30 04 2015261V2 E8 090n

Diunggah oleh

suraj dhulannavarJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

30 04 2015261V2 E8 090n

Diunggah oleh

suraj dhulannavarHak Cipta:

Format Tersedia

Project Paper

Volume 2

April 2015

Issue 8

International Journal of Informative & Futuristic Research

ISSN (Online): 2347-1697

Tracking Of Solar Panel By

Hydraulic System

Paper ID

Key Words

IJIFR/ V2/ E8/ 090

Page No.

2856-2881

Research Area

Mechanical

Engineering

Design and Development, Solar Tracking System, Hydraulic System

Prof. Kusekar S. K 1

Ajinkya Patil

Sachin B. Patil 2

Prasad B. Rajmane 3

Akshay B. Bhosale 4

Professor, Department Of Mechanical Engineering

A G. Patil Institute of Technology,

Solapur, Maharashtra- India

B.E. Student ,Department Of Mechanical Engineering

A G. Patil Institute of Technology,

Solapur, Maharashtra- India

B.E. Student ,Department Of Mechanical Engineering

A G. Patil Institute of Technology,

Solapur, Maharashtra- India

B.E. Student , Department Of Mechanical Engineering

A G. Patil Institute of Technology,

Solapur, Maharashtra- India

B.E. Student ,Department Of Mechanical Engineering

A G. Patil Institute of Technology,

Solapur, Maharashtra- India

Abstract

In this project work, with the title Tracking of Solar Panel by Hydraulic System,

we were planning for design and developing a solar tracking system which will

utilize mechanical energies for the tracking operation. At present, the solar

tracking system use electrical energy for tracking operations and this electrical

energy for operations is supplied by same solar panels or by external electrical

storage or supply lines, this reduces efficiency of the solar panels. Using

mechanical energy for tracking will increase the output of solar panels and

remove the constraint on the location of the tracking system.

www.ijifr.com

Copyright IJIFR 2015

2856

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

1. Introduction

1.1 Solar Energy

Energy from the sun travels to the earth in the form of electromagnetic radiation similar to

radio waves, but in a different frequency range called solar energy. Solar power is the conversion of

received solar radiation into usable energy. It is a process that consists of harnessing the sun's

present emissions of heat or light. This heat and light are the effects of the sun's constant nuclear

fusion of hydrogen nuclei. The process of fusion produces helium nuclei as well as large amounts of

energy.

Available solar energy is often expressed in units of energy per time per unit area, such as

watts per square meter (W/m2). The amount of energy available from the sun outside the earths

atmosphere is approximately 1367 W/m2. Some of the solar energy is absorbed as it passes through

the Earths atmosphere. As a result, on a clear day the amount of solar energy available at the

Earths surface in the direction of the sun is typically 1000 W/m2. The level of solar radiation a

region receives depends on latitude and local weather conditions.

1.2 Solar Tracking

Solar tracking is the process of varying the angle of solar panels, to take advantage of the

full amount of the sun`s energy. In remote places sun is the cheap source of electricity. The output

from solar panel depends on the intensity of sunlight falling on it and also on the angle of incidence.

It means to get maximum efficiency; the solar panel must remain in front of sun during the whole

day. But due the rotation of earth the panel cant maintain their position always in front of sun. Thus

to get maximum and a constant output, a system is required which should be capable to constantly

rotate the solar panel. Initial tests in industry suggest that this process can increase the efficiency of a

solar power system by up to 50%. Given those gains, it is an attractive way to enhance an existing

solar power system.

1.3 Solar Panels

Solar Panels are the devices for capturing the energy in sunlight. Solar photovoltaic panels

contain arrays of solar cells that convert light into electricity. The solar cells sometimes called

photovoltaic cells, photovoltaic meaning literally .light-electricity. Solar cells or PV cells rely on the

photovoltaic effect to absorb the energy of the sun and cause current to flow between two oppositely

charged layers. Crystalline silicon and Gallium arsenide are typical choices of materials for solar

cells. When exposed to sunlight, a 6 cm diameter silicon cell can produce a current of about 0.5 A at

0.5 V. Gallium arsenide is more efficient than Crystalline silicon.

A solar panel is a collection of solar cells. Solar panels are constructed of these cells cut into

appropriate shapes, protected from radiation and handling damage on the front surface by bonding

on a cover glass, and cemented onto a substrate (either a rigid panel or a flexible blanket). Electrical

connections are made in series-parallel to determine total output voltage. The cement and the

substrate must be thermally conductive, because the cells heat up from absorbing infrared energy

that is not converted to electricity. Since cell heating reduces the operating efficiency it is desirable

to minimize the heating. The resulting assemblies are called solar panels or solar arrays.

1.4 Electrical Solar Tracking Systems

The most of todays Solar tracking systems are electrical systems. Elements of these systems

are an electric servo drive and an electronic control system. The electric servo drive includes a

stepper motor, which rotates the solar panels with a pre-set angular displacement. The control

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2857

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

system gives an input signal to servo drive system to drive the stepper motor with the help of sensor

and electronic counters.

In these systems, the major portion of energy produced by the solar panel is utilized for

tracking operation. If not, these systems should have a battery storage unit or should be connected to

power supply grid or the combination of both.

1.5 Mechanical Solar Tracking Systems

Mechanical engineering is one of the largest, broadest and oldest engineering disciplines and

uses principles of energy, materials, and mechanics to design and manufacture machines and devices

of all types. Mechanics, energy and heat, mathematics, engineering sciences, design and

manufacturing form the foundation of mechanical engineering.

Fundamentally, mechanical engineering involves with the mechanics of motion and the

transfer of energy from one form to another or one place to another.

The various fields of application of mechanical engineering are,

Energy conversion

Energy resource

Environment and Transportation

Engineering and Technology management

Manufacturing

Materials and Structures

Systems and Design

In above fields the Solar Engineering falls in the category of Energy resource. Mechanical

engineers are effectively involved in solar energy in finding new ways to produce mechanical and

electrical power for heating, refrigeration and water purification and also in the design of devices

and structure to collect solar energy.

Mechanical solar tracking systems are the systems which use the mechanical energy for

operation and involve the fundamental concepts of various fields, related to mechanical engineering.

The tracking of solar panels can be effectively done with mechanical systems. These systems are

robust in design and are very less sensitive to seasonal changes. Mechanical systems, built with high

precision are well suited for tracking operation.

2. Problem Definitions And Identification

The position of the sun keeps on changing every day. Solar panels as we know are entirely

dependent on the sun. The more the sun rays fall on the panels the more outcomes we get and it serves

our purpose of installing a solar panel. The challenge nowadays is to keep a track of the position of the

sun so that we get the maximum output from the panels. We hope to achieve this with a Mechanical

tracking system.

2.1 Identification

i.

There are many problems associated with conventional solar panel because they are fixed in one

direction.

ii.

The positions of the sun keeps on changing every day, along with the sun, solar panel have to move

in same direction.

iii.

The other system also used for solar tracking but they consumes most of the energy produced by

solar panels for tracking, which effects the efficiency of solar panel.

