Effects of Paving Conditions On Built-In Curling and Pavement Performance

Diunggah oleh

tibammJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Effects of Paving Conditions On Built-In Curling and Pavement Performance

Diunggah oleh

tibammHak Cipta:

Format Tersedia

This article was downloaded by: [Cumhuriyet University]

On: 07 February 2015, At: 23:01

Publisher: Taylor & Francis

Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House,

37-41 Mortimer Street, London W1T 3JH, UK

International Journal of Pavement Engineering

Publication details, including instructions for authors and subscription information:

http://www.tandfonline.com/loi/gpav20

Effects of paving conditions on built-in curling and

pavement performance

a

W. Hansen , Y. Wei , D. L. Smiley , Y. Peng & E. A. Jensen

Department of Civil and Environmental Engineering , University of Michigan , 2350

Hayward, Ann Arbor, MI, 48109, USA

b

Michigan Department of Transportation , P. O. Box 30049, Lansing, MI, 48909, USA

Civil Engineering Department , Lawrence Technological , 21000 West Ten Mile Road,

Southfield, MI, 48075, USA

Published online: 24 Nov 2006.

To cite this article: W. Hansen , Y. Wei , D. L. Smiley , Y. Peng & E. A. Jensen (2006) Effects of paving conditions

on built-in curling and pavement performance, International Journal of Pavement Engineering, 7:4, 291-296, DOI:

10.1080/10298430600798952

To link to this article: http://dx.doi.org/10.1080/10298430600798952

PLEASE SCROLL DOWN FOR ARTICLE

Taylor & Francis makes every effort to ensure the accuracy of all the information (the Content) contained

in the publications on our platform. However, Taylor & Francis, our agents, and our licensors make no

representations or warranties whatsoever as to the accuracy, completeness, or suitability for any purpose of the

Content. Any opinions and views expressed in this publication are the opinions and views of the authors, and

are not the views of or endorsed by Taylor & Francis. The accuracy of the Content should not be relied upon and

should be independently verified with primary sources of information. Taylor and Francis shall not be liable for

any losses, actions, claims, proceedings, demands, costs, expenses, damages, and other liabilities whatsoever

or howsoever caused arising directly or indirectly in connection with, in relation to or arising out of the use of

the Content.

This article may be used for research, teaching, and private study purposes. Any substantial or systematic

reproduction, redistribution, reselling, loan, sub-licensing, systematic supply, or distribution in any

form to anyone is expressly forbidden. Terms & Conditions of access and use can be found at http://

www.tandfonline.com/page/terms-and-conditions

Downloaded from http://www.elearnica.ir

International Journal of Pavement Engineering, Vol. 7, No. 4, December 2006, 291296

Effects of paving conditions on built-in curling and pavement

performance

W. HANSEN*, Y. WEI, D. L. SMILEY, Y. PENG and E. A. JENSEN{

Department of Civil and Environmental Engineering, University of Michigan, 2350 Hayward, Ann Arbor, MI 48109, USA

Michigan Department of Transportation, P. O. Box 30049, Lansing, MI 48909, USA

{Civil Engineering Department, Lawrence Technological, 21000 West Ten Mile Road, Southfield, MI 48075, USA

Downloaded by [Cumhuriyet University] at 23:01 07 February 2015

(Received 4 October 2005; revised 27 March 2006)

The effective temperature difference between the slabs top and bottom at time of final set is an

important input parameter for the recently developed mechanistic-empirical pavement design guide

(M-EPDG). However, very limited guidelines are available for the selection of this parameter. The

major focus of this work is to quantify built-in curl from field temperature measurements for Michigan

pavements. The results of this study show that built-in curl can be substantial for hot weather paving

conditions. Early morning paving on a sunny summer day allows a maximum positive (i.e. top warmer

than bottom) temperature difference at time of final set due to maximum heat of hydration and added

solar radiation effects. The temperature difference between the slabs top and bottom was found to be

10 128C. Consequently, the slab stays flat and in full contact with the base from this time only if this

range is maintained. Unfortunately, this only occurs for a short time-period near mid-day, so the slab is

mostly in a permanently upward curled condition. For late fall temperature conditions, the difference

was slightly negative (about 2 28C) at time of set. Late fall construction therefore is favorable for

maintaining slab base contact. Despite combined built-in curl and daily curling changes, slab stress

predictions using finite element analysis (ISLAB2000) for multi-axle loading at joints found the total

stresses for a typical summertime 24 h period to be below the tensile stress necessary to initiate fatigue

failure (i.e. below 45% of the flexure strength). This suggests that additional slab uplift from moisture

warping is a factor for top down cracking to develop.

