Wtia Fatigue Design Seminars and Workshop 2012 - Glinka

Diunggah oleh

Nur Syahroni0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

98 tayangan2 halamanWtia Fatigue Design Seminars and Workshop 2012 - Glinka

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniWtia Fatigue Design Seminars and Workshop 2012 - Glinka

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

98 tayangan2 halamanWtia Fatigue Design Seminars and Workshop 2012 - Glinka

Diunggah oleh

Nur SyahroniWtia Fatigue Design Seminars and Workshop 2012 - Glinka

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

REGISTRATION

WELD FATIGUE DESIGN AND PERFORMANCE

WTIA Federal Office (Fatigue design events)

PO Box 6165, SILVERWATER, NSW, 1811

Phone: (02) 9748 4443 Fax: (02) 9748 2858

EMAIL: info@wtia.com.au (WTIA ABN 69 003 696 526)

EVENT PLEASE TICK (one or both events)

Venue locations to be supplied on confirmation of enrolment

1-DAY SEMINAR

Sydney

Brisbane

Melbourne

Adelaide

19 June 2012

20 June 2012

22 June 2012

25 June 2012

The degradation of products and structures imposes a significant cost

for the owners and operators of plant and equipment. Besides the

financial aspects, the possible risk to human life and health and the

environment is always a major consideration.

Welding is the most common method of joining metal structures and

components, yet the special considerations necessary to ensure

satisfactory performance from a welded joint under fatigue loading

are often not appreciated by designers, fabricators and

manufacturers.

2-DAY WORKSHOP

Perth

Besides corrosion, fatigue is the main source (more than 75%) of

failures of welded components. In many instances failures occur

prematurely due to inadequate design, manufacturing defects, or

inadequate maintenance and inspection.

27-28 June 2012

Surname: _______________First Name: _______________

Position: _________________________________________

Company Name: __________________________________

Address: ________________________________________

Prof Grzegorz Glinka is one of the worlds leading experts on weld

fatigue design. His popular seminars have already been offered in

many countries around the glob including the USA, Europe and NZ.

The seminar gives a comprehensive update on advanced fatigue

design methods and prevention techniques.

Mobile: __________________________________________

Seminars will be followed by a 2-day comprehensive workshop in

Perth that will give hands-on examples of fatigue calculation

according to various techniques. The workshop is an ideal add-on to

the seminar for those interested in expanding their understanding of

the subject. Do not miss this excellent professional development

event!

PAYMENT DETAILS:

REGISTRATION FEES (GST inclusive)

Suburb:________________State:______Postcode:_______

Email: ___________________________________________

Tel: ____________________________________________

Please ensure all details below are filled in correctly.

All payments should be made payable to WTIA.

Cheque/Money Order

Mastercard

Visa

Member

WTIA, ASI, EA

$495.00

National Australia Bank BSB: 082 330 Account: 047162875

Branch: 28 George Street, Parramatta, NSW

Account Name: Welding Technology Institute of Australia

1-Day Seminar around Australia in June 2012

2-Day Advanced Workshop, Perth WA

27-28 June 2012

$550.00

Prof Grzegorz Glinka

$880.00

$990.00

Signature: ______________________ Date: ______/_____

Funds Transfer

Funds may be transferred to the

following account details. Please return a remittance advice

by Fax: 02 9748 2858 or Email info@wtia.com.au.

World Authority

Non

Members

2-DAY WORKSHOP

Expiry Date: ________/_______ Amount $_____________

Card No: __________/_________/_________/__________

A Practical Approach

1-DAY SEMINAR

Amount: _______________ Member no: ___________

Cardholders Name: _______________________________

Fatigue Design of

Welded Structures

Fees include coffee/tea, lunch and seminar or workshop notes

IMPORTANT NOTICE

Cancellations received within 10 working days

of the

seminar/workshop, 100% of the fees will be charged. Replacement

delegates may be sent however, in lieu of those cancelled. WTIA

reserves the right to cancel either event due to insufficient registrations

or other reasons beyond their control. WTIA also reserves the right to

refuse registrations.

University of Waterloo, Ontario, Canada

Stress and Fatigue-Fracture Design, SaFFD, Inc.

