P4a-MT-103, Rev.3

Diunggah oleh

Hatem RagabJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

P4a-MT-103, Rev.3

Diunggah oleh

Hatem RagabHak Cipta:

Format Tersedia

8740 Pie IX Blvd.

,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

P4a-MT-103

Rv. 3

MAGNETIC PARTICLE TESTING

MAGNETIC PARTICLE TESTING

FOR

ASME CODE OF WORKS

PREPARED BY:

Stphane Grimard, Level II

APPROVED BY:

Robert Desautels, Level III

2010-12-15

Page 1 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

P4a-MT-103

Rv. 3

2010-12-15

Page 2 of 67

CERTIFICATION STATEMENT

We hereby certify that procedure P4a-MT-103 rev. 3, meets the requirements

of ASME Section V. Edition 2010.

LABORATOIRE D'ESSAI MEQUALTECH

_____________________

Robert Desautels

SNT-TC-1A, Level III

2010-12-15

Date

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

P4a-MT-103

Rv. 3

MAGNETIC PARTICLE TESTING

DEMONSTRATION STATEMENT

We hereby certify that this is procedure number P4a-MT-103 rev. 3

has been demonstrated as required by art. T-150 of that same

Section.

LABORATOIRE D'ESSAI MEQUALTECH INC.

_______________________

Robert Desautels

SNT-TC-1A, Level III

2010-12-15

Date

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

2010-12-15

Page 3 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

P4a-MT-103

Rv. 3

2010-12-15

Page 4 of 67

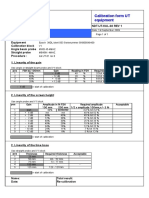

TABLE OF REVISION

DATE

REV.NO.

CHANGE MADE

REVISED/APPROVED BY

2007/12/01

Original

______________________

Robert Desautels Level III

2008-06-27

Addendum 2008; Supplement 3 & 4.

______________________

Robert Desautels Level III

2010-03-16

General Revision.

______________________

Robert Desautels Level III

2010-12-15

Art.8.7

______________________

Robert Desautels Level III

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

APPLICATION

BUILDINGS

BRIDGES

TRANSMISSION PIPELINES

PRESSURE VESSELS

BOILERS

HEAT EXCHANGERS

FABRICATED PIPE

SHIPS

STORAGE TANKS

MACHINERY

TANK CARS AND TANK TRUCKS

PENSTOCKS, SCROLL CASES

WATER TURBINESGATES AND APPURTENANCES

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 5 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

P4a-MT-103

Rv. 3

2010-12-15

Page 6 of 67

TABLE OF CONTENTS

CERTIFICATION STATEMENT .......................................................................................................... 2

DEMONSTRATION STATEMENT ..................................................................................................... 3

TABLE OF REVISION .......................................................................................................................... 4

APPLICATION ....................................................................................................................................... 5

TABLE OF CONTENTS ....................................................................................................................... 6

1. INTRODUCTION ........................................................................................................................... 7

2. SCOPE ........................................................................................................................................... 7

3. REFERENCE DOCUMENTS ...................................................................................................... 7

4. PERSONNEL QUALIFICATIONS .............................................................................................. 8

5. GENERAL ...................................................................................................................................... 8

6. SURFACE PREPARATION AND CLEANING ......................................................................... 9

7. EXAMINATION MEDIUM .......................................................................................................... 10

8. BATH CONCENTRATION AND CONTAMINATION CHECK ............................................. 12

9. PRELIMINARY EXAMINATION................................................................................................ 12

10. METHODS ................................................................................................................................... 13

11. DEMAGNETIZATION ................................................................................................................. 15

12. POST-CLEANING ....................................................................................................................... 15

13. DEFINITION OF INDICATIONS ............................................................................................... 16

14. INTERPRETATION .................................................................................................................... 16

15. EVALUATION OF INDICATIONS ............................................................................................ 16

16. RECORDING OF INDICATIONS ............................................................................................. 16

17. REPORTING................................................................................................................................ 17

18. Annexes ........................................................................................................................................ 18

TABLE OF CONTENT OF SUPPLEMENT ..................................................................................... 22

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

P4a-MT-103

Rv. 3

MAGNETIC PARTICLE TESTING

1.

2.

2010-12-15

Page 7 of 67

INTRODUCTION

1.1.

Magnetic particle examination applies to the detection of discontinuities on welds,

forgings, casting wrought materials and other ferromagnetic materials. This method is

limited to the detection of discontinuities open or near the surface of ferromagnetic

materials.

1.2.

It is applicable to ferromagnetic materials on any shape or size used in fabrication and

maintenance, of components listed on the cover sheet.

1.3.

This magnetic particle examination procedure shall be used when ASME Codes

applies or is specified as reference.

SCOPE

2.1.

This magnetic particle examination procedure describes the methods and techniques

to be used whenever magnetic particle examination is specified, to ensure that the

requirements of the applicable Codes, customers specification and other Standards

are fulfiled.

2.2.

This procedure covers the following magnetic particles techniques:

1- Yoke with dry and wet both non-fluorescent and fluorescent particle

2- Prod with dry particle

3.

REFERENCE DOCUMENTS

This magnetic particle examination procedure is written in accordance with the following

Codes and Standards:

-

ASME SECT. V

ASME SECT. VIII div. 1 app. 6

ASME SECT. VIII div. 2 app. 1

ASME SECT. I

ASME/ANSI B31.1

ASME/ANSI B31.3

API 650

ASTM E 709

ASNT-TC-1A edition 2006

CAN/CGSB-48.9712-2006

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

3.1.

P4a-MT-103

Rv. 3

2010-12-15

Page 8 of 67

PROCEDURE QUALIFICATION

When procedure qualification is specified, a change of a requirement in Table T-721

identified as an essential variable from the specified value, or range values, shall

require requalification of the written procedure. A change of a requirement identified as

a nonessential variable from the specified value, or range of values, does not require

requalification of the written procedure. All changes of essential or nonessential

variable from the value, or range of values, specified by the written procedure shall

require revision of, or an addendum to, the written procedure.

4.

5.

PERSONNEL QUALIFICATIONS

4.1.