Keywords: Built-in curl; Corner uplift; Tensile stress; Top down cracking; Zero-stress temperature

1. Introduction

In concrete pavements, temperature differences between

the top and bottom of a slab cause curling deformations

and stresses (Westergaard 1926). Unless actual field

measurements are made, normally a maximum temperature gradient of 0.055 0.0778C/mm (2.5 3.58F/in.) is

assumed to occur during the day and about half of that is

assumed to occur over night (Huang 1993).

Temperature curling and moisture warping can significantly reduce slab base contact area and result in early

failure of jointed plain concrete pavements (JPCPs)

(Poblete et al. 1990, Darter et al. 1995, Yu et al. 1998,

Khazanovich et al. 2000a,b, Hansen et al. 2002).

Temperature curling of a slab is caused by a temperature

gradient existing along slab depth. Slabs curl upward when

the top is cooler than the bottom, with edges lifting from the

base and leaving an unsupported portion. Moisture warping

occurs when there is a difference in moisture between the

top and bottom surfaces of concrete slab. The slab surface

can dry out, but below about 50 mm from the surface, the

moisture level remains at a relatively constant high level.

This results in upward warping of the slab. A part of the

drying shrinkage in PCC is reversible. The irreversible

shrinkage causes permanent moisture warping and the

reversible part causes seasonal variation in moisture

warping (Janssen 1986, Rao 2001, Suprenant 2002).

In most cases, upward curved shape of a concrete

pavement is evident at an early age and can consequently

influence the slabs long-term performance (Eisenmann

and Leykauf 1990, Springenschmid and Hiller 1998,

Yu et al. 1998, Khazanovich et al. 2000a,b, National

Ready Mix Concrete Association 2004, Guo et al. 2005).

Built-in curl, a permanent form of curling formed in young

pavement, has been reported (Franklin et al. 1969,

Eisenmann and Leykauf 1990, Poblete et al. 1990). This

condition is prevalent during hot weather construction if a

high positive temperature differential exists through the

*Corresponding author. Tel: 1-734-763-9660. Fax: 1-734-764-4292. Email: whansen@umich.edu

International Journal of Pavement Engineering

ISSN 1029-8436 print/ISSN 1477-268X online q 2006 Taylor & Francis

http://www.tandf.co.uk/journals

DOI: 10.1080/10298430600798952

Downloaded by [Cumhuriyet University] at 23:01 07 February 2015

292

W. Hansen et al.

slab thickness at time of final set; upward corner and edge

curling may occur shortly thereafter when the temperature

gradient dissipates. The construction curl reaches its

maximum under a morning placement condition, because

the maximum heat of hydration and the maximum solar

radiation coincide at about the same time resulting in a

large positive temperature gradient when the slab hardens

(Rhodes 1950).

Rhodes (1950) and Eisenmann and Leykauf (1990)

found that the built-in temperature gradient from

construction is of the same importance in its effect on

upward curling as the daily temperature gradient. Springenschmid and Hiller (1998) developed test methods to

study the influence of built-in temperature gradient on slab

deformation and contact conditions. Field and analytical

studies in the US also confirmed the importance of this

effect (Yu et al. 1998, Rao et al. 2001).

The effective temperature difference due to permanent

curl/warp is an important input parameter for the recently

developed M-EPDG (NCHRP 2003). However, very

limited guidelines are available for the selection of this

parameter.

In this study, temperature results from field-instrumented pavements for summer and fall construction in

Michigan are presented. These temperatures are used to

determine the respective magnitude of construction curl

for summer and fall construction. This study evaluated the

effects of construction conditions (summer vs. fall paving)

on construction curl, slab uplift, fatigue stress and zerostress temperature of JPCPs.

2. Measured field temperature gradient for summer

and fall construction in Michigan

Two JPCP projects, constructed on a hot and sunny day in

early summer and on a cold and cloudy day in late fall,

were investigated to determine the effect of paving

conditions on the magnitude of built-in curl. Both projects

were instrumented with wireless temperature sensors,

which were programmed to collect temperature data from

start of construction in 30 min intervals. The concrete

section used for sensor placement was hand-scooped

immediately after placement. The sensors were placed at

four different depths at the same location (mid-slab and

approximately 0.6 m from the longitudinal edge with

shoulder) starting from the top of the base, then

approximately 50, 100, 150 and 200 mm above from the

slab bottom. One sensor was located off the shoulder for

ambient temperature measurements.

