Gicale Phy12l B2 E302 4Q1516

Diunggah oleh

Idate PatrickJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Gicale Phy12l B2 E302 4Q1516

Diunggah oleh

Idate PatrickHak Cipta:

Format Tersedia

MAPUA INSTITUTE OF TECHNOLOGY

Department of Physics

E302: HEAT AND CALORIMETRY

GICALE, PATRICK EMMANUEL T.

gicalep@gmail.com/2014106318/CE-2

PHY12L-B2 Group 2

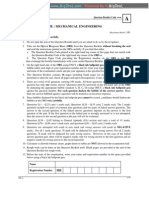

SCORE

Signed Data Sheet

(5)

Observations & Results

(15)

Graphs

(10)

Conclusion (15)

References

(5)

Photos (10)

Performance

(40)

TOTAL

(100)

17 May, 2016

____

____

____

____

____

____

____

____

E302: HEAT AND CALORIMETRY

Gicale, Patrick Emmanuel T.1,

1

School of Civil, Environmental, and Geological Engineering, Mapa Institute of Technology

658 Muralla St., Intramuros, Manila City, Philippines

gicalep@gmail.com

OBSERVATIONS AND RESULTS

Materials possess, it may be a solid, liquid or a gas, a specific amount of heat, which differs from

all of the bodies also relative to its size, needed to be absorb to raise its temperature and this is

Specific Heat.

In our experiment, we are tasked to determine the metal samples, aluminium and copper, specific

heat capacity through the formula of sensible heat.

=

(1)

The second part of the experiment is the determination of the latent heat of fusion of ice. It is a

constant which will dictates the needed heat to be absorb or taken off. Latent Heat of fusion is solve

through the formula.

=

(2)

After doing two trials of determining the specific heat capacity of the two metals, we achieved a

relevant specific heat capacity. Below are the relevant values that weve gathered.

Table 1: Data Gathered for Determining the Specific Heat of Metals

Aluminium metal

Copper metal

Mass of metal (g)

32.7

19.6

Mass of calorimeter (g)

46.3

46.3

Mass of water (g)

127.1

133.3

Initial temperature of metal (oC)

100

100

Initial temperature of calorimeter (oC)

26

27

o

Initial temperature of water ( C)

26

27

Final temperature of mixture (oC)

30

28

Experimental specific heat of metal

0.2397

0.1016

(cal/g-Co)

Actual specific heat of metal (cal/g0.2174

0.0932

o

C)

Percentage of error

10.26%

9.0035%

As you can see, the following metals have different specific heat where aluminium being the

greater. Hence, the aluminium metal needed greater heat than the copper to raise its temperature.

Below were represents the data gathered to determine the ices latent heat of fusion and as you

can see, the experimental values have a minimal deficiency to its actual value. Sources of error

will be discussed on the conclusion.

Table 2: Data Gathered to Determine the Latent Heat of Fusion of Ice

1st Trial

2nd Trial

Mass of calorimeter (g)

46.3

46.3

Mass of water (g)

114.3

139.2

Mass of mixture (g)

160.3

167.6

Mass of ice (g)

46.3

46.3

o

Initial temperature of ice ( C)

0

0

Initial temperature of calorimeter (oC)

62

65

Initial temperature of water (oC)

62

65

Final temperature of mixture (oC)

19

34

Experimental latent heat of fusion

96.5015

65.9403

(cal/g)

Actual specific latent heat of fusion

80

80

(cal/g)

Percentage of error

17.57 %

20.63 %

Below is a sample computation for solving the specific heat.

+ + = 0

Aluminium metal:

(46.3) (0.2174 ) (30 26) +

(127.1) (

(30 26) +

)

Copper metal:

(46.3) (0.0932

(133.3) (

(32.7) (30 100) = 0

cm=0.2397

) (28 27) +

) (28 27) +

(19.6) (28 100) = 0

cal/g-Co

() = .

cm=0.1016 cal/g-Co

%

%

=|

0.2174 0.2397/

0.2174 /

=|

0.0932 0.1016/

| 100

0.0932 /

| 100

% = . %

% = . %

Sample Computation for solving Latent Heat of Fusion of ice:

( ) + ( ) + + ( 0) = 0

1

(114.3) ( ) (19 62) + (46.3)(0.2174 )(19 62) + (46.3) +

(46.3 )(19 0) = 0

LF=96.5015

GRAPHS

The table below represents the comparison of the relevant values that weve gathered to the

actual value. As you can see, Aluminum metal has greater specific heat capacity thus, the metal

needs greater heat to raise its temperature.