Personnel performing inspection to this procedure shall be certified in accordance with

CAN/CGSB-48.9712-2006 and SNT-TC-1A edition 2006. Personnel shall also meet

paragraph. 6.2.3 of API 650.

4.2.

All test reports relating the complete magnetic particles examination and results must

be signed by a qualified technician Level II or Level III.

4.3.

An eyes test shall be performed annually as per art. 8.2 of the written practice P4aSNT-100,rev1

4.4.

The level III is certified as per art. 5.1 of the written practice P4a-SNT-100, rev1 and as

per art UW-54 (a) code ASME section VIII Division 1.

GENERAL

5.1.

The sensitivity of the method is greatest for surface discontinuities and diminishes

rapidly with depth below the surface.

5.2.

One hundred percent (100%) of the surface of the finished welds shall be examined.

Components sections (other than welds) shall be examined as required by the

governing Code section, and/or customer specifications.

5.3.

This method involves magnetizing an area to be examined, and applying ferromagnetic

particles (the examinations medium) to the surface. The particles will form patterns on

the surface where cracks and other discontinuities cause distortions in the normal

magnetic field. These patterns are usually characteristic of the type of discontinuity

that is detected.

5.4.

Whichever technique is used to produce the magnetic flux in the part, maximum

sensitivity will be to linear discontinuities oriented perpendicular to the lines of flux. For

optimum effectiveness in detecting all types of discontinuities, each area should be

examined at least twice, with the lines of flux during one examination approximately

perpendicular to the lines of flux during the other.

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

5.5.

6.

P4a-MT-103

Rv. 3

2010-12-15

Page 9 of 67

Surface discontinuity is indicated by accumulations of magnetic particle which should

contrast with the examination surface. The color of the magnetic particles shall be

sufficiently different than the color of the examination surface.

SURFACE PREPARATION AND CLEANING

6.1.

The surface may be in the as-welded, as-rolled, as-cast or as-forged condition.

However, irregularities shall be grinded or machined when the following conditions

occurs :

1

2

3

When they may mask discontinuities

When they might restrict particle movements

When they cause difficulty in the interpretations, because of mechanical

entrapment of the magnetic particles. In case of doubt, any questionable

area should be reconditioned and re-examined.

6.2.

Prior to magnetic particle examination, the surfaces to be inspected and adjacent area

(at least one inch on either side) shall be dry and free of all dirt, grease, lint, scale,

welding flux and spatter, oil or other extraneous matter that could interfere with the

examination.

6.3.

Cleaning may be accomplish using the following methods:

-

Detergent

Organic solvents

Decaling solutions

Paint removers

Vapour degreasing

Sand and grid blasting

Ultrasonic cleaning method

Mechanical or manual brushing

6.4.

If coating is left on the part in the area being examined, it must be demonstrated that

indications can be detected through the existing coating thickness applied. When AC

yoke technique is used on ferretic coated material a procedure shall be written

according to appendix 1 of art. 7 of ASME code Section V.

6.5.

Nonmagnetic surface contrast may be applied by the examiner to uncoated surfaces,

only in amounts sufficient to enhance particle contrast. When nonmagnetic surface

contrast enhancement is used, it shall be demonstrated that indications can be

detected through the enhancement. Thickness measurement of this nonmagnetic

surface contrast enhancement neither is nor required.

6.6.

If nonmagnetic coatings are left on the part in the area being examined, it shall be

demonstrated that indications can be detected through the existing maximum coating

thickness applied.

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

7.

P4a-MT-103

Rv. 3

2010-12-15

Page 10 of 67

EXAMINATION MEDIUM

7.1. Dry Particles

7.1.1. The dry particles may be applied on the surface to be examined, by spraying or

dusting from bulb applicators.

7.1.2. Excess of dry particle shall be removed with a light air stream from a bulb or

syringe providing low pressure dry air. The current shall be maintained while

removing the excess of particles.

7.1.3. The colour of the particles shall provide adequate contrast with the background

of the surface being examined

7.1.4. Magnetic particles may be used in the red, black, yellow or gray colours. The

colour given the better contrast shall be chosen.

7.1.5. The powder shall be dry to permit ease of application.

7.1.6. Magnetic particle examination shall not be performed on the parts surface

where temperature exceeds 600F (316C).

7.2. Wet non fluorescent particles.

7.2.1. The colour of the particles shall provide adequate contrast with the surface

being examined.

7.2.2. The particles shall be suspended in a vehicle such as water or light petroleum,

distillate the concentration of the particles shall be maintained between 1.2 to

2.4 ml. The instructions of the manufacturer shall be followed for the choice of

suspended medium and mixing when they are supplied as dry or post

concentration.

7.2.3. The concentration of the batch shall be measured at the beginning of each shift

or before doing any inspection using a 100 ml. setting tube.

7.2.4. The wet particles may be applied on the surface to be examined by spraying

bottle, air pressure can or from an aerosol can. The container of the magnetic

liquor shall be thoroughly shaken before the first use and agitated frequently

during the time of examination.

7.2.5. The magnetizing current shall be turned on after the particles have been

applied.

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

P4a-MT-103

Rv. 3

MAGNETIC PARTICLE TESTING

2010-12-15

Page 11 of 67

7.2.6. The temperature of the wet particle suspension and the surface of the part shall

not exceed 135F (57C).

7.2.7. Ardrox 8031 or Magnaflux 7HF particles shall be used in black colour.

7.2.8. Ardrox 8901W or Magnaflux WCP-2 shall be used for white contrast paint.

7.3. Wet fluorescent particles

7.3.1. With fluorescent particles, the examination shall be performed using an

ultraviolet light. (Black light).

7.3.2. The particles shall be suspended in a vehicle such as water or light petroleum

distillate. The concentration of the particles shall be maintained between 0.1 to

0.4ml per 100ml of liquor.

7.3.3. The concentration of the magnetic liquor shall be measured as per art. 8.0

7.3.4. The application of the wet fluorescent particles shall be as per art. 7.2.4 and

7.2.5.

7.3.5. The temperature of the magnetic liquor and the surface to be examined shall be

as per art. 7.2.6.

