2399

Diunggah oleh

BAlaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

2399

Diunggah oleh

BAlaHak Cipta:

Format Tersedia

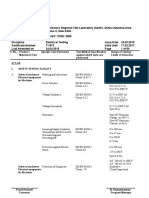

Laboratory

Central Power Research Institute, Prof. Sir C.V. Raman Road,

Sadashivnagar P.O., Bangalore, Karnataka

Accreditation Standard

ISO/IEC 17025: 2005

Discipline

Certificate Number

Last Amended on

Chemical Testing

T-0008

26.06.2015

S. No. Product /

Material of Test

I.

LUBRICANTS

1.

Inhibited &

Un-Inhibited

Mineral

Insulating Oil,

Turbine Oil,

Hydraulic Oil

2.

Turbine Oil

Hydraulic Oil

Turbine Oil

Hydraulic Oil

Rajeshwar Kumar

Convenor

Issue Date

Valid Until

Page

10.06.2015

09.06.2017

1 of 5

Specific Test Performed

Test Method Specification

against which tests are

performed

Range of Testing /

Limits of Detection

Appearance

IS 335: 1993 (RA 2010) Cl. 6.0

IEC 60296: 12 Cl.6.6

ASTM D 4176: 14

Qualitative

(Visual)

Density

IS 1448 (Part 16): 1990 (RA 2013)

ISO 3675: 1998

ASTM D 1298: 12b

0.80 g/ml to 0.90 g/ml

Kinematic viscosity at 27 C,

40 C 100 C & (-)30 C

IS 1448 (Part 25): 1976 (RA 2013)

ISO 3104: 1994

ASTM D 445: 15

2 cSt to 2000 cSt

Neutralization value(Total Acidity)

IS 1448 (Part 2): 2007 (RA 2013)

ISO 6619: 1988

IEC 62021-1: 2003

ASTM D 664: 2011a

0 to 2.0 mg KOH/g

Oxidation Stability by RPVOT

IS12958: 90 (RA 2011)

ASTM D 2272: 14a

100 min to 3000 min

Pour Point

ISO 3016: 1994

ASTM D 97: 2012

(-) 50 C to 10 C

Viscosity Index

IS 1448 (Part 56): 2013

ASTM D 2270: 2010

ISO 2909: 2002

50 to 200

Flash and Fire Point

IS 1448 (Part 69): 2013

ASTM D 92: 12a

80 C to 400 C

Water content by KF

Potentiometric method

ASTM D 4377: 11

0 to 2 % wt

Colour

ASTM D 1500: 12

0.05 to 8

Foaming Characteristics

After 5 Min

ASTM D892: 13

IS 1448 (Part 67): 2011

10 ml to 1000 ml

N. Venkateswaran

Program Manager

Laboratory

Central Power Research Institute, Prof. Sir C.V. Raman Road,

Sadashivnagar P.O., Bangalore, Karnataka

Accreditation Standard

ISO/IEC 17025: 2005

Discipline

Certificate Number

Last Amended on

Chemical Testing

T-0008

26.06.2015

S. No. Product /

Material of Test

3.

Inhibited & UnInhibited Mineral

Insulating Oil

Inhibited & UnInhibited Mineral

Insulating Oil

10.06.2015

09.06.2017

2 of 5

Specific Test Performed

Test Method Specification

against which tests are

performed

After 10 Min

Amendment 1

Water separability Time

Volume of Water

Volume of Oil

Volume of Emulsion

ASTM D 1401: 12

IS 1448 (Part 91): 2013

Demulsibility/ Emulsion

Characteristics

Total Free Water

Water in Oil

Emulsion

ASTM D2711: 11

Rust Prevention

Characteristics

ASTM D665: 14

IS 1448 (Part 96): 2013

Qualitative

(Rusted /Rust Free)

Copper Strip Corrosion

ASTM D130: 12

IS 1448 (Part 15): 2011

ISO 2160: 1998

Slight Tarnish to

Corrosion (1A to 4C)

Air Release Value

ASTM D3427: 14

IS 1448 (Part 102): 2013

0 to 30 min

Trace Sediment

ASTM D 2273: 12

0 to 0.05 % vol.