SPECIFIC HEAT CAPACITY

Specific Heat Capacity of the

Metals

0.3

0.2

0.1

0

0.2397 0.2174

1.02E-01 0.0932

Experimental Value of

Specific Heat Capacity

Actual Value of Specific

Heat Capacity

COMPARISON OF RELEVANT VALUE TO THE ACTUAL VALUE

Aluminium Metal

Copper Metal

LATENT HEAT OF

FUSION

The table below represents the difference of the experimental value from the actual value. As

you can see, the following experimental data are close to the actual value.

Latent Heat of Fusion (Ice)

150

100

50

0

80

Actual Value

9.65E+01

Trial 1

6.59E+01

Trial 2

VALUE PER TRIAL

CONCLUSIONS

Objectively, we've solved the metals specific heat and the ices latent heat of fusion. Comparing

the experimental data to the actual values, the percentage error from the first part are 10.26%

(Aluminum) and 9.0035% (Copper). Hence, the data gathered is acceptable. Next part, the

comparison from the experimental values to the actual values are somehow big. The percentage

error is 20.63% and 17.57%. Possible source of these big errors might be the initial temperature of

the water. Since, the environment is cold and heat travels from hot to cold thus, we can say that

the ice didn't melt. Thus, the final temperature of the mixture might not be accurate. To improve

the data, the experiment must be done in a normal room temperature.

Based on the data, specific heat capacity is relative to its mass and the heat transferred. As to the

data, since the change of the temperature of calorimeter and water of the aluminium is greater than

the copper hence the heat transferred is greater than the mass. Thus, aluminiums specific heat is

still greater. As to the latent heat of fusion, it is also relative to the heat transferred and mass. Since

the mass of the ice of both trial is the same, the greater the heat transferred the greater the computed

latent heat of fusion. Thus, we can say that it is proportional to the heat transferred and inversely

proportional to the mass. Whilst, the specific heat is also proportional to the heat transferred but

inversely proportional to mass and the temperature change.

REFERENCES

Serway, R. A., & Jewett Jr., John W. (2014). University Physics. Philippines: Cengage Learning

Asia Pte Ltd.

PHOTOS

Photo 1: Measuring the temperature of the

calorimeter.

Photo 2: Measuring the mass of calorimeter.

Photo 3: Boiling the copper metal.

Figure 4: Set-up of the experiment

Anda mungkin juga menyukai

- E302 - Analysis and ConclusionDokumen5 halamanE302 - Analysis and ConclusionSkye JabaBelum ada peringkat

- Formal Lab Report 2 - CalorimetryDokumen11 halamanFormal Lab Report 2 - Calorimetryapi-26628770586% (7)

- Thermodynamic Lab 7 (Group7) (Formal)Dokumen11 halamanThermodynamic Lab 7 (Group7) (Formal)Remmey KiraBelum ada peringkat

- Calorimetry Villanueva CristyMaeDokumen11 halamanCalorimetry Villanueva CristyMaeCristy Mae U. VillanuevaBelum ada peringkat

- Ray Bradbury - There Will Come Soft RainsDokumen5 halamanRay Bradbury - There Will Come Soft RainsAndrea RioBelum ada peringkat

- M.E-lab-2 (1) 2Dokumen6 halamanM.E-lab-2 (1) 2Chor FenolBelum ada peringkat

- Front Page - Physics Lab ReportDokumen7 halamanFront Page - Physics Lab ReportRalph Edrean Omadto100% (2)

- Analysis: Q Q Equation 1Dokumen6 halamanAnalysis: Q Q Equation 1Jan Rafael EusebioBelum ada peringkat

- Experiment 4: Specific Heat CapacityDokumen8 halamanExperiment 4: Specific Heat Capacitysyaf100% (1)