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2858

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

To rectify these above problems the solar panel should be such that it always receives maximum

intensity of light. For existing solar panels, which are without any control systems typical level of

efficiency varies from 10% to 4% - a level that should improve measurably if the present interest

continues.

3. Literature Review

One-Axis Trackers Improved Reliability, Durability, Performance, and Cost Reduction Final Subcontract Technical Status Report - 2 May 2006 31 August 2007 by J. Shingleton

Shingleton Design, LLC Auburn, New York page 7:

The work effort focused on reducing the total cost of electricity generated by single-axis

tracking solar energy systems for utility and other large-scale commercial applications.

Developing a factory assembled, modular tracker, while building on the strengths of the

existing technology, resulted in improved performance and reliability and reduced

installation time, cost, and environmental impact.

Low cost tracker by Marliyani Binti Omar This thesis is submitted as partial fulfillment of

the requirements for the award of the Bachelor of Electrical Engineering - Faculty of

Electrical & Electronics Engineering University Malaysia Pahang -MAY, 2009 - page5

Solar tracker is invented because solar panel disables to move toward the sunlight when the

sun moves from east to west. In order to produce maximum power output, solar tracker is

design with motor so that the solar panel will move toward the position of sun.

Atlas solar tracking by Mechatronics Company manual:-Atlas system can achieve up to

40% more output power than fixed tilt systems. It ensures that the PV panels are

optimally orientated towards the sun, converting efficiently direct and indirect solar

radiation into electricity.

Hawe hydraulics manual :- HAWE Hydraulics offers compact positioning systems, which

consist of a hydraulic power pack with a control system that is directly attached. The electric

motor and pump in this closed system is submerged for protection against rain,

condensation, and dirt. HAWEs modular products mean we can easily adjust power and

movement speeds according to customers requirements, as well as provide easier access for

maintenance. With various product sizes, low friction, and minimized stick or slip effect,

tracking movements can be controlled reliably and accurately. Dampened over-center valves

ensure smooth movements, which protects the entire structure.

Rockwell automations solar tracking application manual book:-Concentrated applications

like concentrated photovoltaic panels (CPV) or concentrated solar power (CSP) require a

high degree of accuracy to ensure the sunlight is directed precisely at the focal point of the

reflector or lens. Non-concentrating applications dont require tracking but using a tracker

can improve the total power produced by the system. Photovoltaic systems using high

efficiency panels with trackers can be very effective. There are many types of solar trackers,

of varying costs, sophistication, and performance. The two basic categories of trackers are

single axis and dual axis.

4. Scope Of Work

We search for project related to solar power related, and we got some points to study from that we

select the solar tracker.

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2859

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

i.

ii.

iii.

iv.

v.

vi.

vii.

viii.

To study about solar energy and its efficiency.

To study about PV cells

To study on the PV plate and its overall structure, like its power output, setting angle (the

angle at which solar panel is going to fit), sun light intensity in day hours, etc.

To study on sun tracker systems like electrical solar tracker, mechanical tracker and

hydraulic tracker.

To study on hydraulic tracker and how to implement it in tracking system project.

Study related to fluid mechanics which is we are going to use in this project.

To study on hydraulic system and its components mainly piston, control valves, check

valves and hydraulic oil.

Study on structural design of hydraulic solar tracker.

5. Objective

The need for mechanical systems for tracking operation can be better explained with the drawbacks associated with electrical tracking systems. Those are,

i. The present Electrical tracking systems consumes most of the energy produced by solar panels

which serves as a demerit for the Solar system.

ii. We plan to totally neglect the wastage of electricity generated by the panels. In other words

we hope to increase the output of the solar panels.

iii. The minimum power required for operation may not be available at all times o the day due to

change in atmosphere. Tracking will help solve this problem.

iv. Mechanical systems can work in any environment. Dust and humidity have no ill-effects on

the system.

v. To simplify the system and avoid any complexity in design.

vi. We try to make the entire system compact So that there is no issue when it comes to moving

the system.

vii. The energy required for operation will increase with the increased size of solar Panel.

6. Methodology

The methodology of design for the design of mechanical tracking system is explained by following

steps,

i.

Determining sunray orientation and time range to which the panel has to be tracked.

ii.

Calculating the required angular velocity of the panel.

iii.

Calculating the system pressure and cylinder (actuator) discharge.

iv.

calculating the weight/force required to create the required pressure.

v.

Selecting cylinder of suitable diameter and stroke length.

vi.

Selecting the suitable grade of hydraulic oil.

vii.

Calculating the capacity of reservoir.

viii.

Designing the hydraulic circuit with QUICK RETURN facility to reduce the time required

for bringing the panel to its original position.

ix.

Selecting required mechanical components of suitable dimensions and material.

x.

Preparing production drawings and fabrication of mechanical elements.

xi.

Assembly of the device.

xii.

Demonstration.

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2860

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

6.1 Hydraulic System Design

6.1.1 Introduction to Fluid Power Systems

The basic source in industries comes from three kinds of sources. These are,

1. Electrical Systems

- These systems use electrical prime movers like electrical motors.

2. Mechanical Systems

- These systems use mechanical prime movers like I.C Engines and in olden days the Steam engines

were used.

3. Fluid Power Systems

- The third common source of power that is widely used in modern industries is the fluid power.

6.1.2 Fluid Power Systems

Fluid power refers to the branch of engineering that deals with the use of high pressure fluids (gases

or liquids) within confined areas (like hoses, cylinders) to generate, control and transmit power.

In fluid power systems high pressure fluid both liquid and gases, can be used to transmit

power from the point of source to the point of utilization, which can be used to produce rotary and

linear motions. A fluid is substance which is capable of flowing. Fluid power systems that use

liquids as the working medium are called Hydraulic systems. Fluid power systems that use gases

(commonly air or Nitrogen) are commonly known as Pneumatic systems.

The some of the drawbacks of the Pneumatic system, which resist from using them for

tracking operation are:

Compressibility: Due the higher compressibility of working medium, the calculated

displacement of actuator cannot be obtained.

Precision: Precision of pneumatic systems is less than hydraulic systems.

Operating temperature: Pneumatic systems are high sensitive to operating

Temperature, compared to hydraulic systems.

The two important aspects of the fluid power system are,

1. Power transmission

The power from input point to output point is transmitted without any change in the

magnitude and with the same amount of displacement.

2. Power multiplication

Similar to levers, in fluid power systems, the force at input point can be multiplied to a

greater extent at the output point. Such power multiplication is possible with the use of large output

piston that the input piston. The multiplication process is associated with the change in magnitude of

displacement.

Figure 6.1: Structure Of Hydraulic Power System

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2861

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

The schematic arrangement of a hydraulic power system is illustrated by the figure

Notations:

Pump with electric motor

Flow control valves

Pressure regulating valve

Reservoirs

Pressure gauges

Cylinder with load

The system consists of three main segments (i) Power supply, (ii) Control system and (iii)

Output. All these are connected through a closed loop with suitable hydraulic lines. The hydraulic

line with a filter at the end, running from the reservoir through pump till the output point is called

the pressure line (A). The fluid line running from the output point back to the reservoir is termed the

return line (B), which carries the low pressure fluid, back to the reservoir.