Interfacial Tension

IS 6104: 1971 (RA 2011)

ASTM D 971: 12

0 to 80 mN/m

Flash Point

IS 1448 (Part 21): 1992 (RA 2012)

ISO 2719: 2002

ASTM D 93: 02a

IS 335: 1993 (RA 2010) Annex C

IEC 61125: 1992

IS 12422: 1988 (RA 2013)

40 C to 360 C

DIN 51353: 1985

ASTM D 1275: 2006

IEC 62535: 2008

Qualitative

(Visual)

Oxidation StabilityTotal Acidity

Total Sludge

DDF at 90 C

Corrosive Sulphur

Rajeshwar Kumar

Convenor

Issue Date

Valid Until

Page

Range of Testing /

Limits of Detection

0 to 30 min

0 to 40 ml

0 to 40 ml

0 to 80 ml

0 to 45 ml

0 to 2 ml

0 to 1 ml

0 to 25 mg KOH/g

0 to 5.0 % wt

0.00001 to 9.9

N. Venkateswaran

Program Manager

Laboratory

Central Power Research Institute, Prof. Sir C.V. Raman Road,

Sadashivnagar P.O., Bangalore, Karnataka

Accreditation Standard

ISO/IEC 17025: 2005

Discipline

Certificate Number

Last Amended on

Chemical Testing

T-0008

26.06.2015

S. No. Product /

Material of Test

Inhibited & UnInhibited Mineral

Insulating Oil

Rajeshwar Kumar

Convenor

Issue Date

Valid Until

Page

10.06.2015

09.06.2017

3 of 5

Specific Test Performed

Test Method Specification

against which tests are

performed

Ageing characteristics

Total Acidity

DDF at 90 C

Resistivity 27 C

Resistivity 90 C

Total Sludge

IS 12177: 1987 (RA 2013)

Method A

Presence of Oxidation

Inhibitor

(Phenolic type oxidation

inhibitor)

IS13631: 2000 (RA 2013)

IEC 60666: 10

Qualitative

(Present or Absent)

0 to 1 %

Water Content by KF

Coulometric method

IS 13567: 1992 (RA 2013)

IEC 60814: 1997

0 to 35000 mg/kg

PCB Content

IEC 61619 : 1997

0 to 30 mg/kg

2 Furfural and related

compounds

IEC 61198 : 1993

0 to 30,000 g/kg

Potentially Corrosive Sulphur

IEC 62535 : 2008

Qualitative

(Non Corrosive to

Corrosive)

DBDS

IEC 62697-1: 2012

1 mg/kg to 2000 mg/kg

Metal Passivator Additives

IEC 60666: 2010 Annex B

0 to 10 mg/kg

Dissolved Gas Analysis

IS 9434: 1992 (RA 2013)

IEC 60567: 2011

IS 10593: 2006 (RA 2011)

IEC 60599: 1999

Methane

Ethane

Ethylene

Acetylene

Hydrogen

Carbon Monoxide

Carbon Di Oxide

Oxygen

Nitrogen

Range of Testing /

Limits of Detection

0 to 2.0 mg KOH/g

0.00001 to 9.9

109 cm to 1016 cm

109 cm to 1016 cm

0 to 5.0 % by wt

0 to 25,000 mg/kg

0 to 25,000 mg/kg

0 to 25,000 mg/kg

0 to 25,000 mg/kg

0 to 25,000 mg/kg

0 to 25,000 mg/kg

0 to 25,000 mg/kg

0 to 2,10,000 mg/kg

0 to 7,90,000 mg/kg

N. Venkateswaran

Program Manager

Laboratory

Central Power Research Institute, Prof. Sir C.V. Raman Road,

Sadashivnagar P.O., Bangalore, Karnataka

Accreditation Standard

ISO/IEC 17025: 2005

Discipline

Certificate Number

Last Amended on

Chemical Testing

T-0008

26.06.2015

S. No. Product /

Material of Test

4.

