13 - Drive Controller - Operation Manual

Diunggah oleh

Miguel RodriguezJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

13 - Drive Controller - Operation Manual

Diunggah oleh

Miguel RodriguezHak Cipta:

Format Tersedia

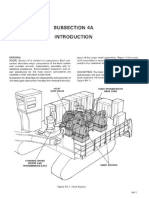

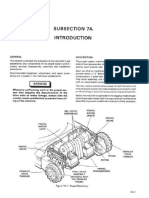

Hydraulic Mining Excavators

CAMP/ SIL Electric System CAT-6040FS AC

Drive Controller Operation Manual

Sebastian Fillinger - 2014

Location of the Drive Control System

Service Training

-3A3

Drive Controller

Service Training

The following pages describe the interconnection inside the servo controller via software.

It is represented in so called functional modules:

And module:

The output is high if input 1 is high and input 2 is high

Input 1

Input 2

&

Output

Or module:

The output is high if input 1 is high or input 2 is high

Input 1

Input 2

OR

Output

Drive Controller

Service Training

Time delay module (turn on time delayed):

The output is high if input 1 is high for at least 15s

15s

Delay

Output

Input 1

Time delay module (turn off time delayed):

The output is high when input 1 is high and turns off after 15s time delay

15s

Delay

Input 1

Output

Drive Controller

Service Training

Negation module:

The incoming signal will be swapped from high to low or from low to high

The output is high if input 1 is low/ The output is low if input 1 is high

Input 1

Output

Main motor start

Service Training

Start interlock

See page 8

1S115 Ignition

Power supply controller outputs

X3/ 98 Emergency chain ok

3S401 Maintenance switch

3B531 Shut off valve 1

3B532 Shut off valve 2

3B533 Shut off valve 3

&

3B534 Shut off valve 4

X3/ 103 Motor protection relay ok

Main motor start

X3/ 102 High voltage ok

X3/ 101 Phase sequence ok

X3/ 100 Power factor correction ok

5S7 Motor start button

CAN Bus

Auxiliary Controller

Main motor stop

1S115 Ignition

Service Training

Power supply controller outputs

1

X3/ 98 Emergency chain ok

1

3S401 Maintenance switch

1

3B531 Shut off valve 1

1

3B532 Shut off valve 2

1

3B533 Shut off valve 3

1

3B534 Shut off valve 4

1

OR

Main motor stop

X3/ 103 Motor protection relay ok

1

X3/ 102 High voltage ok

1

X3/ 101 Phase sequence ok

1

X3/ 100 Power factor correction ok

1

5S8 Motor stop button

CAN Bus

Auxiliary Controller

Start interlock

Service Training

The system allows 2 motor starts per hour. Two starts can be done one after the other. You can start the

motor the third time when the time between first and third start is greater than 1 hour.

Example:

1. Start

1. Start

30 min

10 min

2. Start

2. Start

40 min

30 min

3. Start

1. Start

40 min

3. Start

40 min

1h /

10 min

55 min

2. Start

15 min

3. Start

Overview Pump Control

Service Training

Motor winding temperature via MOD Bus

Hydraulic oil temperature

Voltage

Motor load (active power)

Acceleration

0 - 100%

Pump Requirements

from Servo Controller

via Can-Bus

Signal via CAN-safety-Bus

Joysticks and

Foot pedals

Drive Controller

Servo Controller

PMS Current 200 700mA

(150mA Standby Current)

Angle Main Pumps 0

15

50bar Pressure

8 - 43bar to Main Pumps

Reducing PMS Current / Pressure

Service Training

Hydraulic Oil Temperature exceeds 80C

Motor winding temperature exceeds 120C

Voltage (from grid) is lower than the nominal voltage

OR

Acceleration

0 - 100%

Derated output

current

Pump Requirements

from Servo Controller

via Can-Bus

Signal via CAN-safety-Bus

Joysticks and

Foot pedals

Servo Controller

Drive Controller

10

PMS Reducing PMS current/ pressure

Service Training

If the nominal voltage of the motor drops down, the motor output power will

be reduced (see formula down below).

The min. factor of motor power derating in case of voltage drop down is 60% of the nominal motor output power!

Uact

Derated _ Motor _ Output _ Power =

Unom

Example:

Nominal voltage:

Actual voltage:

Nominal output motor:

2

2

)* P

nom

7200V

6700V

1400KW

2

6700V

Uact 2

Derated _ Motor _ Output _ Power =

* Pnom =

*1400 KW = 1212 KW

2

Unom 2

7200V

Explanation:

In the upper example the Motor can deliver max. 1212KW power to the hydraulic system.

11

PMS Reducing PMS current/ pressure

Service Training

If the winding temperature exceeds 120

C, the motor output power will be

reduced (see Graph down below).

The min. factor of motor power derating in case of winding overheating is 80% of the nominal motor output power!

Motor Output Derating

Motor Output in % of nominal Output Power

120

100

80

60

40

20

0

0

20

40

60

80

100

120

140

160

180

200

Winding Temperature in C

Example:

Nominal motor power:

1400KW

Actual winding temperature:

135

C

Output motor:

1260KW (90%)

Explanation:

In the upper example the motor can deliver max. 1260KW power to the hydraulic system.

