Central Cooling Equipment Clean

Diunggah oleh

zeliteJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Central Cooling Equipment Clean

Diunggah oleh

zeliteHak Cipta:

Format Tersedia

ROWAN UNIVERSITY

Design Guide

2013

SECTION 236000 - CENTRAL COOLING EQUIPMENT

1.0

This Section pertains to:

A.

B.

Local building chillers to maintain cooling capacity during a site chilled water plant

shutdown, process chillers or chillers that supplement the site chilled water capacity at

the building.

Central Utility Plant Chillers.

2.0

The use of refrigerant R-134A is preferred. The use of refrigerant R-407C or R-410 is limited to

local air-cooled or water-cooled chiller systems up to 300 tons. The use of equipment utilizing

low-pressure refrigerants is prohibited.

3.0

The design of all refrigeration equipment must include an analysis addressing the noise impact

upon surrounding areas and the aesthetic impact if located on the exterior of the building. Refer

to Section 230000 for noise criteria that apply to mechanical equipment rooms. On a project by

project basis, exterior installations of air cooled equipment shall be evaluated against local site

noise level goals and criteria. Refer to Part I, General Section XI.

4.0

Spaces which require cooling during chiller plant shut-down periods, and use individual units for

such, must be designed to interface and utilize the central chilled water source as a primary

source of cooling. An automatic changeover system shall be designed to energize the local

system during central plant shut-downs via the site monitoring and control system. This

requirement shall be followed independent of central chilled water availability unless prior

approval for deviation from this standard has been granted by the University Representative.

5.0

Prior to the selection of compressor unit, i.e., reciprocating, centrifugal, screw or scroll, the

Engineer of Record must submit an analysis of the various compressor types, conclusions and

recommendations to the University's Representative for approval. The analysis shall address

operating efficiency, costs associated with noise control implementations, minimizing

maintenance costs associated with the training of staff and stocking of parts, maintenance,

service, availability from manufacturer, refrigerant type, part load performance, electrical

characteristics, and estimated installation cost.

6.0

All chillers above 300 tons shall be of the centrifugal or screw type.

7.0

Compressors may be of the high-speed open drive or hermetic type. Magnetic bearing oilless

compressors will be considered.

8.0

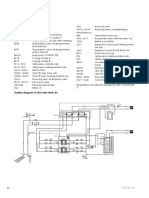

The Minimum Efficiency Requirements for water chiller packages, when rated at ARI 550/590

standard conditions of 44F leaving chilled water at 2.4 gpm/ton, 85F entering condenser water

at 3.0 gpm/ton shall be as indicated in the following table:

CENTRAL COOLING EQUIPMENT

236000 - 1

ROWAN UNIVERSITY

Equipment Type

Design Guide

2013

Size Category

COP

IPLV

Air Cooled, with condenser

All Capacities

2.80

3.05

Water Cooled Reciprocating

All Capacities

4.20

5.05

< 150 tons

4.45

5.20

150 tons and <300 tons

4.90

5.60

300 tons

5.50

6.15

150 tons and <300 tons

5.55

5.90

300 tons

6.10

6.40

Water Cooled (Rotary Screw or Scroll)

Water Cooled Centrifugal

Reference ASHRAE Standard 90.1-2010.

COP = Coefficient of Performance.

IPLV = Integrated Part Load Value.

9.0

Drawings shall indicate routing of refrigerant relief piping. Relief piping shall be sized per

ASHRAE Standard 15. Each chiller location (single chiller installation or multiple chillers in one

location) shall be designed with a refrigerant recovery system.

10.0

Consideration should be given to the use of speed controls on chillers to improve part load

performance or enhance the life of the equipment. Variable speed controls shall be required for

chillers above 300 tons.

11.0

The A/E will analyze various water-cooled chiller selections based upon energy efficiency and

cost, and consider single pass units to reduce condenser and chilled water pumping system costs

(operating and first cost). Units should be analyzed based upon 100% cooling tower(s) operation

to minimize tower supply water temperatures. A/E shall prepare annual operating level table that

bidding manufacturers can complete with actual part-load energy usage data to aid in the

selection of chiller equipment for all chillers greater than 300 tons. Table will have (3) columns:

Load level; hours during year at that load; and energy usage at that load (to be completed by

manufacturer).

12.0

All water cooled chillers must be capable of operation with 55F entering condenser water

temperature, at full and all part load conditions, without the use of flow control or by-pass flow.

Marine boxes shall be specified on water cooled condensers.

13.0

PLC based controls shall be furnished for chillers with a capacity of 300 tons or greater. The

controls shall include a communication interface to communicate directly with the Operations and

Control Center (OCC). Sequences for activation of supplemental or back-up chilled water

systems shall be reviewed closely with the University Representative..