7.3.6. The Ardrox No. 8800A, No. 8810L or Magnaflux 14AM fluorescent particles

shall be used.

7.3.7. The fluorescent particles examination shall be performed as follow :

-

The examination is to be conducted in a dark area.

The examiner shall be in the dark area for at least 5 minutes prior

performing the examination to enable its eyes to adapt to dark viewing.

If the examiner wears glasses or lenses, they shall not be

photosensitive or exhibit any fluorescence.

The black light shall be allowed to warm up for a minimum of 5 minutes

prior using or measuring the intensity of the black light. Reflectors,

filters, glasses, or lenses shall be checked and clean daily when in use.

Cracked or broken filters, reflectors, glasses, or lenses shall be

replaced immediately.

The black light intensity shall be measured with a black light meter. A

minimum of 1000 W/cm2 shall be required at 15" from the light lens

filter. It shall be measured at least once every 8 hours, and whenever

the work station or the bulb is changed and at the completion of the

examination or a series of examination.

The examination shall be conducted in a darkened area. The intensity of

ambient visible light shall not exceed 2 foot candles. (20 lux)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

8.

9.

P4a-MT-103

Rv. 3

2010-12-15

Page 12 of 67

BATH CONCENTRATION AND CONTAMINATION CHECK

8.1.

The container shall be thoroughly agitated to ensure thorough mixing of all particles in

the solutions.

8.2.

Take a 100ml portion of the suspension in the container to the centrifuge tube.

8.3.

Allow a settling time for approximately 60 min with petroleum distillate suspensions or

30 min with water-based suspensions.

8.4.

Read the volume settling out at the bottom of the tube.

8.5.

The concentration shall be as per art. 7.2.2 for non fluorescent particles and as per art.

7.3.2 for fluorescent particles.

8.6.

If the concentration is out of tolerance add particles or suspension vehicle, as required

and re-determine the particles concentration.

8.7.

The graduated portion of the tube shall be examined under fluorescent excitation light if

the bath is fluorescent and under visible light (for both fluorescent and nonfluorescent

particles) for striations or bands, differences in color or appearance. Bands or striations

may indicate contamination. If the total volume of the contaminates, including bands or

striations exceeds 30% of the volume magnetic particles, or if the liquid is noticeably

fluorescent, the bath shall be replaced.

8.8.

The contamination check shall be done every time that concentration check is made.

PRELIMINARY EXAMINATION

9.1.

Before the magnetic particle examination is conducted, a check of the examination

surface shall be conducted to locate any discontinuity surface openings which may not

attack and hold magnetic particles because of their width.

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

P4a-MT-103

Rv. 3

MAGNETIC PARTICLE TESTING

2010-12-15

Page 13 of 67

10. METHODS

10.1. Yoke method

10.1.1.

This method shall only be applied to detect discontinuities that are open to the

surface of the part.

10.1.2.

Electromagnetic yoke with AC or DC current shall be used.

10.1.3.

Magnetic particle examination shall be continuous. The current shall remain

on during the examination process including powder application. For wet

medium, remove the magnetism after and additional of 5 seconds.

10.1.4.

The examination shall be carried out in two directions on each area; in the

second examination, the line of magnetic flux shall be approximately

perpendicular to those used for the first examination in that area

10.1.5.

Coverage shall be such that the area being examined will ensure 100%

overlap or total coverage at the established test sensitivity.

10.1.6.

The minimum pole spacing shall be 3 inches and the maximum shall be the

pole spacing used for the calibration, but in no case more than 8 inches.

10.1.7.

The calibration of the equipment shall be carried out annually, after major

equipment repairs or whenever equipment has been damaged. If equipment

has not been in use for a year or more, a check shall be done prior to the first

use.

10.1.8.

For the calibration, each alternating current electromagnetic yoke shall have a

lifting power of at least 10 pounds at the maximum pole spacing that will be

used (in no case more than 8 inches).

10.1.9.

The DC Yoke shall have a lifting power of at least 50 pounds at the maximum

pole spacing that will be used (in no case more than 8 inches).

10.1.10. Each weight shall be weighed with a scale from a reputable manufacturer and

stencilled with the applicable nominal weight prior first use. A weight needs

only to be verified against damage in a manner that could have caused

potential loss of material.

10.1.11. Permanent magnet Yoke shall not be used.

NOTE: See technical data MT-01 attached to this procedure.

10.1.12. Yoke technique with fluorescent particles in an undarkened area is not

permitted.

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

P4a-MT-103

Rv. 3

2010-12-15

Page 14 of 67

10.2. Magnaflux field adequacy and direction.

When it is necessary to verify the adequacy of magnetic field strength, it shall be

verified by using pie-shaped magnetic particle field indicator (see figure 1). The

indication shall be positioned on the surface to be examined, such that the copperplated side is away from the inspected surface. A suitable field strength is indicated

when a clearly defined line(s) of magnetic particle form(s) across the copper face of the

indicator when the magnetic particle are applied simultaneously with the magnetizing

force. When a clearly defined line of particle is not formed, the magnetizing technique

shall be changed as needed.

10.3. Multidirectional Magnetisation

Multidirectional magnetisation technique is not permitted.

10.4. Requirement of Magnetic Examination procedure ( Table T721

from ASME sect V 2007 edition, Addendum 2009)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

P4a-MT-103

Rv. 3

2010-12-15

Page 15 of 67

Lighting for non-fluorescent particles

10.4.1.A minimum light intensity of 100 foot candle or (1000 LUX) is required to ensure

adequate sensitivity during the examination and evaluation of indications.

10.4.2.For the Yoke technique the following light shall be used :

See Supplement 5.

11. DEMAGNETIZATION

11.1.

When required by the client, or when residual magnetism in the part could interfere

with subsequent processing or usage, the part shall be demagnetized any time after

completion of the examination. Complete demagnetization is required.

12. POST-CLEANING

12.1.

When using dry particle post-cleaning is not required.

12.2.

When using wet particles, post-cleaning may be done at the customer and the

inspection companys discretion. When post-cleaning is required, it should be

conducted as soon as practical using a process that does not adversely affect the part.