- Lab Experiment: Specific Heat of MetalDokumen13 halamanLab Experiment: Specific Heat of MetalHafiz Mohd Basir100% (2)

- Experiment 2 Calorimetry and Specific HeatDokumen8 halamanExperiment 2 Calorimetry and Specific HeatGodfrey SitholeBelum ada peringkat

- E302: Heat and CalorimetryDokumen5 halamanE302: Heat and CalorimetryPJ BundalianBelum ada peringkat

- E302 - Heat and CalorimetryDokumen9 halamanE302 - Heat and CalorimetryGael Canillas RabeBelum ada peringkat

- 4B - Specific Heat: Part 1 - Different MaterialsDokumen5 halaman4B - Specific Heat: Part 1 - Different MaterialsYessenia Velasquez ZuñigaBelum ada peringkat

- Lab ReportDokumen7 halamanLab ReportAristotle LeventidisBelum ada peringkat

- Sample Data Specific HeatDokumen4 halamanSample Data Specific Heathualing222Belum ada peringkat

- Physics 2 Lab 1Dokumen5 halamanPhysics 2 Lab 1Peter ZawyckyBelum ada peringkat

- Lab 12Dokumen15 halamanLab 12Saddam HossainBelum ada peringkat

- Lab Exercise No. 5: Latent Heat of Ice: Department of Mechanical EngineeringDokumen3 halamanLab Exercise No. 5: Latent Heat of Ice: Department of Mechanical EngineeringJino BalingBelum ada peringkat

- Lab Report Physic210Dokumen5 halamanLab Report Physic210Ahmed FiziBelum ada peringkat

- PHYS 1401 General Physics I Experiment 12 Specific Heat: H H I, H F C C F I, CDokumen4 halamanPHYS 1401 General Physics I Experiment 12 Specific Heat: H H I, H F C C F I, CMariam SalminBelum ada peringkat

- PHYS 1401 General Physics I Experiment 12 Specific Heat: H H I, H F C C F I, CDokumen4 halamanPHYS 1401 General Physics I Experiment 12 Specific Heat: H H I, H F C C F I, CHafidzSecretzboyzBelum ada peringkat

- PHYS 1401 General Physics I Experiment 12 Specific Heat: H H I, H F C C F I, CDokumen4 halamanPHYS 1401 General Physics I Experiment 12 Specific Heat: H H I, H F C C F I, CShera IeraBelum ada peringkat

- 6.5.3 Specific Heat Capacity: Using An Electric HeaterDokumen3 halaman6.5.3 Specific Heat Capacity: Using An Electric HeaterNguyễn QuânBelum ada peringkat

- Physics (Phy400) : Experiment 4 Specific HeatDokumen5 halamanPhysics (Phy400) : Experiment 4 Specific HeatMay LeeBelum ada peringkat

- Table of Specific Heat Capacities: List of Thermal ConductivitiesDokumen34 halamanTable of Specific Heat Capacities: List of Thermal Conductivitiesduta_nugraha0% (1)

- Formal Report 2Dokumen4 halamanFormal Report 2Marc PunongbayanBelum ada peringkat

- LabreportphysicdDokumen4 halamanLabreportphysicdapi-263436863Belum ada peringkat

- Worksheet #1Dokumen2 halamanWorksheet #1Sethe AllenBelum ada peringkat

- Results and Discussion Expt 4 Specific HeatDokumen2 halamanResults and Discussion Expt 4 Specific Heatcristina_punzalan_267% (6)

- Exp 302Dokumen9 halamanExp 302Kristianne Mae EchavezBelum ada peringkat

- 1 Energy-12Dokumen4 halaman1 Energy-12Mae TadaBelum ada peringkat

- Fundamentals of Iron and SteelmakingDokumen145 halamanFundamentals of Iron and SteelmakingMichela CarmeliBelum ada peringkat

- Lab 4 Phy400Dokumen11 halamanLab 4 Phy400AUNI SAKINAH BINTI NOR HASNAN KM-PelajarBelum ada peringkat

- Calorimetry (Pre-Laboratory Assignment)Dokumen4 halamanCalorimetry (Pre-Laboratory Assignment)Quirino Arzadon IVBelum ada peringkat