Expert of the International Institute of Welding Working

Group Fatigue of Welded Components

THE PRESENTER

1-DAY SEMINAR CONTENT

Prof Glinka has been with the

University of Waterloo, Ontario,

Canada since 1989. Prior to this he

was a Post-Doctoral Fellow at The

University of Iowa, USA and also

lectured at the University of Metz,

France and at the University College

London, England. He holds a PhD and

DSc from the Warsaw University of

Technology in Poland and is also an Honorary Professor of

the Warsaw University of Technology and Distinguished

Finland Professor at the Aalto University in Helsinki.

Ideally, everything required to design a component or structure would

be covered by published standards. For various reasons, however,

design standards do not usually prescribe the optimal design

solution for every situation leaving designers with open options.

Prof Glinka is a specialist in fracture and fatigue assessment

of steel structures and mechanical engineering machinery.

He has also acted as a United Nations expert. His research

interests include fracture of materials, fatigue of structures,

multi-axial fatigue and creep of engineering materials,

computer aided design, FEM-elastic-plastic stress-strain

analysis, reliability and design of welded structures. His

recent research activities concern modelling of fatigue crack

growth under random loading and fatigue optimisation of

welded structures. Prof Glinka has published over 180

related articles in technical journals and textbooks.

He is active in many national and international bodies

including Commission XIII Fatigue of welded components

and structures of the International Institute of Welding (IIW).

WHO SHOULD ATTEND?

The 2-Day Workshop will be in particular relevant for people

involved in design, optimisation and fatigue assessment of

steel structures and machinery components. Therefore

attendance is recommended to designers, structural

engineers, mechanical engineers, fabricators, welding

engineers, quality control, maintenance and inspection

personnel, university lecturers, students and researchers.

The 1-Day Seminar will be especially relevant to the

following industry sectors: Steel construction, infrastructure,

fabrication and maintenance, bridge building, transport

industry, power generation, machinery, shipbuilding,

maintenance and the aviation industry.

This seminar will provide a guideline on the use of some of the

commonly used design standards and fatigue life prediction

techniques with plenty of hands-on guidance for designers and

fabricators. It will give an overview of key methods to improve fatigue

performance at the design and fabrication stage. In the case studies,

everyday fractures and cracks in engineering objects will be

discussed.

Methods to optimise fatigue performance and fabrication cost of

welded joints will be discussed in the last session of the seminar, with

demonstrations of software and reference to useful websites.

Delegates are encouraged to bring along their fatigue problems to

contribute to discussions and local case studies.

1- DAY SEMINAR PROGRAMME

08:45

Registration

09:0010:30 Review of American & European rules concerning

static strength analysis of weldments

10:3010:45 Morning Tea

10:4512:15 Global & local approaches to stress analysis

of weldments

12:1513:00 Lunch

13:0014:30 Fatigue strength of weldments

14:3014:45 Afternoon Tea

14:4515:30 Standard methods - fatigue analysis of welded

structures

15:3016:15 Simple fatigue strength improvement for weldments

16:1517:00 Software tools (demo), websites & summary

17:00

Discussion and close

2-DAY WORKSHOP PROGRAMME (08:45 16:30 each day)

08:30

Registration Wednesday 27 June

1. The standard material stress-strain curve and types of

2-DAY WORKSHOP CONTENT

A fatigue assessment is based on two fundamental components: the

analysis of fatigue actions and fatigue resistance of the welded

structure. On the load side, the fatigue actions can be given in the

form of forces on the component, nominal stress in the section,

structural hot-spot stress at a weld toe, notch stress at an effective

weld notch or stress intensity at a crack tip. The exact knowledge of

the actions is one of the greatest unknowns and a source of many

uncertainties.

On the resistance side, the properties may be given by way of a

Woehler (S-N) curve or crack propagation material parameters for

fracture mechanics assessment. The knowledge of actions and the

resistance is essential for the successful fatigue design and

assessment.

The workshop will consider both elements of fatigue assessment indetail. Assessment techniques such as Nominal Stress (S-N), Local

Stress Stress-Strain ( -N), Hot Spot Stress and Fracture Mechanics

Method will be covered in depth using real assessment examples.

Hot topics such as cycle counting procedures, cumulative damage

and the use of the Finite Element method for the fatigue assessment

will be discussed.

The workshop will offer a forum for discussions of individual fatigue

problems and case studies. The workshop is an ideal add-on to the

seminar for those interested in expanding their understanding of the

subject and design calculation skills.

2.

3.

4.

5.

6.

7.

8.

