Exair - Optimization Presentation

Diunggah oleh

api-322850372Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Exair - Optimization Presentation

Diunggah oleh

api-322850372Hak Cipta:

Format Tersedia

EXAIR Optimization

EXAIR Optimization - EFC

EFC (Electronic Flow

Control)

Electronic flow control

minimizes compressed air use

for blow off, drying, cooling,

conveying and static

elimination operations!

Dramatically reduces

compressed air costs by

turning off the compressed air

when no part is present!

Maximizes efficiency by

minimizing compressed air

use!

EXAIR Optimization - EFC

What Is The EFC?

EXAIRs new EFC is a user-friendly

electronic flow control for compressed air

that is designed to minimize compressed

air use on blow off, drying, cooling,

conveying and static elimination operations

The EFC combines a photoelectric sensor

with a timing control that limits

compressed air use by turning it off when

no part is present. The timing control

permits easy tuning to the application

requirements while providing flexibility in

sensing distance.

EXAIR Optimization - EFC

Why The EFC?

For most companies, the air compressor uses more electricity than

any other type of equipment

One simple operation that uses compressed air can easily waste

thousands of those electricity dollars per year if not properly

controlled

The EFC improves efficiency by minimizing compressed air use,

providing just enough air to complete a specific task or operation

The EFC has an easy electrical connection for voltages from 100 to

240VAC, 50/60Hz making it suitable for applications throughout the

world

EXAIR Optimization - EFC

Applications

Auto body blowoff

Package cleaning

Part drying after wash

Dust removal prior to packaging

Scrap removal

Filling operations

Pre-paint dust removal

Wiping contaminants

Cooling hot parts

Neutralizing static

Cleaning molded parts

EXAIR Optimization - EFC

Advantages

Easy electrical hook-up 100-240VAC, 50/60Hz

NEMA 4/IP56 environments

Compact sensor for mounting in tight spaces

Eight function analog timer for on/off, pulsing and delay control

Timer setting from 0.10 sec. to 120 hrs.

Sensor withstands water and dust for accurate readings

Sensor has superior immunity to noise and inductive loads

Sensor has long distance sensing up to 3 feet (1 meter)

RoHS compliant and uses CE compliant components

2006 Product Of The Year

EXAIR Optimization - EFC

$5,030.48 Annual Air Savings For

Pre-Paint Bumper Cleaning

A manufacturer of car bumpers installed a 60

(1524mm) Super Ion Air Knife in the down draft

cleaning area prior to their paint booth. The

bumpers enter that area in the same orientation

as they would when mounted to the automobile,

moving at 10' (3m) per minute with a 12"

(305mm) space between bumpers. The bumpers

are under the blow off for 10 seconds. 6 seconds

pass with no bumper in the ionized airflow. The

operation runs around the clock with three shifts.

The timer was set to the interval setting when

detecting the bumpers. The sensor was mounted

next to the Super Ion Air Knives. When it detected

a bumper, it turned the air on immediately and

started the 10 second timing sequence for closing

the valve (shutting the air off). In the event the

conveyor stopped, the air would no longer cycle on

again until the next bumper was detected (the

conveyor was turned on again).

EXAIR Optimization - EFC

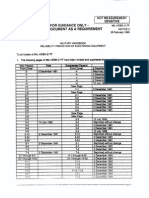

There are four models. Each includes the timing control,

photoelectric sensor, and choice of solenoid valve sizes of

40, 100 and 200 SCFM.

The timing control unit and the photoelectric sensor are

equipped with a 9 (2.74m) power cord. The timing control

unit is housed in a polycarbonate NEMA 4 water tight

enclosure.

Model

Description

9055

EFC Electronic Flow Control (40 SCFM) includes timing control unit, photoelectric sensor, 40

SCFM solenoid valve, 1/4 NPT

9056

EFC Electronic Flow Control (100 SCFM) includes timing control unit, photoelectric sensor, 100

SCFM solenoid valve, 1/2 NPT

9057

EFC Electronic Flow Control (200 SCFM) includes timing control unit, photoelectric sensor, 200

SCFM solenoid valve, 3/4 NPT

9064

EFC Electronic Flow Control (350 SCFM) includes timing control unit, photoelectric sensor, 350

SCFM solenoid valve, 1 NPT

EXAIR Optimization ULD

Locate costly leaks in your

compressed air system!