Issue Date

Valid Until

Page

10.06.2015

09.06.2017

4 of 5

Specific Test Performed

Test Method Specification

against which tests are

performed

Range of Testing /

Limits of Detection

Gassing Tendency

IS 12475 (Part 1): 1988 (RA 2013)

IEC 60628: 1985 Method A

(-)16.66 mm3/min to

(+)33.33 mm3/min

Sediment & sludge

IS 1866: 00 (RA 2010) Annex. A

IEC 6042: 2013-01 Annex. C

0 to 1.0 % by wt.

Carbon Type Analysis (PNA)

CA

CP

CN

IS13155: 1991 (RA 2011)

IEC 60590: 1977

Total Sulphur content

ISO 14596: 2007

0 to 25000 mg/kg

PCA Content

IP 346: 1992

0 to 10 %

Electric Strength

IS 6792: 1972 (RA 2013)

IEC 60156: 1995

5 kV to 100 kV

Dielectric Dissipation Factor

IS 6262: 1971 (RA 2011)

IEC 60247: 2004

0.00001 to 9.9

Inhibited & UnInhibited Mineral

Insulating Oil

Specific Resistance

(Resistivity)

IS 6103: 1971 (RA 2011)

IEC 60247: 2004

At 90 C:

109 cm to 1016 cm

At 27 C:

109 cm to 1016 cm

Polymeric

Materials

Glass Transition

ASTM D 3418: 12e

30 C to 700 C

Melting Temperature by DSC

ASTM D 3417: 83

30 C to 700 C

Thermal AnalysisDecomposition by TGA

(Upto 1000 C)

ASTM D 3850: 94

0 to 100 % wt.

Coefficient of Linear Thermal

Expansion by TMA

ASTM E 831: 14

0 to 2500 m/m C

Rajeshwar Kumar

Convenor

0 to 100 %

0 to 100 %

0 to 100 %

N. Venkateswaran

Program Manager

Laboratory

Central Power Research Institute, Prof. Sir C.V. Raman Road,

Sadashivnagar P.O., Bangalore, Karnataka

Accreditation Standard

ISO/IEC 17025: 2005

Discipline

Certificate Number

Last Amended on

Chemical Testing

T-0008

26.06.2015

S. No. Product /

Material of Test

Specific Test Performed

Issue Date

Valid Until

Page

10.06.2015

09.06.2017

5 of 5

Test Method Specification

against which tests are

performed

Range of Testing /

Limits of Detection

IS 10810 (Part 59): 1988

IEC 60754-1: 2011

0 to 1 % by wt.

Moisture Content

ASTM D 7582-12

0.1 % to 70 %

Volatile Matter

ASTM D 7582-12

0.1 % to 70 %

Ash Content

ASTM D 7582-12

0.1 % to 70 %

Fixed Carbon

ASTM D 7582-12

By difference

Gross Calorific Value

ASTM D 5863-13

3000 cal/g to 8000 cal/g

for 1 g sample

Carbon

ASTM D 5373-14

0.1 % to 95 %

Hydrogen

ASTM D 5373-14

0.1 % to 20 %

Nitrogen

ASTM D 5373-14

0.1 % to 20 %

Sulphur

ASTM D 4239-14

0.2 % to 20 %

(Upto 900 C)

Halogen Acid Test

II.

COAL, COKE & OTHER SOLID FUEL

1.

Coal and Coke

Coal and Coke

-X-X-X-X-X-X-X-X-X-X-X-X-X-X-

Rajeshwar Kumar

Convenor

N. Venkateswaran

Program Manager

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Excel Tool Process Audit Services VDA 6.3 2016 en V1.0Dokumen12 halamanExcel Tool Process Audit Services VDA 6.3 2016 en V1.0Roberto Barbosa100% (1)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Stress Management PolicyDokumen12 halamanStress Management PolicyBAla100% (1)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- 247 0 Coating Brochure Web-EnDokumen36 halaman247 0 Coating Brochure Web-EnjorgeBelum ada peringkat

