CC4624

Diunggah oleh

Ibhar Santos MumentheyHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CC4624

Diunggah oleh

Ibhar Santos MumentheyHak Cipta:

Format Tersedia

Section 4: Lining Specification

CC4624

Crislip black, soft, chlorobutyl lining for maximum service life in concentrated NaOCl (bleach) service. With natural tie gum.

Specifications

FACE MATERIAL DUROMETER,

ATMOSPHERIC CURE:

50 to 65 A

Typical Physical Properties

Tensile Strength PSI

ASTM D412

1200

% Elongation at Break

ASTM D412

265

Pressure Cure:

55 to 65

Durometer

ASTM D2240

60 A

Specific Gravity

ASTM D927

1.36

Available Gauges:

1/8, 3/16, 1/4, 4mm, 5mm, 6mm

Adhesion to Metal

ASTM D429

30 LBS

Skive:

Butt & Cap with CC4624 without tie gum.

Repairs:

Repair with original lining.

See Section 16 Repair Procedures.

Notes: This lining is also available in the following versions: without tie gum which uses

P-100, I-100 and 500 Tack. It is also available with Tacky Back which does not require

Tack #3 on the rubber but uses the Endurabond 1, 2, 3 system. Use 500 Tack when

closing skives.

For the best appearance of the completed rubber lining, always apply plastic side down

against the substrate.

This lining is commonly used for bleach, and locations that require ozone and oxidation

resistance.

Cure Methods and Times:

Autoclave

4 hours 287F (147C)

Internal Pressure

10 hours at 240F (115C)

or 5 hours at 260F (126C)

Atmospheric

40 hours at 200F (93C).

Note: Cure times may require adjustment to compensate for heavy metal thickness, low

exterior temperatures or other unusual factors. See Section 14 Curing Instructions.

5020 Panther Parkway Seville, Ohio 44273

Ph. 800-321-5583 Fx. 330-769-9334

BLAIR ENG 091 V6 Rev. 0

www.blairrubber.com

CC4624 Crislip black, soft, chlorobutyl lining for

maximum service life in concentrated NaOCl (bleach)

service.

Storage Life From Date of

Shipment

32F (0C) to 50F (10C)

180 days

51F (13C) to 65F (19C)

90 days

66F (21C) to 75F (23C)

60 days

76F (23C) to 85F (30C)

30 days

Storage temperature must not exceed 85F (30C)

Applicator Notes

1. Plying up layers of rubber lining thicker than 1/4 could result in

the rubber flowing or sagging during cure. Test plate is required to

determine flow characteristics.

2. The temperature of the substrate must be greater than 60F (15C)

prior to applying primer and rubber. Temperatures should not exceed

120F (49C).

3. A heated table that warms rubber to approximately 120F (49C) is

best for application.

4. Strict adherence to adhesive specifications is required. Tack time is

critical to the success of the bond.

Adhesive System

Endurabond 1*2*3 SYSTEM

1st coat on metal:

Primer #1

2nd coat on metal:

Intermediate #2

3rd coat on metal:

Tack #3

On tie gum rubber:

Tack #3

On Skive

500 Tack

*Each adhesive component requires thorough mixing

before application.

Disclaimer:

The above guidelines are based on general industry practices and not applicable to all installations. Please contact Blair Rubber Company for specific application

instructions. Application methods shall conform to Blair Rubber Company instructions contained in the Engineering & Applicator manual. Deviations from the

specifications must be approved in writing by Blair Rubber Company. Data values are approximate and may vary based on installation techniques and atmospheric

conditions. As such, data values should be used as general guidelines and are not a legally binding warranty of product characteristics. This document is copyright to

and the intellectual property of Blair Rubber Company and may not be copied or distributed without prior consent.