- Lab Reprot Heat CapacityDokumen16 halamanLab Reprot Heat CapacityGalina KhachaturyanBelum ada peringkat

- Calorimetry LabDokumen6 halamanCalorimetry LabchristineBelum ada peringkat

- CalorimetryDokumen5 halamanCalorimetryJerich Ivan PaalisboBelum ada peringkat

- Measuring The Quantity of HeatDokumen18 halamanMeasuring The Quantity of HeatAlmira Kaye CuadraBelum ada peringkat

- Pre Laboratory Assignment Exp 3Dokumen4 halamanPre Laboratory Assignment Exp 3ME1BPOLOBelum ada peringkat

- Heats of Combustion ReportDokumen8 halamanHeats of Combustion ReportNikoBelum ada peringkat

- 43 Specific HeatDokumen7 halaman43 Specific HeatChess ManBelum ada peringkat

- Mapua University: School of Chemical, Biological, Material Engineering and Sciences (CBMES)Dokumen12 halamanMapua University: School of Chemical, Biological, Material Engineering and Sciences (CBMES)Ryan NobleBelum ada peringkat

- Guevara & Irons (2011) Part IDokumen12 halamanGuevara & Irons (2011) Part IaarondenboerBelum ada peringkat

- Lab Report CalorimetryDokumen4 halamanLab Report Calorimetryklyn ponteroBelum ada peringkat

- Measuring Enthalpy Change Using Calorimeter SDokumen15 halamanMeasuring Enthalpy Change Using Calorimeter SJovanna BoneoBelum ada peringkat

- Specific Heat of MetalsDokumen3 halamanSpecific Heat of MetalsSukhjeet SinghBelum ada peringkat

- Phy12l E302 2Q1516Dokumen3 halamanPhy12l E302 2Q1516Michelle Mae Gonzaga Raagas100% (1)

- Exp 1 Hess LawDokumen7 halamanExp 1 Hess LawNur Fadhilah100% (1)

- Specific Heat of Metals Lab Report: By, John and Jane DoeDokumen6 halamanSpecific Heat of Metals Lab Report: By, John and Jane DoeLes MartínezBelum ada peringkat

- Einstein Temperature of AluminiumDokumen3 halamanEinstein Temperature of AluminiumMauhing YipBelum ada peringkat

- Specific Heat WorksheetDokumen2 halamanSpecific Heat WorksheetedpherBelum ada peringkat

- Experiment No. 8: Specific Heat of MetalsDokumen2 halamanExperiment No. 8: Specific Heat of MetalsTiny100% (1)

- Unit 5Dokumen5 halamanUnit 5billingsleyBelum ada peringkat

- Experiment 01 SPECIFIC HEATDokumen16 halamanExperiment 01 SPECIFIC HEATNoeh SuguitanBelum ada peringkat

- Learning Activity 1 CalorimetryDokumen6 halamanLearning Activity 1 CalorimetryYhazmin Iris IlustrisimoBelum ada peringkat

- Specific Heat of SolidsDokumen5 halamanSpecific Heat of SolidsJozel Salvacion100% (1)

- Araujo Gorges Rafael, Yang Yuhan, Austen Wang, VL2Dokumen9 halamanAraujo Gorges Rafael, Yang Yuhan, Austen Wang, VL2lucas052800Belum ada peringkat

- Lab Report Phy210 - Mac 2021 - Ogos 2021Dokumen8 halamanLab Report Phy210 - Mac 2021 - Ogos 2021Yuu ShaBelum ada peringkat

- Correl TechniquesDokumen5 halamanCorrel TechniquesIdate PatrickBelum ada peringkat

- Essentials of Modern Business Statistics (7e) : Anderson, Sweeney, Williams, Camm, CochranDokumen57 halamanEssentials of Modern Business Statistics (7e) : Anderson, Sweeney, Williams, Camm, CochranIdate PatrickBelum ada peringkat

- Quiz 4 - GicaleDokumen2 halamanQuiz 4 - GicaleIdate Patrick100% (2)

- Law1101 Chapter 2Dokumen14 halamanLaw1101 Chapter 2Idate PatrickBelum ada peringkat

- Law1101 Chapter 2Dokumen5 halamanLaw1101 Chapter 2Idate PatrickBelum ada peringkat

