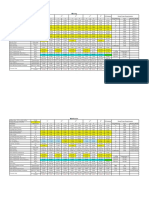

Steam Balance Layout (TPH) Model

Diunggah oleh

Remington SalayaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Steam Balance Layout (TPH) Model

Diunggah oleh

Remington SalayaHak Cipta:

Format Tersedia

WORTHINGTON

TURBO-GENERATOR

(High Pressure Turbine)

Capacity 2500 KW

Steam Rate 78,500 PPH

Inlet Pressure 250 PSIG

Outlet Pressure 15 PSIG

ELLIOTT

TURBO-GENERATOR

(High Pressure Turbine)

Capacity 2,500 KW

Steam Rate 75,250 PPH

Inlet Pressure 250 PSIG

Outlet Pressure 15 PSIG

HP Steam Required: 60,200 PPH

Pressure: 250 PSIG

27.3 TPH

HP Steam Required: 62,600 PPH

Pressure: 250 PSIG

23.39 TPH

TO END USERS

4.0 MW ELECTRICITY

(Projected Load of the Factory)

Exhaust thrown to environment: 427.97 PPH

Pressure: 5.426 PSIG

3 - UNITS SERVICE TRANSFORMERS

Exhaust Available: 116,600 PPH

Pressure: 15.0 PSIG

TURBODYNE TURBO-GENERATOR

(High Pressure Turbine)

Capacity 2,500 KW

Steam Rate 81,000 PPH

Inlet Pressure 250 PSIG

Outlet Pressure 15 PSIG

HP Steam Required:

12.38 TPH @ 12.2 % fiber

15.20 TPH @ 15.0 % fiber

16.76 TPH @ 16.5 % fiber

Exhaust Available: 116,232 PPH

Pressure: 9.574 PSIG

HP Steam Required:

8.24 TPH @ 12.2 % fiber

10.14 TPH @ 15.0% fiber

11.59 TPH @ 16.5 % fiber

HP Steam Required:

7.62 TPH @ 12.2 % fiber

9.38 TPH @ 15.0 % fiber

10.31 TPH @ 16.5 % fiber

ELLIOT TURBO-GENERATOR

(Low Pressure Turbine)

Capacity 800 KW

Steam Rate 32,000 PPH

Inlet Pressure 125 PSIG

Outlet Pressure 15 PSIG

MILL ROLLER #1

Capacity 750 HP

Steam Rate 35.6 lb/hp-hr

Steam Pressure 250 PSIG

HP Steam Required:

7.62 TPH @ 12.2 % fiber

9.38 TPH @ 15.0 % fiber

10.31 TPH @ 16.5 % fiber

HP Steam Required:

8.24 TPH @ 12.2 % fiber

10.14 TPH @ 15.0% fiber

11.59 TPH @ 16.5 % fiber

MILL ROLLER #2

Capacity 650 HP

Steam Rate 32.92 lb/hp-hr

Steam Pressure 250 PSIG

FINAL BAGASSE

52 % Moisture

3.50 Pol in bagasse

31.20 Bagasse % Cane

MILL ROLLER #3

Capacity 650 HP

Steam Rate 32.92 lb/hp-hr

Steam Pressure 250 PSIG

MILL ROLLER #4

Capacity 750 HP

Steam Rate 35.6 lb/hp-hr

Steam Pressure 250 PSIG

SHREDDER TURBINE

Capacity 2500 HP

Steam Rate 22.932 lb/hp-hr

Steam Pressure 250 PSIG

Exhaust Available:

Pressure: 15 PSIG

39.70 TPH @ 12.2 % fiber in cane

98.98 TPH @ 15.0 % fiber in cane

103.87 TPH @ 16.5 % fiber in cane

HP Steam Required: 97,306.6 PPH

Pressure: 250 PSIG 44.13 TPH

HP Steam Required: 122,800 PPH

Pressure: 250 PSIG

55.69 TPH

BOILER MAIN HEADER

EXCESS STEAM

29.0 TPH @ 12.2 % fiber in cane

40.87 TPH @ 15.0 % fiber in cane

35.44 TPH @ 16.5 % fiber in cane

HP Steam Generated: 34.46 TPH

Pressure: 250 PSIG

HP Steam Generated: 34.46 TPH

Pressure: 250 PSIG

HP Steam Generated: 89.85 TPH

Pressure: 250 PSIG

LP Steam Required: 72.84 TPH

Pressure: 125 PSIG @ 12.2 % fiber in cane

@ 12.2 % Fiber in Cane

HP Steam Available: 65,614.94 PPH

Pressure: 250 PSIG

29.75 TPH

LP Steam Required: 13.66 TPH

Pressure: 125 PSIG @ 15.0 % fiber in cane

LP Steam Required: 10.73 TPH

Pressure: 125 PSIG @ 16.5 % fiber in cane

Exhaust Available: 92.43 TPH

Pressure: 15 PSIG @ 12.2 % fiber in cane

@ 12.2 % Fiber in Cane

Live Steam Available: 65,614.94 PPH

Pressure: 125 PSIG

29.75 TPH

Evaporating Capacity 200,000 PPH

Steam Presure 250 PSIG

Steam Temperature 530 F

Fuel Consumption 40 TPH

APRV 125 - 15 PSIG

APRV 250 to 125 PSIG

Make-up Steam: 45.16 TPH

Pressure: 15 PSIG @ 12.2 % fiber in cane

Exhaust Available: 151.6 TPH

Pressure: 15 PSIG @ 15.0 % fiber in cane

Exhaust Available: 156.58 TPH

Pressure: 15 PSIG @ 16.5 % fiber in cane

Make-up Steam: 2.93 TPH

Pressure: 15 PSIG @ 15.0 % fiber in cane

JTA BOILER

ID Fan Turbine Drive

400 HP; 250 PSIG

1,551.68 PPH (703.7 kg/hr)

K- BOILER

UNIT #1

FWP Turbine Drive

200 HP; 250 PSIG

775.84 PPH (351.85 kg/hr)

Evaporating Capacity 80,000 PPH

Steam Presure 250 PSIG

Steam Temperature 508 F

Fuel Consumption 16 TPH

K- BOILER

UNIT #2

Evaporating Capacity 80,000 PPH

Steam Presure 250 PSIG

Steam Temperature 508 F

Fuel Consumption 16 TPH

LP Steam Generated: 43.0 TPH

Pressure: 125 PSIG

Evaporating Capacity 40,000 PPH

Steam Presure 125 PSIG

Steam Temperature 392 F

Fuel Consumption 8 TPH

BOILER-10

LP Excess Steam: 29.4 TPH

Pressure: 125 PSIG @ 15.0 % fiber in cane

BOILER-9

Vapor Required: 137.59 TPH

Pressure: 15 PSIG

LP Excess Steam: 32.27 TPH

Pressure: 125 PSIG @ 16.5 % fiber in cane

Evaporating Capacity 60,000 PPH

Steam Presure 125 PSIG

Steam Temperature 356 F

Fuel Consumption 12 TPH

EVAPORATOR #1

Vapor Required: 65,973.6 PPH

LP Steam Required: 27.68 TPH

Pressure: 125 PSIG @ 12.2 % fiber in cane

LP Steam Required: 10.73 TPH

Pressure: 125 PSIG @ 15.0 % fiber in cane

LP Steam Required: 10.73 TPH

Pressure: 125 PSIG @ 16.5 % fiber in cane

STEAM BALANCE FOR 5,000 TCD

EVAPORATOR #2

Vapor Required: 20,616.75 PPH

Milling Rate --------------------------------- 5,000 TCD

Fiber in Cane ------------------------------ 12.2 : 15.0 ; 16.5

Moisture in bagasse---------------------- 52.0

Pol in bagasse ----------------------------- 3.50

Bagasse % cane -------------------------- 31.20

EVAPORATOR #3

Vapor Required: 41,233.5 PPH

MOLASSES STEAM PUMP,

CENTRIFUGALS, OTHERS

Live Steam Consumed: 10.73 TPH

LEGEND:

HP Steam @ 250 PSIG

LP Steam @ 125 PSIG

Exhaust Steam @ 15 PSIG

LP Steam Required: 16.94 TPH

Pressure: 125 PSIG

MISCELLANEOUS

Exhaust Steam Consumed: 14,180.51 PPH

VACUUM PAN # 3

Vapor Required: 9,105 PPH

Exhaust Consumed: 2,731.50 PPH

Live Steam Consumed: 6,373.50 PPH

VACUUM PAN # 7

Vapor Required: 17,519 PPH

Exhaust Consumed: 5,255.70 PPH

Live Steam Consumed: 12,263.3 PPH

VACUUM PAN # 4

Vapor Required: 6,373 PPH

Exhaust Consumed: 1,911.90 PPH

Live Steam Consumed: 4,461.90 PPH

VACUUM PAN # 8

Vapor Required: 17,519 PPH

PRIMARY HEATER

Vapor Required: 29,767.50 PPH

SECONDARY HEATER

Vapor Required: 44,100 PPH

VACUUM PAN # 5

Vapor Required: 6,373 PPH

Exhaust Consumed: 1,911.90 PPH

Live Steam Consumed: 4,461.10 PPH

VACUUM PAN # 9

Vapor Required: 15,183 PPH

VACUUM PAN # 6

Vapor Required: 14,015 PPH

Exhaust Consumed: 4,204.5 PPH

Live Steam Consumed: 9,810.5 PPH

VACUUM PAN # 10

Vapor Required: 35,038 PPH

Steam Consumed by Boiler

VACUUM PANS USING VAPOR & LIVE STEAM

HAS 30% EXHAUST/70% LIVE STEAM RATIO

PROCESS HOUSE

Total Vapor Required: 340,756.34 PPH

154,538.02 kg/hr

Anda mungkin juga menyukai

- Stainless Steel Price-Jindal ERW Pipes-21-12-2020Dokumen1 halamanStainless Steel Price-Jindal ERW Pipes-21-12-2020SRINIVASAN TBelum ada peringkat

- AlKhaleejEnergyEfficientRefinery1999 PDFDokumen23 halamanAlKhaleejEnergyEfficientRefinery1999 PDFnghiBelum ada peringkat

- Sugar Cane Juice EvaporatorDokumen9 halamanSugar Cane Juice EvaporatornghiBelum ada peringkat

- Kaiser Water CalculatorDokumen32 halamanKaiser Water CalculatorSahil PalBelum ada peringkat

- Capacity - Calculation 8000 TCDDokumen4 halamanCapacity - Calculation 8000 TCDYadav Shweta0% (1)

- MA45 Masonry Handbook PDFDokumen30 halamanMA45 Masonry Handbook PDFRemington SalayaBelum ada peringkat

- Vacuum System ParametersDokumen7 halamanVacuum System ParametersOmar Ahmed ElkhalilBelum ada peringkat

- Ign Schematic Block Diagram of Sugar ProcessingDokumen1 halamanIgn Schematic Block Diagram of Sugar ProcessingTung Bui ThanhBelum ada peringkat

- SRI Jigger Steam ManualDokumen23 halamanSRI Jigger Steam ManualzalabiBelum ada peringkat

- SRI Jigger Tubes System: Design, Installation and Commissioning ManualDokumen16 halamanSRI Jigger Tubes System: Design, Installation and Commissioning ManualSebastiánSaltarenBelum ada peringkat

- Trials of A New Stirrer-Less Juice Sulphiter at Experimental Sugar FactoryDokumen4 halamanTrials of A New Stirrer-Less Juice Sulphiter at Experimental Sugar FactoryInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- Distillery Wastwater Treatment-CDM Project-2012Dokumen60 halamanDistillery Wastwater Treatment-CDM Project-2012tsrinivasan5083Belum ada peringkat

- Ethanol Related Indian StandardsDokumen2 halamanEthanol Related Indian StandardsSRINIVASAN TBelum ada peringkat

- Diagrams PDFDokumen15 halamanDiagrams PDFAhmed M. Abdel HamedBelum ada peringkat

- Spin Flash Dryer General Description: The Wet Product Is Introduced in The Form at Which It Leaves The PrecedingDokumen1 halamanSpin Flash Dryer General Description: The Wet Product Is Introduced in The Form at Which It Leaves The PrecedingDeepakBelum ada peringkat

- Sugarcane ComputeDokumen12 halamanSugarcane ComputeJun Burias Padilla100% (1)

- Cogenerations of Energy From Sugar Factory BagasseDokumen8 halamanCogenerations of Energy From Sugar Factory BagasseTade GaromaBelum ada peringkat