EXAIR Optimization ULD

What Is The ULD?

The Ultrasonic Leak Detector:

Locates costly leaks as part of

your leak prevention program

Reduces operating costs of

your compressed air system

Provides visual LED

confirmation of leaks up to

20 feet away

Includes accessories to

eliminate any non-leak

background noise

EXAIR Optimization ULD

Why The ULD?

Plants that arent maintained can easily

waste up to 30% of the compressor output

through leaks that go undetected

Compressing air is an expensive operation.

Saving the wasted compressed air reduces

overall operating costs

In large plants, the cost of a small air leak

may be insignificant, but many small leaks

when located and repaired can amount to

huge energy savings

LED indicators on the

Ultrasonic Leak

Detector show the

exact source of the

leak or problem.

EXAIR Optimization ULD

Applications

Locates leaks in air, steam and non-flammable gas systems

including pipes, fittings, valves, cylinders and pressure vessels

Finds the source of bearing and gear wear

Locates arcing in an electrical system

Detects refrigeration and air conditioning system leaks

Locates leaks in brake systems, tubes, tires and radiators

Senses cracks in moving rubber v-belts

Detects leaks in vacuum systems

Check condition of engine seals

EXAIR Optimization ULD

Advantages

Detects any pressurized air leak up to 20 feet (6.1m) away

Converts ultrasound to an audible frequency

LED display confirms the leak location

Detects leaks in noisy industrial environments

Sensitivity controls provide accurate detection

Not affected by contaminants or windy conditions

Includes accessories to detect leaks in hard to reach areas

Rugged carrying case

Meets ASTM standards

EXAIR Optimization ULD

What Is Ultrasound?

Ultrasonic sound is a range of sound that is above human hearing

capacity. Most people can hear frequencies from 20 Hz to 20 kHz

Sound from 20 kHz to 100 kHz can not be heard and is called

ultrasonic

The Model 9061 Ultrasonic Leak Detector converts ultrasonic

sound emissions to a range that is audible by people

(The sound generated by the ULD is 2 times lower in frequency

than the sound that is received)

EXAIR Optimization ULD

In a ULD

plantcan

where

loud noise

The

be adjusted

to

levelsout

exist,

it is very noise

difficult to

filter

background

locatethe

leaks

by merely

listening

using

three

sensitivity

for them.ofMost

plantand

noises

are

settings

X1, X10

X100

in the with

normal

of

along

an audible

on/offrange

thumb

humanfor

hearing,

while air

wheel

fine sensitivity

escaping from a small orifice is

adjustment

ultrasonic.

EXAIR Optimization ULD Accessories

The parabola or tubular

extension can also be attached

to the ULD to mask out intense

background noise. The ULD

detects only the ultrasonic

sounds that are generated.

Parabola

Tubular Extension

Tubular Adaptor

Headphones

EXAIR Optimization ULD

Ultrasound is directional in transmission and is loudest at the

source

Turbulence created by the air forced through a small orifice

generates ultrasonic sound called white noise. It occurs when the

air moves from a high pressure area such as a pipe or vessel and

escapes to a low pressure area such as the room.

The Ultrasonic Leak Detector converts the turbulent flow to a

frequency that can be heard using the headphones

As the ULD moves closer to the leak, more LEDs on the display light

to confirm the source of the leak

EXAIR Optimization ULD

Find One Leak - Pay For Your Ultrasonic Leak Detector

Consider one small leak that is equivalent to a 1/16 diameter hole.

At 80 PSIG, it consumes 3.8 SCFM (Standard Cubic Feet per Minute)

or 108 SLPM (Standard Liters Per Minute)

Most large plants know their air cost. If you dont know your actual

cost per 1000 SCF (Standard Cubic Feet), a reasonable average is

$.25 per 1000 SCF (28,329 Standard Liters)

Dollars consumed per hour = SCFM consumed x 60 minutes x

cost/1000 SCF

= .8 x 60 x .25/1000

= $.06 per hour

= $1. 37 per 24 hour period

= $9.58 per week

= $497.95 per year

EXAIR Optimization ULD

The Model 9061 Ultrasonic Leak

Detector comes complete with a

hard-shell plastic case,

headphones, parabola, tubular

adaptor, tubular extension and 9

volt battery

Digital Flowmeter

EXAIR Optimization Digital Flowmeter

Digital Flowmeter

Monitor compressed air usage

and waste!