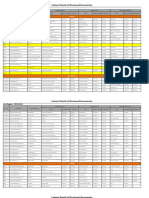

Temperatures at the slabs top and bottom surface,

where no sensors were instrumented, were extrapolated

using the nearest sensor from the top and bottom of the

slab. Figure 1(a) and (b) show the temperature gradients

at four different times after paving for summer and fall

construction, respectively. Based on the field measurements, the temperature difference at the top and bottom

PCC slab surfaces is found to be positive for summer

Figure 1. Field measured temperature profiles along slab depth after

paving (a) summer construction, I-94 JPCP project, (b) fall construction,

US-23 project, temperature data provided by Tim Stallard, MDOT.

construction and it changes from positive to negative

for fall construction within the first few hours after

placement.

The temperature difference at the time of final set was

found to be of great significance as it determines the slab

base contact condition of later ages. The final set time is

affected by the concrete temperature. Figure 2 shows the

relationship between final set time of mortar and curing

temperature tested in the laboratory. This relationship is

used to estimate the final set time of concrete in the field

by converting field pavement temperature into a reference

temperature using maturity concept (ASTM 1995). Based

on the field measured pavement temperature and maturity

concept, the final set time is calculated as 4.5 h for summer

construction and 8.5 h for fall construction in this study.

The temperature differences at final set for summer and

fall construction are shown in figure 1. A positive

Figure 2. Final set time of mortar under different curing temperatures.

Built-in curling and pavement performance

293

temperature difference of about 118C at final set (4.5 h

after placement) is found for summer construction.

Whenever the temperature difference in the slab at later

ages falls below 118C, the slab will curl upward. Thus, for

later age curling analysis, it is assumed that hot weather

construction has resulted in a built-in temperature

difference between top and bottom of 2 118C. For fall

construction project, a negative temperature difference of

2 1.68C is observed at final set (8.5 h after placement).

Thus, slabs constructed during this period will curl

permanently downward if a zero-temperature difference is

measured at later ages.

Downloaded by [Cumhuriyet University] at 23:01 07 February 2015

3. Finite element modeling of JPCPs transverse crack

resistance

3.1 Slab uplift

In this study, the field measured slab temperatures were

used to analyze pavement performance using finite

element software ISLAB2000. ISLAB2000 assumes that

the PCC slab is flat when no temperature gradient or axle

load acts on the slab. As was discussed above, this

assumption is violated for in situ conditions. To account

for the effect of construction curl on slabs performance,

an effective daily temperature difference is used as an

input into ISLAB2000. The effective temperature

difference was obtained by adding the built-in temperature difference of 2 118C (for summer construction) or

1.68C (for fall construction) to the daily temperature

differences.

In figure 3, the effective temperature difference, which

accounts for the built-in temperature gradient, is plotted

together with the measured temperature difference

between top and bottom. The effective temperature

difference during a 24 h cycle for summer temperature

conditions is below zero all the time indicating a permanent

slab uplift condition. A maximum effective temperature

difference of 2 188C can be reached in concrete pavements

at early morning hs during a summer day in Michigan. A

full slab base contact condition is not achieved during the

several 24 h temperature cycles shown in figure 3(a). Late

fall construction on the other hand has minimal effect on the

daily curl as seen from figure 3(b).

It is known that poor curing and dry hot weather

accelerate moisture loss from the surface region of a

concrete slab. Moisture gradient warping will result in slab

corner uplift thus increasing loss of slab support at joints.

Accurate modeling of slab uplift from drying shrinkage

gradient is not realistic due to the complexities involved in

determining moisture gradients for hot and cold weather

construction conditions. It has been reported (Darter et al.