- Blowdown Economizer CalculationDokumen2 halamanBlowdown Economizer CalculationSajjad AhmedBelum ada peringkat

- 1974 Murray Filtering Quallity of RAw Sugar - Mechanism of Starch Influence in CarbonatationDokumen11 halaman1974 Murray Filtering Quallity of RAw Sugar - Mechanism of Starch Influence in CarbonatationnghiBelum ada peringkat

- Mass Balance 3Dokumen22 halamanMass Balance 3barbadosiyBelum ada peringkat

- Pumps and Cooling TowersDokumen51 halamanPumps and Cooling TowersMikho SaligueBelum ada peringkat

- Reference Control PhilosophyDokumen22 halamanReference Control PhilosophyReno MurdaBelum ada peringkat

- CRS Manual - PPPU PumpDokumen27 halamanCRS Manual - PPPU PumpRishabh VermaBelum ada peringkat

- Sugar Industry ChainsDokumen57 halamanSugar Industry Chainszalabi100% (1)

- Dattaproject DONEDokumen25 halamanDattaproject DONEsumit potdarBelum ada peringkat

- Sulphur MelterDokumen9 halamanSulphur MelterabderrahimnBelum ada peringkat

- 21Dokumen29 halaman21Remington SalayaBelum ada peringkat

- DM Water CostingDokumen1 halamanDM Water CostingRaja ManiBelum ada peringkat

- Flue Gas DesulfurizationDokumen4 halamanFlue Gas DesulfurizationPiyush AgarwalBelum ada peringkat

- Instapdf - in Pmegp Business List 260Dokumen19 halamanInstapdf - in Pmegp Business List 260Richy CyrilBelum ada peringkat

- Data SheetDokumen7 halamanData SheetPaulkumar RamaiahBelum ada peringkat

- Double Effect Steam Driven Vapour Absorption Machine: 310 1 Shalina Laboratories PVT LTDDokumen31 halamanDouble Effect Steam Driven Vapour Absorption Machine: 310 1 Shalina Laboratories PVT LTDBashir AliBelum ada peringkat

- 03-Carbonatation, Updated July 08Dokumen32 halaman03-Carbonatation, Updated July 08jantskie100% (2)

- Material Balance ADokumen8 halamanMaterial Balance ATheepa SubramaniamBelum ada peringkat

- Mechanical Vapour Recompression System For The Evaporation of Water From Salt Containing Solution: BackgroundDokumen2 halamanMechanical Vapour Recompression System For The Evaporation of Water From Salt Containing Solution: BackgroundjokishBelum ada peringkat

- Dynasand 1Dokumen2 halamanDynasand 1Pandiaraj MkBelum ada peringkat

- House Rent ReceiptDokumen5 halamanHouse Rent Receipttara akunuriBelum ada peringkat

- 1996 - Misplon - Pinhole Grate Conversions ofDokumen4 halaman1996 - Misplon - Pinhole Grate Conversions ofmchoi23Belum ada peringkat

- Blower and Compressor Sizing and SelectionDokumen42 halamanBlower and Compressor Sizing and SelectionSuryaprakashBelum ada peringkat

- Business Activities ProfileDokumen35 halamanBusiness Activities ProfileKapa KamalakarBelum ada peringkat

- Bill of Quantities of M. S. Pipe Fittings (O-14027)Dokumen4 halamanBill of Quantities of M. S. Pipe Fittings (O-14027)Tanmoy DuttaBelum ada peringkat

- Lect5 - Steam Power BalancesDokumen27 halamanLect5 - Steam Power Balancesrushdi100% (1)

- Lurgi PSI Evaporator PaperDokumen13 halamanLurgi PSI Evaporator PaperMariAle Droz CastroBelum ada peringkat

- Heavy Duty Industrial FanDokumen16 halamanHeavy Duty Industrial FanAli MarsousiBelum ada peringkat

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDokumen2 halamanDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraBelum ada peringkat

- Water Treatment, Storage and Blowdown For Steam Boilers: Academic Manual AC/18/01 - AC/10/04Dokumen78 halamanWater Treatment, Storage and Blowdown For Steam Boilers: Academic Manual AC/18/01 - AC/10/04kISHOREBelum ada peringkat