- External issue registerDokumen1 halamanExternal issue registerBAlaBelum ada peringkat

- Sample RecordsDokumen2 halamanSample RecordsBAlaBelum ada peringkat

- Experiments (tutorial)Dokumen24 halamanExperiments (tutorial)BAlaBelum ada peringkat

- Supreme Court To Centre - Pet Coke, Furnace Oil Main Causes of Pollution in Delhi-NCR, Must Be Banned - Mail Today, News - India TodayDokumen4 halamanSupreme Court To Centre - Pet Coke, Furnace Oil Main Causes of Pollution in Delhi-NCR, Must Be Banned - Mail Today, News - India TodayBAlaBelum ada peringkat

- Mobile Devices Policy 2015 FinalDokumen30 halamanMobile Devices Policy 2015 FinalBAlaBelum ada peringkat

- Scope-CC-3390Dokumen6 halamanScope-CC-3390BAlaBelum ada peringkat

- Int_Cal_WrkDokumen16 halamanInt_Cal_WrkBAlaBelum ada peringkat

- Sample Collection Procedure (HM)Dokumen1 halamanSample Collection Procedure (HM)BAlaBelum ada peringkat

- DocumentDokumen90 halamanDocumentBAlaBelum ada peringkat

- Standard Operating Procedure Index - Food Hygiene & SafetyDokumen1 halamanStandard Operating Procedure Index - Food Hygiene & SafetyBAlaBelum ada peringkat

- FM ENV 015 Land Development and Buildings - Envtal MGTDokumen29 halamanFM ENV 015 Land Development and Buildings - Envtal MGTBAlaBelum ada peringkat

- HSE Hazard Identification SheetDokumen1 halamanHSE Hazard Identification SheetBAlaBelum ada peringkat

- 1436Dokumen7 halaman1436BAlaBelum ada peringkat

- FSSCDokumen2 halamanFSSCBAlaBelum ada peringkat

- 442Dokumen54 halaman442BAlaBelum ada peringkat

- 5095Dokumen2 halaman5095BAlaBelum ada peringkat

- Z Score Altman Z Score TemplateDokumen2 halamanZ Score Altman Z Score TemplateIbrahimKariadiBelum ada peringkat

- 2b. Publicly Available SMETA CAPR Template 10112015Dokumen11 halaman2b. Publicly Available SMETA CAPR Template 10112015BAlaBelum ada peringkat

- 2417Dokumen5 halaman2417BAlaBelum ada peringkat

- Stakeholder AnalysisDokumen4 halamanStakeholder AnalysisBAlaBelum ada peringkat

- MRM AgendaDokumen2 halamanMRM AgendaBAlaBelum ada peringkat

- Layer Process AuditDokumen8 halamanLayer Process AuditBAlaBelum ada peringkat

- C 012760Dokumen14 halamanC 012760BAlaBelum ada peringkat

- Issue RegisterDokumen2 halamanIssue RegisterBAla100% (1)

- OM-UK-0511 SolarDokumen6 halamanOM-UK-0511 SolarCarlos BenavidesBelum ada peringkat

- 5095Dokumen2 halaman5095BAlaBelum ada peringkat

- Axter General Solar PV Inspection and Routine Maintenance GuideDokumen4 halamanAxter General Solar PV Inspection and Routine Maintenance GuideBAlaBelum ada peringkat

- Wheel Alignment SpecificationsDokumen15 halamanWheel Alignment SpecificationsBAla0% (1)

- PMTC Guidance on Cleaning Validation PracticeDokumen15 halamanPMTC Guidance on Cleaning Validation PracticehhBelum ada peringkat

- AtropineDokumen4 halamanAtropinePark EyzBelum ada peringkat

- Cablofil Catalog2014Dokumen116 halamanCablofil Catalog2014Gustavo Montalvo MoralesBelum ada peringkat

- LUBRIZOLr 16005 (English) (PDS)Dokumen2 halamanLUBRIZOLr 16005 (English) (PDS)Sameh Radwan100% (1)