14.0

Chiller Warranty:

A.

B.

C.

Specify written warranty period of two (2) years (one year standard plus one year

additional). The warrantee shall provide unconditional service for parts, labor, refrigerant

and materials to assure that each chiller will perform to the requirements of this

specification.

The warranty period shall commence following Universitys acceptance of the chiller field

performance test and at the completion of the commissioning efforts.

Specify that at no cost to the University, all refrigerant and lubrication oil lost from each

system will be replaced during the warranty period.

CENTRAL COOLING EQUIPMENT

236000 - 2

ROWAN UNIVERSITY

Design Guide

2013

15.0

Specify chillers with factory-applied anti-sweat insulation of the flexible, closed-cell elastomer

type, 3/4 inch thick, attached with vaporproof cement to the cooler shell, flow chamber,

tubesheets, suction connection and as necessary to the auxiliary tubing, and all other surfaces

subject to sweating. The insulation of the water boxes will be furnished and field installed by the

Mechanical Contractor in accordance with the requirements of Section 230700.

16.0

All refrigeration system specifications must be specified to include manufacturers start-up and

servicing. The factory start-up shall include the check-out of all controls, safety components and

performance characteristics. The University Representative shall actively observe the testing and

start-up of the systems. The manufacturer is to submit the start-up report to the University

Engineering Department. Start-up report shall include how much refrigerant is installed in the

chiller.

17.0

When drafting the specifications, the A/E shall consider the requirement for factory and/or field

testing of chillers with respect to the application.

A.

Components of factory testing to be considered are:

1.

2.

3.

4.

5.

B.

Components of field testing and commissioning to be considered are:

1.

2.

3.

4.

C.

Factory Leak Test.

Insulation Resistance Test.

Chiller Performance Test.

Chiller Functional Test.

Eddy current Test (Provide report for baseline data).

Capacity Testing.

Interface to the Site Monitoring and Control System.

Sequence of Operation.

Instrumentation including Safety Controls.

If the chillers fail the Field Performance Test, the chiller manufacturer will have ten (10)

working days to correct any deficiencies and retest the chillers. Should the chillers still be

unable to pass the field performance test after this period of time, the chiller manufacturer

shall remove the chiller or chillers and replace them with chillers that do meet the

specified performance in all aspects. Such replacement shall be at no cost to the Owner

or Mechanical Contractor, and all costs of labor, material, freight, rigging, repiping,

reconnecting and retesting plus any structural changes for access shall be borne by the

chiller manufacturer.

18.0

All refrigerant compressors and chilled water tube bundles must be installed within a

mechanical room. Packaged air cooled chillers are not acceptable unless a glycol based system

is utilized. All glycol applications must be approved by the University's Representative.

19.0

Small individual packaged split systems are inevitable but must be kept to an absolute

minimum. Prior approval for the use of such must be obtained from the University's

Representative.

20.0

All air-cooled condensers must contain condenser fan modulation and staging controls based

on compressor discharge pressure as a means of capacity control for low ambient operation.

Condenser fan dampers are prohibited.

21.0

All critical process equipment cooling, including computer systems, should be designed with a

separate back-up cooling source independent of the central utility system.

CENTRAL COOLING EQUIPMENT

236000 - 3

ROWAN UNIVERSITY

Design Guide

2013

22.0

All communication room cooling and other backup or process cooling systems shall be provided

with an independent source of cooling operating on standby power.

23.0

For local winter cooling applications a waterside economizer system is preferred, where

possible, to avoid the addition of chilled water generation or direct expansion equipment.

24.0

The University is responsible to maintain an inventory of refrigerants. As part of the project

specifications, the A/E shall require the installing contractor to provide data to the University on

the type and quantity of refrigerant utilized for each piece of equipment on the project. The

University will provide project closeout data required.

CENTRAL COOLING EQUIPMENT

236000 - 4

Anda mungkin juga menyukai

- !-Bab 03 Air Circuit Breaker (ACB)Dokumen20 halaman!-Bab 03 Air Circuit Breaker (ACB)zeliteBelum ada peringkat

- 002 Ac Thermal Load Calculation (Substation)Dokumen1 halaman002 Ac Thermal Load Calculation (Substation)Faouzi TlemcenBelum ada peringkat

- 10KV & Low Inst. DrawingsDokumen546 halaman10KV & Low Inst. DrawingszeliteBelum ada peringkat

- Hvac Method StatementDokumen74 halamanHvac Method StatementnafoukhBelum ada peringkat

- Training Courses Descriptions Full PDFDokumen6 halamanTraining Courses Descriptions Full PDFzeliteBelum ada peringkat