Blair Rubber Company Section 4: Lining Specification CC4624

BLAIR ENG 091 V6 Rev. 0

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Golden Book of Chemistry ExperimentsDokumen114 halamanThe Golden Book of Chemistry ExperimentsT4urus-VegaBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- GlassDokumen22 halamanGlassAnonymous RgKKzKGIX3Belum ada peringkat

- IQ Range: Reliability For Critical ApplicationsDokumen48 halamanIQ Range: Reliability For Critical ApplicationsIbhar Santos MumentheyBelum ada peringkat

- Astm C 1202-97Dokumen6 halamanAstm C 1202-97Vasco Sorte100% (1)

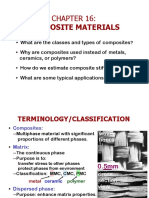

- 10 Chapter 16 Composite MaterialsDokumen27 halaman10 Chapter 16 Composite MaterialsZain FarhanBelum ada peringkat

- Structural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Dokumen38 halamanStructural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Mohammad Yunus Salehi67% (3)

- Total Cooler 30 Plates General Arrangement: - Aansluiting Niveau Meter ? - Positie Support ? - Temperature Sensor ?Dokumen1 halamanTotal Cooler 30 Plates General Arrangement: - Aansluiting Niveau Meter ? - Positie Support ? - Temperature Sensor ?Ibhar Santos MumentheyBelum ada peringkat

- Nevada Slurry Valve 2014 LiteDokumen2 halamanNevada Slurry Valve 2014 LiteIbhar Santos MumentheyBelum ada peringkat

- Floating Suction SystemDokumen12 halamanFloating Suction SystemnainpingleBelum ada peringkat

- PVDF PipeDokumen4 halamanPVDF PipeIbhar Santos MumentheyBelum ada peringkat

- PVDF Material Data Sheet - 1Dokumen1 halamanPVDF Material Data Sheet - 1Ibhar Santos MumentheyBelum ada peringkat

- 02-02 Customer Talking PointsDokumen4 halaman02-02 Customer Talking PointsIbhar Santos MumentheyBelum ada peringkat

- Water HammerDokumen1 halamanWater HammerIbhar Santos MumentheyBelum ada peringkat

- 20-01 Design Din en Iso enDokumen19 halaman20-01 Design Din en Iso enIbhar Santos MumentheyBelum ada peringkat

- 02-06 - LESER in FranceDokumen15 halaman02-06 - LESER in FranceIbhar Santos MumentheyBelum ada peringkat

- General Information For Integral Horsepower (Ihp) Motors On Variable Frequency Drives (VFDS)Dokumen3 halamanGeneral Information For Integral Horsepower (Ihp) Motors On Variable Frequency Drives (VFDS)Ibhar Santos MumentheyBelum ada peringkat

- Customer Talking PointsDokumen4 halamanCustomer Talking PointsIbhar Santos MumentheyBelum ada peringkat

- 19-09 - Assembly of The Main ValveDokumen19 halaman19-09 - Assembly of The Main ValveIbhar Santos MumentheyBelum ada peringkat

- Codes and Standards: (Extension of ASME)Dokumen14 halamanCodes and Standards: (Extension of ASME)Ibhar Santos MumentheyBelum ada peringkat

- 02-06 - LESER in FranceDokumen15 halaman02-06 - LESER in FranceIbhar Santos MumentheyBelum ada peringkat

- Brochure B1510-60Hz Horizontal, Inline Selection PDFDokumen34 halamanBrochure B1510-60Hz Horizontal, Inline Selection PDFIbhar Santos MumentheyBelum ada peringkat

- Volume 3-The Origins of ProtreatDokumen2 halamanVolume 3-The Origins of ProtreatIbhar Santos MumentheyBelum ada peringkat

- Technological Result of Decomposition Sodium Aluminate SolutionDokumen10 halamanTechnological Result of Decomposition Sodium Aluminate SolutionDragana Dragojlović SmiljanicBelum ada peringkat

- FT (Remazol BR Yellow 3GL)Dokumen3 halamanFT (Remazol BR Yellow 3GL)Orlando Yerén ValenciaBelum ada peringkat

- Norelem Grupa 02000 enDokumen56 halamanNorelem Grupa 02000 enBogdan CraciunBelum ada peringkat

- Recycled Glass Utilization in Highway Construction Isaac Finkle, GRA, EITDokumen25 halamanRecycled Glass Utilization in Highway Construction Isaac Finkle, GRA, EITUsama HeneashBelum ada peringkat