12.3.

Medium shall be removed by wiping with a lint free cloth or absorbent paper repeating

the operation, until most traces of medium have been removed.

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

P4a-MT-103

Rv. 3

2010-12-15

Page 16 of 67

13. DEFINITION OF INDICATIONS

13.1.

Valid indication - All valid indications formed by magnetic particle examination are the

results of magnetic leakage field. Indication may be relevant or non relevant.

13.2.

Relevant indications - Relevant indications are produced by leakage fields which are

the result of discontinuities. Relevant indications require evaluation with regards of the

acceptance standard mentioned in art. 15.1 below.

13.3.

Non relevant indications - Non relevant indications can occur as a single or in patterns

as a result of leakage fields created by conditions that requires no evaluation such as

change in section (keyways, drill holes, etc.) inherent material properties, magnetic

writing, etc...

13.4.

False indications - False indications are not the results of magnetic forces. Examples

are; particles held mechanically or by gravity in shallow depressions or particles held

by rust or scale on the surface.

14. INTERPRETATION

14.1.

The interpretation shall identify if an indications is false, nonrelevant, or relevant. False

and non relevant indications shall be proven as false or nonrelevant.

14.2.

Interpretation shall be carried out to identify the locations of indications and the

character of the indication (see art. 17.1 of this procedure)

15. EVALUATION OF INDICATIONS

15.1.

All indications shall be evaluated in terms of the acceptance standards of the

referencing Code Section. See supplement 1 to 4 attached.

15.2.

Discontinuities at the surface are indicated by the retention of examination medium;

however, localised surface irregularities due to machining marks or other surface

conditions may produce false indications. Those areas shall be grinded and reexamined.

15.3.

Broad are particle accumulations which could mask indications of discontinuities are

unacceptable, and those areas shall be cleaned and re-examined.

16. RECORDING OF INDICATIONS

16.1.

Non rejectable indications shall be recorded as specified by the reference Code

Section.

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

P4a-MT-103

Rv. 3

2010-12-15

Page 17 of 67

16.2. Rejectable indications shall be recorded. As a minimum, the type of indications (linear

or rounded), location and extent (length or diameter or aligned) shall be recorded.

17. REPORTING

17.1.

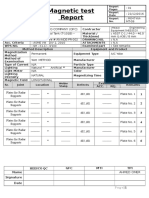

The inspection report shall include the followings :

1.

Customers name and address

2.

Procedure number, issued and revision

3.

Medium used (visible or fluorescent, wet or dry)

4.

Equipment and method used

5.

Method and magnetization

6.

Material and thickness

7.

Lighting equipment

8.

Job number and weld number if not 100%

9.

MT procedure reference (see exhibit 1 attached)

10. Identification of component

11. Drawing no. if available

12. Record indications

13. Standard used for acceptance

14. Results of examination

15. Examiners name and certification level

16. Date of examination.

See exhibit #1 attached to this procedure.

Note 1: Rejectable and non rejectable indication shall be recorded. As a minimum, the type of

indication (linear or rounded), location and extend (length or diameter or aligned shall

be recorded.

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

18. Annexes

FIGURE 1

MAGNETIC PARTICLE FIELD INDICATOR

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 18 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

TECHNIQUE MT-01

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 19 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

TECHNIQUE MT-02

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 20 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

REPORT SAMPLE

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 21 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

P4a-MT-103

Rv. 3

Page 22 of 67

TABLE OF CONTENT OF SUPPLEMENT

SUPPLEMENT 1

Acceptance Standard for ASME SECT. VIII div.1, app. 6

SECT.I & API 650

SUPPLEMENT 2

Acceptance Standard for Power Piping B31.1 and Section I.

SUPPLEMENT 3

Acceptance Standard for ASME SECT. VIII div. 2 app. 1

SUPPLEMENT 4

Acceptance Standard B31.3

SUPPLEMENT 5

Light Source Intensity Demonstration T-777.1

SUPPLEMENT 6

Procedure Demonstration (T-150)

SUPPLEMENT 7

Specimen of Flawtech

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

2010-12-15

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

P4a-MT-103

Rv. 3

2010-12-15

Page 23 of 67

SUPPLEMENT 1 (1/2)

ACCEPTANCE STANDARD FOR PRESSURE VESSEL

SECT. VIII DIV. 1 App.6 AND A.P.I. 650. Art 6.2.3

A) Evaluation of indication

An indication is the evidence of a mechanical imperfection. Only indications which have

any dimension greater than 1/16 in. shall be considered relevant.

B)

a)

A linear indication is one having a length greater than three times the width.

b)

A rounded indication is one of circular or elliptical shape with a length equal to

or less than three times its width.

c)

Any questionable or doubtful indications shall be re-examined to determine

whether or not they are relevant.

Acceptance standards

These acceptance standards shall apply unless other more restrictive standards are

specified for specific materials or applications within this Division.

All surfaces to be examined shall be free of:

a)

b)

c)

d)

C)

relevant linear indications;

relevant rounded indications greater than 3/16 in.;

four or more relevant rounded indications in a line separated by 1/16 in. or less,

edge to edge;

an indication of an imperfection may be larger than the imperfection that caused

it; however, the size of the indication is the basis for acceptance evaluation.

Treatment of indications believed non relevant

Any indication which is believed to be non relevant shall be regarded as an

imperfection unless it is shown by re-examination by the same method or by the use of

other non-destructive methods and/or by surface conditioning that no unacceptable

imperfection is present.

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

P4a-MT-103

Rv. 3

2010-12-15

Page 24 of 67

SUPPLEMENT 1 (2/2)

D)

Examination of areas from which imperfections have been removed. After a defect is

thought being removed and prior to making weld repairs the area shall be examined by

suitable methods to ensure that is has been removed or reduced to an acceptably

sized imperfection.

E)

After repairs have been made, the repaired area shall be blended into the surrounding

surface so as to avoid sharp notches, crevices, or corners and re-examined by the

magnetic particle method and by all other methods of examination that were originally

required for the affected area, except that, when the depth of repair is less than the

radiographic sensitivity required, re-radiography may be omitted.