- Law1101 Chapter 2Dokumen14 halamanLaw1101 Chapter 2Idate PatrickBelum ada peringkat

- TapiksDokumen5 halamanTapiksIdate PatrickBelum ada peringkat

- RES100 4 ProblemDokumen1 halamanRES100 4 ProblemIdate PatrickBelum ada peringkat

- CHAP1!!!!!!!!!!!!!!Dokumen8 halamanCHAP1!!!!!!!!!!!!!!Idate PatrickBelum ada peringkat

- DebateDokumen15 halamanDebateIdate PatrickBelum ada peringkat

- 6 01Dokumen25 halaman6 01Idate PatrickBelum ada peringkat

- A B C D: Toilet ToiletDokumen1 halamanA B C D: Toilet ToiletIdate PatrickBelum ada peringkat

- Student Assistant ShipDokumen1 halamanStudent Assistant ShipIdate PatrickBelum ada peringkat

- Courses To TakeDokumen2 halamanCourses To TakeIdate PatrickBelum ada peringkat

- Ms. Ma. Cecilia OrtizDokumen1 halamanMs. Ma. Cecilia OrtizIdate PatrickBelum ada peringkat

- From Sieve No. 4 Trial 1:: Sample ComputationDokumen3 halamanFrom Sieve No. 4 Trial 1:: Sample ComputationIdate PatrickBelum ada peringkat

- Cook ThesisDokumen100 halamanCook ThesisTasmaqBelum ada peringkat

- CE121F FieldWork1Dokumen6 halamanCE121F FieldWork1Idate PatrickBelum ada peringkat

- CE140-1P Homework 1Dokumen11 halamanCE140-1P Homework 1Idate PatrickBelum ada peringkat

- John Locke The Labor Theory of Value: Karen VaughnDokumen16 halamanJohn Locke The Labor Theory of Value: Karen VaughnIdate PatrickBelum ada peringkat

- Vocal Elements: Voiced - The Vocal Folds Are Set in Voiceless - The Vocal Folds Do Not VibrateDokumen3 halamanVocal Elements: Voiced - The Vocal Folds Are Set in Voiceless - The Vocal Folds Do Not VibrateIdate PatrickBelum ada peringkat

- GmosDokumen2 halamanGmosIdate PatrickBelum ada peringkat

- Symbol Systems: Nonverbal Symbols: Lesson 4Dokumen24 halamanSymbol Systems: Nonverbal Symbols: Lesson 4Idate PatrickBelum ada peringkat

- Letter To My Fellow PauliniansDokumen1 halamanLetter To My Fellow PauliniansIdate PatrickBelum ada peringkat

- Mapúa Institute of Technology: School of Civil, Environmental and Geological EngineeringDokumen1 halamanMapúa Institute of Technology: School of Civil, Environmental and Geological EngineeringIdate PatrickBelum ada peringkat

- ENG 12 Listening Quiz - ENG12 - .Dokumen5 halamanENG 12 Listening Quiz - ENG12 - .Idate PatrickBelum ada peringkat

- CE140-1P - Lab Report Front PageDokumen1 halamanCE140-1P - Lab Report Front PageIdate PatrickBelum ada peringkat

- 1 Fluid-Properties Tutorial-Solution PDFDokumen15 halaman1 Fluid-Properties Tutorial-Solution PDFIdate PatrickBelum ada peringkat

- VolcanoDokumen1 halamanVolcanoIdate PatrickBelum ada peringkat

- CE120 0F FieldWork#1Dokumen5 halamanCE120 0F FieldWork#1Idate PatrickBelum ada peringkat

- AFT Arrow 5 Data Sheet PDFDokumen2 halamanAFT Arrow 5 Data Sheet PDFerjainrachitBelum ada peringkat

- Experiment 6 PhosphorusDokumen4 halamanExperiment 6 PhosphorusMia Domini Juan Loa100% (1)

- Indicator TapeDokumen1 halamanIndicator TapeRaedMohBelum ada peringkat

- Gate 2013 Question Paper With AnswerDokumen16 halamanGate 2013 Question Paper With AnswerGurmail Singh GillBelum ada peringkat