- !-Bab 02 Moulded Case Circuit Breaker (MCCB)Dokumen38 halaman!-Bab 02 Moulded Case Circuit Breaker (MCCB)zeliteBelum ada peringkat

- LV Switchs and EquipmentsDokumen195 halamanLV Switchs and EquipmentszeliteBelum ada peringkat

- Low Voltage Selectivity With ABB Circuit Breakers (1SDC007100G0202)Dokumen56 halamanLow Voltage Selectivity With ABB Circuit Breakers (1SDC007100G0202)Eduardo ZapataBelum ada peringkat

- QFSS-1.02 - Substations & Switch Gear Rooms Rev ADokumen2 halamanQFSS-1.02 - Substations & Switch Gear Rooms Rev ARotsapNayrbBelum ada peringkat

- QFSS-1.02 - Substations & Switch Gear Rooms Rev ADokumen2 halamanQFSS-1.02 - Substations & Switch Gear Rooms Rev ARotsapNayrbBelum ada peringkat

- 01 Fault at FCO 5D-30 (Well 5D-93 & 5D-83) - Substation 5B Feeder 02 - Crew 01-14-07-2014Dokumen1 halaman01 Fault at FCO 5D-30 (Well 5D-93 & 5D-83) - Substation 5B Feeder 02 - Crew 01-14-07-2014zeliteBelum ada peringkat

- TP21 - BEC - DT - 0402 MAS For 11 KV Chiller Starter Panel PDFDokumen139 halamanTP21 - BEC - DT - 0402 MAS For 11 KV Chiller Starter Panel PDFzeliteBelum ada peringkat

- Visual Test 20kv Panel Cubicle PDFDokumen7 halamanVisual Test 20kv Panel Cubicle PDFzeliteBelum ada peringkat

- Voltage Drop Calculation$ PDFDokumen1 halamanVoltage Drop Calculation$ PDFzeliteBelum ada peringkat

- TP21 - BEC - DT - 0316 Rev-4 LVMCC Panel PDFDokumen81 halamanTP21 - BEC - DT - 0316 Rev-4 LVMCC Panel PDFzeliteBelum ada peringkat

- Fire Suppression Systems CleanDokumen4 halamanFire Suppression Systems CleanzeliteBelum ada peringkat

- Voltage Reference Selection BasicsDokumen11 halamanVoltage Reference Selection Basicstonyariel100% (2)

- YF-01-04 HVAC Overlay PDFDokumen1 halamanYF-01-04 HVAC Overlay PDFzeliteBelum ada peringkat

- Total Low PDFDokumen16 halamanTotal Low PDFzeliteBelum ada peringkat

- TP21 - BEC - DT - 0402 MAS For 11 KV Chiller Starter Panel Rev - 3 PDFDokumen127 halamanTP21 - BEC - DT - 0402 MAS For 11 KV Chiller Starter Panel Rev - 3 PDFzeliteBelum ada peringkat

- VG-01-05 HVAC Overlay PDFDokumen1 halamanVG-01-05 HVAC Overlay PDFzeliteBelum ada peringkat

- Wearing of BSP Uniform and Office Attire PDFDokumen1 halamanWearing of BSP Uniform and Office Attire PDFzeliteBelum ada peringkat

- UE12MK03EN (Web) PDFDokumen12 halamanUE12MK03EN (Web) PDFzeliteBelum ada peringkat

- TG MCC Room General Arrangement PDFDokumen1 halamanTG MCC Room General Arrangement PDFzeliteBelum ada peringkat

- The Mosque and The Modern World LowDokumen248 halamanThe Mosque and The Modern World LowzeliteBelum ada peringkat

- Plumbing & Fire Protection Piping Systems CleanDokumen7 halamanPlumbing & Fire Protection Piping Systems CleanzeliteBelum ada peringkat

- CPTG003 en PDFDokumen24 halamanCPTG003 en PDFbyyramBelum ada peringkat

- Rowan University Design Guide 2013Dokumen4 halamanRowan University Design Guide 2013zeliteBelum ada peringkat

- Plumbing Systems CleanDokumen6 halamanPlumbing Systems CleanzeliteBelum ada peringkat

- Plumbing Fixtures CleanDokumen2 halamanPlumbing Fixtures CleanzeliteBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- NT 3036 - Handout 1 - Introduction To Air ConditioningDokumen23 halamanNT 3036 - Handout 1 - Introduction To Air ConditioningAnonymous 1Z5K9QXBelum ada peringkat

- Sample of Technical Description: RefrigeratorDokumen1 halamanSample of Technical Description: RefrigeratorHawaiiChongBelum ada peringkat

