Carbozinc 11 PDS

Diunggah oleh

Lim DongseopHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Carbozinc 11 PDS

Diunggah oleh

Lim DongseopHak Cipta:

Format Tersedia

Carbozinc 11

Selection & Specification Data

Generic Type

Solvent Based Inorganic Zinc

Description

Time-tested corrosion resistant primer that protects

steel galvanically in the harshest environments. For

over five decades, Carbozinc 11 (CZ 11) has been the

industry standard for high-performance inorganic zinc

protection on steel structures worldwide.

Features

Carbozinc 11 meets Class B slip co-efficient and

creep testing criteria for use on faying surfaces.

Rapid cure. Dry to handle in 45 minutes at 60F

(16C) and 50% relative humidity.

Low temperature cure down to 0F (-18C).

High zinc loading.

Meets FDA requirements in gray color.

Very good resistance to salting.

May be applied with standard airless or conventional

spray equipment.

VOC compliant in certain areas

Color

Green (0300); Gray (0700)

Finish

Flat

Primers

Self Priming

Topcoats

May be coated with Acrylics, Epoxies, or

Polyurethanes depending on exposure and need.

Dry Film

Thickness

Surfaces must be clean and dry. Employ adequate

methods to remove dirt, dust, oil and all other

contaminants that could interfere with adhesion of the

coating.

Steel

Non-Immersion: SSPC-SP6 and obtain a 1.0-3.0 mil

(25-75 micron) angular blast profile (Reference ASTM

D4417)

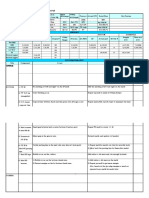

Performance Data

Test Method

AASHTO M300 Bullet

Hole Immersion

Paragraph 4.6.9

System

1 ct. CZ11 over

Abrasive blasted steel

ASTM A-325

Slip Co-efficient

Blasted Steel 1

ct. CZ 11 @6 mils

(150 microns)

1 ct CZ11 at 2 mils

dry film thickness

over blasted steel.

ASTM B117 Salt Spray

Not required for certain exposures. Under certain conditions, a mist coat

is required to minimize topcoat bubbling.

Service

Temperature

Substrates & Surface Preparation

General

Untopcoated

Continuous: 750F (400C)

Non-Continuous: 800F (427C)

With recommended high heat topcoats:

Continuous: 1000F (538C)

Non-Continuous: 1200F (649C)

ASTM D3363

Pencil Hardness

Mixing & Thinning

Mixing

Power mix base, then combine and power mix as

follows. Pour zinc filler very slowly into premixed base

with continuous agitation. Mix until free of lumps. Pour

mixture through a 30 mesh screen. DO NOT MIX

PARTIAL KITS.

Tip: Sifting zinc through a window screen will aid in

the mixing process by breaking up or catching dry zinc

lumps.

Thinning

May be thinned up to 5 oz/gal (4%) with #26 or #33 for

ambient and warm surfaces. For extremely warm or

windy conditions (above 85F/29C)may be thinned

up to 8 oz/gal (6%) with #254. In cool weather (below

40F (4C)), thin up to 7 oz/gal (6%) with #21. Use of

thinners other than those supplied or recommended by

Carboline may adversely affect product performance

and void product warranty, whether expressed or

implied.

Ratio

1 Gal. Kit - Part A - .75 gal

1 Gal Kit - Zinc Filler - 14.6lbs

5 Gal Kit - Part A - 3.75 gal

5 Gal Kit - Zinc Filler - 73 lbs.

Pot Life

8 Hours at 75F (24C) and less at higher

temperatures. Pot life ends when coating becomes too

viscous to use.

2.0 - 3.0 mils (51 - 76 microns) per coat

By Weight 79%

Zinc Content in DryBy Weight 85%

Film

Theoretical

Coverage Rates

1000 square feet at 1 mil (24.5 square meters/liter

at 25 microns) DFT; 333 square feet at 3 mils (8.2

square meters/liter at 75 microns) DFT.

VOC Values

As Supplied

EPA Method 24: 4.0 lbs./gal (479 g/l)

Thinned:

7 oz/gal w/ #21: 4.1 lbs./gal (492 g/l)

5 oz/gal w/ #26: 4.1 lbs./gal (492 g/l)

5 oz/gal w/ #33: 4.1 lbs./gal (492 g/l)

8 oz/gal w/ #254: 4.0 lbs./gal (507 g/l)

These are nominal values.

March 2013

No rusting blistering

cracking delamination

after 43000 hrs.

Moderate salting

of the surface only.

Pencil Hardness "2H"

Test reports and additional data available upon written request.