1995) that slab corners during the dry season can be

upward curled equivalent to a negative temperature

gradient of about 0.011 0.0158C/mm. Therefore, the

combined effects of daily temperature cycles, construction

conditions (summer paving vs. fall paving) and moisture

Figure 3. Daily and effective temperature difference for (a) summer and

(b) fall construction.

warping on slab uplift can be determined using FEM

program by inputting a total equivalent temperature

gradient (Ruiz et al. 2001, NCHRP 2003, Rao and Roesler

2005). The total equivalent temperature gradient is

calculated by superimposing each temperature gradient

and can be written as equation (1):

DT total T top; daily 2 T bottom; daily 2 T top; final set

2 T bottom; final set DT warping equivalent

Where DTtotal, total equivalent temperature difference

resulted from combined effects of daily temperature

difference, built-in temperature difference and moisture

warping; Ttop, daily, top surface temperature due to daily

environmental temperature cycles; Tbottom, daily, bottom

surface temperature due to daily environmental temperature cycles; Ttop, final-set, top surface temperature at final

set; Tbottom, final-set, bottom surface temperature at final set;

and DTwarping-equivalent, equivalent temperature difference

due to moisture warping

The modeling on slab uplift is conducted using

ISLAB2000, a finite element program specifically

developed for concrete pavements (Khazanovich et al.

2000a,b). The modeling parameters were determined from

the field and laboratory testing and are listed as follows:

The slab is 305 mm (12.5 in) in thickness, 4.57 m (15 ft)

in length. Youngs modulus, E, is 24,138 MPa

(3.5 106 psi). Coefficient of Thermal Expansion

294

W. Hansen et al.

during a typical summer day in Michigan for the four

climate loading cases shown in figure 4. Combined effect

of daily temperature gradient, summer construction and

moisture warping results in the largest slab corner uplift of

2500 microns, which occurs during early morning hours

and slab curls upward for the entire day. For summer

construction and daily temperature gradient without

warping being involved, slabs curl upward for most time

of the day and are flat during a short period around 3 p.m.

Thus, significant upward curling stresses can develop

associated with hot weather construction.

3.2 Fatigue stresses

Downloaded by [Cumhuriyet University] at 23:01 07 February 2015

Figure 4. Temperature difference for different climate loading cases

during a typical summer day, h 318 mm.

(CTE) of concrete is 10 1026/8C (5.6 1026/8F).The

subgrade reaction k is 68 kPa/mm (250 pci). The current

temperature used in equation (1) is from field measurements at seven different times during a typical summer

day in Michigan. Temperature profiles at final set for

summer and fall construction are taken from figure 1.

The total equivalent temperature differences, calculated using equation (1) are shown in figure 4 for four

climate loading cases: summer 24 h temperature gradient

only; summer 24 h temperature gradient and fall

construction; summer 24 h temperature gradient and

summer construction; and summer 24 h temperature

gradient and summer construction and moisture warping.

Summer construction and/or moisture warping shifts the

24 h temperature difference downward to negative values

resulting in a large maximum negative temperature

difference, fall construction shifts the later age 24 h

temperature cycles only slightly in the opposite direction.

Daily temperature gradient, construction condition and

moisture warping can all add together to cause a large slab

upward curling and tensile stresses at the top of the slab

which could lead to top down transverse cracking (Darter

et al. 1995) or even longitudinal or corner cracking (Hiller

and Roesler 2005). Figure 5 shows the slab corner uplift

Finite element analysis was conducted to investigate the

induced stresses in JPCP when truck loading is applied

at joints and outer edge for the four climate loading

cases. The modeling parameters are the same as in the

previous section. For top down transverse cracking, the

most critical loading position is directly above the

unsupported portion of slab due to upward curling and

warping near the joint corners. Thus, simultaneous joint

loading is the most critical loading condition (Khazanovich et al. 2000a,b, Hansen et al. 2002, Hiller and

Roesler 2002). Figure 6(a) demonstrates the critical

truck loading configuration used in this study taken from

the Michigan weight and axle load limits (www.truckingsafety.org/guidebook). The critical truck loading

position was obtained by moving the truck in 0.5 m

increment along the traffic direction. Six successive

JPCP slabs were used in modeling. A joint load transfer

efficiency (LTE) value of 100% was assumed. Finite

element-based stress contour predictions show that the

maximum total stresses are found at mid-slab and outer

edge, as shown in figure 6(c).

The maximum tensile stresses exceed the lower fatigue

limit for combined effects of summer daily temperature

gradient, built-in curl, moisture warping and truck

loading as seen in figure 7. The lower fatigue limit

(2.2 MPa) corresponding to 45% of the flexural tensile

strength (4.8 MPa), is shown. It appears that drying

shrinkage tips the scale towards top down fatigue

cracking. Fall time paving, on the other hand, can be

beneficial in terms of preventing top down transverse

cracking, as less slab uplift and tensile stresses are

generated in concrete slab.