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

P4a-MT-103

Rv. 3

2010-12-15

Page 25 of 67

SUPPLEMENT 2 (1/2)

ACCEPTANCE STANDARD FOR POWER PIPING B31.1 art.136.4.3

AND SECTION I art A-260.3

Evaluation of Indications

1)

Mechanical discontinuities at the surface will be indicated by the retention of the

examination medium. All indications are not necessarily defects, however, since certain

metallurgical discontinuities and magnetic permeability variations may produce similar

indications which are not relevant to the detection of unacceptable discontinuities.

2)

Any indication which is believed to be non relevant shall be re-examined to verify

whether or not actual defects are present. Surface conditioning may proceed the reexamination. Non relevant indications which would mask indications of defects are

unacceptable.

3)

Relevant indications are those which result from unacceptable mechanical

discontinuities. Linear indications are those indications in which the length is more than

three times the width. Rounded indications are indications which are circular or

elliptical with the length less than or equal to three times the width.

4)

An indication of a discontinuity may be larger than the discontinuity that caused it;

however, the size of the indication and not the size of the discontinuity is the basis of

acceptance or rejection.

Acceptance standards

The following relevant indications are unacceptable :

a)

b)

c)

d)

any cracks or linear indications;

rounded indications with dimensions greater than 3/16 in. (5.0 mm);

four or more rounded indications in a line separated by 1/16 in. (2.0mm) or less

edge to edge;

ten or more rounded indications in any 6 sq. in. (3870 mm2) of surface with the

major dimension of this area not to exceed 6 in. (150mm) with the area taken in

the most unfavourable location relative to the indications being evaluated.

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

P4a-MT-103

Rv. 3

2010-12-15

Page 26 of 67

SUPPLEMENT 2 (2/2)

ACCEPTANCE STANDARD FOR POWER PIPING B31.1

AND SECTION I

Evaluation of Indications

CASTING ACCORDING TO Section I (page 25)

The technique for magnetic particle examination shall be in accordance, with Article 7

of Section V. Imperfections causing magnetic particle indications exceeding degree 1

of Type I, degree 2 off Type II, and degree 3 off Type III, and exceeding degree 1 off

Types IV and V of ASTM E 125, Standard Reference Photographs for Magnetic

Particle Indications on Ferrous Castings, are unacceptable.

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

P4a-MT-103

Rv. 3

2010-12-15

Page 27 of 67

SUPPLEMENT 3 (1/1)

ACCEPTANCE STANDARDS

ASME SECT. VIII DIV. 2 art 7.5.6.1

Evaluation of indications

d) - Indications will be revealed by retention of magnetic particles. All such indications are not

necessarily imperfections, however, since excessive surface roughness, magnetic

permeability variations (such as at the edge of heat affected zones, etc), may produce similar

indications.

Any indication is the evidence of a mechanical imperfection. Only indications which have any

dimension greater than 1/16 in. shall be considered relevant.

(a)

(b)

(c)

A linear indication is one having a length greater than three times the width.

A rounded indications is one of circular or elliptical shape with a length equal to or

less than three times its width.

Any questionable or doubtful indications shall be re-examined to determine

whether or not they are relevant.

ACCEPTANCE STANDARDS

These acceptance standards shall apply unless other more restrictive standards are specified

for specific materials or applications within Division 2.

All surfaces to be examined shall be free of :

(a)

(b)

(c)

relevant linear indications;

relevant rounded indications greater than 3/16 in.;

four or more relevant rounded indications in a line separated by 1/16 in. or less,

edge to edge.

Crack like indications detected, irrespective of surface conditions are unacceptable.

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 4 (1/3)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 28 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 4 (2/3)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 29 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 4 (3/3)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 30 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (1/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 31 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (2/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 32 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (3/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 33 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (4/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 34 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (5/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 35 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (6/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 36 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (7/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 37 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (8/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 38 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (9/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 39 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (10/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 40 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (11/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 41 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (12/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 42 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (13/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 43 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (14/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 44 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 5 (15/15)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 45 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 6 (1/14)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 46 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 6 (2/14)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 47 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 6 (3/14)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 48 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 6 (4/14)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 49 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 6 (5/14)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 50 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 6 (6/14)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 51 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 6 (7/14)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 52 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 6 (8/14)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 53 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 6 (9/14)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 54 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 6 (10/14)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 55 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 6 (11/14)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 56 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 6 (12/14)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 57 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 6 (13/14)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 58 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 6 (14/14)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 59 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 7 (1/8)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 60 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 7 (2/8)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 61 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 7 (3/8)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 62 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 7 (4/8)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 63 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 7 (5/8)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 64 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 7 (6/8)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 65 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 7 (7/8)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 66 of 67

8740 Pie IX Blvd.,

Montreal, Qubec, H1Z 3V1

tel.: 514-593-5755 or

1-800-625-7577

fax.: 514-593-8338

MAGNETIC PARTICLE TESTING

SUPPLEMENT 7 (8/8)

Q:\PROCDURES\TECHNIQUES\E.N.D. (4a)\MT\P4a-MT-103, rev.3.doc

P4a-MT-103

Rv. 3

2010-12-15

Page 67 of 67

Anda mungkin juga menyukai

- Welding Interview Question His Answers GuideDokumen8 halamanWelding Interview Question His Answers GuideHatem RagabBelum ada peringkat

- PCN GenDokumen27 halamanPCN GenMohammed ShamilBelum ada peringkat

- NDT HistoryDokumen4 halamanNDT HistorygriselramoniBelum ada peringkat

- Ut PWPS 001Dokumen1 halamanUt PWPS 001Goutam Kumar Deb100% (1)

- DN Wind Systems India Pvt. LTD.: Ultrasonic Procedure FOR Wind Mill TowerDokumen23 halamanDN Wind Systems India Pvt. LTD.: Ultrasonic Procedure FOR Wind Mill TowermaheshBelum ada peringkat

- Ut Procedure OnsDokumen10 halamanUt Procedure OnsPARTHBelum ada peringkat

- Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011Dokumen11 halamanLarsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011Saut Maruli Tua SamosirBelum ada peringkat

