FRP Carbon Fiber

Diunggah oleh

Victor Alejandro Calderón GonzálezHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

FRP Carbon Fiber

Diunggah oleh

Victor Alejandro Calderón GonzálezHak Cipta:

Format Tersedia

The FRP Retrofit Experts

QuakeWrap, Inc.

2055 E. 17th Street

Tucson, AZ 85719 U.S.A.

Phone: (520) 791-7000

FAX: (520) 791-0600

Toll Free: (866) QuakeWrap [782-5397]

www.QuakeWrap.com

Product Data Sheet

QuakeWrap VU27G Glass Fabric

for Structural Strengthening

DESCRIPTION

QuakeWrap VU27G is a high-strength unidirectional glass fabric. The fabric

is white and is impregnated in the field using QuakeBond J300SR Saturating

Resin to form a glass fiber reinforced polymer (GFRP) used to strengthen

structural elements. The fabric weighs 27 oz/yd2 (915 g/m2).

USE

Increased live load capacity in buildings and bridges, hospital floors, roofs of

buildings, etc.

Seismic retrofit of structural elements such as columns, unreinforced

masonry walls, etc.

Repair of large diameter pipes to achieve strengthening and water-proofing

Repair of damaged structural components caused by aggressive

environments, fire, vehicle impact, aging, etc.

Changes in structural system: new openings in floors, removal of existing

walls, etc.

Correction of design or construction errors: misplaced reinforcing bars,

insufficient structural depth

ADVANTAGES

Strong and lightweight fabric ideal for confined spaces.

Used for flexure and shear strengthening as well as confinement.

Fully compatible and excellent adhesion to QuakeBond resins.

Non-corrosive.

Versatile; can be wrapped around complex shapes.

Light weight does not alter mass & dynamic loads on structure.

Special manufacturing of the fabric makes it very stable & prevents fraying.

PACKAGING

Rolls: 25 in. X 100 yards (0.65 m x 91 m). The fabric can be easily cut in the

field to various lengths.

Saturate QuakeWrap VU27G fabric thoroughly with QuakeBond J300SR; for

more details, refer to the Product Data Sheet for J300SR. Before the epoxies

harden, apply saturated fabric to the substrate surface that has been coated with

J201TC. Using gloved hands, carefully remove any entrapped air bubbles under

the fabric; a plastic laminating roller can be used for this purpose. If required,

additional layers of saturated fabric can be directly applied on top of previous

layers. Feather the edges of the fabric with QuakeBond J201TC.

Installation of QuakeWrap fabrics must be performed only by specially trained

and approved contractors.

Fabric can be cut to appropriate length using a commercial quality heavy duty

scissor. Since dull or worn cutting tools can damage, weaken or fray the fiber,

their use should be avoided.

LIMITATIONS

Design calculations must be made and certified by an independent licensed

professional engineer. System is a vapor barrier. Concrete should not be

encapsulated in areas of freeze/thaw.

CAUTION

QuakeWrap VU27G is non-reactive. However, caution must be used when

handling since a fine glass dust may be present on the surface. Gloves must

therefore be worn to protect against skin irritation. Caution must also be used

when cutting the fabric to protect against airborne glass dust generated by the

cutting procedure. Use of an appropriate, properly fitted NIOSH approved

respirator is recommended.

STORAGE CONDITIONS

Store in dry place at 45-95 F (7-35 C).

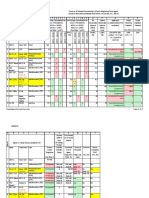

TYPICAL DRY FIBER PROPERTIES

US Units

Aerial Weight Fabric Only

27 oz/yd2

Tensile Strength

470,000 psi

Tensile Modulus

10.5x 106 psi

Ultimate Elongation

4.5%

Density

0.092 lbs/in.3

APPLICATION

Surface must be clean and sound; it may be dry or damp but must be free of

standing water and frost. Remove dust, laitance, grease, curing compounds,

disintegrated materials and other bond inhibiting materials from the surface.