12

PMS Reducing PMS current/ pressure

Service Training

In case of voltage drop down and exceeded winding temperature both

factors will be multiplied

Example:

Motor Output Derating

7200V

Actual voltage:

6700V

Actual winding temperature:

135

C

Nominal output power:

1400KW

Motor Output in % of nominal Output Power

120

Nominal voltage:

100

80

60

40

20

0

0

20

40

60

80

100

120

140

160

180

200

Winding Temperature in C

Derating factor under voltage:

0,86 (see formula)

Derating factor winding temperature: 0,9 (see graph)

2

6700V

Uact 2

Derating _ Factor _ Under _ Voltage =

* Pnom =

= 0,86

2

Unom 2

7200V

Derating factor under voltage

0,86

* Derating factor winding temperature

* 0,9

= Total derating factor

= 0,774

Total derating factor

0,774

* Nominal output motor

* 1400KW

= Actual output motor

= 1083KW

13

Overview Hydraulic Oil cooling

Service Training

Hydraulic Oil Temperature

-50C - +150C

4 20mA

150 650mA

Drive Controller

Angle Oil cooling Pump

0 15

Low Speed level Fan

(50C)

Fan Oil cooling

Module

High Speed level Fan

(60C)

14

Questions?

Service Training

Questions are free of charge!!!

15

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Embody Chairs Disassembly InstructionsDokumen4 halamanEmbody Chairs Disassembly Instructionsguiness_joe9154Belum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hussain Rabia - Drill Bits (Chapter 9)Dokumen44 halamanHussain Rabia - Drill Bits (Chapter 9)Andreas Ansen VitalisBelum ada peringkat

- Name of The Company: Columbia Wire and Cable Corporation Date of Tour: October 23, 2019 Overview of The CompanyDokumen3 halamanName of The Company: Columbia Wire and Cable Corporation Date of Tour: October 23, 2019 Overview of The CompanyJhun Michael LocusBelum ada peringkat

- 13 - Drive Controller - Operation ManualDokumen14 halaman13 - Drive Controller - Operation ManualMiguel RodriguezBelum ada peringkat

- 3 Zone Lincoln PDFDokumen1 halaman3 Zone Lincoln PDFMiguel RodriguezBelum ada peringkat

- Diagrama de Bloque de 3 Zonas PDFDokumen1 halamanDiagrama de Bloque de 3 Zonas PDFMiguel RodriguezBelum ada peringkat

- Esquema Hidráulico AtualizadoDokumen3 halamanEsquema Hidráulico AtualizadoMiguel RodriguezBelum ada peringkat

- 014 CAT-6060 AC 60Hz E-Drive CAMP + SIL + BCS4 FS Legend H-Schematic Canada No New AvailableDokumen13 halaman014 CAT-6060 AC 60Hz E-Drive CAMP + SIL + BCS4 FS Legend H-Schematic Canada No New AvailableMiguel RodriguezBelum ada peringkat

- Diagrama de Bloque de 4 Zonas PDFDokumen1 halamanDiagrama de Bloque de 4 Zonas PDFMiguel RodriguezBelum ada peringkat

- NDT-PQ PDFDokumen7 halamanNDT-PQ PDFMiguel RodriguezBelum ada peringkat

- Extension - Cable Grease SystemDokumen3 halamanExtension - Cable Grease SystemMiguel RodriguezBelum ada peringkat

- Bronze Bushing Shrinkage On Diameter PDFDokumen1 halamanBronze Bushing Shrinkage On Diameter PDFMiguel RodriguezBelum ada peringkat

- Nondestructive Test Procedure: Acceptance Criteria For Nondestructive Testing of P&H ProductDokumen3 halamanNondestructive Test Procedure: Acceptance Criteria For Nondestructive Testing of P&H ProductMiguel RodriguezBelum ada peringkat

- Section 4 Hoist SystemDokumen32 halamanSection 4 Hoist SystemMiguel RodriguezBelum ada peringkat

- Manufacturing Operating Procedure: Appendix "B" Deviation Requests (MRB)Dokumen3 halamanManufacturing Operating Procedure: Appendix "B" Deviation Requests (MRB)Miguel RodriguezBelum ada peringkat

- Manufacturing Operating Procedure: Recommended Filler Material and Preheat/Interpass TemperaturesDokumen5 halamanManufacturing Operating Procedure: Recommended Filler Material and Preheat/Interpass TemperaturesMiguel Rodriguez100% (1)

- Bypass Kit Hoist FilterDokumen2 halamanBypass Kit Hoist FilterMiguel RodriguezBelum ada peringkat

- Table of Contents:: User InstructionsDokumen2 halamanTable of Contents:: User InstructionsMiguel RodriguezBelum ada peringkat

- Section 9 Maintenance WeldingDokumen4 halamanSection 9 Maintenance WeldingMiguel RodriguezBelum ada peringkat

- Section 10 LubricationDokumen16 halamanSection 10 LubricationMiguel RodriguezBelum ada peringkat

