4906-w1 Guideline For Specification of Fracture Toughness of Line Pipe

Diunggah oleh

LorenaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

4906-w1 Guideline For Specification of Fracture Toughness of Line Pipe

Diunggah oleh

LorenaHak Cipta:

Format Tersedia

Engineering Standards

Standard

4906

Page

1 of 2

GUIDELINE FOR SPECIFICATION OF

FRACTURE TOUGHNESS OF LINE PIPE

Issue Date

Rev. No.

Date

1.

10/87

1

06/91

SCOPE

This standard provides guidelines for the specification of supplemental fracture toughness testing of line pipe, if

required, including the determination of the test parameters and acceptance criteria to be specified in Engineering

Standard 4905, Standard for Purchase of Line Pipe.

2.

CODES AND STANDARDS

American Petroleum Institute (API), Spec. 5L and RP 5L3

American Society for Testing and Materials (ASTM), A370

3.

GENERAL

3.1

It is desirable that the fracture toughness of line pipe be of a level sufficient to resist or arrest the

propagation of a ductile fracture of the pipe. The fracture toughness level may be specified in terms of

percent shear area and/or ft-lbs of absorbed energy as determined by Charpy impact tests or in percent

shear area for drop-weight-tear tests. Charpy impact testing is the more commonly used method of

determining fracture toughness of pipe and absorbed energy should be used as the acceptance criteria

while percent shear area should be reported for informational purposes only to assure ductile behavior.

3.2

Supplemental fracture toughness testing should be specified for the purchase of pipe in cases in which all

of the following conditions are met.

3.2.1

Pipe grade is X-42 or higher,

3.2.2

Pipe diameter is 10-3/4 inches or greater,

3.2.3

The minimum design temperature of the pipe is not significantly above typical cross-country

pipeline operating temperature.

3.2.4

The pipe to be purchased is of sufficient quantity (150 tons or greater) to make supplemental

fracture toughness requirements practical and the installed location and length will be such

that the risk of propagation of a ductile fracture in the pipeline is unacceptable.

4.

TEST REQUIREMENTS

4.1

Charpy V-Notch Impact Test (SR5)

When specified on the specification sheet in the standard for purchase, the pipe manufacturer is to

perform Charpy impact tests in accordance with API 5L, SR5. The following test requirements should

also be specified on the specification sheet.

4.1.1

The specimens should be tested at 32F.

4.1.2

The average shear value of the fracture appearance of the three (3) specimens per SR5A

should not be less than 60% and the all-heat average for each order per diameter, size and

grade should not be less than 80%.

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4906

Page

2 of 2

GUIDELINE FOR SPECIFICATION OF

FRACTURE TOUGHNESS OF LINE PIPE

Issue Date

Rev. No.

Date

4.1.3

10/87

1

06/91

Minimum acceptance criteria for absorbed energy should be 26 foot-pounds or the energy

calculated from the formula below, whichever is greater.

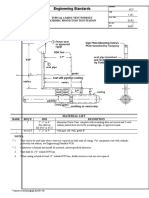

CVN = 0.0108 (DF x SMYS)2 (_D/2 x t)1/3,

where

CVN =

DF

=

SMYS =

D

t

=

=

full-size Charpy V-notch absorbed energy (ft-lbs),

design factor (fraction of SMYS),

specified minimum yield strength (thousands of pounds per square

inch - ksi),

pipe outside diameter (inches),

pipe wall thickness (inches).

4.1.4

When multiple heats or lots are involved, the minimum average of three samples from any

one heat or lot (heat minimum) should be no less than 80% of the minimum all-heat

average (CVN) determined above.

4.1.5

The largest Charpy sample size (full-size, 2/3 or 1/2) obtainable from the pipe wall shall

be used. When it is not possible to obtain full size samples, the CVN required will be that

calculated above multiplied by the Charpy size fraction.

4.2

Drop-Weight-Tear Test (SR6)

When specified on the specification sheet in the standard for purchase, the pipe manufacturer is to

conduct drop-weight-tear tests in accordance with API 5L, SR6, to determine fracture toughness. A heat

minimum shear area of 50% and an all heat minimum average shear area of 75% should also be

specified on the specification sheet.

* Indicates revised paragraph, this Rev. No.

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Yamaha Ef2800iDokumen45 halamanYamaha Ef2800ik barron0% (1)

- Astm F1506-22 PDFDokumen12 halamanAstm F1506-22 PDFEnrique Valdez ArévaloBelum ada peringkat

- Fire Ratings of Masonry Walls - tcm68-1374563Dokumen3 halamanFire Ratings of Masonry Walls - tcm68-1374563ervikas34Belum ada peringkat

- XYLEM Water PumpsDokumen268 halamanXYLEM Water PumpsKamal DeshapriyaBelum ada peringkat

- SAVANNAHSPASDokumen29 halamanSAVANNAHSPASeriechris80% (5)

- Guidelines For Enhancing Power Plant Response To Partial Load RejectionsDokumen4 halamanGuidelines For Enhancing Power Plant Response To Partial Load RejectionsManahan SinagaBelum ada peringkat

- 4780-w8 Selection and Design of Branch Connections and ReinforcementDokumen8 halaman4780-w8 Selection and Design of Branch Connections and ReinforcementLorenaBelum ada peringkat

- Series 1500 Cooling Tower SpecificationDokumen9 halamanSeries 1500 Cooling Tower SpecificationLorenaBelum ada peringkat

- 4802-w2 Concrete Anchor Block - Installation DetailsDokumen2 halaman4802-w2 Concrete Anchor Block - Installation DetailsLorenaBelum ada peringkat

- 4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineDokumen1 halaman4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineLorenaBelum ada peringkat