- Ventilation Lecture 4 PH Alleen LezenDokumen25 halamanVentilation Lecture 4 PH Alleen LezenNazimAhmedBelum ada peringkat

- March Samsung VRF SeminarDokumen129 halamanMarch Samsung VRF SeminarEdmund Yoong100% (1)

- ASHRAE Journal - A New Approach To Museum HVAC DesignDokumen8 halamanASHRAE Journal - A New Approach To Museum HVAC DesignSandy :pBelum ada peringkat

- Vapour Compression SystemDokumen15 halamanVapour Compression SystemAnonymous 5HYsyrddpBelum ada peringkat

- ME8395 Thermal Engineering-2 Part - B QuestionsDokumen5 halamanME8395 Thermal Engineering-2 Part - B QuestionsMuruganBelum ada peringkat

- Detailed Design: A B C D E F G H I JDokumen1 halamanDetailed Design: A B C D E F G H I JTyrone PotterBelum ada peringkat

- Liebert Datamate BrochureDokumen4 halamanLiebert Datamate Brochurejgjidesa2937Belum ada peringkat

- Problem Set RefrigerationDokumen1 halamanProblem Set RefrigerationGem CarpioBelum ada peringkat

- 48 50p-4tDokumen238 halaman48 50p-4tMickey MayoBelum ada peringkat

- Mong Duong 1 Thermal Plant Fire Layout Underground PipingDokumen1 halamanMong Duong 1 Thermal Plant Fire Layout Underground Pipingtvpham123Belum ada peringkat

- Energy Use Analysis of The Variable Refrigerant Flow (VRF) System Versus The Multi - Split Unit Using TRNSYS PDFDokumen20 halamanEnergy Use Analysis of The Variable Refrigerant Flow (VRF) System Versus The Multi - Split Unit Using TRNSYS PDFroger_shBelum ada peringkat

- Automotive Technology: Cooling SystemDokumen43 halamanAutomotive Technology: Cooling Systempreethu02Belum ada peringkat

- Carrier 30XW Water-Cooled Liquid ChillerDokumen20 halamanCarrier 30XW Water-Cooled Liquid ChillerDu NguyễnBelum ada peringkat

- Ichiban Air-Cooled ChillerDokumen8 halamanIchiban Air-Cooled ChillerpubudunishanthaBelum ada peringkat

- Product Data: 50HJQ014,016 Single-Package Rooftop Heat Pump Units 50 HZDokumen36 halamanProduct Data: 50HJQ014,016 Single-Package Rooftop Heat Pump Units 50 HZexpressclimaBelum ada peringkat

- Master List of Instrument For ISO (Version 1)Dokumen76 halamanMaster List of Instrument For ISO (Version 1)Eng Ali Al-MarzohBelum ada peringkat

- 3.5 110318 R11-833 Rev 2Dokumen102 halaman3.5 110318 R11-833 Rev 2JSF315Belum ada peringkat

- Daikin Fancoily enDokumen90 halamanDaikin Fancoily ennikipshBelum ada peringkat

- DISTRICT COOLING Design and Water Managementcode 2016Dokumen45 halamanDISTRICT COOLING Design and Water Managementcode 2016waelroustomBelum ada peringkat

- مركزي كاريير ٢٠١٨ PDFDokumen1 halamanمركزي كاريير ٢٠١٨ PDFHamada HegabBelum ada peringkat

- SS 553-2009 - PreviewDokumen9 halamanSS 553-2009 - PreviewsakthiBelum ada peringkat

- Single Unit Package System: Installation Split Air ConditionerDokumen1 halamanSingle Unit Package System: Installation Split Air ConditionerShubham SarkarBelum ada peringkat

- Performansi Mesin Pendingin Tipe Chiller Untuk Cold Storage Dan IndoorDokumen8 halamanPerformansi Mesin Pendingin Tipe Chiller Untuk Cold Storage Dan IndoorMamad ParidBelum ada peringkat

- Fire Alarm System Loops I To 4Dokumen4 halamanFire Alarm System Loops I To 4shahbazalam4a5Belum ada peringkat

- Investigatory Project Built in Air Cooler Out of Ice DispenserDokumen14 halamanInvestigatory Project Built in Air Cooler Out of Ice DispenserOnin SoldevilloBelum ada peringkat

- Schema NIBE F1345 Cu HPAC45Dokumen1 halamanSchema NIBE F1345 Cu HPAC45Istvan MadacsyBelum ada peringkat

- 125 Years of Cooling Innovation and LeadershipDokumen32 halaman125 Years of Cooling Innovation and Leadershippsjjoshi100% (1)

- XR15 Performance DataDokumen16 halamanXR15 Performance Databarber bobBelum ada peringkat