EXAIR Optimization Digital Flowmeter

What Is The Digital

Flowmeter?

The easy way to monitor

compressed air consumption and

waste!

The digital display shows the

exact amount of compressed air

being used downstream

This makes it possible to save

thousands of dollars per year in

compressed air waste

Helps identify costly leaks or

inefficient air products

EXAIR Optimization Digital Flowmeter

Why The Digital Flowmeter?

The Digital Flowmeter has an LED display

that directly indicates the SCFM of airflow

through that pipe

Other flowmeters require the reading to be

multiplied by a specific conversion factor to

be accurate

Two models are available for use on

Schedule 40 iron pipe one designed for 1

and the other for 2. Each Digital

Flowmeter is calibrated for the specific pipe

size it is mounted to.

Model

Pipe Size

Range

9092

1 (Schedule 40 iron)

1 80 SCFM

9095

2 (Schedule 40 iron)

2 350 SCFM

EXAIR Optimization Digital Flowmeter

Specifications

Accuracy 5% of reading. Add 1% of full scale for air temperature

between 40 to 120F (4 to 49C). Accuracy will be reduced when

flow is outside the specified range.

Operating Pressure 30 to 140 PSIG for best accuracy 200 PSIG

max

Input Power 250mA at 18 VDC/Power Adapter 120VAC

Wetted Metals Stainless steel, gold, thermal epoxy and Viton

(seal)

Ring Material Aluminum

Display Four-digit LED display

Compliance CE and RoHS

Note: For use with compressed air and nitrogen only

*For use with compressed air and nitrogen only

EXAIR Optimization Digital Flowmeter

Advantages

Easy to install

No moving parts

Sensitive at low flows

No calibration or setup required

Includes necessary components for installation

Two models for use on 1 and 2 Schedule 40 iron pipe.

EXAIR Optimization Digital Flowmeter

Each Digital Flowmeter comes

complete with a 18 VDC power

supply, 3/16 drill bit, and hole

locating fixture

Digital Sound Level Meter

EXAIR Optimization Digital Sound Level Meter

Digital Sound Level Meter

Prevent worker-related hearing

loss!

EXAIR Optimization Digital Sound Level Meter

What Is The Digital Sound Level Meter?

An easy to use instrument that can measure

and monitor the sound level pressure in a

wide variety of industrial environments

The source of loud noises can be quickly

identified and isolated

Corrective measures can be taken to reduce

or eliminate the noise problem

In many cases, the EXAIR products can

reduce noise levels by 10dBA which is

perceived as cutting the sound volume in half

EXAIR Optimization Digital Sound Level Meter

Why The Digital Sound Level Meter?

Exposure to high noise levels for an

extended period of time can lead to

permanent hearing loss for workers not

wearing proper hearing protection

The Digital Sound Level Meter can help

employers protect workers by monitoring

noise levels so they do not exceed the limits

shown in OSHA Standard 29 CFR

1910.95(a)

Failure to comply can result in hefty fines

OSHA Maximum Allowable Noise Exposure

Hours per day (constant noise)

0.5

Sound level dBA

90

91

95

97

100

105

110

OSHA Standard 29 CFR-1910.95(a)

EXAIR Optimization Digital Sound Level Meter

Specifications

Accurate and responsive, the Digital Sound Level Meter measures

the decibels of the sound and displays the reading on the large LCD

display.

A backlight button is provided for easier viewing

An F/S response time button provides a choice of slow or fast

measurements.

Max Hold setting will measure the maximum noise level of sounds

and update continuously if a louder sound is detected.

Certification of accuracy and calibration traceable to NIST (National

Institute of Standards and Technology) is included.