Reservoir or sump is an oil container, whose capacity depends on the capacity of oil

required for the fluid power system, with enough reserve oil to cater for leakage loss and continuous

operation.

i) Power Supply

The power supply segment comprises the prime mover, and the pump. The fluid from pump

passes through a filter, where foreign particles are removed. The pump supplies the input power to

fluid to convert it into hydraulic power.

ii) Control System

The control unit is intermediate but most important part between the power supply and

output segments. Control unit comprises different valves for various purposes. A typical control unit

includes the types of valves,

a. Directional control valves: to control the direction of actuator movement.

b. Pressure control valves: to control the fluid pressure, this in turn controls the output force.

c. Flow control valves: to control the flow rate of the fluid, to regulate the speed of the actuator

iii) Output

The output segment of hydraulic system includes the actuator and the load. The function of

actuator is to convert the fluid power back to mechanical power. Depending upon the end use the

actuator can be either linear type (hydraulic cylinder) or rotary type (hydraulic motor).

Examples of fluid system

Following devices are the common examples of the fluid systems,

i.

Hydraulic press

ii.

Hydraulic accumulator

iii.

Hydraulic intensifier

iv.

Hydraulic ram

v.

Hydraulic lift

vi.

Hydraulic crane

vii.

Fluid or hydraulic coupling

viii.

Fluid or hydraulic torque converter

ix.

Air lift pump

x.

Gear wheel pump

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2862

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

6.1.3

Fundamentals of Fluid Mechanics:

Fluid mechanics is that branch of science which deals with the behavior of fluids (liquids or

gases) at rest as well as in motion. Thus this branch of science which deals with the static,

kinematics and dynamic aspects of the fluids. The design of a hydraulic system involves the basic

concepts and principles of the fluid mechanics. The study of fluids at rest is called fluid statics. The

study of fluid in motion, where pressure forces are not considered, is called fluid kinematics and if

the pressure forces are also considered for the fluids in motion, that branch of science is called fluid

dynamics.

6.1.4 Fluid properties:

Following are some of important fluid properties which are to be considered while designing

the hydraulic system.

01. Mass density: It is the mass per unit volume whereas weight density (or Specific weight) is the

weight per unit volume at the standard temperature and pressure.

02. Specific gravity: It is the ratio of the specific weight of the liquid to the specific weight of

standard fluid. It is a dimensionless quantity.

03. Viscosity: It is the property of fluid which determines its resistance to shearing stresses.

04. Compressibility: It is the property by virtue of which fluids undergo a change in volume under

the action of external pressure. It is the inverse of bulk modulus.

05. Pressure: Pressure is defined as the force exerted on the unit area. The pressure on a fluid is

measured in two different systems. In one system, it is measured above the absolute zero or

complete vacuum and it is called absolute pressure and in other system pressure is measured above

the atmospheric pressure it is called gauge pressure.

6.1.5 Pascals Law:

The basic principle underlying all the fluid power applications is the Pascal's law this law

deals with a hydrostatics, the subject related to the transmission of power through a confined fluid

under pressure. In fact, it is the fundamental principle based on which all the fluid power systems

work.

Referring to figure the Pascal's law can be stated as;

The pressure exerted on to a confine fluid is transmitted undiminished in all directions, and

acts uniformly at the right angle to the containing surfaces.

6.1.6 Continuity equation

The equation is based on conservation of mass is called continuity equation. Thus for a fluid

flowing through the pipe at all the cross-section, the quantity of fluid per second is constant.

Consider two cross-sections of a pipe, as in figure

Figure 6.2:- Continuity Equation

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2863

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

Continuity equation

Let,

V1 = Average velocity at cross-section 1-1

r1 = Density at section 1-1

A1 = Area of pipe at section 1-1

And V2, r2, A2 are corresponding values at section 2-2.

Then the rate of flow at section 1-1 = r1A1V1

And rate of flow at section 2-2 = r2A2V2

According to law of conservation of mass,

Rate of flow at section 1-1 = Rate of flow at section 2-2

r1A1V1=r2A2V2

The above equation is applicable to the compressible as well as incompressible fluids and is called

continuity equation. If the fluid is incompressible (e.g. Hydraulic oils), then

r1= r2

and the above continuity equation reduces to

A1V1= A2V2

6.1.7 Bernoullis equation and its applications

Statement: It states that in a steady, ideal flow of an incompressible fluid, the total energy at any

point of the fluid is constant. The total energy consists of pressure energy, kinetic energy and

potential energy or datum energy.

These energies are,

Pressure energy = p/rg in m of fluid

Kinetic energy = v2/2g in m of fluid

Datum energy = z in m of fluid

Thus mathematically, Bernoulli's theorem is written as,

p/w + v2/2g + z = Constant - - - - - - - - - - - - (here w = rg)

Applications: Bernoulli's equation is applied in all problem of incompressible fluid flow where

energy considerations are involved. The sum of common applications of Bernoulli's theorem is,

1. Venturimeter - for measuring the rate of fluid flow

2. Orifice meter - for measuring the rate of fluid flow

3. Pitot tube - for measuring velocity of fluid flow

Orifice:

Orifice is a small opening of any cross-section, through which a fluid is flowing.

Orifice may be of any cross-section such as circular, triangular, rectangular etc.

Classification of orifice:

Orifice are classified based on,

Size: Small orifice and large orifice

Cross-sectional areas: Circular orifice, triangular orifice, rectangular orifice & square orifice

Shape of upstream edge: Sharpe-edged orifice and bell-mouthed orifice

Nature of discharge: Free discharging orifice and drowned or sub-merged orifices

Co-efficient of discharge for orifice:

It is defined as the ratio of actual discharge from an orifice to theoretical discharge. It is denoted by

Cd.

Cd = Actual velocity

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2864

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

Theoretical velocity

And Theoretical velocity is given by the equation,

v2 = 2gH m/s

Where,

v = velocity of fluid flowing through the orifice in m/s

g = acceleration due to gravity in m2/s

H = head in m

- Discharge through orifice:

The rate of discharge from orifice is expressed by the equation,

Q = Cd A (2gH)0.5m3/s

Where A = cross-sectional area of orifice in m2

6.1.8 Characteristics of Hydraulic systems

01. High forces (torques) with compact size.

02. Step less change (control or regulation) of speed.

03. Suitable for heavy duty operations.

04. Suitable for heavy load applications.

05. Simple overload protection.

06. Higher response time.

07. Hydraulic means of transferring energy are usually slower when compared to

pneumatics or

electrics.

08. Suitable for controlling fast movement process and for high precision movement.

09. High capital cost.

10. Flexibility may not be as good as pneumatics or electrics.

11. Unavoidable leakages, due to higher system pressure.

12. Prone to fire hazards.

6.2 Mechanical Design

This section of design includes the details of hardware elements used in the tracking system

and also the design analysis of those elements

6.2.1 Machine Design

Machine design is the creation of new and better machines and improving the existing once.

A new machine is one which is more economical in the overall cost of production and operation.