Dry film thickness up to 6.0 mils (150 microns) is acceptable

Solids Content

1 ct. CZ11

Results

No blistering or

rusting of coating or

rusting of bare steel

area after 650 hrs.

Immersion in 5% sod

0.68; meets requirement

for Class B rating

0250

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company

to verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Carboguard

are registered trademarks of Carboline Company.

Page 1 of 2

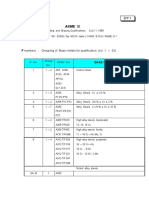

Carbozinc 11

Application Equipment Guidelines

Cleanup & Safety

Listed below are general equipment guidelines for the application of this product. Job site conditions

may require modifications to these guidelines to achieve the desired results.

Spray Application The following spray equipment has been

(General)

found suitable and is available from equipment

manufacturers. Keep material under mild agitation

during application. If spraying stops for more than

10 minutes, recirculate the material remaining in the

spray line. Do not leave mixed primer in the hoses

during work stoppages.

Conventional

Spray

Agitated pressure pot equipped with dual regulators,

3/8 I.D. minimum material hose, with a maximum

length of 50 feet; 0.070 I.D. fluid tip and appropriate

air cap.

Airless Spray

Pump Ratio: 30:1 (min.)

GPM Output: 3.0 (min.)

Material Hose: 3/8 I.D. (min.)

Tip Size: 0.019-0.023

Output PSI: 1500-2000 Filter Size: 60 mesh

PTFE packings are recommended and available from

the pump manufacturer.

Brush

For touch-up of areas less than one square foot only.

Use medium bristle brush and avoid rebrushing.

Roller

Not recommended.

Application Conditions

Condition

Minimum

Maximum

Material

Surface

Ambient

0 F (-18 C) 0 F (-18 C) 0 F (-18 C)

130 F (54 C) 200 F (93 C) 130 F (54 C)

Humidity

30%

95%

Cleanup

Use Thinner #21 or Isopropyl Alcohol. In case of

spillage, absorb and dispose of in accordance with

local applicable regulations.

Safety

Read and follow all caution statements on this product

data sheet and on the MSDS for this product. Employ

normal workmanlike safety precautions.

Ventilation

When used as a tank lining or in enclosed areas,

thorough air circulation must be used during and after

application until the coating is cured. The ventilation

system should be capable of preventing the solvent

vapor concentration from reaching the lower explosion

limit for the solvents used. In addition to ensuring

proper ventilation, appropriate respirators must be

used by all application personnel.

Packaging, Handling & Storage

Shelf Life

Part A: 12 months at 75F (24C)

Part B: 24 months at 75F (24C)

*Shelf Life: (actual stated shelf life) when kept at recommended storage

conditions and in original unopened containers.

Shipping Weight

(Approximate)

1 Gallon Kit - 23 lbs (10 kg)

5 Gallon Kit - 113 lbs (51 kg)

Storage

Temperature &

Humidity

40 -100F (4-38C).

0-90% Relative Humidity

Flash Point

(Setaflash)

Part A: 55F (13C)

Zinc Filler: NA

Storage

Store Indoors.

This product simply requires the substrate temperature to be above the dew point. Condensation

due to substrate temperatures below the dew point can cause flash rusting on prepared steel and

interfere with proper adhesion to the substrate. Special application techniques may be required

above or below normal application conditions.

Curing Schedule

Surface Temp. & 50%

Relative Humidity

Dry to Handle

0 F (-18 C)

40 F (4 C)

60 F (16 C)

80 F (27 C)

100 F (38 C)

4 Hours

1 Hours

45.0 Minutes

45.0 Minutes

15.0 Minutes

Dry to Recoat

& Topcoat w/

other finishes

7 Days

48 Hours

24 Hours

18 Hours

16 Hours

These times are based on a 3.0-4.0 mil (75-100 micron) dry film thickness. Higher film thickness,

insufficient ventilation or cooler temperatures will require longer cure times and could result in

solvent entrapment and premature failure. Humidity levels below 50% will require longer cure times.

Notes: Any salting that appears on the zinc surface as a result of prolonged weathering exposure

must be removed prior to the application of additional coatings. Also, loose zinc must be removed

from the cured film by rubbing with fiberglass screen wire if: 1) The Carbozinc 11 is to be used

without a topcoat in immersion service and "zinc pick up" could be detrimental, or 2) When "dry

spray/overspray" is evident on the cured film and a topcoat will be applied. For accelerated curing

or where the relative humidity is below 40%, allow an initial 2-hour ambient cure. Follow 2 hour

cure with water misting or steam to keep the coated surface wet for a minimum of 8 hours and until

the coated surface achieves a "2H" pencil hardness per ASTM D3363.