9.

failure (brittle, ductile and fatigue failure, nominal and actual

stress in notched and welded components)

Contemporary fatigue analysis methods (nominal stress SN analysis, local strain life, fracture mechanics, similarities and

differences, advantages and disadvantages)

Global and local approaches to stress analysis of

weldments (stress distributions, geometric effects, nominal v

hot spot stress, stress concentration factors, shell FE v 3-D

FE modelling, residual stresses in structures and weldments)

Cyclic load and stress patterns (histories) in engineering

objects (sources, characteristic features and time domain

characterisation of cyclic stress histories, Rain-Flow cycle

counting, frequency domain characterisation, standard loading

histories and spectra)

The Nominal Stress (S-N) Method (Fatigue S-N curve,

modification factors, mean stress effect, the notch effect,

standard S-N curves, fatigue damage accumulation and live

estimation)

Simple fatigue strength improvement methods (reduction

of stress concentration and nominal stress, stiffness, local and

global geometry improvements, macro- and microscopic

analysis of failures)

Local strain-life (-N) fatigue analysis method (elasticplastic behaviour, stress concentration, Neuber and ESED

methods, modelling of mean and residual stress, example)

Fracture mechanics fatigue analysis method (linear fracture

mechanics, stress intensity factor K and solutions, weight

function, fatigue crack growth, load sequence, geometry and

residual stress effects, numerical example)

Summary and discussion

Anda mungkin juga menyukai

- Honda Fit Timing ChainDokumen14 halamanHonda Fit Timing ChainJorge Rodríguez75% (4)

- IHGStandards-IHG Technical SpecificationsDokumen36 halamanIHGStandards-IHG Technical Specificationsatlcomputech100% (2)

- Design and Estimation of Dry DockDokumen78 halamanDesign and Estimation of Dry DockPrem Kumar100% (4)

- Solutions To Design of Weldments - BlodgettDokumen80 halamanSolutions To Design of Weldments - Blodgettstudent_bl94% (17)

- ITL Semester II Seminar Booklet 1Dokumen29 halamanITL Semester II Seminar Booklet 1Sabyasachi GhoshBelum ada peringkat

- Final Exam SheetDokumen2 halamanFinal Exam Sheetbobtheblob94Belum ada peringkat

- Computer Based Fatigue Analysis For Welded Joints TWIDokumen4 halamanComputer Based Fatigue Analysis For Welded Joints TWIDele TedBelum ada peringkat

- NX Fea TutorialDokumen5 halamanNX Fea TutorialRAI MUNDO0% (1)

- CE134P ESCRUZ SyllabusDokumen5 halamanCE134P ESCRUZ SyllabusAsa KaBelum ada peringkat

- Tow HookDokumen8 halamanTow HookAmulya ManthaBelum ada peringkat

- GeniE Code Checking BeamsDokumen38 halamanGeniE Code Checking BeamsajayBelum ada peringkat

- OE June 17 EditionDokumen92 halamanOE June 17 EditionPerumal KesavanBelum ada peringkat

- MSDS - LPGDokumen9 halamanMSDS - LPGPrathamesh ShevaleBelum ada peringkat

- Feasibility Study Notes Revised PDFDokumen10 halamanFeasibility Study Notes Revised PDFGilbert BettBelum ada peringkat

- Semi-Submersible Drilling PlatformDokumen4 halamanSemi-Submersible Drilling PlatformyoungfpBelum ada peringkat

- Overhead Analysis SheetDokumen1 halamanOverhead Analysis SheetVijay KingBelum ada peringkat

- B Law Ass Complete Ny CheckDokumen19 halamanB Law Ass Complete Ny CheckLeven LimBelum ada peringkat

- Orca FlexDokumen473 halamanOrca FlexLava SatBelum ada peringkat

- CDM Industry Guidelines For Designers 2007Dokumen51 halamanCDM Industry Guidelines For Designers 2007paris062Belum ada peringkat

- Post Test Chapter 9Dokumen3 halamanPost Test Chapter 9Liana Febrianti100% (1)

- Jacket Miscellaneous Structure DesignDokumen6 halamanJacket Miscellaneous Structure DesignBolarinwaBelum ada peringkat

- Cel 2103 - WP Task 5 - Argumentative Essay Draft 1 - Abdulrahman-191476Dokumen3 halamanCel 2103 - WP Task 5 - Argumentative Essay Draft 1 - Abdulrahman-191476Mohammad BappyBelum ada peringkat