Classifications of machine design:

a. Adaptive design

b. Development design

c. New design

6.2.2 Mechanics

Mechanics may be defined as that science which describes and predicts the conditions of

rest or motion of bodies under the action of forces. Mechanics is a physical science, since it deals

with the study of physical phenomenon. The three divisions of mechanics and their sub-divisions are

given as below,

a. Mechanics of rigid bodies

I. Statics

II. Dynamics

b. Mechanics of deformable bodies

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2865

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

c. Mechanics of fluids

I. study of compressible fluids

II. Study of incompressible fluids (Hydraulics)

6.2.3 Space, time, mass and force

These are basic concepts of the mechanics. These concepts are not truly defined; they should

be accepted on the basis of our intuition and experience and used as mental frame of reference of our

study. The concept of space is associated with the notation of the position of a point P. the position

of P may be defined by three lengths measured from a certain reference point, or origin, given in

three directions. These lengths are known as co-ordinate of P. To define an event, it is not sufficient

to indicate its position in space. The time of the event should also be given. The concept of mass

used to characterize and compare the bodies on the basis of certain fundamental mechanical

experiments. Two bodies of same mass, for example, will be attracted by earth in the same manner;

they will also offer the same resistance to a change in translational motion. A force represents the

action of one body on another. It may be excreted by actual contact or at a distance, as in the case

gravitational forces and magnetic forces. A force is characterized by its point of application, its

magnitude and direction. A force is represented by a vector.

6.2.4 Energy and Power

Energy may be defined as capacity to do work. The energy exists in many forms e.g.

mechanical, electrical, chemical etc. The three types of mechanical energies are Potential energy,

Kinetic energy and Strain energy. The S.I unit of energy is Joule (J) and the symbol is E. Power may

be defined as rate of doing work per unit time. The S.I unit of power is watt (W) and the symbol is

P.

6.2.5 Tracking mechanism

The mechanism selected for tracking system is based on lever principle. The type of lever

used manipulate the required load is Second type lever. Basically, a lever is rod or bar capable of

turning about a fixed point called fulcrum. It is used as a machine to lift / transmit a load by the

application of small effort. The ratio of load lifted to the effort applied is called mechanical

advantage. A lever may be Straight or curved and the forces applied on the lever (or by the lever)

may be parallel or inclined to one another.

6.3 Application Of Levers In Engineering Practice

The load (W) and the effort (P) may be applied to the lever in three different ways. The

Fulcrum is denoted by F and direction of reaction is indicated by an arrow mark.

6.3.1 First type/First class lever

In the first type of levers, the fulcrum is in between load and effort. These levers are

commonly used in railway signalling, rocker arms, hand pumps, foot levers etc.

Figure 6.3:-First Type Of Lever

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2866

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

6.3.2 Second type/Second class lever

In this type, the load is in between the fulcrum and effort. The application of such type of

lever is found in levers of loaded safety valves.

Figure 6.4:- Second Type Of Lever

6.3.3 Third type/Third class levers

In this type of levers, the effort is in between the fulcrum and load. The use of such type of

levers is not recommended in engineering practice. However a pair of tongs, the treadle of sewing

machine is the examples of this type of lever.

Figure 6.5:- Third Type Of Lever

6.4 Schematic Diagram

The arrangement of the hydraulic components and other mechanical elements are illustrated

by the following schematic diagram.

The components of the system are,

i. Panel seat

ii. Column

iii. Base

iv. Weight

v. Weight holder

vi. Double acting cylinder

vii. Check valve

viii. Flow control valve

ix. Reservoir

x. Filter

xi. Rod end mounting

xii. Piston end hinge

xiii. Handle

xiv. Counter weight platform

xv. Connecting hose

xvi. T-Connector

xvii. Stopper

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2867

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

Figure 6.6:-Schematic Diagram Of Tracking Of Solar Panel

6.4.1 Working procedure

Working procedure of the designed tracking system is explained by the hydraulic circuit

diagram and by the schematic diagrams. Each duty cycle of the system contains two steps, those are,

6.4.2 Tracking

As the tracking weight acts on the piston through piston rod, it pushes the oil out of the

cylinder and the oil flows towards reservoir. While, due to the restricted cross sectional area at flow

control valve the piston moves with the velocity equal to calculated tracking velocity. During this

action the check valve remains closed, hence oil is allowed to flow only through flow control valve.

At the rod end of the cylinder, the oil is sucked into cylinder due to the vacuum pressure created by

the applied weight.

Figure 6.7: Tracking

6.4.3 Return

As the tracking time finishes, the panel seat has to be rotated by applying the torque,

manually, to bring back into initial position. The vacuum pressure is created at piston end chamber

and oil from reservoir rushes towards cylinder. As soon as the system pressure exceeds the cracking

pressure of check valve, check valve opens and allowing full flow of oil from it, reducing the time

required for repositioning operation.

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2868

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

The flow control valve also allows the oil to flow from it, increasing rate of flow and reduced panel

repositioning time. At rod end of cylinder the piston forces the oil. The oil pressure increases and oil

flows out of the cylinder. Oil returns to reservoir through a filter placed in the return line.

Figure 6.8:- Return

The lever mechanism used for the current tracking system is illustrated by the figure

Figure 6.9: Lever Mechanism

6.4.4 Tracking mechanism

Here, the load is the resistance offered by the cylinder for displacement, which while

depends on the rate of flow from the cylinder. The weight of the disc is the applied driving force,

hence it is the effort applied on the system to perform the desired operation. The weight is applied

through a weight holder. Comparing with the types of lever systems, as the load is between fulcrum

and effort point, this is a system with second type lever system. The arrow on the points shows the

direction of force.

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2869

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

6.5 Hydraulic Circuit Design

Hydraulic circuit is representation of various components of the hydraulic system by using

graphic symbols. The design of hydraulic circuit which precedes the design of actual components,

does not really involve any calculations as it is the mere representation of the system using different

graphic symbols.

Figure 6.10: Hydraulic Circuit Diagram

6.6 Hydraulic Circuit Diagram:

Hydraulic circuit diagram for the mechanical solar tracking system is illustrated by the

figure 6.11,

6.7 Symbol Representation

In the design of hydraulic systems, it is not possible to draw the construction details of the

component on drawing. To make it convenient for representation of different components, various

graphic symbols were developed.

6.7.1 Rules for symbol usage:

The following are the rules for the using graphic symbols,

I. A graphic symbol represents function only. It does not describe any construction features.

II. A circuit diagram with graphic symbol is functional only. It only shows the sequence in which

various components are connected.

III. Valves are essentially drawn in their unactuated position.

IV. The orientation of the symbol on the drawing in no way indicates the actual orientation of the

component in the actual system. The orientation shown has no functional meaning for symbol.

Elements of Hydraulic system.

The components of the hydraulic circuit and their functions are,

Hydraulic actuator (Hydraulic Cylinder)

The actuators are used in hydraulic systems to convert the fluid energy (i.e. fluid with high

pressure) back into mechanical energy by reducing the pressure of fluid. The power developed by

the actuator depends on,

a. Flow rate

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2870

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

b. Pressure drop across the actuator

c. Efficiency of actuator

There are three types of hydraulic actuators,

1. Linear actuators

2. Rotary actuators (Continuous)

3. Rotary actuators (Limited angle)

Linear actuators are nothing but hydraulic cylinders, which produce straight line motion.