3.3 Zero-stress temperature

Figure 5. Slab corner uplifts during a typical summer day under the four

climate loading cases shown in figure 4.

Another consequence of hot weather construction is a

large inelastic compressive creep during the first heating

cycle, which will result in a greater joint opening upon

cooling than fall construction. This is concluded from

laboratory tests of a fully-restrained concrete specimen

(800 mm length by 100 mm width and 100 mm height)

subjected to a similar heating cooling temperature

history as in the field. During this time, the thermal stress

in the specimen is recorded continuously using a load cell

Downloaded by [Cumhuriyet University] at 23:01 07 February 2015

Built-in curling and pavement performance

295

Figure 6. Tensile stresses at slab top surface under combined truck and temperature loading.

while the specimen is 100% restrained. The zero-stress

temperature is an indicator of inelastic behavior when

compared to temperature at final set. Hot weather

construction results in a substantially higher zero-stress

temperature than the final set temperature. It is concluded

from the measurements that summer construction can

cause high zero-stress temperature, which is 8 108C

higher than the temperature at final set. However, creep

associated with fall construction is small and shifts the

zero-stress temperature 1 28C below the final set

temperature. This means that later age joint opening is

much smaller and thus beneficial for LTE and long-term

performance of PCC pavement constructed during fall.

Figure 8 shows the temperature and stress development in

a concrete specimen for summer and late fall construction

Figure 7. Tensile stresses at slab top surface under combined climate

and truck loadings.

simulations. The zero-stress temperatures obtained from

laboratory tests agree with previous findings (NCHRP

2003) for hot weather construction.

4. Summary and conclusions

The major focus of this work is to quantify built-in curl

from field temperature measurements for Michigan

pavements.

A built-in temperature gradient for summertime

temperature conditions was found to be of the same

importance in its effect on upward curling as the daily

temperature gradient. These findings are in agreement

with those of Eisenmann and Leykauf (1990). The result is

an unfavorable slab shape that forms permanent slab uplift

at transverse joints and outer edges, leading to associated

loss of slab support. Late fall construction on the other

hand is favorable for maintaining permanent slab base

contact as it reduced the combined slab uplift from daily

temperature curl.

Finite element analysis using ISLAB2000 for multiaxle loading at joints corresponding to a loss of slab

support condition shows that total daily stresses (from

built-in curl, daily temperature curl and heavy axle

loading) are below the tensile stress necessary for

initiating fatigue failure (i.e. below 45% of the flexure

strength). However, if an equivalent negative temperature

gradient based on data from the literature corresponding to

adverse differential drying shrinkage is included in the

analysis (Darter et al. 1995), then, fatigue failure resulting

in top down, mid-slab cracking beginning at the outer

edge is predicted for a JPCP project with substantial builtin curl from hot weather paving.

Laboratory stress tests on a concrete specimen show

that early-age compressive creep is substantial for hot

296

W. Hansen et al.

Downloaded by [Cumhuriyet University] at 23:01 07 February 2015

Figure 8. Stress temperature testing for summer and fall construction simulations.

weather paving conditions as it shifts the zero-stress

temperature substantially (8 108C) above the temperature

at time of final set, while creep associated with cold

weather paving is insignificant and the zero-stress

temperature is shifted slightly below (1 28C) the final

set temperature.

Acknowledgements

The authors would like to thank Michigan Department of

Transportation (MDOT) for sponsoring the project PCC

Pavement Acceptance Criteria for new Construction when

Built-in Curling Exists, UM project number F009839047121. The authors thank Tim Stallard, MDOT, for

providing the field temperature results. The opinions and

findings by the authors do not necessarily reflect the views

or policies of the Michigan Department of Transportation.

This work does not constitute a standard, specification, or

regulation by MDOT.

References

ASTM, Estimating concrete strength by the maturity method, C107487.

Annual Book of ASTM Standard, 1995.

Darter, M.I., Hall, K.T. and Kuo, C.M., Support under portland cement

concrete pavements. NCHRP Report 372, pp. 150, 1995.

Eisenmann, J. and Leykauf, G., Effect of paving temperatures on

pavement performance. 2nd International Workshop on the Design

and Evaluation of Concrete Pavements, pp. 419 431, 1990

(Siguenza, Spain).