- Isq-O&G Manual Ultrasonic Thickness & Corrosion Examination: ASNT Document UT-PTP7 Revision 2Dokumen14 halamanIsq-O&G Manual Ultrasonic Thickness & Corrosion Examination: ASNT Document UT-PTP7 Revision 2muhammadazhanudinBelum ada peringkat

- NDT-P-029, UT Procedure B & C Scan TechniqueDokumen10 halamanNDT-P-029, UT Procedure B & C Scan TechniqueMohamed HassanBelum ada peringkat

- A Review of Advanced Phased Array Approaches TechniquesDokumen17 halamanA Review of Advanced Phased Array Approaches Techniquesbhargav121Belum ada peringkat

- XRSIM Lessons - Student PacketDokumen59 halamanXRSIM Lessons - Student PacketWilliam Pinto HernándezBelum ada peringkat

- XRSIM Lessons - Student PacketDokumen59 halamanXRSIM Lessons - Student PacketWilliam Pinto HernándezBelum ada peringkat

- UT Procedure Rev.8Dokumen15 halamanUT Procedure Rev.8kalaiselvanBelum ada peringkat

- Digital Radiography ReportDokumen7 halamanDigital Radiography ReportadityaromasBelum ada peringkat

- Calibration Sheet Ultrasonic Test EquipmentDokumen1 halamanCalibration Sheet Ultrasonic Test EquipmentjohnBelum ada peringkat

- Ust ProcedureDokumen18 halamanUst ProcedureVikiseptBelum ada peringkat

- WPS PQR Checklist 2014Dokumen2 halamanWPS PQR Checklist 2014Sebastian Rajesh100% (1)

- Jireh Circ It ScannerDokumen2 halamanJireh Circ It ScannerMarcos Kaian Moraes RodriguesBelum ada peringkat

- D-p5-Bv-pd-002 - MT, Issue 01, Rev 00 - Magnetic Particle ExaminationDokumen54 halamanD-p5-Bv-pd-002 - MT, Issue 01, Rev 00 - Magnetic Particle ExaminationThinh Nguyen100% (1)

- Asme Sec V A-2-2004 PDFDokumen39 halamanAsme Sec V A-2-2004 PDFjaire esparzaBelum ada peringkat

- NDT ISO IEC 17025 Application DocumentDokumen41 halamanNDT ISO IEC 17025 Application DocumentVicky SinghBelum ada peringkat

- Itp AsntDokumen33 halamanItp AsntSYED FADZIL SYED MOHAMED100% (1)

- PCN OutlineDokumen26 halamanPCN Outlinekendall0609Belum ada peringkat

- Syllabus For Radiographic Testing-Level Ii I. Theory: 40 Hours-40x60 2400 Min. I. Practical:40 HoursDokumen9 halamanSyllabus For Radiographic Testing-Level Ii I. Theory: 40 Hours-40x60 2400 Min. I. Practical:40 HoursSathia SeelanBelum ada peringkat

- P91 Welding and PWHT ProcedureDokumen4 halamanP91 Welding and PWHT ProcedureHatem Ragab100% (2)

- API 578 Sample QuestionsDokumen8 halamanAPI 578 Sample Questionshenjisu100% (1)

- EX - NO:1a Data Definition Languages (DDL) Commands of Base Tables and ViewsDokumen44 halamanEX - NO:1a Data Definition Languages (DDL) Commands of Base Tables and Viewslalit thakur100% (1)

- D-p5-Bv-pd-005 - Paut, Issue 01, Rev 00 - Phased Array TestingDokumen40 halamanD-p5-Bv-pd-005 - Paut, Issue 01, Rev 00 - Phased Array TestingThinh NguyenBelum ada peringkat

- MSE Class 9 - Nondestructive Testing PDFDokumen74 halamanMSE Class 9 - Nondestructive Testing PDFelijah nderitu100% (1)

- Zott Business ModelDokumen25 halamanZott Business ModelNico LightBelum ada peringkat

- UTDokumen17 halamanUTArputharaj Maria Louis100% (2)

- Guidelines For The Preparation and Grading of NDTDokumen4 halamanGuidelines For The Preparation and Grading of NDTL...nBelum ada peringkat

- 3.PAUT Qualification ProcedureDokumen8 halaman3.PAUT Qualification ProcedurePhan Tri ThongBelum ada peringkat

- Interpretation of Weld RadiographsDokumen14 halamanInterpretation of Weld RadiographsJuliogBelum ada peringkat

- D-p5-Bv-pd-001 - RT, Issue 01, Rev 00 - Radiographic ExaminationDokumen101 halamanD-p5-Bv-pd-001 - RT, Issue 01, Rev 00 - Radiographic ExaminationThinh NguyenBelum ada peringkat

- P 14 Cover Sheets 10 07Dokumen4 halamanP 14 Cover Sheets 10 07carlos100% (1)

- General DNV Qualification Applus RTD Rotoscan AUT System - 2009-4129 - Rev.03 - SignedDokumen60 halamanGeneral DNV Qualification Applus RTD Rotoscan AUT System - 2009-4129 - Rev.03 - SignedfayyazdnvBelum ada peringkat

- Industrial radiography A Complete Guide - 2019 EditionDari EverandIndustrial radiography A Complete Guide - 2019 EditionBelum ada peringkat

- Partial List of ISO SpecificationsDokumen4 halamanPartial List of ISO Specificationsskynyrd75Belum ada peringkat

- AWS Procedure - Rev 2Dokumen40 halamanAWS Procedure - Rev 2Mario Perez100% (1)

- Amigos Technical Services (S) Pte LTD Operating Procedure Ultrasonic TestingDokumen27 halamanAmigos Technical Services (S) Pte LTD Operating Procedure Ultrasonic TestingHoque AnamulBelum ada peringkat

- CA-40-02 Rev.03E UT Procedure Fer AWS D1.1-2015Dokumen24 halamanCA-40-02 Rev.03E UT Procedure Fer AWS D1.1-2015hoangdiep phanBelum ada peringkat

- SMS-603-UT-003 Ultrasonic - API 1104 - B31.8 - Rev 3 PDFDokumen20 halamanSMS-603-UT-003 Ultrasonic - API 1104 - B31.8 - Rev 3 PDFDewAngga YudistiraBelum ada peringkat