The linear motion achieved in a hydraulic cylinder depends on the stroke length. These actuators are

generally termed hydraulic cylinders. Other specific terms like rams and jacks are also used for

hydraulic actuators, depending on their end use. The term ram is used for single acting cylinder that

causes linear motion in horizontal plane and the term jack refers to a hydraulic cylinder that is used

to lift the loads.

The common types of linear actuators are,

a. Single acting cylinder

b. Double acting cylinder

c. Displacement cylinder

Double acting cylinder: Double acting cylinder produces linear motion in two directions.

Hydraulic power is applied on either side of the piston. The construction of double acting

cylinder is similar to single acting cylinder except that rod end of the cylinder also has oil port.

The constructional details of the double acting cylinder is as shown in fig,Constructional details

of double acting cylinder

Figure 6.11-Constructional Details Of Double Acting Cylinder

Double acting cylinder has a hollow cylinder (barrel), piston and piston rod. Both the ends are sealed

with the end caps, which are either threaded or welded to the main cylinder. In some designs, the

end caps are held with the cylinder by tie rods. The piston is provided with a piston seal, commonly

used are piston rings to protect the leakage of oil. The rod is provided with seal to protect the

leakage, a bearing to carry the radial loads, a wiper to protect the foreign particles like dust entering

into cylinder. Oil ports are provided on either side of the piston, so that the fluid pressure can be

applied alternatively on both the sides.

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2871

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

Graphical symbol:

I.

Flow control valve (FCV)

The function of flow control valve is to regulate the flow rate of fluid in a hydraulic system.

This in turn used to control the speed of actuator/s. These valves are basically variable area orifices,

in which increasing the area of orifice increases the flow rate and decreasing the area of orifice

reduces the flow rate.

The common types of FCVs are,

1. Simple needle valve

2. Needle valve with integral check

3. Pressure compensated FCV

Graphical Symbol:

II.

Check Valve

Check valves are also known as directional control valves. The function of check valve is to

direct the free flow in only one direction, and block any flow in reverse direction. These are similar

in operational analogy of electronic diodes.

The three types of check valves are generally used.

a. Ball type valve

b. Poppet type valve

c. Pilot operated check valve

A spring operated direction valve requires a small pressure to open, which is

called as cracking pressure. Due to this it can work like low pressure relief valve to some extent.

Graphical symbol:

III.

Filter

Filters are used in hydraulic systems to remove both the solid and liquid contaminants. Filter

is a device that consist of an element (called filter element) having the openings. When the

contaminated oil passes through the filter element, the particles remain/get filtered, while the clean

fluid passes out of the element. Filter elements are available in sizes as small as 1 micron, which

mean even a dust particle of size 1 micron gets filtered through this filter element.

The three common types of filter elements used in hydraulic systems are,

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2872

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

a. Mechanical elements

b. Absorbent elements

c. Adsorbent elements

The types of filters are,

a. Full-flow filter

b. Proportional-flow filter

Graphical symbol:

IV.

Hydraulic oil

The working fluid in all hydraulic systems is a fluid. Various oil based fluids which had the

desirable properties were developed for the use in hydraulic systems.

The functions of the hydraulic fluid are,

a. To transmit power, this is the primary function.

b. To lubricate various moving parts, so as to avoid metal-to-metal contact, and reduce wear and

noise.

c. To carry the heat generated in the system due to friction between moving parts and moving fluid,

and to dissipate to the environment either through a suitable heat exchanger or through the reservoir.

V.

Desirable properties of hydraulic fluids:

For the fluid to perform efficiently, it must possess certain properties. Certain additives are

added to achieve/preserve the desirable properties. The various properties required for an ideal

hydraulic fluid are as follows,

a. Viscosity

The most basic desirable property of hydraulic fluid is the optimum viscosity. Viscosity

refers to the resistance of a fluid to flow. A low viscous fluid is a thin and can flow easily, but causes

leakages and a very high viscous fluid is thick and doesn't flow easily. In practice, ideal hydraulic oil

should have optimum viscosity.

b. Lubrication

The other major requirement of hydraulic oil is the lubricating ability. A thin film of

lubrication should present to avoid direct contact between two mating surfaces; else both surfaces

rub with each other resulting in high wear rates. The extent to which direct metal-to-metal contact is

avoided depends on the strength of the fluid film which is a function of the viscosity of the fluid. In

hydraulic systems, the fluids themselves act as lubricating medium.

c. Chemical and environmental stability

For a good hydraulic fluid, a good chemical and environmental stability is desirable. Most

fluids are vulnerable to oxidization, as they come in contact with oxygen in air. The oxidation

products are highly soluble in oil, and being acidic in nature, they can easily corrode the metallic

parts. Oxidation leads to deterioration in the chemical nature of the fluid, which may form some

chemical sludges, gum or varnish at low velocity or stagnation points in the system. These chemical

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2873

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

products increase the viscosity of the fluid. Rust is the formation of iron oxide by the chemical

reaction between steel and oxygen. Corrosion is another chemical phenomenon, occurring between

any metal part and acid. These problems can be minimized by adding certain chemical additives to

the fluid, that inhibit oxidation, within the fluid, or that form a thin chemical layer on the metal parts

and avoid direct contact, and hence reduce rusting and corrosion problems.

d. Incompressibility

The incompressibility of a fluid is measure of its stiffness, and given by its bulk modulus

(B). The compressibility of a fluid has influence on the system response, and makes it susceptible to

shock waves. In normal hydraulic systems its effect on system response is not considered, while the

compression values are used to avoid shock wave problems.

e. Fire resistance

Fire resistance is one important property required for applications in aircraft engines, steel

mills, foundries and mines, where the working environment are hot. Through petroleum based oils

are suitable and have many desirable characteristics, they are highly vulnerable to fire hazards. In

such cases fire resistant fluids are used. Fire resistance of a hydraulic fluid measured by some of the

characteristics, those are flash point, fire point and autogenously temperature.

f. Foam resistance

Dissolved air reacts with the fluid to form acidic products which in turn cause corrosion and

sludge problems. The presence of foam in the fluid causes serious operational problems. Certain

additives are added to fluid, which act as foam-depressants.

VI.

Reservoir

Reservoirs are basically storage tanks for the hydraulic oil. The functions of a hydraulic

reservoir are,

a. To act as a storage tank.

b. To provide heat exchange, thus cooling the oil.

c. To allow entrained air to escape from fluid.

d. To allow fluid contaminations to settle down.

e. To make-up any leakages in the system.

f. To provide filling point for the system.

The reservoir design should be optimum. A smaller size reservoir then required causes

problems like overheating, increased contamination, higher wear and tear. An over sized reservoir

will increase the cost of tank and longer warming period.

VII.

Hydraulic System Design

Hydraulic system design includes the determination force required for the cylinder and

system pressure. The details of calculation steps for the hydraulic system design are given as below,

6.6 Nomenclature

i.

ii.

iii.

iv.

v.

vi.

vii.

viii.

D = Cylinder diameter in m

A = Cross sectional area of cylinder in m2

L = Length of stroke in m

d = Diameter of orifice in m

Cd = Co-efficient of discharge for orifice

Vp = Velocity of piston in m/s

Vo = Velocity of oil at orifice in m/s

Qc = Cylinder discharge in m3/s

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2874

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

ix.

x.

xi.

xii.

xiii.

xiv.

xv.