March 2013

0250

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company

to verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Carboguard

are registered trademarks of Carboline Company.

Page 2 of 2

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Activate Adobe Photoshop CS5 Free Using Serial KeyDokumen3 halamanActivate Adobe Photoshop CS5 Free Using Serial KeyLukmanto68% (28)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Magnetrol TypesDokumen20 halamanMagnetrol Typesbhargav103Belum ada peringkat

- Fundamentals and Applications of Renewable Energy by Mehmet Kanoglu, Yunus Cengel, John CimbalaDokumen413 halamanFundamentals and Applications of Renewable Energy by Mehmet Kanoglu, Yunus Cengel, John CimbalaFrancesco Nocera100% (1)

- ASTM Clad Steel StandardDokumen12 halamanASTM Clad Steel StandardLim DongseopBelum ada peringkat

- Single Country DeclarationDokumen2 halamanSingle Country DeclarationLim DongseopBelum ada peringkat

- Negative DeclarationDokumen1 halamanNegative DeclarationLim DongseopBelum ada peringkat

- Goods consigned certificate of originDokumen1 halamanGoods consigned certificate of originLim DongseopBelum ada peringkat

- Goods consigned from exporter's businessDokumen1 halamanGoods consigned from exporter's businessLim DongseopBelum ada peringkat

- Upper RFC (Target) Tooling RFC (Target) : FA'04 / A Maddie Max / SS Revisions Review (12/15)Dokumen4 halamanUpper RFC (Target) Tooling RFC (Target) : FA'04 / A Maddie Max / SS Revisions Review (12/15)Lim DongseopBelum ada peringkat

- There's Quite A Bit of TrafficDokumen2 halamanThere's Quite A Bit of TrafficLim DongseopBelum ada peringkat

- Global System of Trade Preferences Certificate of Origin (Combined Declaration and Certificate)Dokumen1 halamanGlobal System of Trade Preferences Certificate of Origin (Combined Declaration and Certificate)Lim DongseopBelum ada peringkat

- Multiple Country DeclarationDokumen2 halamanMultiple Country DeclarationLim DongseopBelum ada peringkat

- Guarantee letter cargo deliveryDokumen1 halamanGuarantee letter cargo deliveryLim DongseopBelum ada peringkat

- GSP원산지증명서bDokumen1 halamanGSP원산지증명서bLim DongseopBelum ada peringkat

- KCC DataSheet EH2350 (P) (ENG) PDFDokumen3 halamanKCC DataSheet EH2350 (P) (ENG) PDFLim DongseopBelum ada peringkat

- GATT 원산지증명서Dokumen1 halamanGATT 원산지증명서Lim DongseopBelum ada peringkat

- 무역용어Dokumen22 halaman무역용어Lim DongseopBelum ada peringkat

- I Know What You WantDokumen4 halamanI Know What You WantLim DongseopBelum ada peringkat

- Chemical Compatibility TableDokumen49 halamanChemical Compatibility TableLim DongseopBelum ada peringkat

- Plain Tube Dimension: OD Wall Thickness ID Outside SurfaceDokumen2 halamanPlain Tube Dimension: OD Wall Thickness ID Outside SurfaceLim DongseopBelum ada peringkat

- D1e 101Dokumen40 halamanD1e 101Wirna_Wirdani_9320Belum ada peringkat

- New Method and Standards for Measuring Ferrite in Austenitic Stainless Steel WeldsDokumen6 halamanNew Method and Standards for Measuring Ferrite in Austenitic Stainless Steel WeldslkarolinoBelum ada peringkat

- P Numbers: Grouping of Base Metals For Qualification (No. 1Dokumen5 halamanP Numbers: Grouping of Base Metals For Qualification (No. 1Lim DongseopBelum ada peringkat

- Romney Boyd 2010Dokumen21 halamanRomney Boyd 2010Lim DongseopBelum ada peringkat

- Shoulder/Insulating Washers: Natural NylonDokumen2 halamanShoulder/Insulating Washers: Natural NylonLim DongseopBelum ada peringkat

- P Numbers: Grouping of Base Metals For Qualification (No. 1Dokumen5 halamanP Numbers: Grouping of Base Metals For Qualification (No. 1Lim DongseopBelum ada peringkat

- Dubo Worldwide: DUBO and KORREX Products Maryland MetricsDokumen26 halamanDubo Worldwide: DUBO and KORREX Products Maryland MetricsSuresh Kumar MittapalliBelum ada peringkat