EXAIR Optimization Digital Sound Level Meter

Advantages

Measuring sound level range from 35dB 130dB

(Low: 35 to 100; High: 65 to 130dBA)

Frequency range 31.5Hz 8kHz

A and C weightings (check compliance with safety regulations

and acoustic analysis)

Slow (1 sec) and fast (125ms) response settings to check peak

and average noise levels

Maximum Hold feature to measure peak sound levels

Accuracy is 1.5dB

NIST Certification

EXAIR Optimization Digital Sound Level Meter

Model 9104 Digital Sound Level

Meter comes complete with

removable wind screen, battery,

and a protective case

Copyright 2007 EXAIR Corporation.

All Rights reserved.

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Davey Water PumpDokumen8 halamanDavey Water PumpMohamedAbdel-Rahman0% (1)

- F6TesT 2.21 Training Settings - Transformer Diff (MCBH)Dokumen324 halamanF6TesT 2.21 Training Settings - Transformer Diff (MCBH)Chhimi WangchukBelum ada peringkat

- Cathodic Protection For Tank Bottoms (Underside)Dokumen28 halamanCathodic Protection For Tank Bottoms (Underside)Ali Raza Kaisrani100% (1)

- Sheet 2: Example 1: A 20 kVA, 2500/250 V, 50Hz, Single-Phase Transformer Gave TheDokumen3 halamanSheet 2: Example 1: A 20 kVA, 2500/250 V, 50Hz, Single-Phase Transformer Gave Thetareq omar67% (6)

- Chauvin Arnoux 8350Dokumen56 halamanChauvin Arnoux 8350Marc PettyBelum ada peringkat

- Exair - Static Eliminator Cleaning Training PresentationDokumen11 halamanExair - Static Eliminator Cleaning Training Presentationapi-322850372Belum ada peringkat

- Exair - Vac U Gun PresentationDokumen6 halamanExair - Vac U Gun Presentationapi-322850372Belum ada peringkat

- Exair - Reversible Drum Vac PresentationDokumen10 halamanExair - Reversible Drum Vac Presentationapi-322850372Belum ada peringkat

- Exair - Vac U Gun PresentationDokumen6 halamanExair - Vac U Gun Presentationapi-322850372Belum ada peringkat

- Exair - Product 2011 PresentationDokumen56 halamanExair - Product 2011 Presentationapi-322850372Belum ada peringkat

- Exair - Reversable Drum Vac Cleaning Instruction PresentationDokumen10 halamanExair - Reversable Drum Vac Cleaning Instruction Presentationapi-322850372Belum ada peringkat

- Exair - Chip Vac PresentationDokumen11 halamanExair - Chip Vac Presentationapi-322850372Belum ada peringkat

- Exair - Mini Cooler PresentationDokumen11 halamanExair - Mini Cooler Presentationapi-322850372Belum ada peringkat

- Exair - Product 2011 PresentationDokumen56 halamanExair - Product 2011 Presentationapi-322850372Belum ada peringkat

- Exair - Deep Hole Vac U Gun PresentationDokumen7 halamanExair - Deep Hole Vac U Gun Presentationapi-322850372Belum ada peringkat

- Exair - E-Vac Vacuum Generators PresenationDokumen17 halamanExair - E-Vac Vacuum Generators Presenationapi-322850372Belum ada peringkat

- Exair - Air Disk Air Stik PresentationDokumen11 halamanExair - Air Disk Air Stik Presentationapi-322850372Belum ada peringkat

- Exair - Air Wipes PresenationDokumen13 halamanExair - Air Wipes Presenationapi-322850372Belum ada peringkat

- Exair - Atomizing Nozzles PresentationDokumen13 halamanExair - Atomizing Nozzles Presentationapi-322850372Belum ada peringkat

- Exair - Air Knives PresentationDokumen25 halamanExair - Air Knives Presentationapi-322850372Belum ada peringkat

- Exair - Air Operated Conveyors Line Vac PresentationDokumen33 halamanExair - Air Operated Conveyors Line Vac Presentationapi-322850372Belum ada peringkat

- Exair - Air Nozzles and Jets PresentationDokumen33 halamanExair - Air Nozzles and Jets Presentationapi-322850372Belum ada peringkat

- Exair - Air Amplifiers PresentationDokumen26 halamanExair - Air Amplifiers Presentationapi-322850372Belum ada peringkat

- Ide&Sdcc C CompilerDokumen24 halamanIde&Sdcc C Compileriik MubarakBelum ada peringkat