Qo = Orifice discharge in m3/s

P = System pressure in N/m2

F = Force in N

W = Weight in N

r = Density of hydraulic oil in kg/m3

a = Distance from rod end to panel hinge in m

b = Distance from loading point to panel hinge in m

Available data:

i.

ii.

iii.

iv.

v.

vi.

vii.

viii.

ix.

x.

Time range = 8 AM to 4 PM (8 Hrs)

Pressure drop across the check valve = 50.8 mm Hg = 6772.77 N/m2

Pressure drop across the filters = 1 inch of Hg = 3386.38 N/m2

Size of the panel (L x B x H) = 1 m x 0.5 m x 0.025 m

Selected Hydraulic oil = SAE20 W40

r = 880 kg/m3

D = 0.05 m and A = 0.00196 m2

L = 0.21 m

d = 0.001 m

Cd = 0.62

6.7 Calculations

I.

Velocity of piston

Vp = Stroke length / Time range

= 0.21 / 28800

Vp = 7.29E-6 m/s

II.

Cylinder discharge

Qc = Cross-sectional area A x Velocity of piston Vp

= 1.963E-3 x 7.29E-6

Qc = 1.43E-8 m3/s

III.

Velocity of oil at orifice

By the relation for discharge from orifice,

Qo = Cd x a x Vo

1.43E-8 = 0.62 x 7.85E-7 x Vo

Vo = 0.029 m/s

IV.

System pressure

2 x P = Vo x r - - - - - - - (by V = (2gH)0.5 & P = rgH)

2 x P = 0.0292 x 880

P = 0.37 Pa or N/m2

And also considering the pressure drop across the filters = 3386.68 Pa

(Note: As check valve is closed during tracking operation, pressure drop across check valve is not

considered.)

The Total system pressure,

P = 0.37 + 3386.38

i.e. P = 3386.75 Pa

V.

Force required,

F=PxA

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2875

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

= 3386.75 x 1.963E-3

F = 6.64 N

The force required on the cylinder for tracking = 6.64 N

VI.

Reservoir Design

Reservoir design is essential to determine the capacity of tank, hence to assure proper

functionality. Some of the common rules to be followed in reservoir design are as follows,

a. The minimum size of the reservoir should be at least twice the pump delivery per minute.

b. Its capacity should be adequate enough to hold all the oil from the system that might drain into

tank.

c. It should have oil level much above the intake strainer, so that no whirling effect will occur.

d. Its capacity should enough to allow for thermal expansion.

Calculations:

Displacement of cylinder,

Vc = (3.142/4) x D2 x L

= (3.142/4) x 0.052 x 0.21

Vc = 0.000412 m3

Volume of oil in hoses and other accessories,

Va = (3.142/4) x 0.012 x 0.6

Va = 0.0000471 m3

Theoretical volume of tank,

Vt = Vc + Va

= 0.000412 + 0.0000471

Vt = 0.00046 m3

As per optimum design practices, the actual volume of tank should be at least twice the theoretical

volume of tank.

Hence,

Minimum Volume of tank = 2 x Vt

= 2 x 0.00046

i.e. Minimum volume of tank = 0.00092 m3 or 0.92 Liter

VII.

Force and Energy Calculation

Due the application of lever principle the effort required for the tracking operation is

different from the calculated value of force in the hydraulic system calculation.

(Note: All dimensions are in mm)

The force required is different for both steps of operation and they are calculated as below.

Step 1: Tracking

Referring to the mechanism and by the lever principles, taking reaction at fulcrum point,

We have,

Load x 0.13 m = Effort x 0.5 m

13.295 N x 0.13 m = W x 0.5 m - - -( F = 13.295 N )

i.e.

W = 3.456 N

Load required for the tracking operation = 3.456 N

and energy consumed for tracking,

Energy = Force x Distance (Cylinder displacement)

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2876

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

= 3.456 x 0.21

i.e. E = 0.725 J

Energy required for tracking operation = 0.725 J

Step 2: Return

The force applied for return operation is manual. Assuming a normal person can exert 5 kg

of force against gravity, then

Force required for return operation = 49.05 N

Energy consumed for the return operation = Force x Angular displacement

= 5 x 9.81 x (/180) x 0.5 x 120

i.e. E = 51.36 J

Energy consumed for return operation = 51.36 J

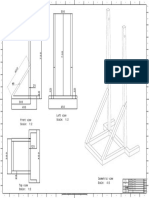

6.8 Assembly

I. Column and base

This is the load bearing structure of machine which takes all forces acting on the system.

The column and base are welded together to provide more strength and to carry the solar panels of

larger sizes than designed. It also includes two stoppers to restrict the displacement of panel seat to

the required position. These are plates of 4mm thickness and welded to the column.

II.

Panel seat

Panel seat is a fabricated frame on which solar panel is mounted. It is fabricated element and

sufficient numbers of holes are provided to facilitate the mounting of solar panel. It also supports the

weight holder and transmits tracking force to cylinder. A provision also made on the frame to mount

the counter weight, for flexibility in selection of weight disc/s. A handle is provided with the frame

to facilitate the lifting the panel seat for return operation.

III.

Weight holder and weight disc

The function of weight holder is to hold the weight disc in its place. Another important

function of weight holder is to provide proper moment to overcome static friction of cylinder at the

beginning of tracking operation. The static friction is very high at the beginning of tracking

operation. Weight disc is a molded disc which is mounted on weight holder to exert driving torque

for tracking operation. Multiple discs can be used according to their unit weight and requirement.

FLUID FLOW

CONTROL VALVE

CHECK VALVE

Figure 6.12 : Control Valve And Check Valve

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2877

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

WEIGHT AND WEIGHT HOLDER

Figure 6.13: Weight And Weight Holder

PANNEL SET

Figure 6.14: Panel Set

PANNEL SET SUPPORTING HINGE

PISTON END HINGE

DOUBLE ACTING

CYLINDER

Figure 6.15: Showing Hinges And Double Acting Cylinder

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2878

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

Figure 6.16: Overall Assembly Of Hydraulic Solar Tracker

7 Advantages, Disadvantages and Limitations

7.1 Advantages

1. Hydraulic solar tracker is easy to design and manufacture compare to other tracker system.

2. Increased reliability and robustness of hydraulic control system compared with other solar

tracker.

3. Hydraulic solar trackers generate more energy than other tracking system like electric solar

tracker.

4. Lubrication of system is not necessary due to less moving parts.

5. Compare to other tracking system hydraulic tracking system cost is less.

6. Important reduction of whole life maintenance cost of solar tracker .

7.2 Disadvantages

1. Structurally less rigid then permanent mounts and hence can be vulnerable to storm damage.

2. More chances to leakage of hydraulic oil.

3. Required manual power to pump the oil in cylinder.

7.3 Limitation

The Track Rack begins the day facing west as the morning sun rises in the east we need to

pump the oil in cylinder with the help of manual power.

8. Bill Of Materials

Table 8.1: Bill Of Materials

Sr No.