- S/Mime (Secure/Multipurpose Internet Mail Extensions)Dokumen15 halamanS/Mime (Secure/Multipurpose Internet Mail Extensions)Vishnupriya100% (1)

- Calibration NDTDokumen11 halamanCalibration NDTAnbalagan RenuBelum ada peringkat

- MT Procedure Rkl-Pro-08-ThocDokumen26 halamanMT Procedure Rkl-Pro-08-ThocEmmad JriBelum ada peringkat

- AsuuuuuuuuuuuuDokumen22 halamanAsuuuuuuuuuuuuyusuf akbar100% (1)

- Cal BlocksDokumen2 halamanCal BlocksRamy HusseinBelum ada peringkat

- Welds With Single Side Access: Technique Sheet - 01 Scanning Technique For Butt WeldsDokumen1 halamanWelds With Single Side Access: Technique Sheet - 01 Scanning Technique For Butt WeldsSrikant GanjiBelum ada peringkat

- Ultrasonic Performance Check Report (4.6.2010)Dokumen1 halamanUltrasonic Performance Check Report (4.6.2010)MohdHuzairiRusliBelum ada peringkat

- ATT VT-1.0A Rev. 2 ProcedureDokumen5 halamanATT VT-1.0A Rev. 2 Procedureskynyrd75Belum ada peringkat

- TWI-2008-Reliability of Manually Applied Phased Array Ultrasonic Inspection For Detection and Sizing of Flaws PDFDokumen176 halamanTWI-2008-Reliability of Manually Applied Phased Array Ultrasonic Inspection For Detection and Sizing of Flaws PDFRicardoSchayerSabinoBelum ada peringkat

- NDT TestDokumen109 halamanNDT TestAnonymous uXdS9Y7Belum ada peringkat

- Ultrasonic Phased Array Approach To Detection and Measurement of Corrosion at Pipe SupportsDokumen10 halamanUltrasonic Phased Array Approach To Detection and Measurement of Corrosion at Pipe SupportsPetrBelum ada peringkat

- Radiographic TestingDokumen2 halamanRadiographic TestingAbdul Hakam Mohamed YusofBelum ada peringkat

- Magnetic Particle Inspection Reference: Goodrich NDT Manual Chapter: 32-40-75Dokumen5 halamanMagnetic Particle Inspection Reference: Goodrich NDT Manual Chapter: 32-40-75Dinesh GuptaBelum ada peringkat

- DMTA 20102 01EN - Rev - 2 OmniScan - X3 User PDFDokumen90 halamanDMTA 20102 01EN - Rev - 2 OmniScan - X3 User PDFpjhollowBelum ada peringkat

- E 1065 - 99-UT-transdDokumen22 halamanE 1065 - 99-UT-transdDemian PereiraBelum ada peringkat

- AITIS - NDT Services Company Saudi Arabia Company ProfileDokumen7 halamanAITIS - NDT Services Company Saudi Arabia Company ProfileassurendranBelum ada peringkat

- ASNTDokumen5 halamanASNTshifaBelum ada peringkat

- WPS at FormateDokumen134 halamanWPS at FormateMohammad Rizwan100% (1)

- NDT Eng Probe PDFDokumen60 halamanNDT Eng Probe PDFPuguh CahyonoBelum ada peringkat

- NDT of Composite Materials Bond of Wind Turbine Blade Using UT - NDT JournalDokumen6 halamanNDT of Composite Materials Bond of Wind Turbine Blade Using UT - NDT Journalpokeboy19Belum ada peringkat

- Magnetic Particle Examination Procedure: Document No.: POS-MT-01 Rev.01Dokumen11 halamanMagnetic Particle Examination Procedure: Document No.: POS-MT-01 Rev.01Nguyen Anh TuanBelum ada peringkat

- PAUT CatalogueDokumen2 halamanPAUT CataloguebenmedBelum ada peringkat

- Importance of Quality Assurance in TheDokumen6 halamanImportance of Quality Assurance in TheniroBelum ada peringkat

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989Dari EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookBelum ada peringkat

- Intumescent Method Statement - UGDC - R00 14Dokumen1 halamanIntumescent Method Statement - UGDC - R00 14Hatem RagabBelum ada peringkat

- Intumescent Method Statement - UGDC - R00 13Dokumen1 halamanIntumescent Method Statement - UGDC - R00 13Hatem RagabBelum ada peringkat

- Intumescent Method Statement - UGDC - R00 11Dokumen1 halamanIntumescent Method Statement - UGDC - R00 11Hatem RagabBelum ada peringkat

- Influence of Heat Input and Post-Weld Heat Treatment On Boiler Steel P91 (9Dokumen10 halamanInfluence of Heat Input and Post-Weld Heat Treatment On Boiler Steel P91 (9Hatem RagabBelum ada peringkat

- Intumescent Method Statement - UGDC - R00 15Dokumen1 halamanIntumescent Method Statement - UGDC - R00 15Hatem RagabBelum ada peringkat

- Intumescent Method Statement - UGDC - R00 12Dokumen1 halamanIntumescent Method Statement - UGDC - R00 12Hatem RagabBelum ada peringkat

- 7T04 CS Kma PR ND 0005Dokumen12 halaman7T04 CS Kma PR ND 0005Hatem Ragab100% (1)

- Job DescribtionDokumen2 halamanJob DescribtionHatem RagabBelum ada peringkat

- Dear SirDokumen1 halamanDear SirHatem RagabBelum ada peringkat

- Magnetic Test: Client: Gas Filling Company (GFC) ContractorDokumen1 halamanMagnetic Test: Client: Gas Filling Company (GFC) ContractorHatem RagabBelum ada peringkat

- p91 WeldingDokumen5 halamanp91 Weldingsaji_t1984100% (1)

- Real Time Radiography Course BookletDokumen48 halamanReal Time Radiography Course BookletAnonymous gFcnQ4goBelum ada peringkat