- Shock-Wave Studies of PMMA, Fused Silica, and SapphireDokumen19 halamanShock-Wave Studies of PMMA, Fused Silica, and SapphirejasonmsusolarBelum ada peringkat

- Jin 2020 - A Critical Review On Bismuth and Antimony HalidesDokumen32 halamanJin 2020 - A Critical Review On Bismuth and Antimony HalidesFernando HeelerBelum ada peringkat

- Megha Engineering & Infrastructures LTD: List of Register TechnicalDokumen31 halamanMegha Engineering & Infrastructures LTD: List of Register TechnicalLaxmikanta swainBelum ada peringkat

- Mech 325-Strength of Materials SyllabusDokumen2 halamanMech 325-Strength of Materials Syllabuspicefeati100% (1)

- [Synthetic Metals 1985-oct vol. 11 iss. 6] Boehm, H.P._ Setton, R._ Stumpp, E. - Nomenclature and terminology of graphite intercalation compounds. Report by a subgroup of the international committee for charac (198Dokumen9 halaman[Synthetic Metals 1985-oct vol. 11 iss. 6] Boehm, H.P._ Setton, R._ Stumpp, E. - Nomenclature and terminology of graphite intercalation compounds. Report by a subgroup of the international committee for charac (198Ricardinho1987Belum ada peringkat

- Wiring Cable StandardDokumen6 halamanWiring Cable StandardAli AhmadBelum ada peringkat

- Installation PracticesDokumen28 halamanInstallation PracticesKelly QuicenoBelum ada peringkat

- Cylindrical Mandrel TesterDokumen1 halamanCylindrical Mandrel TesterAbiem SebastyanBelum ada peringkat

- Pre-Final Bill Supplimentary works-MVGR 02.07.2019Dokumen112 halamanPre-Final Bill Supplimentary works-MVGR 02.07.2019Anonymous ImoZI0363Belum ada peringkat

- 12CHEM Long Response Dot PointsDokumen11 halaman12CHEM Long Response Dot PointsJane YooBelum ada peringkat

- Sampling Plan PDFDokumen3 halamanSampling Plan PDFamitBelum ada peringkat

- Phosphorus, Reactive, PhosVer 3 Method 8048, 02-2009, 9th EdDokumen7 halamanPhosphorus, Reactive, PhosVer 3 Method 8048, 02-2009, 9th EdzvjesosBelum ada peringkat

- Standard For Colour Coding of Pipework For Identification of Fluids & ServicesDokumen13 halamanStandard For Colour Coding of Pipework For Identification of Fluids & Servicessudeesh kumarBelum ada peringkat

- Deewane: IES & GATE: Material ScienceDokumen33 halamanDeewane: IES & GATE: Material ScienceMayank SaxenaBelum ada peringkat

- Polymer Chemistry For B.SC - Sem-6th PDFDokumen49 halamanPolymer Chemistry For B.SC - Sem-6th PDFSohel Ansari0% (1)

- Tds PP 502 Bi32anDokumen2 halamanTds PP 502 Bi32anzuhrotun urfiyah100% (1)

- Advances in Ethanol ReformingDokumen9 halamanAdvances in Ethanol ReformingDhrupad ParikhBelum ada peringkat

- Johnson Rajkot Elite Plus Elite WallDokumen148 halamanJohnson Rajkot Elite Plus Elite WallSiddhartha AgnihotriBelum ada peringkat

- App 10093Dokumen9 halamanApp 10093Omkar BordeBelum ada peringkat

- Aurocoat - FDokumen2 halamanAurocoat - FNandha NiraiBelum ada peringkat

- 1Dokumen4 halaman1Anonymous 6MI1wMBelum ada peringkat

![[Synthetic Metals 1985-oct vol. 11 iss. 6] Boehm, H.P._ Setton, R._ Stumpp, E. - Nomenclature and terminology of graphite intercalation compounds. Report by a subgroup of the international committee for charac (198](https://imgv2-1-f.scribdassets.com/img/document/613195716/149x198/cd1cc2775e/1710575975?v=1)