- Seismic Assessment of RC Structures Considering Vertical Ground MotionDokumen274 halamanSeismic Assessment of RC Structures Considering Vertical Ground MotionAnonymous 9ZDpDZwqrrBelum ada peringkat

- WSH Guidelines Managing Safety and Health For SME S in The Metalworking Industry Final 2Dokumen22 halamanWSH Guidelines Managing Safety and Health For SME S in The Metalworking Industry Final 2Thupten Gedun Kelvin OngBelum ada peringkat

- "Offshore Platforms".: Seminar Report On TopicDokumen24 halaman"Offshore Platforms".: Seminar Report On TopicNIRAJ DUBEYBelum ada peringkat

- Design Concrete and Steel For Oil and Gas-Online Course - Rev5Dokumen4 halamanDesign Concrete and Steel For Oil and Gas-Online Course - Rev5elreedymanBelum ada peringkat

- (DNV) Det Norske Veritas - 2005 - Material Risk - Ageing Offshore InstallationsDokumen66 halaman(DNV) Det Norske Veritas - 2005 - Material Risk - Ageing Offshore InstallationsKaroline Neumann100% (1)

- Welding of Hollow Structural Sections PDFDokumen5 halamanWelding of Hollow Structural Sections PDFKooroshBelum ada peringkat

- Vibration Contro of Steel Jacket Offshore Platform Structures With Damping Isolation Systems - OuDokumen14 halamanVibration Contro of Steel Jacket Offshore Platform Structures With Damping Isolation Systems - OuRicardo RamirezBelum ada peringkat

- Wtia Training Program 2014Dokumen6 halamanWtia Training Program 2014Syed Mahmud Habibur RahmanBelum ada peringkat

- FragmDokumen51 halamanFragmAnonymous Ub9nEDlBelum ada peringkat

- Principia North 4 Subsea Riser Analysis CalculationDokumen1 halamanPrincipia North 4 Subsea Riser Analysis Calculationsaeed-21Belum ada peringkat

- 57 Promenade Pty LTD: BISM7202 Assignment - Semester 1, 2020 Assignment TemplateDokumen207 halaman57 Promenade Pty LTD: BISM7202 Assignment - Semester 1, 2020 Assignment Templateharoon nasirBelum ada peringkat

- Design, Analysis and Fabrication of Welded StructuresDokumen22 halamanDesign, Analysis and Fabrication of Welded StructurestaosyeBelum ada peringkat

- MATLAB Modeling and Analysis of The Electro-Hydraulic Control System of Injection Molding MachineDokumen14 halamanMATLAB Modeling and Analysis of The Electro-Hydraulic Control System of Injection Molding MachinehachanBelum ada peringkat

- OMAE2008-57082: A New Wind and Wave Atlas of The Hellenic SeasDokumen9 halamanOMAE2008-57082: A New Wind and Wave Atlas of The Hellenic SeaspanBelum ada peringkat

- TBM GasketDokumen5 halamanTBM GasketenginsurucuBelum ada peringkat

- Soroosh and Nowrooz Integrated Development Project: SO EST AN Spp1 55000 D0Dokumen54 halamanSoroosh and Nowrooz Integrated Development Project: SO EST AN Spp1 55000 D0AnjuBelum ada peringkat

- Gujarat Transformers PVT - Ltd. E-Mail Copy: As Per IS 1180 - Level-2Dokumen5 halamanGujarat Transformers PVT - Ltd. E-Mail Copy: As Per IS 1180 - Level-2THANGAVEL PBelum ada peringkat

- PDF OCW Topic 4 - Design of Steel Structures BS EN 1993 1Dokumen18 halamanPDF OCW Topic 4 - Design of Steel Structures BS EN 1993 1Nasrul TorresBelum ada peringkat

- Offshore Fixed Platform Design In-Place Analysis: Pbt750@mun - CaDokumen60 halamanOffshore Fixed Platform Design In-Place Analysis: Pbt750@mun - CaJOSE LUIS GUTIERREZ GARCIABelum ada peringkat

- Hindustan Shipyard-10Dokumen75 halamanHindustan Shipyard-10anshul21Belum ada peringkat