- 4910-w1 Engineering Guideline For Flexible Metal HoseDokumen1 halaman4910-w1 Engineering Guideline For Flexible Metal HoseLorenaBelum ada peringkat

- 4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSDokumen2 halaman4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSLorenaBelum ada peringkat

- 4762-w0 Typical Canal Undercrossing, Lined or UnlinedDokumen1 halaman4762-w0 Typical Canal Undercrossing, Lined or UnlinedLorenaBelum ada peringkat

- 4760-w0 Typical Stream or Ditch Pipeline UndercrossingDokumen1 halaman4760-w0 Typical Stream or Ditch Pipeline UndercrossingLorena100% (1)

- 4776 Subsea Pipeline CrossingDokumen4 halaman4776 Subsea Pipeline CrossingLorenaBelum ada peringkat

- 4737-w2 Typical Casing Vent Without Junction Box AssemblyDokumen1 halaman4737-w2 Typical Casing Vent Without Junction Box AssemblyLorenaBelum ada peringkat

- 4758-w0 Restoration of TerracesDokumen1 halaman4758-w0 Restoration of TerracesLorenaBelum ada peringkat

- 4910-w1 Engineering Guideline For Flexible Metal HoseDokumen1 halaman4910-w1 Engineering Guideline For Flexible Metal HoseLorenaBelum ada peringkat

- 4861 Gathering System - Type 10 Drip For 4,6 & 8 Gathering Lines-Dwg Available From Eng. RecordsDokumen2 halaman4861 Gathering System - Type 10 Drip For 4,6 & 8 Gathering Lines-Dwg Available From Eng. RecordsLorenaBelum ada peringkat

- 4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)Dokumen3 halaman4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)LorenaBelum ada peringkat

- RE18306-01 - 2018-12 - Gruppo 05Dokumen82 halamanRE18306-01 - 2018-12 - Gruppo 05Giovanni TrinidadBelum ada peringkat

- Materiales Serie XL PDFDokumen1 halamanMateriales Serie XL PDFcarolina PortocarreroBelum ada peringkat

- Blueprint Job Description PDFDokumen1 halamanBlueprint Job Description PDFTaufiq RabbaniBelum ada peringkat

- Chapter-8 ElectrolysisDokumen4 halamanChapter-8 ElectrolysisOhi AhmedBelum ada peringkat

- Lincoln Composites: Fuel Tank Manufacturing, Testing, Field Performance, and CertificationDokumen26 halamanLincoln Composites: Fuel Tank Manufacturing, Testing, Field Performance, and CertificationsajawalBelum ada peringkat

- Hot Work PermitDokumen17 halamanHot Work Permituday0% (1)

- Advanced Lattice Support Structures For Metal Additive ManufacturingDokumen8 halamanAdvanced Lattice Support Structures For Metal Additive Manufacturinghadi32Belum ada peringkat

- Replacing Downdraft Kiln With Chamber Kiln in A Refractory IndustryDokumen2 halamanReplacing Downdraft Kiln With Chamber Kiln in A Refractory IndustryKauser ImamBelum ada peringkat

- Wiper BladeDokumen3 halamanWiper Bladeghyd artiagaBelum ada peringkat

- China Display 2011 Kevin Long FINALDokumen29 halamanChina Display 2011 Kevin Long FINALPedro ReynosoBelum ada peringkat

- Knauf Sheetrock Firestop 12.5mm-16mm - Technical Datasheet - PB02 - LE - FL - 0422 - V1Dokumen2 halamanKnauf Sheetrock Firestop 12.5mm-16mm - Technical Datasheet - PB02 - LE - FL - 0422 - V1Matt WilliamsBelum ada peringkat

- Cryo CarDokumen21 halamanCryo CarAnup PatilBelum ada peringkat

- Jeta MSDS PDFDokumen9 halamanJeta MSDS PDFjose RujanoBelum ada peringkat

- Eml 5233 HWK #6Dokumen3 halamanEml 5233 HWK #6jack dealerBelum ada peringkat

- NetSure 212 C23 User Manual V1.0 20130617 PDFDokumen23 halamanNetSure 212 C23 User Manual V1.0 20130617 PDFdasha100% (1)

- Startbucks Mini Case 8th April 2021Dokumen9 halamanStartbucks Mini Case 8th April 2021Nirvana ShresthaBelum ada peringkat

- Distillation Column Tray Selection & Sizing - 1 - Separation TechnologiesDokumen30 halamanDistillation Column Tray Selection & Sizing - 1 - Separation TechnologiesHuzefa Calcuttawala0% (1)

- Village of Fredonia Inspection Report 2015Dokumen16 halamanVillage of Fredonia Inspection Report 2015WGRZ-TV100% (1)

- RDT TEMPERATURE TRAINER ManualDokumen7 halamanRDT TEMPERATURE TRAINER ManualSHANKARBelum ada peringkat

- Zit 64 BVDokumen12 halamanZit 64 BVVT86Belum ada peringkat

- Exampro GCSE Chemistry: C3 Chapter 2 HigherDokumen26 halamanExampro GCSE Chemistry: C3 Chapter 2 HigherAref DahabrahBelum ada peringkat

- FlowLine Level Switch EchoSwitch LU74 LU77 LU78 ManualDokumen27 halamanFlowLine Level Switch EchoSwitch LU74 LU77 LU78 ManualPromagEnviro.comBelum ada peringkat

- SS Stub End Thickness CalculationDokumen1 halamanSS Stub End Thickness CalculationSrinivas KadivetiBelum ada peringkat

- Robinson Om ManualDokumen26 halamanRobinson Om ManualJualan ExhaustfanBelum ada peringkat