1.

2.

3.

4.

5.

Part Code

TPSH -1

TPSH -2

TPSH -3

TPSH -4

TPSH -5

Description

PANEL SEAT

COLUMN

BASE

WEIGHT

WEIGHT HOLDER

Qty

01

01

01

01

01

Material

MS

MS

MS

MS

MS

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2879

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

TPSH -6

TPSH -7

TPSH 8

TPSH 9

TPSH 10

TPSH 11

TPSH 12

TPSH 13

TPSH 14

TPSH 15

TPSH 16

DOUBLE ACTING CYLINDER

CHECK VALVE

FLOW CONTROL VALVE

RESERVOIR

ROD END MOUNTING

PISTON END HINGE

CONNECTOR HOSE

COUNTERWEIGHT PLATFORM

T-CONNECTORS

HOSE CLIPS

CONNECTOR NOZZLES

01

01

01

01

01

01

01

01

02

20

08

STD

STD

STD

MS

MS

MS

STD

MS

STD

STD

STD

9. Result

The results obtained after the detailed calculations are given as below,

i.

Velocity of piston = Vp = 7.29E-6 m/s

ii.

Cylinder = Qc = 1.43E-8 m3/s

iii.

Velocity of oil at orifice = Vo = 0.029 m/s

iv.

System pressure = P = 3386.75 Pa

v.

The force required on the cylinder for tracking = F = 6.64 N

vi.

Considering mechanism for tracking, weight required for tracking,

i. W = 3.456 N

vii.

Energy required for tracking operation = 0.725 J

viii.

Force required for return operation = 49.05 N

ix.

Energy consumed for return operation = 51.36 J

x.

Minimum volume of tank = 0.00092 m3 or 0.92 Liter

xi.

Increased power output and returns = 87.6 kW-hr worth of Rs.403 /solar panel of area 0.456 m2 and analysis period of 1 year)

------

(Considering a

10. Conclusion

It is observed that the designed mechanical tracking system is a system, which consumes no energy

for operation and contributing towards increasing the productivity of the solar panels. This is the

first attempt made towards utilizing the gravitational energy as a driving force for solar tracking

systems and also in providing a suitable tracking system for the remote places. In view of increasing

demand for the electrical power, this tracking system can contribute a little (around 87.6 kW-hr per

year) in the fulfilment this demand

11. Future Scope

Further research work will be suggested towards reducing the material cost, towards implementation

of suitable sensors to assure ease in operations and towards obtaining the preferred essential

requirements. Some of the preferred essentials and the guidelines associated with design and

development of this tracking device are;

I.

A sensor with electronic counter, which will provide input signal to a buzzer, to indicate the

start of tracking cycle. On basis of this, the panel is tilted by means of handle to perform

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2880

ISSN (Online): 2347-1697

International Journal of Informative & Futuristic Research (IJIFR)

Volume - 2, Issue - 8, April 2015

20th Edition, Page No: 2856- 2881

II.

III.

return operation. The electronic system, if used, should consume very little electric energy,

making the device suitable for remote applications by providing small & long lasting

batteries.

Use of multiple panels on panel seat, to increase the returns from tracking system.

System can be modified to suite other solar applications like solar air heating and solar

water heaters.

References

PUBLISHED PAPER REFERANCE

[1] One-Axis Trackers Improved Reliability, Durability, Performance, and Cost Reduction - Final

Subcontract Technical Status Report - 2 May 2006 31 August 2007 by J. Shingleton Shingleton

Design, LLC Auburn, New York

[2] Low cost tracker by Marliyani Binti Omar This thesis is submitted as partial fulfillment of the

requirements for the award of the Bachelor of Electrical Engineering - Faculty of Electrical &

Electronics Engineering University Malaysia Pahang -MAY, 2009

[3] A review of principle and sun-tracking methods for maximizing solar systems output by Hossein

Mousazadeh, Alireza Keyhani, Arzhang Javadi, Hossein Mobli Karen Abrinia, Ahmad Sharifi Department of Agricultural Machinery Engineering, University of Tehran, Iran

BOOK REFERANCE

[1] Fluid mechanics and Hydraulic machines by R.K.Bansal.

[2] Basic hydraulics and hydraulic plumbing US army division.

[3] Machine design by R.S.Khurmi and J.K Gupta.

[4] Vector mechanics for engineers by F.B Beer.

[5] Atlas solar tracking by mechatron company manual.

WEB REFERENCE

We have followed several links on the internets which are as follows:

[1] http://www.canren.gc.ca/tech_appl/about solar energy.htm.

[2] http://www.palmdalewater.org/alternative solarenergy.htm.

[3] http://www.careercornerstone.org/careers for mechanical engineers

[4] http://www.burkoil.com.

[5] http://www.bull-electrical.com/solar panels, electrical and water, controllers, panels, solar

shargers.htm.

S. K. Kusekar, Ajinkya Patil, Sachin Patil, Prasad Rajmane, Akshay

Bhosale:: Tracking of Solar Panel by Hydraulic System

2881

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Average Waiting Time at Dental ClinicDokumen12 halamanAverage Waiting Time at Dental ClinicJonas Ciabis100% (1)

- Analysis of Vibration Damping in Machine ToolsDokumen6 halamanAnalysis of Vibration Damping in Machine Toolssuraj dhulannavarBelum ada peringkat

- Left View Scale: 1:2: 1:1 XXX A0Dokumen1 halamanLeft View Scale: 1:2: 1:1 XXX A0suraj dhulannavarBelum ada peringkat

- E RationingDokumen3 halamanE Rationingsuraj dhulannavarBelum ada peringkat

- 2 Suku - Mar o Automatic PDFDokumen4 halaman2 Suku - Mar o Automatic PDFsuraj dhulannavarBelum ada peringkat

- FrameDokumen1 halamanFramesuraj dhulannavarBelum ada peringkat

- Visvesvaraya Technological University BelgaumDokumen2 halamanVisvesvaraya Technological University Belgaumsuraj dhulannavarBelum ada peringkat

- 199 Iphv7i3008xDokumen7 halaman199 Iphv7i3008xsuraj dhulannavarBelum ada peringkat

- (IJCST-V4I4P3) :reema Patel, A.N.Shewale, C.S.PatilDokumen3 halaman(IJCST-V4I4P3) :reema Patel, A.N.Shewale, C.S.PatilEighthSenseGroupBelum ada peringkat

- Mobile Wind Charger for Automobile BatteriesDokumen7 halamanMobile Wind Charger for Automobile Batteriessuraj dhulannavarBelum ada peringkat

- 1:1 XXX A1: Designed By: DateDokumen1 halaman1:1 XXX A1: Designed By: Datesuraj dhulannavarBelum ada peringkat

- 44 Tapsa Mech 006Dokumen9 halaman44 Tapsa Mech 006suraj dhulannavarBelum ada peringkat

- 5Dokumen4 halaman5suraj dhulannavarBelum ada peringkat

- 03 e Pipetube en WebDokumen18 halaman03 e Pipetube en Websuraj dhulannavarBelum ada peringkat

- 1:1 XXX A1: Toshavi PCDokumen1 halaman1:1 XXX A1: Toshavi PCsuraj dhulannavarBelum ada peringkat