- Admit Card: Examination Centre: Centre CodeDokumen1 halamanAdmit Card: Examination Centre: Centre CodezahidBelum ada peringkat

- Military HandbookDokumen80 halamanMilitary HandbookLuthfyatma HardyBelum ada peringkat

- XFCN Xf508pab Apr22 XonlinkDokumen2 halamanXFCN Xf508pab Apr22 Xonlinkvivanjoao6Belum ada peringkat

- Schedule TrainningDokumen43 halamanSchedule TrainningdarkbertBelum ada peringkat

- Oculus Link Compatibility InstructionsDokumen4 halamanOculus Link Compatibility Instructionsmichaelkan10% (1)

- COA 2013 Application and SyllabusDokumen7 halamanCOA 2013 Application and SyllabusLohanathan VkBelum ada peringkat

- Mtech HandoutsDokumen4 halamanMtech HandoutsJyothi PoornaBelum ada peringkat

- Equitrac Embedded For Kyocera - PDFDokumen14 halamanEquitrac Embedded For Kyocera - PDFkjgBelum ada peringkat

- Transformer Overflux ProtectionDokumen3 halamanTransformer Overflux ProtectionkarthikBelum ada peringkat

- Induction Motors PPT v1Dokumen10 halamanInduction Motors PPT v1Alessio ScarabelliBelum ada peringkat

- At Command Set For Nokia GSM and WCDMA Products v1 2 enDokumen111 halamanAt Command Set For Nokia GSM and WCDMA Products v1 2 endhwanil_k8031Belum ada peringkat

- Exploracion Geofisica PDFDokumen188 halamanExploracion Geofisica PDFJose Joaquin Alvarez EncisoBelum ada peringkat

- Compal LA 6741PDokumen36 halamanCompal LA 6741PGirleisson AraujoBelum ada peringkat

- Product Data Sheet: Relayaux - Instantaneous Fast Trip Relay - 4 C/O - Pick-Up Time 8 Ms - 110 VDCDokumen3 halamanProduct Data Sheet: Relayaux - Instantaneous Fast Trip Relay - 4 C/O - Pick-Up Time 8 Ms - 110 VDCJoemark YangagBelum ada peringkat

- EMV Multi Cable Transit Modular System (EMC-System) : PDFDokumen7 halamanEMV Multi Cable Transit Modular System (EMC-System) : PDFbakien-canBelum ada peringkat

- Liebert GXT MT+ CX 1/2/3 kVA Technical Specifications: Model GXT MT+ CX I GXT MT+ CX I GXT MT+ CX Phase Capacity InputDokumen1 halamanLiebert GXT MT+ CX 1/2/3 kVA Technical Specifications: Model GXT MT+ CX I GXT MT+ CX I GXT MT+ CX Phase Capacity Inputsasa hhBelum ada peringkat

- I4-Immobilizer Emulator Mercedes CR1, CR2 CANDokumen11 halamanI4-Immobilizer Emulator Mercedes CR1, CR2 CANعلي ابزيزBelum ada peringkat

- Basic Digital Electronics - Unit 4newDokumen25 halamanBasic Digital Electronics - Unit 4newSoni Mishra TiwariBelum ada peringkat

- TC-2450 Equipment Case User's Manual ISI-4421-0061 Rev BDokumen16 halamanTC-2450 Equipment Case User's Manual ISI-4421-0061 Rev BPeter BoongBelum ada peringkat

- Edition 7 Arcing Faults in Medium and Low Voltage Switchgear PDFDokumen12 halamanEdition 7 Arcing Faults in Medium and Low Voltage Switchgear PDFE.ANANDANBelum ada peringkat

- AlphaSpotHPE700 Manual Rev.2 (02.11) enDokumen28 halamanAlphaSpotHPE700 Manual Rev.2 (02.11) enrobrtBelum ada peringkat

- Operating Instructions: KX-T7420 KX-T7425 KX-T7431 KX-T7433 KX-T7436Dokumen34 halamanOperating Instructions: KX-T7420 KX-T7425 KX-T7431 KX-T7433 KX-T7436Marina BoljanovicBelum ada peringkat

- Expt 5.1Dokumen6 halamanExpt 5.1Joel Catapang0% (1)