- 화공약품listDokumen10 halaman화공약품listLim DongseopBelum ada peringkat

- Sample Safety ProgramDokumen79 halamanSample Safety ProgramNeal Lester100% (1)

- Rubber & AddictivesDokumen9 halamanRubber & AddictivesLim DongseopBelum ada peringkat

- E Pamphlet 1502 HPDokumen4 halamanE Pamphlet 1502 HPLim DongseopBelum ada peringkat

- Oscar Ortega Lopez - 1.2.3.a BinaryNumbersConversionDokumen6 halamanOscar Ortega Lopez - 1.2.3.a BinaryNumbersConversionOscar Ortega LopezBelum ada peringkat

- 01 NumberSystemsDokumen49 halaman01 NumberSystemsSasankBelum ada peringkat

- Superior University: 5Mwp Solar Power Plant ProjectDokumen3 halamanSuperior University: 5Mwp Solar Power Plant ProjectdaniyalBelum ada peringkat

- Payroll Canadian 1st Edition Dryden Test BankDokumen38 halamanPayroll Canadian 1st Edition Dryden Test Bankriaozgas3023100% (14)

- PDF Problemas Ishikawa - Free Download PDF - Reporte PDFDokumen2 halamanPDF Problemas Ishikawa - Free Download PDF - Reporte PDFNewtoniXBelum ada peringkat

- Mint Delhi 13-12-2022Dokumen18 halamanMint Delhi 13-12-2022Ayush sethBelum ada peringkat

- Sugar Milling Contract DisputeDokumen3 halamanSugar Milling Contract DisputeRomy IanBelum ada peringkat

- Tutorial Manual Safi PDFDokumen53 halamanTutorial Manual Safi PDFrustamriyadiBelum ada peringkat

- BC Specialty Foods DirectoryDokumen249 halamanBC Specialty Foods Directoryjcl_da_costa6894Belum ada peringkat

- What Role Can IS Play in The Pharmaceutical Industry?Dokumen4 halamanWhat Role Can IS Play in The Pharmaceutical Industry?Đức NguyễnBelum ada peringkat

- 34 Annual Report 2019 20Dokumen238 halaman34 Annual Report 2019 20Rahul N PatelBelum ada peringkat

- Company Profi Le: IHC HytopDokumen13 halamanCompany Profi Le: IHC HytopHanzil HakeemBelum ada peringkat

- Examination: Subject CT5 - Contingencies Core TechnicalDokumen7 halamanExamination: Subject CT5 - Contingencies Core TechnicalMadonnaBelum ada peringkat

- IBM TS3500 Command Line Interface (CLI) ExamplesDokumen6 halamanIBM TS3500 Command Line Interface (CLI) ExamplesMustafa BenmaghaBelum ada peringkat

- Triblender Wet Savoury F3218Dokumen32 halamanTriblender Wet Savoury F3218danielagomezga_45545100% (1)

- Admission Checklist (Pre-) Master September 2021Dokumen7 halamanAdmission Checklist (Pre-) Master September 2021Máté HirschBelum ada peringkat

- AssDokumen9 halamanAssJane SalvanBelum ada peringkat

- The Non Technical Part: Sample Interview Questions For Network EngineersDokumen5 halamanThe Non Technical Part: Sample Interview Questions For Network EngineersblablaBelum ada peringkat

- nrcs143 009445Dokumen4 halamannrcs143 009445mdsaleemullaBelum ada peringkat

- BCM Risk Management and Compliance Training in JakartaDokumen2 halamanBCM Risk Management and Compliance Training in Jakartaindra gBelum ada peringkat

- Telangana Budget 2014-2015 Full TextDokumen28 halamanTelangana Budget 2014-2015 Full TextRavi Krishna MettaBelum ada peringkat

- RF Power Measurements Basic PrinciplesDokumen27 halamanRF Power Measurements Basic PrinciplesHector Velasco100% (1)

- Keynes Presentation - FINALDokumen62 halamanKeynes Presentation - FINALFaith LuberasBelum ada peringkat

- MMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDDokumen6 halamanMMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDHenry Jose OlavarrietaBelum ada peringkat

- Lirik and Chord LaguDokumen5 halamanLirik and Chord LaguRyan D'Stranger UchihaBelum ada peringkat

- NDU Final Project SP23Dokumen2 halamanNDU Final Project SP23Jeanne DaherBelum ada peringkat

- The Study of Accounting Information SystemsDokumen44 halamanThe Study of Accounting Information SystemsCelso Jr. AleyaBelum ada peringkat

- Book Two - 2da. EdiciónDokumen216 halamanBook Two - 2da. EdiciónJhoselainys PachecoBelum ada peringkat