- Large GapDokumen1 halamanLarge GapHatem RagabBelum ada peringkat

- English Language CourseDokumen216 halamanEnglish Language CourseHatem RagabBelum ada peringkat

- Level III Responsibilities According To ASNTDokumen1 halamanLevel III Responsibilities According To ASNTHatem RagabBelum ada peringkat

- PT General - Hellier No 2Dokumen11 halamanPT General - Hellier No 2Hatem RagabBelum ada peringkat

- Fu/ e ,'. C-.J Ef GK"-T, F SUDokumen1 halamanFu/ e ,'. C-.J Ef GK"-T, F SUHatem RagabBelum ada peringkat

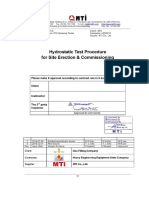

- Hydrostatic Test Procedure For Site & Commissioning HT-031-R1Dokumen7 halamanHydrostatic Test Procedure For Site & Commissioning HT-031-R1Hatem Ragab100% (1)

- UT Report Data For Equator 9-9-2016Dokumen2 halamanUT Report Data For Equator 9-9-2016Hatem RagabBelum ada peringkat

- DCTR : - Prhe Ah, M,,HBTZ T+WZDokumen1 halamanDCTR : - Prhe Ah, M,,HBTZ T+WZHatem RagabBelum ada peringkat

- Ut Report Data For Upper Part 10-9-2016Dokumen3 halamanUt Report Data For Upper Part 10-9-2016Hatem RagabBelum ada peringkat

- Site Consumable Part List For LPG Spherical TankDokumen13 halamanSite Consumable Part List For LPG Spherical TankHatem RagabBelum ada peringkat

- ARTICLE 4 Û Mandatory AppendixDokumen10 halamanARTICLE 4 Û Mandatory AppendixHatem RagabBelum ada peringkat

- AlternatorDokumen14 halamanAlternatorTaraknath MukherjeeBelum ada peringkat

- Formula SheetDokumen3 halamanFormula SheetgogogogoBelum ada peringkat

- Data Sheet - enDokumen2 halamanData Sheet - enrodriggoguedesBelum ada peringkat

- 310 011 SDokumen34 halaman310 011 SvigneshwaranmBelum ada peringkat

- AUTOSAR SWS UDPNetworkManagementDokumen103 halamanAUTOSAR SWS UDPNetworkManagementStefan RuscanuBelum ada peringkat

- Tutorial On Setting Up OpenERP 6.1Dokumen35 halamanTutorial On Setting Up OpenERP 6.1aryienneBelum ada peringkat

- Guest WiFi With MikroTik RoutersDokumen1 halamanGuest WiFi With MikroTik Routersmahad3vaBelum ada peringkat

- Red Bin Analysis PDF Notes - 10020477 - 2023 - 10 - 13 - 09 - 28Dokumen7 halamanRed Bin Analysis PDF Notes - 10020477 - 2023 - 10 - 13 - 09 - 28Sameer SutarBelum ada peringkat

- Bipolar Junction Transistor ModelsDokumen21 halamanBipolar Junction Transistor ModelsecedepttBelum ada peringkat

- 03 VEX SpotDokumen2 halaman03 VEX SpottemamBelum ada peringkat

- Service Manual: Fully Automatic Washing MachineDokumen41 halamanService Manual: Fully Automatic Washing MachineSơn PhạmBelum ada peringkat

- Evaluasi Pengelolaan Sampah Di Kawasan Pantai Kabupaten Bantul, D. I. YogyakartaDokumen14 halamanEvaluasi Pengelolaan Sampah Di Kawasan Pantai Kabupaten Bantul, D. I. YogyakartaRavyola AzzahraBelum ada peringkat

- Remote Sensing of Environment: SciencedirectDokumen28 halamanRemote Sensing of Environment: SciencedirectAmmara HabibBelum ada peringkat

- Effect of Salinity On Proteins in Some Wheat CultivarsDokumen9 halamanEffect of Salinity On Proteins in Some Wheat Cultivarsray m deraniaBelum ada peringkat

- Scopus Crystal NeedleDokumen256 halamanScopus Crystal NeedleDr. Ramchandra Gosavi PatilBelum ada peringkat

- Pure Component VLE in Terms of Fugacity: CHEE 311 1Dokumen8 halamanPure Component VLE in Terms of Fugacity: CHEE 311 1scienziatoBelum ada peringkat

- JVR Fingerprint Attendance User ManualDokumen30 halamanJVR Fingerprint Attendance User ManualDomingo MonteroBelum ada peringkat

- Bohmian Mechanics Versus Madelung Quantum HydrodynamicsDokumen8 halamanBohmian Mechanics Versus Madelung Quantum HydrodynamicsregectBelum ada peringkat

- Soil Bearing Capacity CalculationDokumen29 halamanSoil Bearing Capacity CalculationJohn Jerome TerciñoBelum ada peringkat

- Building Utilities 3: Room AcousticsDokumen11 halamanBuilding Utilities 3: Room AcousticsIzzah LBelum ada peringkat

- Lab Report Instructions - Isolation of Cinnamaldehyde - SP16Dokumen4 halamanLab Report Instructions - Isolation of Cinnamaldehyde - SP16Al SharptonBelum ada peringkat

- DigfiltDokumen237 halamanDigfiltJuhi SinghBelum ada peringkat

- CATL 37V 50ah Lithium Ternary Battery Cell - LiFePO4 BatteryDokumen4 halamanCATL 37V 50ah Lithium Ternary Battery Cell - LiFePO4 BatterymlutfimaBelum ada peringkat

- 3g3JX InverterDokumen262 halaman3g3JX InverterdatdttvuBelum ada peringkat

- Dynamic Group Number Assignment (DGNA)Dokumen16 halamanDynamic Group Number Assignment (DGNA)afkaeBelum ada peringkat

- Draft NADCADokumen8 halamanDraft NADCAPierre MackenzieBelum ada peringkat

- DSI - MPS® Transfer System Compact Trainer I4.0 - EN - DID1089 (Screen)Dokumen2 halamanDSI - MPS® Transfer System Compact Trainer I4.0 - EN - DID1089 (Screen)mhafizanBelum ada peringkat