Franklin, R.E., The effect of weather conditions on early strains in

concrete slabs, RRL Report No. LR266, Crowthorne, Berkshire, UK,

1969.

Guo, E.H., Dong, M.M. and Daiutolo, H., Curling under different

environmental variations as monitored in a singel concrete slab.

Proceedings of the 8th International Conference on Concrete

Pavements, Innovations for Concrete Pavement: Technology Transfer

for the Next Generation, August 14 18, pp. 11891203, 2005

(Colorado).

Hansen, W., Smiley, D., Peng, Y. and Jensen, E.A., Validating topdown

premature transverse slab cracking in jointed plain concrete pavement

(JPCP). Transportation Research Record 1809, pp. 52 59, 2002

(Transportation Research Board: Washington, DC).

Hiller, J.E. and Roesler, J.R., Transverse joint analysis for use in

mechanistic-empirical design of rigid pavements. Transportation

Research Record 1809, pp. 4251, 2002 (Transportation Research

Board: Washington, DC).

Hiller, J.E. and Roesler, J.R., Determination of critical concrete pavement

fatigue damage locations using influence lines. J. Transp. Eng. ASCE,

2005, 131(8), 599607.

Huang, Y.H., Pavement Design and Analysis, 1993 (Prentice Hall: New

Jercey).

Janssen, D.J., Moisture in portland cement concrete. Transportation

Research Record 1121, pp. 4044, 1986 (Transportation Research

Board: Washington, DC).

Khazanovich, L., Yu, H.T. and Beckemeyer, C.A., Application of ISLAB

for forensic studies. 2nd Int. Symp. 3D Finite Element Pavement

Analysis, Design & Research, 2000a (Charleston, Virginia).

Khazanovich, L., Yu, H.T., Rao, S., Galasova, K., Shats, E. and Jones, R.,

ISLAB2000finite element analysis program for rigid and

composite pavements. Users Guide, 2000b (ERES Division of

ARA, Inc. Champaign, IL).

National Ready Mix Concrete Association, CIP19curling of concrete

slabs, concrete in practice, 2004, www.nrmca.org

NCHRP, Guide for mechanistic-empirical design for new and

rehabilitated pavement structures. Appendix KKTransverse Cracking of JPCP, 2003 (Transportation Research Board, National

Research Council).

Poblete, M., Garcia, A., David, J., Ceza, P. and Espinosa, R., Moisture

effects on the behavior of PCC pavements. Proceedings, 2nd

International Workshop on the Design and the Evaluation of

Concrete Pavements, 1990 (Siguenza, Spain).

Rao, S. and Roesler, J.R., Characterizing effective built-in curling from

concrete pavement field measurements. J. Transp. Eng. ASCE, 2005,

131(4), 320 327.

Rao, C., Barenberg, E.J., Snyder, M.B. and Schmidt, S., Effects of

temperature and moisture on the response of jointed concrete

pavements. Proceedings, 7th International Conference on Concrete

Pavements, 2001 (Orlando, Florida).

Rhodes, C.C., Curing Concrete Pavements with Membranes. Research

Report No. 145, 1950 (Michigan Department of Transportation).

Ruiz, J.M., Kim, P.J., Schindler, A.K. and Rasmussen, R.O., Validation of

HIPERPAV for prediction of early-age jointed concrete pavement

behavior. Transportation Research Record 1778, pp. 1725, 2001

(Washington, DC).

Springenschmid, R. and Hiller, E., Influence of temperature during curing

on stresses in concrete pavements. Proceedings, 8th International

Symposium of Concrete Roads, 1998 (Lisbon).

Westergaard, H.M., Analysis of stresses in concrete pavement due to

variations of temperature, Proceedings, Highway Research Board,

Vol. 6, pp. 201215, 1926.

Yu, H.T, Darter, M.I., Smith, K.D., Jiang, J. and Khazanovich, L.,

Performance of Concrete Pavements, Vol IIIImproving Concrete

Pavement Performance, Report No. FHWA-RD-95-111, 1997

(Federal Highway Administration: Washington, DC).

Yu, H.T., Khazanovich, L., Darter, M.I. and Ardani, A., Analysis of

concrete pavement responses to temperature and wheel loads

measured from instrumented slabs. Transportation Research Record

1639, 1998 (Washington, DC).