- (2017) A Frame Work To Assess Structural Integrity of Ageing Offshore Jacket Structures For Life ExtensionDokumen23 halaman(2017) A Frame Work To Assess Structural Integrity of Ageing Offshore Jacket Structures For Life ExtensionRaghu MahadevappaBelum ada peringkat

- Shaft Alignment GN E-Feb14Dokumen122 halamanShaft Alignment GN E-Feb14supriadi90315Belum ada peringkat

- ANSYS Offshore Products 14-0 Update - SchofieldDokumen44 halamanANSYS Offshore Products 14-0 Update - SchofieldZhiqiang GuBelum ada peringkat

- Offshore Structures Design Construction and Maintenance - Online Course - 2019Dokumen5 halamanOffshore Structures Design Construction and Maintenance - Online Course - 2019elreedymanBelum ada peringkat

- Cross Sea Detection Based On Synthetic Aperture Radar (Sar) Data and Numerical Wave Model (Wam)Dokumen6 halamanCross Sea Detection Based On Synthetic Aperture Radar (Sar) Data and Numerical Wave Model (Wam)Gautam SudhirBelum ada peringkat

- Investigation of Jack-Up Leg Extension For Deep Water OperationsDokumen14 halamanInvestigation of Jack-Up Leg Extension For Deep Water OperationsKerim Ilgin ErtaşBelum ada peringkat

- Subsea StructureDokumen2 halamanSubsea StructureobumuyaemesiBelum ada peringkat

- Final Report WP 4.2 Support Structure Concepts For Deep Water SitesDokumen210 halamanFinal Report WP 4.2 Support Structure Concepts For Deep Water SitesLai QuocBelum ada peringkat

- Basis of Structural DesignDokumen8 halamanBasis of Structural DesignMoisescu SimonaBelum ada peringkat

- Principal StressesDokumen13 halamanPrincipal StressestehpohkeeBelum ada peringkat

- Exam Solution 2009-10gDokumen9 halamanExam Solution 2009-10gConstAntinosBelum ada peringkat

- Wajac StandardDokumen22 halamanWajac StandardajayBelum ada peringkat

- Optimization of Fatigue Life of Welded Joints by Vikrant Ullhas Garud.Dokumen89 halamanOptimization of Fatigue Life of Welded Joints by Vikrant Ullhas Garud.vikrant GarudBelum ada peringkat

- Saso A-166Dokumen63 halamanSaso A-166ashrafbookBelum ada peringkat

- Marin Report 102Dokumen13 halamanMarin Report 102ayman_32Belum ada peringkat

- FractureDokumen57 halamanFractureAdool FighterBelum ada peringkat

- OMAE2017-62059: Guidelines For Estimating Remaining Fatigue Life of Ageing Offshore Jacket StructuresDokumen9 halamanOMAE2017-62059: Guidelines For Estimating Remaining Fatigue Life of Ageing Offshore Jacket Structuresklop disposableBelum ada peringkat

- Fatigue Analysis of Welding Seams and Spot Joints in Automotive StructuresDokumen9 halamanFatigue Analysis of Welding Seams and Spot Joints in Automotive StructuresAndreyBelum ada peringkat

- FEM Reporting Guidelines-2014Dokumen5 halamanFEM Reporting Guidelines-2014rch_ngBelum ada peringkat

- Offshore Petroleum Production SystemsDokumen48 halamanOffshore Petroleum Production SystemsPungguh Ikhsan PBelum ada peringkat

- Lecture 01 IntroductionDokumen74 halamanLecture 01 IntroductionMustapha BelloBelum ada peringkat

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsDari EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsBelum ada peringkat

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityDari EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityBelum ada peringkat

- 2010-10!11!13-Finite Element Analysis LeafletDokumen2 halaman2010-10!11!13-Finite Element Analysis Leafletsamprof4vwBelum ada peringkat

- Design Review On Fpso-Belanak: Kerjasama Antara: FT. Kelautan - ITS Dan Direktorat Teknik - Dirjen MIGASDokumen47 halamanDesign Review On Fpso-Belanak: Kerjasama Antara: FT. Kelautan - ITS Dan Direktorat Teknik - Dirjen MIGASNur Syahroni100% (1)

- Welding Metallurgy-2Dokumen9 halamanWelding Metallurgy-2Nur SyahroniBelum ada peringkat

- Location Selection of Wave Power PlantDokumen3 halamanLocation Selection of Wave Power PlantNur SyahroniBelum ada peringkat