Existing uneven surfaces must be filled with an appropriate repair mortar.

The adhesive strength of the substrate must be verified after surface

preparation by random pull-off testing (ACI 503R) at the discretion of the

engineer. Minimum tensile strength of 200 psi (1.4 MPa) with substrate

failure is required.

PROPERTIES OF FABRIC LAMINATED WITH J300SR

US Units

SI Units

Tensile Strength

85,200 psi

587 MPa

Tensile Modulus

3,980 ksi

27.4 GPa

Ultimate Elongation

2.3%

2.3%

Breaking Force

3490 lb/in.

611 N/mm

Ply Thickness

0.05 in.

1.3 mm

SHELF LIFE

Unlimited shelf life in proper storage conditions.

SI Units

915 g/m2

3.24 GPa

72.4 GPa

4.5%

2.55 g/cm3

Blast clean, shot-blast, scarify or use other approved mechanical means to

clean the substrate surface. Any sharp edges (i.e. fins, form-marks, etc.)

must be ground smooth and flush. Sharp edges must be rounded to a

minimum radius of in. (19 mm). Apply QuakeBond J201TC onto the

substrate with a trowel or spatula to a nominal thickness of 40 mil (1 mm). A

notched trowel may be used for this application.

KEEP OUT OF REACH OF CHILDREN.

NOT FOR INTERNAL CONSUMPTION.

FOR INDUSTRIAL USE ONLY.

KEEP CONTAINER CLOSED TIGHTLY.

QuakeWrap, Inc. warrants this product for one year from date of installation to be free from manufacturing defects and to meet the technical properties on the current technical

data sheet if used as directed within shelf life. User determines suitability of product for intended use and assumes all risks. Buyers sole remedy shall be limited to the

purchase price or replacement of product exclusive of labor or cost of labor.

NO OTHER WARRANTIES EXPRESS OR IMPLIED SHALL APPLY INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. QUAKEWRAP, INC. SHALL NOT BE LIABLE UNDER ANY LEGAL THEORY FOR SPECIAL OR CONSEQUENTIAL DAMAGES.

Anda mungkin juga menyukai

- Beam Moment Diagram TablesDokumen2 halamanBeam Moment Diagram TablesVictor Alejandro Calderón GonzálezBelum ada peringkat

- Tapata Juntas SismicaDokumen3 halamanTapata Juntas SismicaVictor Alejandro Calderón GonzálezBelum ada peringkat

- Cat MachinesDokumen600 halamanCat MachinesSonia Pérez0% (1)

- 1197 1212 PDFDokumen18 halaman1197 1212 PDFVictor Alejandro Calderón GonzálezBelum ada peringkat

- Programacion DinamicaDokumen15 halamanProgramacion DinamicaVictor Alejandro Calderón GonzálezBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Clean Agent ComparisonDokumen9 halamanClean Agent ComparisonJohn ABelum ada peringkat

- Kahveci: OzkanDokumen2 halamanKahveci: OzkanVictor SmithBelum ada peringkat

- Conceptual FrameworkDokumen24 halamanConceptual Frameworkmarons inigoBelum ada peringkat

- Failure Analysis Case Study PDFDokumen2 halamanFailure Analysis Case Study PDFScott50% (2)

- Capacity PlanningDokumen19 halamanCapacity PlanningfarjadarshadBelum ada peringkat

- Variable Speed Pump Efficiency Calculation For Fluid Flow Systems With and Without Static HeadDokumen10 halamanVariable Speed Pump Efficiency Calculation For Fluid Flow Systems With and Without Static HeadVũ Tuệ MinhBelum ada peringkat

- BPO UNIT - 5 Types of Securities Mode of Creating Charge Bank Guarantees Basel NormsDokumen61 halamanBPO UNIT - 5 Types of Securities Mode of Creating Charge Bank Guarantees Basel NormsDishank JohriBelum ada peringkat