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Changes in The Physiological Response Between Leaves and Fruits During A Moderate Water Stress in Table Olive Trees PDFDokumen7 halamanChanges in The Physiological Response Between Leaves and Fruits During A Moderate Water Stress in Table Olive Trees PDFtibammBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- AirportDokumen11 halamanAirporttibammBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Time Variant Flexural Reliability of RC Beams With Externally Bonded CFRPDokumen36 halamanTime Variant Flexural Reliability of RC Beams With Externally Bonded CFRPtibammBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Bitcoin Manifesto - Satoshi NakamotoDokumen9 halamanBitcoin Manifesto - Satoshi NakamotoJessica Vu100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Crack in PavementDokumen20 halamanCrack in PavementtibammBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Thermal Cracking Prediction Model and Software For Asphalt PavementsDokumen10 halamanThermal Cracking Prediction Model and Software For Asphalt PavementstibammBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Bitcoin Manifesto - Satoshi NakamotoDokumen9 halamanBitcoin Manifesto - Satoshi NakamotoJessica Vu100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Airport Engineering Planning DesignDokumen11 halamanAirport Engineering Planning DesigntibammBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Long-Life Concrete Pavements in Europe and Canada: I T S PDokumen1 halamanLong-Life Concrete Pavements in Europe and Canada: I T S PtibammBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Long-Life Concrete Pavements in Europe and Canada: I T S PDokumen1 halamanLong-Life Concrete Pavements in Europe and Canada: I T S PtibammBelum ada peringkat

- Softbank Ebook Center Tehran, Phone: 66403879,66493070 For Educational Use. WWW - Ebookcenter.IrDokumen2 halamanSoftbank Ebook Center Tehran, Phone: 66403879,66493070 For Educational Use. WWW - Ebookcenter.IrtibammBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Airport Engineering Planning Design and Development of 21st Century Airports 2011Dokumen10 halamanAirport Engineering Planning Design and Development of 21st Century Airports 2011tibamm40% (5)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- 06stability Analysis of Large Slurry Shield-Driven Tunnel in Soft ClayDokumen10 halaman06stability Analysis of Large Slurry Shield-Driven Tunnel in Soft ClaytibammBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Long-Life Concrete Pavements in Europe and Canada: I T S PDokumen1 halamanLong-Life Concrete Pavements in Europe and Canada: I T S PtibammBelum ada peringkat

- MarshallDokumen265 halamanMarshalltibamm100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Thermal CrackingDokumen10 halamanThermal CrackingtibammBelum ada peringkat

- The Behaviour of Jacke Concrete Pipes During Site InstallationDokumen227 halamanThe Behaviour of Jacke Concrete Pipes During Site InstallationtibammBelum ada peringkat

- Design of Sequential Excavation Tunneling in Weak Rocks Through FindingsDokumen8 halamanDesign of Sequential Excavation Tunneling in Weak Rocks Through FindingstibammBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Tunnelling and Underground Space TechnologyDokumen6 halamanTunnelling and Underground Space TechnologytibammBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- DowelBarsfolio Feb2013FinalDokumen2 halamanDowelBarsfolio Feb2013FinaltibammBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Road Pavements of Cement ConcreteDokumen20 halamanRoad Pavements of Cement ConcreteKarthika AvulaBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Concrete Road DefectDokumen32 halamanConcrete Road DefectEncik Badrul50% (2)

- Ermco Guide RCCDokumen24 halamanErmco Guide RCCtibammBelum ada peringkat

- Road Pavements of Cement ConcreteDokumen20 halamanRoad Pavements of Cement ConcreteKarthika AvulaBelum ada peringkat

- (Elearnica - Ir) - ABAQUS Model For PCC Slab CrackingDokumen12 halaman(Elearnica - Ir) - ABAQUS Model For PCC Slab CrackingtibammBelum ada peringkat

- Road Pavements of Cement ConcreteDokumen20 halamanRoad Pavements of Cement ConcreteKarthika AvulaBelum ada peringkat

- Slurry TB M TunnellingDokumen32 halamanSlurry TB M Tunnellinglee_kchan4371100% (1)

- Types of IndexDokumen4 halamanTypes of IndexKantha EnduriBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- 1580823068890043Dokumen6 halaman1580823068890043Cristopher Dave CabañasBelum ada peringkat

- MITSUBISHI I-MievDokumen297 halamanMITSUBISHI I-Mievtavaelromo84Belum ada peringkat