- Lab 4 - P-NitroacetanilideDokumen5 halamanLab 4 - P-Nitroacetanilidechamanyusuff100% (2)

- Mid Term Igcse Physics Grade 10 Sem 1 2014 Soal - RevisiDokumen10 halamanMid Term Igcse Physics Grade 10 Sem 1 2014 Soal - RevisiJoshuaUntungBelum ada peringkat

- Chemistry Perfect Score Module Form 4 2011 No LogoDokumen96 halamanChemistry Perfect Score Module Form 4 2011 No Logohome8008100% (2)

- BS 6 EmissionsDokumen32 halamanBS 6 EmissionsKawaljeet SinghBelum ada peringkat

- Electron Configuration and The Periodic PropertiesDokumen4 halamanElectron Configuration and The Periodic Propertiesapi-240883010Belum ada peringkat

- Design of WTP and STPDokumen14 halamanDesign of WTP and STPVenu Ch100% (1)

- Comparison of Post and Pre CombustionDokumen12 halamanComparison of Post and Pre CombustionMuhammad AtifBelum ada peringkat

- Advanced Material Modeling in AbaqusDokumen13 halamanAdvanced Material Modeling in AbaqusUdhamBelum ada peringkat

- Aspen Exchanger Design and Rating Shell & Tube V9Dokumen1 halamanAspen Exchanger Design and Rating Shell & Tube V9MAYANK AGRAWALBelum ada peringkat

- Asian PaintsDokumen13 halamanAsian PaintsGurnoor SinghBelum ada peringkat

- Multiphase Modelling of Hydrocyclones - Prediction of Cut-SizeDokumen12 halamanMultiphase Modelling of Hydrocyclones - Prediction of Cut-Sizeenivaldo.sb3897Belum ada peringkat

- A Review On Safety Operation Methods of A Cryogenic Air Separation UnitDokumen9 halamanA Review On Safety Operation Methods of A Cryogenic Air Separation UnitdigecaBelum ada peringkat

- Cell Metabolism - Cell Homeostasis and Stress ResponseDokumen218 halamanCell Metabolism - Cell Homeostasis and Stress ResponseguadialvarezBelum ada peringkat

- Vectra LCP Brochure PDFDokumen76 halamanVectra LCP Brochure PDFbhuniakanishkaBelum ada peringkat

- Biochemistry First LectureDokumen14 halamanBiochemistry First LectureMatthew HallBelum ada peringkat

- Table 6Dokumen1 halamanTable 6sekharsappaBelum ada peringkat

- CHEMISTRY 0620 Learner Guide 2023 - 25Dokumen50 halamanCHEMISTRY 0620 Learner Guide 2023 - 25Varun MangotraBelum ada peringkat

- Report For Experiment #21 Radioactive Decay: Monique DesrochersDokumen9 halamanReport For Experiment #21 Radioactive Decay: Monique DesrochersMonique DesrochersBelum ada peringkat

- Chapter 2Dokumen5 halamanChapter 2AubreyBelum ada peringkat

- Datos de Densidad de MicroalgaDokumen148 halamanDatos de Densidad de MicroalgaViviana Quintero DallosBelum ada peringkat

- Green Chemistry - Wikipedia, The Free EncyclopediaDokumen3 halamanGreen Chemistry - Wikipedia, The Free Encyclopedia9894786946Belum ada peringkat

- Distillation Column Design MethodsDokumen4 halamanDistillation Column Design Methodsramu karriBelum ada peringkat

- Organic ChemistryDokumen10 halamanOrganic ChemistryAshutosh paniBelum ada peringkat

- Probing The Degree of Crosslinking of A Cellulose Based Superabsorbing Hydrogel Through Traditional and NMR TechniquesDokumen12 halamanProbing The Degree of Crosslinking of A Cellulose Based Superabsorbing Hydrogel Through Traditional and NMR Techniquesdeni.sttnBelum ada peringkat

- D7528 - 21 Standard Test Method For Bench Oxidation of Engine Oils by ROBO ApparatusDokumen23 halamanD7528 - 21 Standard Test Method For Bench Oxidation of Engine Oils by ROBO ApparatusProvocateur SamaraBelum ada peringkat