- 004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and Powertrain PDFDokumen12 halaman004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and Powertrain PDFMiguel RodriguezBelum ada peringkat

- Tarjetas 2800XPBDokumen3 halamanTarjetas 2800XPBMiguel RodriguezBelum ada peringkat

- Section 3 Swing SystemDokumen35 halamanSection 3 Swing SystemMiguel RodriguezBelum ada peringkat

- Sis Web User Guide v3-5-1Dokumen60 halamanSis Web User Guide v3-5-1Miguel RodriguezBelum ada peringkat

- Section 7 Propel SystemDokumen50 halamanSection 7 Propel SystemMiguel RodriguezBelum ada peringkat

- NPR & Kits PDFDokumen11 halamanNPR & Kits PDFMiguel RodriguezBelum ada peringkat

- Service Technician Workbench: What's New in 2004BDokumen53 halamanService Technician Workbench: What's New in 2004BMiguel RodriguezBelum ada peringkat

- Capsules VDokumen36 halamanCapsules VrandatagBelum ada peringkat

- Process Flow Chart of Woven Dyeing - Textile FlowchartDokumen5 halamanProcess Flow Chart of Woven Dyeing - Textile FlowchartGOWTHAM CHANDRUBelum ada peringkat

- Gestra Check ValveDokumen4 halamanGestra Check Valvetilakthakar1Belum ada peringkat

- So Lubi LizerDokumen3 halamanSo Lubi LizerfushiersBelum ada peringkat

- 5R110W Assembly PDFDokumen16 halaman5R110W Assembly PDFLuis VelazquezBelum ada peringkat

- MSCMS Issue 6 Rev-0-Pages-32Dokumen1 halamanMSCMS Issue 6 Rev-0-Pages-32Bilal JavaidBelum ada peringkat

- A Preliminary Study On Bladder-Assisted Rotomolding of Thermoplastic Polymer CompositesDokumen12 halamanA Preliminary Study On Bladder-Assisted Rotomolding of Thermoplastic Polymer Compositespetrusz1Belum ada peringkat

- Methods, Processes, and Equipment in Size Reduction of Solids - 5ME2Dokumen35 halamanMethods, Processes, and Equipment in Size Reduction of Solids - 5ME2Ana Marie Baysa100% (3)

- Types of PaintDokumen17 halamanTypes of PaintdhanyaBelum ada peringkat

- Airflow Pattern StudiesDokumen18 halamanAirflow Pattern Studiessainath_84100% (1)

- Te 710 WebDokumen57 halamanTe 710 WebRoman KrautschneiderBelum ada peringkat

- Water and Wastewater Treatment-Monroe EnvironmentalDokumen20 halamanWater and Wastewater Treatment-Monroe EnvironmentalHussein Ali Mahdi Al-ZubaidyBelum ada peringkat

- Wiper BladeDokumen3 halamanWiper Bladeghyd artiagaBelum ada peringkat

- Dow Corning 732 Multi-Purpose Sealant: Product InformationDokumen2 halamanDow Corning 732 Multi-Purpose Sealant: Product InformationProject Sales CorpBelum ada peringkat

- b3850 Series Terminal Controllers: Andover ContinuumDokumen6 halamanb3850 Series Terminal Controllers: Andover ContinuumrbelduaBelum ada peringkat

- ETICS Details SubmissionDokumen11 halamanETICS Details SubmissionbarunBelum ada peringkat

- Rheem ManualDokumen20 halamanRheem ManualeurobobBelum ada peringkat

- Thesis (1997-2006)Dokumen7 halamanThesis (1997-2006)picefeati0% (1)

- Secondary 1 - Science - SA2 - 2019 - 1Dokumen17 halamanSecondary 1 - Science - SA2 - 2019 - 1DigitalTransformation MitrpholBelum ada peringkat

- Home ScienceDokumen3 halamanHome ScienceCricket ClutchBelum ada peringkat

- Defects and CausesDokumen58 halamanDefects and CausesPrasannaVenkatesan100% (2)

- Electron Beam Welding AbstractDokumen3 halamanElectron Beam Welding AbstractEmmanuel PeterBelum ada peringkat

- Geclearning: Step 1. Choose or Calculate Inert O Concentration Required (Vol%)Dokumen4 halamanGeclearning: Step 1. Choose or Calculate Inert O Concentration Required (Vol%)sandy4u2k2Belum ada peringkat

- Practice Set 2Dokumen6 halamanPractice Set 2Marielle CastañedaBelum ada peringkat

- Hydraulic Shovel: Engine BucketDokumen32 halamanHydraulic Shovel: Engine BucketJulio CRBelum ada peringkat

- Additive Manufacturing - Question Bank With Answers - May 2023Dokumen13 halamanAdditive Manufacturing - Question Bank With Answers - May 2023Surya100% (2)

- MSDS - Fuel-Protect, Keep Clean Solution, For Diesel InjectorDokumen5 halamanMSDS - Fuel-Protect, Keep Clean Solution, For Diesel InjectorDaniel OlanoBelum ada peringkat