- MSDS Dynamic DescalerDokumen4 halamanMSDS Dynamic DescalerEurotech Tra TranBelum ada peringkat

- Bitter PrinciplesDokumen6 halamanBitter PrinciplesPankaj BudhlakotiBelum ada peringkat

- Ruchi Soya Project ReportDokumen45 halamanRuchi Soya Project ReportAnkita Toshniwal75% (4)

- For The Steam and Condensate Loop - 01Dokumen4 halamanFor The Steam and Condensate Loop - 01zoraze32Belum ada peringkat

- Improve Salt Purity With New Washery UnitDokumen7 halamanImprove Salt Purity With New Washery UnitABelum ada peringkat

- Fosroc Structuro W435: Constructive SolutionsDokumen2 halamanFosroc Structuro W435: Constructive SolutionsVincent JavateBelum ada peringkat

- Types of Fuels and Their Characteristics for Internal Combustion EnginesDokumen26 halamanTypes of Fuels and Their Characteristics for Internal Combustion EnginesMuhammad HarisBelum ada peringkat

- BSC2011 Animals Exam 2 ReviewDokumen72 halamanBSC2011 Animals Exam 2 ReviewDan TranBelum ada peringkat

- Multistage Boiler Feed Water PumpDokumen12 halamanMultistage Boiler Feed Water Pumpbalaji_jayadeva9546100% (1)

- Kami Export - Physical and Chemical Changes WorksheetDokumen2 halamanKami Export - Physical and Chemical Changes WorksheetTheo MillsBelum ada peringkat

- Class XI Chemistry Unit-8 Redox Reactions: TopicDokumen60 halamanClass XI Chemistry Unit-8 Redox Reactions: TopicBaljit Singh100% (1)

- VNM-IPGN-PPL-SPC-EDG-0000-00019-00-G03 FBE SpecDokumen29 halamanVNM-IPGN-PPL-SPC-EDG-0000-00019-00-G03 FBE SpecĐiệnBiênNhâm100% (1)

- Glucose Oxidase Effect On Dough Rheology and Bread QualityDokumen8 halamanGlucose Oxidase Effect On Dough Rheology and Bread Qualitym_luchianBelum ada peringkat

- Use of Phosphates in Meat ProductsDokumen9 halamanUse of Phosphates in Meat ProductsNabil SouissiBelum ada peringkat

- Chapter IDokumen24 halamanChapter ICrystaelechanBelum ada peringkat

- Piht0f402 Icmts Icad600tsDokumen2 halamanPiht0f402 Icmts Icad600tsamruta21Belum ada peringkat

- Cat DapusDokumen2 halamanCat DapushaidirBelum ada peringkat

- Spartan 14 ManualDokumen570 halamanSpartan 14 ManualDavor ŠestanBelum ada peringkat

- ABB CorrosionDokumen8 halamanABB CorrosionForexFFBelum ada peringkat

- Quality Improvement of Argeli Paper (Edgeworthia Gardneri) Through Improved TechnologyDokumen5 halamanQuality Improvement of Argeli Paper (Edgeworthia Gardneri) Through Improved TechnologykhilendragurungBelum ada peringkat

- Banana Peels As Paper Final OutputDokumen20 halamanBanana Peels As Paper Final OutputA - CAYAGA, Kirby, C 12 - HermonBelum ada peringkat

- Helical Twisted Roots Pump E00636Dokumen10 halamanHelical Twisted Roots Pump E00636Ade Bagus SetiawanBelum ada peringkat

- Research Article: Synthesis of New Benzofuran-2-Carboxylic Acid DerivativesDokumen8 halamanResearch Article: Synthesis of New Benzofuran-2-Carboxylic Acid Derivativesfatriani smakBelum ada peringkat

- Lab 3 HysysDokumen8 halamanLab 3 HysysZulhafizi Kamaruddin100% (2)

- Softwood and Hardwood in Dissolving PulpDokumen126 halamanSoftwood and Hardwood in Dissolving PulpAlan KurniawanBelum ada peringkat