- Ks3 Science 2008 Level 5 7 Paper 1Dokumen28 halamanKs3 Science 2008 Level 5 7 Paper 1Saima Usman - 41700/TCHR/MGBBelum ada peringkat

- Weekly Choice - Section B - February 16, 2012Dokumen10 halamanWeekly Choice - Section B - February 16, 2012Baragrey DaveBelum ada peringkat

- Modern Indian HistoryDokumen146 halamanModern Indian HistoryJohn BoscoBelum ada peringkat

- Condy LatorDokumen11 halamanCondy LatorrekabiBelum ada peringkat

- EnerSys Global Leader in Industrial BatteriesDokumen32 halamanEnerSys Global Leader in Industrial BatteriesAshredBelum ada peringkat

- Standard Deviation IntroductionDokumen3 halamanStandard Deviation IntroductionShyam ShresthaBelum ada peringkat

- Obligations and Contracts Bar Questions and Answers PhilippinesDokumen3 halamanObligations and Contracts Bar Questions and Answers PhilippinesPearl Aude33% (3)

- The Effect of Dodd-Frank On Divorcing Citizens 1Dokumen5 halamanThe Effect of Dodd-Frank On Divorcing Citizens 1Noel CookmanBelum ada peringkat

- WWW - Istructe.pdf FIP UKDokumen4 halamanWWW - Istructe.pdf FIP UKBunkun15Belum ada peringkat

- Restructuring Egypt's Railways - Augst 05 PDFDokumen28 halamanRestructuring Egypt's Railways - Augst 05 PDFMahmoud Abo-hashemBelum ada peringkat

- Daftar PustakaDokumen4 halamanDaftar PustakaRamli UsmanBelum ada peringkat

- School Quality Improvement System PowerpointDokumen95 halamanSchool Quality Improvement System PowerpointLong Beach PostBelum ada peringkat

- Assessing Gross Efficiency and Propelling Efficiency in Swimming Paola Zamparo Department of Neurological Sciences, Faculty of Exercise and Sport Sciences, University of Verona, Verona, ItalyDokumen4 halamanAssessing Gross Efficiency and Propelling Efficiency in Swimming Paola Zamparo Department of Neurological Sciences, Faculty of Exercise and Sport Sciences, University of Verona, Verona, ItalyVijay KumarBelum ada peringkat

- ExpDokumen425 halamanExpVinay KamatBelum ada peringkat

- Lecture 1 Family PlanningDokumen84 halamanLecture 1 Family PlanningAlfie Adam Ramillano100% (4)

- Chapter 1: The Critical Role of Classroom Management DescriptionDokumen2 halamanChapter 1: The Critical Role of Classroom Management DescriptionJoyce Ann May BautistaBelum ada peringkat

- A General Guide To Camera Trapping Large Mammals in Tropical Rainforests With Particula PDFDokumen37 halamanA General Guide To Camera Trapping Large Mammals in Tropical Rainforests With Particula PDFDiego JesusBelum ada peringkat

- Cisco CMTS Feature GuideDokumen756 halamanCisco CMTS Feature GuideEzequiel Mariano DaoudBelum ada peringkat

- B. Ing Kls 6Dokumen5 halamanB. Ing Kls 6siskaBelum ada peringkat

- Microsoft Word 2000 IntroductionDokumen72 halamanMicrosoft Word 2000 IntroductionYsmech SalazarBelum ada peringkat

- The Changing Face of War - Into The Fourth GenerationDokumen5 halamanThe Changing Face of War - Into The Fourth GenerationLuis Enrique Toledo MuñozBelum ada peringkat

- 2019-10 Best Practices For Ovirt Backup and Recovery PDFDokumen33 halaman2019-10 Best Practices For Ovirt Backup and Recovery PDFAntonius SonyBelum ada peringkat

- EE290 Practice 3Dokumen4 halamanEE290 Practice 3olgaBelum ada peringkat