- 55Dokumen3 halaman55md junuBelum ada peringkat

- 1:1 XXX A4: Designed By: DateDokumen1 halaman1:1 XXX A4: Designed By: Datesuraj dhulannavarBelum ada peringkat

- D e S I G N o F A N A U T o M A T e D S o R T I N G o F o B J e C T R e J e C T I o N A N D C o U N T I N G M A C H I N eDokumen13 halamanD e S I G N o F A N A U T o M A T e D S o R T I N G o F o B J e C T R e J e C T I o N A N D C o U N T I N G M A C H I N esuraj dhulannavarBelum ada peringkat

- FrameDokumen1 halamanFramesuraj dhulannavarBelum ada peringkat

- Dam Shutter Control Using Servo MotorDokumen3 halamanDam Shutter Control Using Servo MotorkarthikBelum ada peringkat

- FrameDokumen1 halamanFramesuraj dhulannavarBelum ada peringkat

- 1:1 XXX A1: Toshavi 5/3/2016Dokumen1 halaman1:1 XXX A1: Toshavi 5/3/2016suraj dhulannavarBelum ada peringkat

- 437NDokumen8 halaman437Nsuraj dhulannavarBelum ada peringkat

- Automatic Rain Operated Wiper Group ProjectDokumen5 halamanAutomatic Rain Operated Wiper Group Projectsuraj dhulannavarBelum ada peringkat

- 1:1 XXX A4: Designed By: DateDokumen1 halaman1:1 XXX A4: Designed By: Datesuraj dhulannavarBelum ada peringkat

- 1:1 XXX A1: Designed By: DateDokumen1 halaman1:1 XXX A1: Designed By: Datesuraj dhulannavarBelum ada peringkat

- 1:1 XXX A1: Toshavi 5/3/2016Dokumen1 halaman1:1 XXX A1: Toshavi 5/3/2016suraj dhulannavarBelum ada peringkat

- Dam Shutter Control Using Servo MotorDokumen3 halamanDam Shutter Control Using Servo MotorkarthikBelum ada peringkat

- MSHDokumen20 halamanMSHsuraj dhulannavar100% (1)

- WWW Mechengg Net 2015 09 Design and Fabrication of InjectionDokumen17 halamanWWW Mechengg Net 2015 09 Design and Fabrication of Injectionsuraj dhulannavarBelum ada peringkat

- Square Hole Drilling MachineDokumen4 halamanSquare Hole Drilling Machineedisonmech_erfBelum ada peringkat

- Slabs Are Plate Elements Forming Floors andDokumen5 halamanSlabs Are Plate Elements Forming Floors andyasas89Belum ada peringkat

- Restaurant Pub VIP Lounge Camp Pune SaleDokumen4 halamanRestaurant Pub VIP Lounge Camp Pune SaleChandrashekhar Naikare0% (1)

- Specialized Epic EVO 2021Dokumen3 halamanSpecialized Epic EVO 2021MTB-VCOBelum ada peringkat

- How To Enable Nationality Field in IrecruitmentDokumen2 halamanHow To Enable Nationality Field in IrecruitmentnhawiBelum ada peringkat

- FREE UX Books @UXlinksDokumen4 halamanFREE UX Books @UXlinksSyaifudin MashuriBelum ada peringkat

- Abstract Substructure Conc - Frame Westgate RealDokumen4 halamanAbstract Substructure Conc - Frame Westgate RealTashamiswa MajachaniBelum ada peringkat

- 0806 02 Los5 - UgDokumen124 halaman0806 02 Los5 - Ugbmds kocakBelum ada peringkat

- BS Basics Boundary Scan PDFDokumen2 halamanBS Basics Boundary Scan PDFShankar ArunmozhiBelum ada peringkat

- Tugas Dinamika Struktur Shape Function - Kelompok 6Dokumen8 halamanTugas Dinamika Struktur Shape Function - Kelompok 6Mochammad Choirul RizkyBelum ada peringkat

- Dwg. No. 63170016 - ER-15Dokumen1 halamanDwg. No. 63170016 - ER-15GiantcanaBelum ada peringkat

- Blasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyDokumen3 halamanBlasting and Painting of Sheds, Pipes, Pipe Fittings, Vessels and Tanks DailyEjike Francis ChizobaBelum ada peringkat

- II B.Tech II Semester Regular Examinations, Apr/May 2007 Chemical Engineering Thermodynamics-IDokumen7 halamanII B.Tech II Semester Regular Examinations, Apr/May 2007 Chemical Engineering Thermodynamics-IrajaraghuramvarmaBelum ada peringkat

- Feature Setup Description: Software Basic Data Mcs - TCBCDokumen77 halamanFeature Setup Description: Software Basic Data Mcs - TCBCAlexis MauricioBelum ada peringkat

- DevelopmentThatPays ScrumToScrumban CheatSheet 2 - 0Dokumen1 halamanDevelopmentThatPays ScrumToScrumban CheatSheet 2 - 0tarikBelum ada peringkat

- Model Manajemen Rantai Pasok Industri Perikanan Tangkap Berkelanjutan Di Propinsi MalukuDokumen12 halamanModel Manajemen Rantai Pasok Industri Perikanan Tangkap Berkelanjutan Di Propinsi MalukuEmanuellaBelum ada peringkat

- Stock PartDokumen20 halamanStock PartGReyBelum ada peringkat

- Manual em Portugues DGX230Dokumen120 halamanManual em Portugues DGX230Agosthis0% (1)

- Fire Fighting LayoutDokumen1 halamanFire Fighting LayoutNoufal OthupurayilBelum ada peringkat

- Air Car SeminarDokumen24 halamanAir Car SeminarSatyajit MenonBelum ada peringkat

- Dekut Teaching Practice ManualDokumen20 halamanDekut Teaching Practice Manualstephen njorogeBelum ada peringkat

- BK - Scrum and CMMIDokumen132 halamanBK - Scrum and CMMIcoolgoroBelum ada peringkat

- C Programming: Charudatt KadolkarDokumen34 halamanC Programming: Charudatt KadolkarDhiliban SwaminathanBelum ada peringkat

- Manual de Partes Gen Set DQFADDokumen272 halamanManual de Partes Gen Set DQFADJorge Calcaneo MartinezBelum ada peringkat

- Types of Camera AnglesDokumen2 halamanTypes of Camera AnglesMaJudith JavilloBelum ada peringkat

- Certification Authorities Software Team (CAST) Cast 10Dokumen8 halamanCertification Authorities Software Team (CAST) Cast 10Anastasia SuckallahBelum ada peringkat

- Object-Oriented Programming Lab Manual RDokumen63 halamanObject-Oriented Programming Lab Manual RKLR CETBelum ada peringkat

- 7 Strategies For Developing Your Own Curriculum As A New TeacherDokumen5 halaman7 Strategies For Developing Your Own Curriculum As A New TeacherKhusnul KhotimahBelum ada peringkat

- ExMED Debrief 2019Dokumen16 halamanExMED Debrief 2019Hamilton WintersBelum ada peringkat

- Computed TomographyDokumen94 halamanComputed TomographyBMT100% (3)