- Azhar Marketing Final PPRDokumen9 halamanAzhar Marketing Final PPRafnain rafiBelum ada peringkat

- Bearing SettlementDokumen4 halamanBearing SettlementBahaismail100% (1)

- Bureau of Indian Standards Conformity Assessment Scheme For Milk and Milk ProductsDokumen51 halamanBureau of Indian Standards Conformity Assessment Scheme For Milk and Milk Productsatvenu16160Belum ada peringkat

- 1a. Create Your Yosemite Zone USB DriveDokumen9 halaman1a. Create Your Yosemite Zone USB DriveSimon MeierBelum ada peringkat

- Guia de Desinstalación de ODOO EN UBUNTUDokumen3 halamanGuia de Desinstalación de ODOO EN UBUNTUjesusgom100% (1)

- The Properties of Chopped Basalt Fibre Reinforced Self-CompactingDokumen8 halamanThe Properties of Chopped Basalt Fibre Reinforced Self-CompactingEjaz RahimiBelum ada peringkat

- Writing NuocRut Ver02Dokumen118 halamanWriting NuocRut Ver02thuy linhBelum ada peringkat

- Module 7 - Materials Management Configuration For Goods Receipts Reach - Ucf.eduDokumen12 halamanModule 7 - Materials Management Configuration For Goods Receipts Reach - Ucf.eduAjitabh SinghBelum ada peringkat

- 010 Informed Search 2 - A StarDokumen20 halaman010 Informed Search 2 - A StarRashdeep SinghBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- DACReq 016Dokumen19 halamanDACReq 016jillianixBelum ada peringkat

- Industrial Training HandbookDokumen26 halamanIndustrial Training HandbookChung tong Betty wongBelum ada peringkat

- Yashu Internship Report 21Dokumen45 halamanYashu Internship Report 21Lakshmi dayanand DayaBelum ada peringkat

- Divisional Sec. Contact Details 2019-03-01-UpdateDokumen14 halamanDivisional Sec. Contact Details 2019-03-01-Updatedotr9317Belum ada peringkat

- Week 7 Module 7 TAX2 - Business and Transfer Taxation - PADAYHAGDokumen23 halamanWeek 7 Module 7 TAX2 - Business and Transfer Taxation - PADAYHAGfernan opeliñaBelum ada peringkat

- Lolcat - Linux Cat Command Make Rainbows & Unicorns - LinuxsecretsDokumen1 halamanLolcat - Linux Cat Command Make Rainbows & Unicorns - LinuxsecretsAli BadBelum ada peringkat

- The Dell Direct Model: What It Means For Customers (Users) : - ProsDokumen12 halamanThe Dell Direct Model: What It Means For Customers (Users) : - ProsAbhinandan MattelaBelum ada peringkat

- Oxidation Ponds & LagoonsDokumen31 halamanOxidation Ponds & LagoonsDevendra Sharma100% (1)

- Alex FordDokumen4 halamanAlex FordElectroventica ElectroventicaBelum ada peringkat

- Piston EffectDokumen11 halamanPiston EffectBK180Belum ada peringkat

- One For All Urc-8350 Instruction Manual PDF DownloadDokumen5 halamanOne For All Urc-8350 Instruction Manual PDF DownloademinaBelum ada peringkat

- CANVASS FORM MerchandiseDokumen1 halamanCANVASS FORM MerchandiseJuan VicenteBelum ada peringkat

- HSE - Made Gde PanduDokumen3 halamanHSE - Made Gde Pandurezki_WSBelum ada peringkat

- Philippine Metal Foundries v. CADokumen2 halamanPhilippine Metal Foundries v. CAMarcus AureliusBelum ada peringkat

- Assignment 1: Unit 3 - Week 1Dokumen80 halamanAssignment 1: Unit 3 - Week 1sathiyan gsBelum ada peringkat

- Hospital DocumentsDokumen17 halamanHospital DocumentsRaviraj PisheBelum ada peringkat

- Leadership Skills For Project ManagersDokumen146 halamanLeadership Skills For Project Managerswrite_to_sandeep100% (1)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseDari EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniversePenilaian: 3.5 dari 5 bintang3.5/5 (69)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldDari EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldPenilaian: 4 dari 5 bintang4/5 (595)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessDari EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessBelum ada peringkat

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDari EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingPenilaian: 5 dari 5 bintang5/5 (5)