- Lifeboat Study PDFDokumen48 halamanLifeboat Study PDFNur SyahroniBelum ada peringkat

- Engineering MechanicsDokumen1 halamanEngineering MechanicsNur SyahroniBelum ada peringkat

- XZDD Asterms - and - Conditions PDFDokumen1 halamanXZDD Asterms - and - Conditions PDFTanmay Achal JonnadulaBelum ada peringkat

- Kendriya Vidyalaya, Tagore Garden Recruitment of Contractual Teachers For The Session 2013-14Dokumen8 halamanKendriya Vidyalaya, Tagore Garden Recruitment of Contractual Teachers For The Session 2013-14ombidasarBelum ada peringkat

- ASME VIII Unfired Vessel Relief ValvesDokumen53 halamanASME VIII Unfired Vessel Relief Valvessaid530Belum ada peringkat

- A30050-X6026-X-4-7618-rectifier GR60Dokumen17 halamanA30050-X6026-X-4-7618-rectifier GR60baothienbinhBelum ada peringkat

- Six Tsakalis Pedal ManualDokumen1 halamanSix Tsakalis Pedal ManualAdedejinfoBelum ada peringkat

- ' ' Shail Ahmad: Privet of India Acres N Inches List of ClientDokumen3 halaman' ' Shail Ahmad: Privet of India Acres N Inches List of Clientapi-243316402Belum ada peringkat

- Ancient Civilizations AssignmentDokumen3 halamanAncient Civilizations Assignmentapi-240196832Belum ada peringkat

- Digital Data, Digital SignalDokumen8 halamanDigital Data, Digital SignalBastomi Adi NugrohoBelum ada peringkat

- Parametri TobyDokumen111 halamanParametri TobyZoran MilovicBelum ada peringkat

- Homework 1Dokumen3 halamanHomework 1Bukhosi MsimangaBelum ada peringkat

- Laboratorio de Microondas - Medicion en Lineas de TX Usando Lineas RanuradasDokumen5 halamanLaboratorio de Microondas - Medicion en Lineas de TX Usando Lineas RanuradasacajahuaringaBelum ada peringkat

- Automotive Engg. & TechnologyDokumen15 halamanAutomotive Engg. & TechnologysayuuishotBelum ada peringkat

- Promt MidjourneyDokumen2 halamanPromt MidjourneyMarcelo PaixaoBelum ada peringkat

- 103096-CG9-20AD IIDokumen30 halaman103096-CG9-20AD IICristian Eduardo Chavez GallardoBelum ada peringkat

- Aiwa RM-77 Service ManualDokumen9 halamanAiwa RM-77 Service Manualcristianhumberto_reyesaguileraBelum ada peringkat

- SMAC CA12 BrochureDokumen2 halamanSMAC CA12 BrochureElectromateBelum ada peringkat

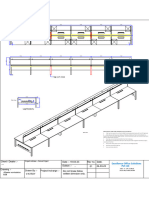

- 6seater Workstation B2BDokumen1 halaman6seater Workstation B2BDid ProjectsBelum ada peringkat

- Pds Maestro Alkyd Primer 12070 En-GbDokumen2 halamanPds Maestro Alkyd Primer 12070 En-GbKhyle Laurenz DuroBelum ada peringkat

- FGRU URAN 08.12.2015 Rev.02Dokumen3 halamanFGRU URAN 08.12.2015 Rev.02Hitendra PanchalBelum ada peringkat

- JFo 2 1 PDFDokumen45 halamanJFo 2 1 PDFAkbar WisnuBelum ada peringkat

- Hi 8586pdiDokumen9 halamanHi 8586pdiDunkMeBelum ada peringkat

- AcknowledgementDokumen4 halamanAcknowledgementPurna GuptaBelum ada peringkat

- FTJ Series Product Guide PDFDokumen12 halamanFTJ Series Product Guide PDFJhon SendokBelum ada peringkat

- Rigmaster 304 Stainless Steel Fluorescent LuminairesDokumen2 halamanRigmaster 304 Stainless Steel Fluorescent LuminairesErikaGaitanGonzalezBelum ada peringkat

- Polyvalve Poly-Gas Polyvalve For Gas ApplicationsDokumen4 halamanPolyvalve Poly-Gas Polyvalve For Gas ApplicationsVasco FerreiraBelum ada peringkat