- Screw Screw Screw Screw Pump Pump Pump PumpDokumen2 halamanScrew Screw Screw Screw Pump Pump Pump PumpvictorvikramBelum ada peringkat

- Mill Extraction Mangal SinghDokumen7 halamanMill Extraction Mangal SinghGun SmithBelum ada peringkat

- 1 TPH 10.54 KG, Vapi Care PharmaDokumen16 halaman1 TPH 10.54 KG, Vapi Care PharmashastrysnBelum ada peringkat

- Properties of Compressed Air at Required PressureDokumen3 halamanProperties of Compressed Air at Required PressureErol AydinBelum ada peringkat

- Phosphate Hideout PDFDokumen4 halamanPhosphate Hideout PDFAHMAD DZAKYBelum ada peringkat

- 20tips Purchasing Bio ReactorDokumen8 halaman20tips Purchasing Bio Reactorglq223Belum ada peringkat

- Material Balance in MillDokumen6 halamanMaterial Balance in MillNikhilBelum ada peringkat

- Raw Water SystemDokumen11 halamanRaw Water SystemChandraBelum ada peringkat

- Caking of Raw SugarDokumen52 halamanCaking of Raw Sugarmarcelo22061970Belum ada peringkat

- Bulletin - 118 - E Audit in Sugar & DistilleryDokumen4 halamanBulletin - 118 - E Audit in Sugar & DistilleryBala MuruganBelum ada peringkat

- Rev-1 of Bbu For DM Plant-SupplyDokumen3 halamanRev-1 of Bbu For DM Plant-SupplydeyprasenBelum ada peringkat

- 7.5 KLHR MEE Offer (5%)Dokumen10 halaman7.5 KLHR MEE Offer (5%)kezaihrajBelum ada peringkat

- Data Sheet For Pump: Client NameDokumen1 halamanData Sheet For Pump: Client NameMarathwada ChemicalsBelum ada peringkat

- Chlorine: International Thermodynamic Tables of the Fluid StateDari EverandChlorine: International Thermodynamic Tables of the Fluid StateBelum ada peringkat

- Boiler SchematicDokumen1 halamanBoiler SchematicChristine GriffithBelum ada peringkat

- 21Dokumen29 halaman21Remington SalayaBelum ada peringkat

- Metal Milling Mach ProcedureDokumen2 halamanMetal Milling Mach ProcedureRemington SalayaBelum ada peringkat

- Hazop WWTPDokumen3 halamanHazop WWTPRemington SalayaBelum ada peringkat

- Circ16 2008Dokumen2 halamanCirc16 2008Remington SalayaBelum ada peringkat

- Energy Efficiency and Conservation Law PhilippinesDokumen19 halamanEnergy Efficiency and Conservation Law PhilippinesRemington SalayaBelum ada peringkat

- Draft Irr of Ra 11285-6th Revision PDFDokumen37 halamanDraft Irr of Ra 11285-6th Revision PDFRemington SalayaBelum ada peringkat

- U.S. Sugar: Agriculture Division - Clewiston, FloridaDokumen5 halamanU.S. Sugar: Agriculture Division - Clewiston, FloridaRemington SalayaBelum ada peringkat

- Ionic Vs MolecularDokumen1 halamanIonic Vs MolecularRemington SalayaBelum ada peringkat

- 1165 Sugarcane Farm Mechanization Is The Solution. What Are The Problems ?Dokumen10 halaman1165 Sugarcane Farm Mechanization Is The Solution. What Are The Problems ?Remington SalayaBelum ada peringkat

- FS QuestionnaireDokumen9 halamanFS QuestionnaireRemington SalayaBelum ada peringkat

- CMO 87 S. 2017 BS Computer EngineeringDokumen81 halamanCMO 87 S. 2017 BS Computer EngineeringRemington Salaya50% (2)

- Five Stage HeatingDokumen2 halamanFive Stage HeatingRemington SalayaBelum ada peringkat

- Summary Global Q & A of Factory Machine-Equipments Mill, Boiler, PW and BHDokumen5 halamanSummary Global Q & A of Factory Machine-Equipments Mill, Boiler, PW and BHRemington SalayaBelum ada peringkat

- Quadruple Evaporator EvaluationDokumen8 halamanQuadruple Evaporator EvaluationRemington SalayaBelum ada peringkat