9 halamanYear 11 MathsEedris akinwandeBelum ada peringkat

- FourierDokumen22 halamanFourierBochiBelum ada peringkat

- AFM 34 en PDFDokumen4 halamanAFM 34 en PDFDee RajaBelum ada peringkat

- TFX02 Torque ChartDokumen1 halamanTFX02 Torque ChartArnulfo SánchezBelum ada peringkat

- 2 Conservation of Mass EnergyDokumen30 halaman2 Conservation of Mass Energyvaughn santos100% (1)

- AQA IGCSE FM "Full Coverage": Trig in 2D and 3DDokumen12 halamanAQA IGCSE FM "Full Coverage": Trig in 2D and 3DEinsteinBelum ada peringkat

- Lec4 PDFDokumen91 halamanLec4 PDFArun ShalBelum ada peringkat

- Sturm-Liouville EquationsDokumen16 halamanSturm-Liouville Equationsvanaj123Belum ada peringkat

- Combact 1Dokumen2 halamanCombact 1Francis DacutananBelum ada peringkat